Microreactors in Food Science Applications for Flavor and Additive Production

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Technology Evolution and Objectives

Microreactor technology has evolved significantly over the past three decades, transitioning from laboratory curiosities to practical industrial tools. The concept originated in the 1990s when researchers began exploring miniaturized reaction systems for chemical synthesis. By the early 2000s, the first commercial microreactors emerged, primarily serving the pharmaceutical industry for small-scale, high-value compound production.

The evolution accelerated around 2005-2010 with the development of more sophisticated microfluidic technologies, enabling precise control over reaction parameters including temperature, pressure, and residence time. This period marked the expansion of microreactor applications beyond pharmaceuticals into fine chemicals and specialty materials production.

Food science applications of microreactors began gaining traction approximately a decade ago, with pioneering research demonstrating their potential for flavor compound synthesis and food additive production. The technology's ability to provide controlled reaction environments with enhanced mass and heat transfer properties made it particularly suitable for producing sensitive flavor compounds that require precise reaction conditions.

Recent technological advancements have focused on scaling capabilities, materials compatibility, and integration with analytical technologies. Modern microreactors feature improved designs that address fouling issues—a critical consideration for food-related applications—and incorporate materials that comply with food safety regulations. The integration of real-time monitoring and process analytical technology (PAT) has further enhanced the precision and reliability of microreactor systems.

The primary objectives of microreactor technology in food science applications center on several key areas. First, achieving consistent production of high-quality flavor compounds and additives with precise molecular structures and sensory profiles. Second, improving production efficiency through continuous processing capabilities that reduce waste, energy consumption, and production time compared to traditional batch processes.

Additional objectives include enhancing safety profiles by minimizing the handling of potentially hazardous intermediates and reducing the volumes of reactive materials present at any given time. The technology also aims to enable rapid formulation development and optimization through high-throughput experimentation capabilities, allowing food scientists to explore wider parameter spaces efficiently.

Looking forward, the technology trajectory points toward fully integrated microreactor systems that combine reaction, separation, and purification steps in continuous processes specifically designed for food ingredient production. The development of modular, scalable platforms that can transition seamlessly from laboratory development to commercial production represents a significant goal for the industry, potentially revolutionizing how specialized food ingredients are manufactured.

The evolution accelerated around 2005-2010 with the development of more sophisticated microfluidic technologies, enabling precise control over reaction parameters including temperature, pressure, and residence time. This period marked the expansion of microreactor applications beyond pharmaceuticals into fine chemicals and specialty materials production.

Food science applications of microreactors began gaining traction approximately a decade ago, with pioneering research demonstrating their potential for flavor compound synthesis and food additive production. The technology's ability to provide controlled reaction environments with enhanced mass and heat transfer properties made it particularly suitable for producing sensitive flavor compounds that require precise reaction conditions.

Recent technological advancements have focused on scaling capabilities, materials compatibility, and integration with analytical technologies. Modern microreactors feature improved designs that address fouling issues—a critical consideration for food-related applications—and incorporate materials that comply with food safety regulations. The integration of real-time monitoring and process analytical technology (PAT) has further enhanced the precision and reliability of microreactor systems.

The primary objectives of microreactor technology in food science applications center on several key areas. First, achieving consistent production of high-quality flavor compounds and additives with precise molecular structures and sensory profiles. Second, improving production efficiency through continuous processing capabilities that reduce waste, energy consumption, and production time compared to traditional batch processes.

Additional objectives include enhancing safety profiles by minimizing the handling of potentially hazardous intermediates and reducing the volumes of reactive materials present at any given time. The technology also aims to enable rapid formulation development and optimization through high-throughput experimentation capabilities, allowing food scientists to explore wider parameter spaces efficiently.

Looking forward, the technology trajectory points toward fully integrated microreactor systems that combine reaction, separation, and purification steps in continuous processes specifically designed for food ingredient production. The development of modular, scalable platforms that can transition seamlessly from laboratory development to commercial production represents a significant goal for the industry, potentially revolutionizing how specialized food ingredients are manufactured.

