Microreactors with Integrated Sensors for Process Monitoring and Control

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Technology Evolution and Objectives

Microreactor technology has evolved significantly over the past three decades, transforming from laboratory curiosities to sophisticated process intensification tools. The concept originated in the 1990s when researchers began exploring miniaturized reaction systems to enhance chemical process efficiency. By the early 2000s, the first generation of microreactors demonstrated improved heat and mass transfer capabilities compared to conventional batch reactors, establishing their potential for precise reaction control.

The evolution accelerated in the mid-2000s with the integration of basic sensing capabilities, primarily temperature and pressure monitoring. This period marked a critical transition from purely mechanical systems to intelligent reaction platforms. Between 2010 and 2015, microreactor technology witnessed substantial advancement with the incorporation of more sophisticated materials and fabrication techniques, enabling complex channel geometries and enhanced chemical compatibility.

Recent developments have focused on creating fully integrated systems combining reaction channels with advanced sensing technologies. Modern microreactors now incorporate multiple sensor types—spectroscopic, electrochemical, and thermal—enabling real-time monitoring of reaction parameters. This integration represents a paradigm shift from periodic sampling to continuous process analytics, fundamentally changing how chemical processes are monitored and controlled.

The technological trajectory clearly points toward increasingly autonomous microreactor systems capable of self-regulation and optimization. Current research emphasizes the development of sensor arrays that can simultaneously monitor multiple reaction parameters with minimal interference, addressing the longstanding challenge of sensor miniaturization without compromising analytical performance.

The primary objective of contemporary microreactor technology development is to create fully integrated reaction systems that combine efficient chemical processing with comprehensive real-time monitoring capabilities. This integration aims to enable precise process control, rapid optimization, and enhanced safety protocols through immediate feedback mechanisms. Secondary objectives include reducing the footprint of chemical manufacturing, minimizing waste generation, and enabling distributed production models.

Looking forward, the field is moving toward microreactors with embedded artificial intelligence capabilities, where sensor data directly informs automated decision-making processes. The ultimate goal is developing self-optimizing reaction systems that can adapt to changing conditions, predict potential issues before they occur, and automatically adjust parameters to maintain optimal performance—effectively creating "smart" chemical factories at the microscale.

The evolution accelerated in the mid-2000s with the integration of basic sensing capabilities, primarily temperature and pressure monitoring. This period marked a critical transition from purely mechanical systems to intelligent reaction platforms. Between 2010 and 2015, microreactor technology witnessed substantial advancement with the incorporation of more sophisticated materials and fabrication techniques, enabling complex channel geometries and enhanced chemical compatibility.

Recent developments have focused on creating fully integrated systems combining reaction channels with advanced sensing technologies. Modern microreactors now incorporate multiple sensor types—spectroscopic, electrochemical, and thermal—enabling real-time monitoring of reaction parameters. This integration represents a paradigm shift from periodic sampling to continuous process analytics, fundamentally changing how chemical processes are monitored and controlled.

The technological trajectory clearly points toward increasingly autonomous microreactor systems capable of self-regulation and optimization. Current research emphasizes the development of sensor arrays that can simultaneously monitor multiple reaction parameters with minimal interference, addressing the longstanding challenge of sensor miniaturization without compromising analytical performance.

The primary objective of contemporary microreactor technology development is to create fully integrated reaction systems that combine efficient chemical processing with comprehensive real-time monitoring capabilities. This integration aims to enable precise process control, rapid optimization, and enhanced safety protocols through immediate feedback mechanisms. Secondary objectives include reducing the footprint of chemical manufacturing, minimizing waste generation, and enabling distributed production models.

Looking forward, the field is moving toward microreactors with embedded artificial intelligence capabilities, where sensor data directly informs automated decision-making processes. The ultimate goal is developing self-optimizing reaction systems that can adapt to changing conditions, predict potential issues before they occur, and automatically adjust parameters to maintain optimal performance—effectively creating "smart" chemical factories at the microscale.

Market Demand Analysis for Integrated Sensing Microreactors

The global market for microreactors with integrated sensors is experiencing significant growth, driven by increasing demand for efficient, precise, and automated chemical processing systems. Current market valuations indicate that the integrated sensing microreactor segment reached approximately 2.5 billion USD in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030. This growth trajectory reflects the expanding applications across pharmaceutical, fine chemical, and specialty materials industries.