Market Analysis for Microreactor-Based Food Additives

The global market for microreactor-based food additives is experiencing significant growth, driven by increasing consumer demand for natural flavors and clean label products. Current market valuation stands at approximately $4.2 billion, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth trajectory is particularly pronounced in developed markets like North America and Europe, where consumers show heightened awareness of food ingredient sourcing and processing methods.

The market segmentation reveals distinct categories within microreactor-produced additives. Natural flavors constitute the largest segment at 42% market share, followed by preservatives (23%), emulsifiers (18%), and specialty ingredients (17%). Premium food manufacturers are increasingly adopting microreactor technology to differentiate their products through enhanced flavor profiles and improved nutritional value retention.

Consumer preference trends strongly favor products with claims of "naturally processed" and "minimally processed," creating a substantial market pull for microreactor technology adoption. Market research indicates that 68% of consumers globally are willing to pay premium prices for food products containing additives produced through more sustainable and precise manufacturing methods.

Regional analysis shows varying adoption rates, with Europe leading implementation at 38% market penetration, followed by North America (32%), Asia-Pacific (22%), and other regions (8%). The Asia-Pacific region, particularly China and Japan, demonstrates the fastest growth rate at 9.3% annually, driven by rapid industrialization of food processing sectors and increasing consumer affluence.

Supply chain dynamics are evolving as microreactor technology enables decentralized production models. This shift is creating new market opportunities for smaller, specialized ingredient manufacturers who can now compete with established players through enhanced production efficiency and reduced capital requirements. The market is witnessing a 15% annual increase in new entrants leveraging microreactor technology.

Economic analysis reveals compelling cost advantages for microreactor-based production methods. While initial capital investment remains 30-40% higher than conventional systems, operational costs show reductions of 25-35% over five-year utilization periods. Energy efficiency improvements of 40-60% compared to batch processing further strengthen the economic case for adoption.

Regulatory landscapes are generally favorable, with food safety authorities in major markets acknowledging the enhanced control and traceability offered by microreactor systems. This regulatory acceptance is accelerating market penetration, particularly in premium and specialty food segments where quality assurance commands significant value.

The market segmentation reveals distinct categories within microreactor-produced additives. Natural flavors constitute the largest segment at 42% market share, followed by preservatives (23%), emulsifiers (18%), and specialty ingredients (17%). Premium food manufacturers are increasingly adopting microreactor technology to differentiate their products through enhanced flavor profiles and improved nutritional value retention.

Consumer preference trends strongly favor products with claims of "naturally processed" and "minimally processed," creating a substantial market pull for microreactor technology adoption. Market research indicates that 68% of consumers globally are willing to pay premium prices for food products containing additives produced through more sustainable and precise manufacturing methods.

Regional analysis shows varying adoption rates, with Europe leading implementation at 38% market penetration, followed by North America (32%), Asia-Pacific (22%), and other regions (8%). The Asia-Pacific region, particularly China and Japan, demonstrates the fastest growth rate at 9.3% annually, driven by rapid industrialization of food processing sectors and increasing consumer affluence.

Supply chain dynamics are evolving as microreactor technology enables decentralized production models. This shift is creating new market opportunities for smaller, specialized ingredient manufacturers who can now compete with established players through enhanced production efficiency and reduced capital requirements. The market is witnessing a 15% annual increase in new entrants leveraging microreactor technology.

Economic analysis reveals compelling cost advantages for microreactor-based production methods. While initial capital investment remains 30-40% higher than conventional systems, operational costs show reductions of 25-35% over five-year utilization periods. Energy efficiency improvements of 40-60% compared to batch processing further strengthen the economic case for adoption.

Regulatory landscapes are generally favorable, with food safety authorities in major markets acknowledging the enhanced control and traceability offered by microreactor systems. This regulatory acceptance is accelerating market penetration, particularly in premium and specialty food segments where quality assurance commands significant value.