Pharmaceutical companies represent the largest market segment, accounting for nearly 40% of current demand. This dominance stems from the industry's need for precise reaction control during drug development and production processes. The ability to monitor critical parameters in real-time allows for improved product quality, reduced development cycles, and enhanced regulatory compliance—all crucial factors in an industry facing increasing cost pressures and stringent quality requirements.

The fine chemicals sector constitutes approximately 25% of the market, with manufacturers seeking technologies that enable process intensification and quality improvement. These companies value integrated sensing microreactors for their ability to optimize yield and selectivity while minimizing waste generation, directly impacting production economics and environmental footprint.

Academic and research institutions represent a smaller but rapidly growing segment, currently at 15% of the market. Their demand is primarily driven by the need for versatile research platforms that can accelerate materials discovery and process development. The remaining market share is distributed across specialty chemicals, petrochemicals, and emerging applications in biopharmaceuticals.

Regional analysis reveals that North America leads the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in China, Japan, and South Korea, where investments in advanced manufacturing technologies are accelerating.

Key market drivers include increasing pressure for sustainable manufacturing processes, growing adoption of continuous flow chemistry, and the broader industry trend toward digitalization and automation. End-users consistently identify real-time process monitoring, improved process control, and reduced development time as the most valuable benefits of integrated sensing microreactors.

Market research indicates that customers are willing to pay premium prices for systems offering comprehensive sensing capabilities, particularly those that integrate multiple sensor types (temperature, pressure, spectroscopic) with advanced data analytics. The highest demand exists for systems capable of monitoring reaction kinetics, detecting impurities, and enabling closed-loop control based on real-time measurements.

Despite positive growth indicators, market penetration remains constrained by factors including high initial investment costs, technical complexity requiring specialized expertise, and challenges related to technology validation and regulatory acceptance, particularly in highly regulated industries.

Pharmaceutical companies represent the largest market segment, accounting for nearly 40% of current demand. This dominance stems from the industry's need for precise reaction control during drug development and production processes. The ability to monitor critical parameters in real-time allows for improved product quality, reduced development cycles, and enhanced regulatory compliance—all crucial factors in an industry facing increasing cost pressures and stringent quality requirements.

The fine chemicals sector constitutes approximately 25% of the market, with manufacturers seeking technologies that enable process intensification and quality improvement. These companies value integrated sensing microreactors for their ability to optimize yield and selectivity while minimizing waste generation, directly impacting production economics and environmental footprint.

Academic and research institutions represent a smaller but rapidly growing segment, currently at 15% of the market. Their demand is primarily driven by the need for versatile research platforms that can accelerate materials discovery and process development. The remaining market share is distributed across specialty chemicals, petrochemicals, and emerging applications in biopharmaceuticals.

Regional analysis reveals that North America leads the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in China, Japan, and South Korea, where investments in advanced manufacturing technologies are accelerating.

Key market drivers include increasing pressure for sustainable manufacturing processes, growing adoption of continuous flow chemistry, and the broader industry trend toward digitalization and automation. End-users consistently identify real-time process monitoring, improved process control, and reduced development time as the most valuable benefits of integrated sensing microreactors.

Market research indicates that customers are willing to pay premium prices for systems offering comprehensive sensing capabilities, particularly those that integrate multiple sensor types (temperature, pressure, spectroscopic) with advanced data analytics. The highest demand exists for systems capable of monitoring reaction kinetics, detecting impurities, and enabling closed-loop control based on real-time measurements.

Despite positive growth indicators, market penetration remains constrained by factors including high initial investment costs, technical complexity requiring specialized expertise, and challenges related to technology validation and regulatory acceptance, particularly in highly regulated industries.

Current Challenges in Microreactor Sensor Integration

Despite significant advancements in microreactor technology, the integration of sensors for real-time process monitoring and control faces several critical challenges. The miniaturized nature of microreactors, typically operating at submillimeter scales, creates substantial spatial constraints for sensor placement. This limited physical space makes it difficult to incorporate conventional sensing technologies without disrupting fluid dynamics or reaction kinetics within the microchannels.

Material compatibility represents another major hurdle, as sensors must withstand potentially harsh chemical environments, high temperatures, and pressure conditions while maintaining accuracy and longevity. Many conventional sensor materials degrade rapidly under these conditions, limiting their practical application in industrial microreactor systems. Additionally, the interface between sensing elements and microreactor structures often creates sealing and integration challenges that can lead to system failures or contamination.