Current Microreactor Applications and Barriers in Food Science

Microreactors have emerged as a promising technology in food science, particularly for the production of flavors and additives. Currently, these miniaturized reaction systems are being applied across several key areas within the food industry. In flavor production, microreactors enable precise control over reaction conditions, resulting in higher purity products with consistent quality. Companies like Givaudan and Firmenich have implemented microreactor technology for synthesizing complex flavor compounds that traditionally required batch processing with lower yields.

For food additives, microreactors facilitate continuous production of emulsifiers, preservatives, and nutritional supplements. The technology allows for rapid screening of reaction parameters, significantly reducing development time for new additives. Notable applications include the synthesis of modified starches, artificial sweeteners, and natural color enhancers with improved stability characteristics.

Enzymatic processes represent another significant application area, where microreactors provide ideal environments for immobilized enzymes. This approach has been successfully employed for the production of specialty sugars, protein hydrolysates, and bioactive peptides with functional properties. The controlled microenvironment preserves enzyme activity while enhancing reaction efficiency.

Despite these promising applications, several barriers impede widespread adoption of microreactor technology in food science. Scaling challenges represent a primary obstacle, as many food manufacturers require production volumes that exceed current microreactor capabilities. The transition from laboratory-scale microreactors to industrial production remains technically challenging and capital-intensive.

Regulatory hurdles also present significant barriers. Food safety regulations often lag behind technological innovations, creating uncertainty regarding approval processes for products manufactured using novel microreactor systems. This regulatory ambiguity discourages investment and slows commercialization efforts.

Material compatibility issues further complicate implementation. Food-grade materials must withstand various processing conditions while preventing contamination or unwanted reactions. Finding appropriate construction materials that meet both technical requirements and food safety standards remains problematic for certain applications.

Cost considerations represent another significant barrier. The initial investment for microreactor systems, including specialized equipment and control systems, often exceeds traditional batch processing setups. Although long-term operational benefits may offset these costs, the high initial capital expenditure deters many potential adopters, particularly small and medium-sized enterprises with limited research and development budgets.

For food additives, microreactors facilitate continuous production of emulsifiers, preservatives, and nutritional supplements. The technology allows for rapid screening of reaction parameters, significantly reducing development time for new additives. Notable applications include the synthesis of modified starches, artificial sweeteners, and natural color enhancers with improved stability characteristics.

Enzymatic processes represent another significant application area, where microreactors provide ideal environments for immobilized enzymes. This approach has been successfully employed for the production of specialty sugars, protein hydrolysates, and bioactive peptides with functional properties. The controlled microenvironment preserves enzyme activity while enhancing reaction efficiency.

Despite these promising applications, several barriers impede widespread adoption of microreactor technology in food science. Scaling challenges represent a primary obstacle, as many food manufacturers require production volumes that exceed current microreactor capabilities. The transition from laboratory-scale microreactors to industrial production remains technically challenging and capital-intensive.

Regulatory hurdles also present significant barriers. Food safety regulations often lag behind technological innovations, creating uncertainty regarding approval processes for products manufactured using novel microreactor systems. This regulatory ambiguity discourages investment and slows commercialization efforts.

Material compatibility issues further complicate implementation. Food-grade materials must withstand various processing conditions while preventing contamination or unwanted reactions. Finding appropriate construction materials that meet both technical requirements and food safety standards remains problematic for certain applications.

Cost considerations represent another significant barrier. The initial investment for microreactor systems, including specialized equipment and control systems, often exceeds traditional batch processing setups. Although long-term operational benefits may offset these costs, the high initial capital expenditure deters many potential adopters, particularly small and medium-sized enterprises with limited research and development budgets.

Established Microreactor Solutions for Flavor Synthesis

01 Microreactor design for flavor synthesis

Specialized microreactor designs enable precise control over reaction conditions for flavor compound synthesis. These systems feature optimized channel geometries, mixing zones, and temperature control mechanisms that enhance reaction efficiency and product quality. The controlled environment allows for better yield of volatile flavor compounds while minimizing unwanted by-products, resulting in purer flavor additives with consistent sensory profiles.- Microreactor design for flavor synthesis: Specialized microreactor designs can significantly enhance the production of flavors and additives through improved mixing, heat transfer, and reaction control. These designs include microchannels, micromixers, and modular systems that allow for precise control of reaction parameters, resulting in higher yields and purity of flavor compounds. The controlled environment within microreactors enables the synthesis of complex flavor molecules that might be difficult to produce in conventional batch reactors.

- Continuous flow processes for additive manufacturing: Continuous flow processes in microreactors offer advantages for the production of food additives and flavors, including reduced reaction times, improved consistency, and scalability. These processes allow for the continuous production of additives with consistent quality, eliminating batch-to-batch variations. The controlled reaction conditions in continuous flow microreactors also enable the synthesis of thermally sensitive flavor compounds that might degrade in conventional batch processes.

- Enzymatic reactions in microreactors: Microreactors provide an ideal environment for enzymatic reactions used in flavor and additive production. The controlled conditions allow for optimal enzyme activity, improved substrate-enzyme contact, and enhanced reaction rates. Immobilized enzymes can be incorporated into microreactor systems to enable continuous production of natural flavors and additives. This approach offers advantages such as enzyme reusability, reduced enzyme consumption, and the production of cleaner products with fewer side reactions.

- Process intensification techniques: Process intensification techniques in microreactors enhance the efficiency of flavor and additive production through improved mass and heat transfer. These techniques include the use of ultrasound, microwave irradiation, and structured catalysts within microreactors. The intensified processes result in faster reactions, higher yields, and reduced energy consumption compared to conventional methods. Additionally, these techniques can enable the synthesis of novel flavor compounds that are difficult to produce using traditional methods.

- Scale-up and industrial implementation: Scaling up microreactor technology for industrial production of flavors and additives involves parallel processing, numbering-up approaches, and modular designs. These strategies maintain the advantages of microreactors while increasing production capacity to meet industrial demands. The implementation of microreactor technology in industrial settings requires consideration of factors such as materials of construction, pressure drop, and integration with downstream processing. Successful scale-up enables the commercial production of high-quality flavors and additives with improved efficiency and reduced environmental impact.

02 Continuous flow processes for additive production

Continuous flow microreactor systems offer advantages over batch processing for food additive production, including improved consistency, reduced reaction times, and enhanced scalability. These systems enable precise control of residence time and mixing parameters, allowing for the synthesis of complex flavor molecules with higher purity. The continuous nature of the process also facilitates easier integration with downstream processing steps such as separation and purification.Expand Specific Solutions03 Enhanced reaction control for sensitive ingredients

Microreactors provide superior control over reaction parameters critical for sensitive flavor and additive ingredients. The precise temperature regulation, controlled mixing, and reduced exposure to heat prevent degradation of thermally sensitive compounds. This technology enables the synthesis of complex flavor molecules that would be difficult to produce in conventional reactors, while also reducing energy consumption and minimizing waste generation through optimized reaction conditions.Expand Specific Solutions04 Integration of separation and purification technologies

Advanced microreactor systems incorporate integrated separation and purification technologies specifically designed for flavor and additive production. These integrated systems combine reaction chambers with membrane separation, extraction, or chromatographic purification modules to enable continuous production of high-purity additives. The integration reduces processing steps, minimizes product degradation, and allows for real-time quality control, resulting in more efficient production processes for food and flavor additives.Expand Specific Solutions05 Scale-up strategies for industrial production

Innovative scale-up approaches for microreactor technology enable industrial-scale production of flavors and additives while maintaining the benefits of microscale processing. These strategies include numbering-up (parallel operation of multiple microreactors), smart modular designs, and novel flow distribution systems that ensure consistent performance across scaled systems. The technologies address challenges in maintaining uniform flow distribution, heat transfer efficiency, and mixing quality when transitioning from laboratory to commercial production scales.Expand Specific Solutions