Signal-to-noise ratio optimization remains problematic in microreactor environments due to the extremely small sample volumes being measured. Detecting minute changes in parameters such as temperature, pressure, or concentration requires highly sensitive instruments that can distinguish true signals from background noise. This challenge is particularly pronounced when monitoring fast reactions with transient intermediates or when working with dilute solutions.

Power management and data transmission present significant obstacles, especially for distributed or remote microreactor systems. Wireless sensors require miniaturized power sources with sufficient longevity, while wired solutions must overcome space constraints without compromising reactor performance. The integration of power and communication components adds complexity to already intricate microreactor designs.

Calibration and standardization of integrated sensors pose ongoing difficulties, as each microreactor-sensor system often requires custom calibration protocols. The lack of standardized approaches hampers reproducibility across different laboratories and scaling to industrial applications. Furthermore, sensor drift over time necessitates recalibration strategies that don't interrupt continuous processes.

Cost considerations remain a substantial barrier to widespread implementation, as sophisticated integrated sensing technologies can significantly increase the overall system price. This economic factor often forces compromises between measurement accuracy, response time, and system affordability, particularly for commercial applications.

Multifunctional sensing capabilities that can simultaneously monitor multiple parameters without cross-interference represent an emerging challenge. As microreactor applications become more sophisticated, the demand for comprehensive process monitoring increases, requiring innovative approaches to sensor integration and data interpretation.

Material compatibility represents another major hurdle, as sensors must withstand potentially harsh chemical environments, high temperatures, and pressure conditions while maintaining accuracy and longevity. Many conventional sensor materials degrade rapidly under these conditions, limiting their practical application in industrial microreactor systems. Additionally, the interface between sensing elements and microreactor structures often creates sealing and integration challenges that can lead to system failures or contamination.

Signal-to-noise ratio optimization remains problematic in microreactor environments due to the extremely small sample volumes being measured. Detecting minute changes in parameters such as temperature, pressure, or concentration requires highly sensitive instruments that can distinguish true signals from background noise. This challenge is particularly pronounced when monitoring fast reactions with transient intermediates or when working with dilute solutions.

Power management and data transmission present significant obstacles, especially for distributed or remote microreactor systems. Wireless sensors require miniaturized power sources with sufficient longevity, while wired solutions must overcome space constraints without compromising reactor performance. The integration of power and communication components adds complexity to already intricate microreactor designs.

Calibration and standardization of integrated sensors pose ongoing difficulties, as each microreactor-sensor system often requires custom calibration protocols. The lack of standardized approaches hampers reproducibility across different laboratories and scaling to industrial applications. Furthermore, sensor drift over time necessitates recalibration strategies that don't interrupt continuous processes.

Cost considerations remain a substantial barrier to widespread implementation, as sophisticated integrated sensing technologies can significantly increase the overall system price. This economic factor often forces compromises between measurement accuracy, response time, and system affordability, particularly for commercial applications.

Multifunctional sensing capabilities that can simultaneously monitor multiple parameters without cross-interference represent an emerging challenge. As microreactor applications become more sophisticated, the demand for comprehensive process monitoring increases, requiring innovative approaches to sensor integration and data interpretation.

Current Integration Approaches for Microreactor Sensing

01 Integration of sensors in microreactors for real-time monitoring

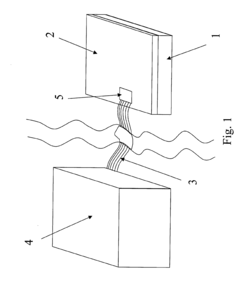

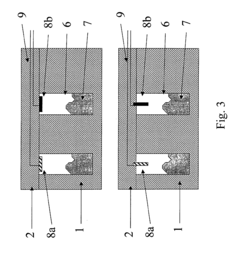

Microreactors equipped with integrated sensors enable real-time monitoring of various process parameters such as temperature, pressure, flow rate, and chemical composition. These sensors provide continuous data streams that allow for immediate detection of process deviations and ensure optimal reaction conditions are maintained. The integration of sensing elements directly within microreactor channels minimizes response time and increases measurement accuracy compared to external monitoring systems.- Integration of sensors in microreactors for real-time monitoring: Microreactors equipped with integrated sensors enable real-time monitoring of various process parameters such as temperature, pressure, flow rate, and chemical composition. These sensors provide continuous data streams that allow for immediate detection of process deviations and ensure optimal reaction conditions are maintained. The integration of sensing elements directly within microreactor channels minimizes response time and increases measurement accuracy, making them particularly valuable for critical chemical processes requiring precise control.