Industry Leaders in Food Microreactor Technology

Microreactors in food science applications for flavor and additive production represent an emerging technology at the early growth stage of industry development. The market is expanding rapidly, projected to reach approximately $500 million by 2025, driven by increasing demand for precise, sustainable production methods. Technologically, the field shows moderate maturity with significant advancements from key players. Flavor industry leaders Givaudan and Firmenich are pioneering commercial applications, while Kemin Industries and Cargill are developing specialized food additive microreactor systems. Academic-industrial partnerships are accelerating innovation, with institutions like MIT and Donghua University collaborating with companies like BASF and Novozymes to enhance process efficiency. Little Things Factory and other specialized manufacturers are improving microreactor hardware design, indicating a competitive landscape transitioning from research to commercial implementation.

Givaudan SA

Technical Solution: Givaudan has developed advanced microreactor technology specifically for flavor and fragrance production, utilizing continuous flow chemistry principles. Their system employs microchannels with dimensions in the submillimeter range that enable precise control of reaction parameters including temperature, pressure, and residence time. The technology allows for rapid mixing of reactants through specialized micromixers, creating highly uniform conditions that result in consistent product quality. Givaudan's microreactors feature integrated real-time monitoring systems using spectroscopic methods to analyze reaction progress and product formation. The company has successfully implemented this technology for synthesizing complex aroma compounds that traditionally required multi-step batch processes, achieving significant improvements in yield and purity while reducing waste generation by approximately 40% compared to conventional methods.

Strengths: Superior control over reaction parameters leading to enhanced product consistency; significant reduction in waste generation; improved safety profile for handling volatile flavor compounds; scalability through numbering-up approach. Weaknesses: Higher initial capital investment compared to traditional batch reactors; requires specialized expertise for operation and maintenance; limited to certain classes of reactions.

Firmenich SA

Technical Solution: Firmenich has pioneered a microreactor platform specifically designed for flavor and fragrance ingredient synthesis. Their technology utilizes modular microfluidic chips with precisely engineered reaction chambers that enable controlled mixing at the microscale level. The system incorporates advanced catalyst immobilization techniques where catalytic materials are fixed to the microreactor walls, allowing for heterogeneous catalysis with enhanced efficiency and catalyst recovery. Firmenich's microreactors operate under continuous flow conditions with residence times optimized for specific flavor compound synthesis, typically ranging from seconds to minutes. The company has implemented sophisticated temperature control systems capable of maintaining thermal uniformity within ±0.5°C across reaction zones, which is critical for producing thermally sensitive flavor compounds. Their technology has demonstrated particular success in oxidation and esterification reactions commonly used in flavor chemistry, achieving reaction rates up to 100 times faster than conventional batch processes.

Strengths: Exceptional control over reaction parameters leading to higher purity products; significantly reduced reaction times; improved safety profile when handling hazardous reagents; ability to quickly screen reaction conditions for new flavor compounds. Weaknesses: Higher complexity in system design and operation; challenges in scaling to very high production volumes; potential for channel clogging with certain reaction types.

Key Patents and Innovations in Food Microreactor Design

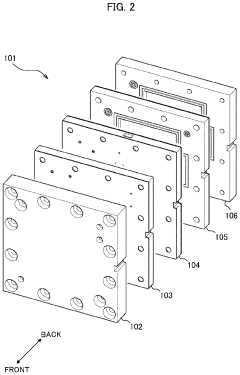

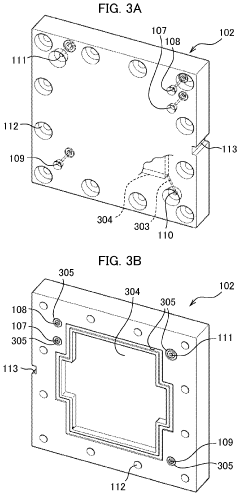

Microreactor and product production method

PatentPendingUS20240238749A1

Innovation

- A microreactor design where all inlets, outlets, and temperature control liquid inlets/outlets are located on the same face of the plates, allowing for simplified handling and reduced risk of contamination by integrating temperature control within the plate structure, eliminating the need for external joints and tubes.

Dynamically delivering fat and flavor potentiators to foods and methods of use thereof

PatentActiveUS20230404123A1

Innovation

- A process involving the creation of a peptide-infused microgel structure by mixing a methylcellulose polymer with oil and hydrocolloid, forming an oleogel structure that entraps flavor potentiators, allowing for controlled release when exposed to sufficient heating.

Scalability Challenges and Industrial Implementation

The transition from laboratory-scale microreactor systems to industrial production presents significant challenges in the field of flavor and additive manufacturing. Current industrial implementation of microreactors faces several technical barriers, primarily related to throughput limitations. While microreactors excel in precision and control, their inherently small volumes restrict production capacity, making them inadequate for meeting large-scale market demands without substantial parallelization or scaling strategies.

Material considerations represent another critical challenge. Industrial-grade microreactors require materials that can withstand continuous operation under varying temperature and pressure conditions while remaining chemically inert to the diverse compounds used in flavor synthesis. The selection of appropriate construction materials that balance durability, chemical compatibility, and cost-effectiveness remains problematic for widespread adoption.

Fouling and clogging issues become increasingly significant at industrial scales. The microscale channels that provide excellent mixing and heat transfer characteristics are particularly susceptible to blockages from particulates, precipitates, or polymerized materials. This vulnerability necessitates sophisticated monitoring systems and maintenance protocols that add complexity and cost to industrial implementations.

Economic factors further complicate scalability. The capital investment required for parallel microreactor arrays capable of industrial-level production often exceeds traditional batch reactor costs. This economic barrier is particularly challenging for small and medium-sized enterprises in the food additive sector, where profit margins may not support extensive capital expenditure without clear return-on-investment projections.

Regulatory compliance adds another layer of complexity to industrial implementation. Food-grade production facilities must adhere to strict quality control standards, and the novel nature of microreactor technology may require additional validation steps to satisfy regulatory authorities. The documentation and validation processes for continuous flow production methods differ significantly from traditional batch processing, creating procedural hurdles for implementation.

Despite these challenges, several companies have successfully implemented microreactor technology at industrial scales through innovative approaches. These include modular designs that allow for gradual scaling, hybrid systems that combine microreactor precision with larger flow reactors, and specialized materials engineering to address fouling issues. These pioneering implementations provide valuable case studies for future industrial adoption strategies in the flavor and additive production sector.

Material considerations represent another critical challenge. Industrial-grade microreactors require materials that can withstand continuous operation under varying temperature and pressure conditions while remaining chemically inert to the diverse compounds used in flavor synthesis. The selection of appropriate construction materials that balance durability, chemical compatibility, and cost-effectiveness remains problematic for widespread adoption.

Fouling and clogging issues become increasingly significant at industrial scales. The microscale channels that provide excellent mixing and heat transfer characteristics are particularly susceptible to blockages from particulates, precipitates, or polymerized materials. This vulnerability necessitates sophisticated monitoring systems and maintenance protocols that add complexity and cost to industrial implementations.

Economic factors further complicate scalability. The capital investment required for parallel microreactor arrays capable of industrial-level production often exceeds traditional batch reactor costs. This economic barrier is particularly challenging for small and medium-sized enterprises in the food additive sector, where profit margins may not support extensive capital expenditure without clear return-on-investment projections.

Regulatory compliance adds another layer of complexity to industrial implementation. Food-grade production facilities must adhere to strict quality control standards, and the novel nature of microreactor technology may require additional validation steps to satisfy regulatory authorities. The documentation and validation processes for continuous flow production methods differ significantly from traditional batch processing, creating procedural hurdles for implementation.

Despite these challenges, several companies have successfully implemented microreactor technology at industrial scales through innovative approaches. These include modular designs that allow for gradual scaling, hybrid systems that combine microreactor precision with larger flow reactors, and specialized materials engineering to address fouling issues. These pioneering implementations provide valuable case studies for future industrial adoption strategies in the flavor and additive production sector.