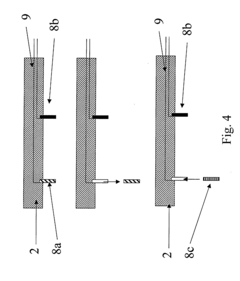

- Automated control systems for microreactor process optimization: Advanced control systems coupled with microreactors enable automated process optimization through feedback loops. These systems analyze sensor data in real-time and make automatic adjustments to process parameters to maintain optimal conditions. The implementation of control algorithms, including PID controllers and more sophisticated machine learning approaches, allows for dynamic response to changing conditions within the microreactor. This automation significantly improves process consistency, reduces operator intervention, and enables complex reaction sequences to be performed with high precision.

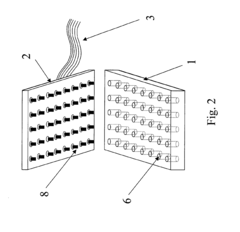

- Microfluidic platforms with multi-parameter sensing capabilities: Microfluidic platforms incorporate multiple sensing modalities to provide comprehensive process monitoring. These systems combine various detection methods such as optical, electrochemical, thermal, and spectroscopic techniques within a single microreactor platform. The multi-parameter sensing approach enables simultaneous monitoring of different reaction aspects, providing a more complete understanding of the process dynamics. This integration is particularly valuable for complex reactions where multiple parameters must be monitored simultaneously to ensure product quality and process safety.

- Miniaturized sensor technologies for space-constrained microreactors: Specialized miniaturized sensor technologies have been developed to overcome the space constraints inherent in microreactor systems. These include micro-electromechanical systems (MEMS), nanosensors, and integrated optical sensing elements that can be embedded directly within microchannels without disrupting flow patterns. The miniaturization of sensing elements enables high-density sensor arrays that provide spatially resolved measurements across the microreactor, allowing for detailed mapping of reaction progress and identification of localized phenomena that might be missed by conventional sensing approaches.

- Data integration and analysis frameworks for microreactor systems: Sophisticated data integration and analysis frameworks have been developed to handle the large volumes of sensor data generated by microreactor systems. These frameworks incorporate data fusion techniques to combine information from multiple sensors, statistical analysis methods to identify trends and anomalies, and visualization tools to present complex data in an accessible format. Advanced systems also implement predictive modeling capabilities that can anticipate process deviations before they occur, enabling proactive intervention. The integration of these analytical capabilities with microreactor control systems creates a comprehensive platform for process monitoring and optimization.

02 Automated control systems for microreactor process optimization

Advanced control systems coupled with microreactors enable automated process optimization through feedback loops. These systems process sensor data in real-time and make autonomous adjustments to reaction parameters to maintain desired conditions or respond to changing process requirements. The implementation of control algorithms allows for precise manipulation of reaction variables, resulting in improved yield, selectivity, and product quality while reducing manual intervention requirements.Expand Specific Solutions03 Microfluidic platforms with integrated analytical capabilities

Microfluidic platforms incorporate both reaction channels and analytical capabilities within a single integrated device. These systems combine microreactors with spectroscopic, chromatographic, or electrochemical analysis tools to enable in-situ characterization of reaction products. The integration of analytical functions eliminates the need for sample extraction and external analysis, reducing time delays and potential contamination while providing comprehensive data for process understanding and control.Expand Specific Solutions04 Wireless sensor networks for distributed microreactor monitoring

Wireless sensor networks enable distributed monitoring across multiple microreactor units or within complex microreactor systems. These networks collect and transmit data from various sensing points to central control systems without requiring physical connections. The implementation of wireless communication protocols facilitates flexible deployment, scalability, and reconfiguration of monitoring systems while reducing installation complexity and enabling remote operation capabilities.Expand Specific Solutions05 Machine learning and AI for predictive process control in microreactors

Machine learning and artificial intelligence algorithms enhance microreactor control systems by enabling predictive capabilities based on historical and real-time sensor data. These advanced computational methods can identify patterns, predict process deviations before they occur, and suggest optimal operating conditions. The implementation of AI-driven control strategies allows for adaptive process optimization that continuously improves based on accumulated operational data, leading to enhanced efficiency and product consistency.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

The microreactor with integrated sensors market is currently in a growth phase, characterized by increasing adoption across pharmaceutical, chemical, and biotechnology industries. The global market size is estimated to reach $2.5-3 billion by 2025, driven by demand for process intensification and real-time monitoring capabilities. From a technological maturity perspective, established players like Siemens AG and Corning are leading with comprehensive commercial solutions, while academic institutions (RWTH Aachen, ETH Zurich) contribute fundamental research advances. Companies such as Finesse Solutions and Hamilton Bonaduz AG are specializing in sensor integration technologies, while STMicroelectronics and Endress+Hauser focus on miniaturized sensing components. The competitive landscape shows a mix of large industrial conglomerates and specialized technology providers collaborating with research institutions to advance this interdisciplinary field.

Finesse Solutions, Inc.

Technical Solution: Finesse Solutions has developed a specialized microreactor platform called SmartMicro™ that integrates advanced sensing technologies specifically optimized for biopharmaceutical applications. Their system incorporates disposable microreactors with pre-calibrated sensor patches that monitor critical parameters including dissolved oxygen, pH, cell density, and metabolite concentrations in real-time. The microreactors utilize a combination of optical and electrochemical sensing technologies that are non-invasive and maintain sterility throughout the bioprocess[4]. A key innovation is their TruBio® automation software that provides closed-loop control based on the integrated sensor data, enabling precise maintenance of optimal conditions for cellular productivity. The platform features wireless communication capabilities that allow for remote monitoring and control of multiple parallel microreactors, facilitating high-throughput process development. Finesse's technology is particularly valuable for perfusion culture applications, where their integrated sensors can continuously monitor product quality attributes during extended manufacturing campaigns.

Strengths: Specialized expertise in bioprocess monitoring; disposable technology eliminating cross-contamination risks; seamless integration with existing bioprocess development workflows. Weaknesses: Limited application outside of biological processes; higher consumable costs due to disposable nature; less suitable for high-temperature or chemically aggressive reactions.

Siemens AG

Technical Solution: Siemens has pioneered an integrated microreactor platform called SIMATIC PCS neo that combines advanced microfluidic technology with comprehensive digital monitoring capabilities. Their system incorporates multiple microsensor arrays directly fabricated into reactor channels using MEMS technology, enabling real-time monitoring of critical process parameters. The microreactors feature embedded temperature, pressure, flow, and spectroscopic sensors that communicate with Siemens' industrial automation infrastructure. A key innovation is their distributed control architecture that allows for autonomous operation of individual reactor modules while maintaining centralized data collection and analysis[2]. The system employs machine learning algorithms to predict process deviations before they occur, enabling proactive control adjustments. Siemens' microreactors are designed with modular scaling capabilities, allowing processes to be seamlessly transferred from laboratory to production scale while maintaining consistent monitoring and control parameters.

Strengths: Comprehensive integration with existing industrial automation systems; advanced predictive capabilities through AI implementation; modular design enabling scalable manufacturing solutions. Weaknesses: Complex implementation requiring significant technical expertise; higher initial investment compared to traditional batch processes; potential cybersecurity concerns with highly networked systems.

Key Sensor Technologies for Microreactor Applications

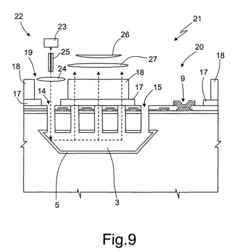

Microsensor system for monitoring biological and chemical processes

PatentInactiveEP1284158A2

Innovation

- A system utilizing multiple microsensors arranged directly in the process environment for immediate signal evaluation, connected to an evaluation and control unit, allowing for real-time monitoring of chemical and biological processes without the need for sample preparation or separation, and enabling simultaneous analysis of multiple reactions.