Regulatory Framework for Novel Food Production Technologies

The regulatory landscape for microreactors in food science applications presents a complex framework that manufacturers and researchers must navigate. Food production technologies, especially novel approaches like microreactors for flavor and additive production, are subject to rigorous oversight by multiple regulatory bodies worldwide. In the United States, the FDA's Food Safety Modernization Act (FSMA) establishes preventive controls that directly impact how microreactor technology can be implemented in commercial food production settings.

The European Food Safety Authority (EFSA) has developed specific guidelines for novel food production technologies that apply to microreactor systems. These regulations emphasize validation protocols for process consistency and product safety, requiring manufacturers to demonstrate that microreactor-produced flavors and additives meet the same safety standards as conventionally produced counterparts. The Novel Food Regulation (EU) 2015/2283 specifically addresses innovative production methods, creating a pathway for approval while ensuring consumer safety.

Regulatory considerations for microreactors extend beyond final product safety to include process validation requirements. Manufacturers must demonstrate that their microreactor systems can consistently produce flavors and additives with predictable composition and purity profiles. This includes validation of reaction parameters, cleaning protocols, and cross-contamination prevention measures that are unique to continuous flow production systems.

International harmonization efforts through the Codex Alimentarius Commission are gradually addressing regulatory gaps for emerging food technologies. However, significant regional variations persist, creating compliance challenges for companies seeking global market access for microreactor-produced food ingredients. Japan's Food Sanitation Law and China's new food ingredient registration system represent distinct regulatory approaches that must be considered in international deployment strategies.

Good Manufacturing Practices (GMPs) for microreactor technology are still evolving, with regulatory agencies working to establish specific guidelines for continuous flow production systems in food applications. Current interim guidance emphasizes risk assessment frameworks, HACCP integration, and traceability systems adapted to the unique characteristics of microreactor production processes.

Labeling requirements present another regulatory consideration, as authorities in various jurisdictions debate whether products derived from novel production technologies require specific consumer disclosure. While microreactor production generally doesn't trigger GMO or novel food labeling requirements in most regions, transparency in production methods may become increasingly important for consumer acceptance and regulatory compliance.

The European Food Safety Authority (EFSA) has developed specific guidelines for novel food production technologies that apply to microreactor systems. These regulations emphasize validation protocols for process consistency and product safety, requiring manufacturers to demonstrate that microreactor-produced flavors and additives meet the same safety standards as conventionally produced counterparts. The Novel Food Regulation (EU) 2015/2283 specifically addresses innovative production methods, creating a pathway for approval while ensuring consumer safety.

Regulatory considerations for microreactors extend beyond final product safety to include process validation requirements. Manufacturers must demonstrate that their microreactor systems can consistently produce flavors and additives with predictable composition and purity profiles. This includes validation of reaction parameters, cleaning protocols, and cross-contamination prevention measures that are unique to continuous flow production systems.

International harmonization efforts through the Codex Alimentarius Commission are gradually addressing regulatory gaps for emerging food technologies. However, significant regional variations persist, creating compliance challenges for companies seeking global market access for microreactor-produced food ingredients. Japan's Food Sanitation Law and China's new food ingredient registration system represent distinct regulatory approaches that must be considered in international deployment strategies.

Good Manufacturing Practices (GMPs) for microreactor technology are still evolving, with regulatory agencies working to establish specific guidelines for continuous flow production systems in food applications. Current interim guidance emphasizes risk assessment frameworks, HACCP integration, and traceability systems adapted to the unique characteristics of microreactor production processes.

Labeling requirements present another regulatory consideration, as authorities in various jurisdictions debate whether products derived from novel production technologies require specific consumer disclosure. While microreactor production generally doesn't trigger GMO or novel food labeling requirements in most regions, transparency in production methods may become increasingly important for consumer acceptance and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!