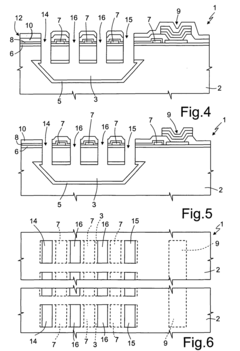

Integrated semiconductor microreactor for real-time monitoring of biological reactions

PatentActiveUS7906321B2

Innovation

- An integrated semiconductor chemical microreactor with buried channels, heating elements, and transparent covers for visual monitoring, allowing real-time tracking of DNA amplification through fluorescent detection using angled walls for light reflection and collection.

Scalability and Manufacturing Considerations

The scalability of microreactor technology with integrated sensors represents a critical factor in their widespread industrial adoption. Current manufacturing approaches for these systems typically involve microfabrication techniques borrowed from the semiconductor industry, including photolithography, etching, and deposition processes. While these methods enable precise fabrication of microchannels and sensor integration, they often face limitations when scaling from laboratory prototypes to industrial production volumes.

Material selection plays a pivotal role in scaling considerations. Glass and silicon substrates offer excellent chemical compatibility and thermal properties but present challenges in cost-effective mass production. Polymeric materials like PDMS (polydimethylsiloxane) provide easier fabrication pathways but may suffer from limited chemical resistance and operational temperature ranges. Advanced ceramic and metal alloy substrates show promise for industrial applications but require specialized manufacturing techniques.

Standardization emerges as a key enabler for scalable manufacturing. The development of modular microreactor designs with standardized interfaces for sensors and control systems would significantly reduce production costs and complexity. Such standardization would facilitate the creation of plug-and-play components that can be assembled into customized systems based on specific process requirements, without necessitating complete redesigns.

Integration of sensors during manufacturing presents unique challenges. Traditional post-fabrication sensor installation increases production complexity and potential failure points. Advanced manufacturing approaches like 3D printing and roll-to-roll processing offer promising pathways for simultaneous fabrication of reactor channels and sensor elements. Recent innovations in printed electronics have demonstrated feasibility for directly printing sensor elements within microreactor structures.

Cost considerations remain paramount for industrial adoption. Current microreactor systems with integrated sensing capabilities typically cost significantly more than conventional reactor technologies. Economic viability requires manufacturing innovations that reduce unit costs while maintaining performance specifications. Economies of scale can be achieved through batch fabrication processes and increased automation in assembly and testing procedures.

Quality control and reproducibility present additional challenges when scaling production. Ensuring consistent performance across manufactured units requires sophisticated in-line testing methodologies and stringent quality assurance protocols. Non-destructive testing techniques such as optical coherence tomography and electrical impedance spectroscopy show promise for rapid assessment of microreactor integrity and sensor functionality during production.

Material selection plays a pivotal role in scaling considerations. Glass and silicon substrates offer excellent chemical compatibility and thermal properties but present challenges in cost-effective mass production. Polymeric materials like PDMS (polydimethylsiloxane) provide easier fabrication pathways but may suffer from limited chemical resistance and operational temperature ranges. Advanced ceramic and metal alloy substrates show promise for industrial applications but require specialized manufacturing techniques.

Standardization emerges as a key enabler for scalable manufacturing. The development of modular microreactor designs with standardized interfaces for sensors and control systems would significantly reduce production costs and complexity. Such standardization would facilitate the creation of plug-and-play components that can be assembled into customized systems based on specific process requirements, without necessitating complete redesigns.

Integration of sensors during manufacturing presents unique challenges. Traditional post-fabrication sensor installation increases production complexity and potential failure points. Advanced manufacturing approaches like 3D printing and roll-to-roll processing offer promising pathways for simultaneous fabrication of reactor channels and sensor elements. Recent innovations in printed electronics have demonstrated feasibility for directly printing sensor elements within microreactor structures.

Cost considerations remain paramount for industrial adoption. Current microreactor systems with integrated sensing capabilities typically cost significantly more than conventional reactor technologies. Economic viability requires manufacturing innovations that reduce unit costs while maintaining performance specifications. Economies of scale can be achieved through batch fabrication processes and increased automation in assembly and testing procedures.

Quality control and reproducibility present additional challenges when scaling production. Ensuring consistent performance across manufactured units requires sophisticated in-line testing methodologies and stringent quality assurance protocols. Non-destructive testing techniques such as optical coherence tomography and electrical impedance spectroscopy show promise for rapid assessment of microreactor integrity and sensor functionality during production.

Safety and Regulatory Framework for Microreactor Systems

The safety and regulatory landscape for microreactor systems with integrated sensors represents a complex framework that continues to evolve alongside technological advancements. Current regulatory approaches must address the unique challenges posed by the miniaturization of chemical processing equipment combined with sophisticated monitoring capabilities. These systems operate at the intersection of multiple regulatory domains, including chemical processing safety, electronic sensor compliance, and data integrity requirements.

Primary regulatory bodies overseeing microreactor systems include the Occupational Safety and Health Administration (OSHA), the Environmental Protection Agency (EPA), and industry-specific organizations such as the American Institute of Chemical Engineers (AIChE). These entities have established baseline safety protocols, though many are still adapting traditional chemical processing regulations to accommodate the novel characteristics of microreactor technology.

Risk assessment methodologies for microreactor systems with integrated sensors require specialized approaches that consider both chemical and electronic failure modes. The integration of sensors introduces additional complexity, as sensor malfunction could potentially lead to process control errors with safety implications. Comprehensive hazard and operability studies (HAZOP) specifically designed for microreactor systems are becoming standard practice in the industry.

Containment strategies and emergency protocols for microreactor failures present unique challenges due to their compact nature. While the reduced volumes of hazardous materials inherently limit potential exposure, the high concentration and reaction rates can create localized risks requiring specialized mitigation approaches. Best practices now include redundant sensor systems, automated shutdown protocols, and physical containment designs that account for potential sensor-related failures.

Certification requirements for microreactor systems vary significantly across jurisdictions and applications. Medical and pharmaceutical applications face particularly stringent requirements under FDA regulations, while industrial applications may follow different standards depending on the specific chemicals and processes involved. The International Electrotechnical Commission (IEC) provides standards relevant to the electronic components and sensors integrated into these systems.

Emerging regulatory trends indicate movement toward performance-based rather than prescriptive approaches, acknowledging the rapid pace of innovation in this field. Regulatory sandboxes are being established in some regions to allow controlled testing of novel microreactor configurations while gathering data to inform future regulatory frameworks. Industry consortia are increasingly collaborating with regulatory bodies to develop standards that balance innovation with safety considerations.

Compliance documentation for microreactor systems with integrated sensors typically requires extensive validation of both the chemical processes and the monitoring systems. This includes sensor calibration protocols, data integrity measures, and comprehensive testing under various operating conditions to demonstrate system reliability and safety performance.

Primary regulatory bodies overseeing microreactor systems include the Occupational Safety and Health Administration (OSHA), the Environmental Protection Agency (EPA), and industry-specific organizations such as the American Institute of Chemical Engineers (AIChE). These entities have established baseline safety protocols, though many are still adapting traditional chemical processing regulations to accommodate the novel characteristics of microreactor technology.

Risk assessment methodologies for microreactor systems with integrated sensors require specialized approaches that consider both chemical and electronic failure modes. The integration of sensors introduces additional complexity, as sensor malfunction could potentially lead to process control errors with safety implications. Comprehensive hazard and operability studies (HAZOP) specifically designed for microreactor systems are becoming standard practice in the industry.

Containment strategies and emergency protocols for microreactor failures present unique challenges due to their compact nature. While the reduced volumes of hazardous materials inherently limit potential exposure, the high concentration and reaction rates can create localized risks requiring specialized mitigation approaches. Best practices now include redundant sensor systems, automated shutdown protocols, and physical containment designs that account for potential sensor-related failures.

Certification requirements for microreactor systems vary significantly across jurisdictions and applications. Medical and pharmaceutical applications face particularly stringent requirements under FDA regulations, while industrial applications may follow different standards depending on the specific chemicals and processes involved. The International Electrotechnical Commission (IEC) provides standards relevant to the electronic components and sensors integrated into these systems.

Emerging regulatory trends indicate movement toward performance-based rather than prescriptive approaches, acknowledging the rapid pace of innovation in this field. Regulatory sandboxes are being established in some regions to allow controlled testing of novel microreactor configurations while gathering data to inform future regulatory frameworks. Industry consortia are increasingly collaborating with regulatory bodies to develop standards that balance innovation with safety considerations.

Compliance documentation for microreactor systems with integrated sensors typically requires extensive validation of both the chemical processes and the monitoring systems. This includes sensor calibration protocols, data integrity measures, and comprehensive testing under various operating conditions to demonstrate system reliability and safety performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!