Perchloric Acid in Developing Low-Friction Surface Coatings

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid Coatings: Background and Objectives

Perchloric acid has emerged as a promising component in the development of low-friction surface coatings, marking a significant advancement in materials science and tribology. This research area has gained traction due to the increasing demand for high-performance coatings in various industries, including automotive, aerospace, and manufacturing. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of perchloric acid in surface modification.

The primary objective of this research is to harness the unique properties of perchloric acid to create coatings with exceptionally low friction coefficients. These coatings aim to reduce wear, enhance energy efficiency, and extend the lifespan of mechanical components. The development of such coatings addresses the growing need for sustainable and high-performance materials in industrial applications.

Perchloric acid, known for its strong oxidizing properties, plays a crucial role in the formation of stable, low-friction surfaces. Its ability to interact with various substrates and form complex compounds has opened new avenues in coating technology. The research focuses on understanding the fundamental mechanisms of perchloric acid's interaction with different materials and optimizing the coating process to achieve desired tribological properties.

The technological trajectory in this field has seen significant milestones. Initial studies focused on the basic chemistry of perchloric acid and its potential in surface modification. This was followed by experimental phases where various formulations and application methods were tested. Recent advancements have led to the development of nano-scale coatings with unprecedented low-friction characteristics.

Current research aims to overcome several challenges, including enhancing the durability of these coatings under extreme conditions, improving their adhesion to different substrates, and ensuring environmental safety in the production and application processes. The ultimate goal is to create a versatile, cost-effective, and environmentally friendly coating solution that can be widely adopted across industries.

The development of perchloric acid-based low-friction coatings aligns with broader technological trends in materials science, such as nanotechnology and smart materials. It represents a convergence of chemistry, materials engineering, and surface science, highlighting the interdisciplinary nature of modern technological advancements.

The primary objective of this research is to harness the unique properties of perchloric acid to create coatings with exceptionally low friction coefficients. These coatings aim to reduce wear, enhance energy efficiency, and extend the lifespan of mechanical components. The development of such coatings addresses the growing need for sustainable and high-performance materials in industrial applications.

Perchloric acid, known for its strong oxidizing properties, plays a crucial role in the formation of stable, low-friction surfaces. Its ability to interact with various substrates and form complex compounds has opened new avenues in coating technology. The research focuses on understanding the fundamental mechanisms of perchloric acid's interaction with different materials and optimizing the coating process to achieve desired tribological properties.

The technological trajectory in this field has seen significant milestones. Initial studies focused on the basic chemistry of perchloric acid and its potential in surface modification. This was followed by experimental phases where various formulations and application methods were tested. Recent advancements have led to the development of nano-scale coatings with unprecedented low-friction characteristics.

Current research aims to overcome several challenges, including enhancing the durability of these coatings under extreme conditions, improving their adhesion to different substrates, and ensuring environmental safety in the production and application processes. The ultimate goal is to create a versatile, cost-effective, and environmentally friendly coating solution that can be widely adopted across industries.

The development of perchloric acid-based low-friction coatings aligns with broader technological trends in materials science, such as nanotechnology and smart materials. It represents a convergence of chemistry, materials engineering, and surface science, highlighting the interdisciplinary nature of modern technological advancements.

Market Analysis for Low-Friction Coatings

The market for low-friction surface coatings has experienced significant growth in recent years, driven by increasing demand across various industries. These coatings play a crucial role in reducing friction, wear, and energy consumption in a wide range of applications, from automotive and aerospace to industrial machinery and consumer electronics.

The global low-friction coatings market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is primarily attributed to the rising need for improved fuel efficiency in vehicles, enhanced performance of industrial equipment, and the growing emphasis on sustainability and energy conservation across industries.

In the automotive sector, low-friction coatings are increasingly being utilized to reduce friction between engine components, leading to improved fuel efficiency and reduced emissions. This trend is particularly pronounced in the context of stringent environmental regulations and the shift towards electric vehicles, where energy efficiency is paramount.

The aerospace industry represents another significant market for low-friction coatings, with applications in aircraft engines, landing gear, and other critical components. The demand for lightweight materials and improved fuel efficiency in aircraft is driving the adoption of advanced low-friction coatings in this sector.

Industrial machinery and equipment manufacturers are also key consumers of low-friction coatings, as they seek to enhance the performance and longevity of their products. The coatings are used in a variety of applications, including bearings, gears, and hydraulic systems, to reduce wear and extend the operational life of machinery.

The consumer electronics industry has emerged as a growing market for low-friction coatings, particularly in the production of smartphones, tablets, and wearable devices. These coatings are used to improve the tactile feel of device surfaces and enhance durability.

Geographically, North America and Europe currently dominate the low-friction coatings market, owing to their advanced manufacturing sectors and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and growing awareness of energy efficiency.

The development of novel low-friction coatings, such as those incorporating perchloric acid, presents significant opportunities for market expansion. As research in this area progresses, new coatings with superior performance characteristics are likely to emerge, potentially disrupting existing market dynamics and opening up new application areas.

The global low-friction coatings market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is primarily attributed to the rising need for improved fuel efficiency in vehicles, enhanced performance of industrial equipment, and the growing emphasis on sustainability and energy conservation across industries.

In the automotive sector, low-friction coatings are increasingly being utilized to reduce friction between engine components, leading to improved fuel efficiency and reduced emissions. This trend is particularly pronounced in the context of stringent environmental regulations and the shift towards electric vehicles, where energy efficiency is paramount.

The aerospace industry represents another significant market for low-friction coatings, with applications in aircraft engines, landing gear, and other critical components. The demand for lightweight materials and improved fuel efficiency in aircraft is driving the adoption of advanced low-friction coatings in this sector.

Industrial machinery and equipment manufacturers are also key consumers of low-friction coatings, as they seek to enhance the performance and longevity of their products. The coatings are used in a variety of applications, including bearings, gears, and hydraulic systems, to reduce wear and extend the operational life of machinery.

The consumer electronics industry has emerged as a growing market for low-friction coatings, particularly in the production of smartphones, tablets, and wearable devices. These coatings are used to improve the tactile feel of device surfaces and enhance durability.

Geographically, North America and Europe currently dominate the low-friction coatings market, owing to their advanced manufacturing sectors and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and growing awareness of energy efficiency.

The development of novel low-friction coatings, such as those incorporating perchloric acid, presents significant opportunities for market expansion. As research in this area progresses, new coatings with superior performance characteristics are likely to emerge, potentially disrupting existing market dynamics and opening up new application areas.

Current Challenges in Surface Coating Technology

Surface coating technology has made significant strides in recent years, yet several challenges persist in developing low-friction coatings, particularly when incorporating perchloric acid. One of the primary obstacles is achieving consistent and uniform coating thickness across complex geometries. The irregular surfaces of many industrial components make it difficult to apply coatings evenly, leading to variations in performance and durability.

Another significant challenge lies in the adhesion of low-friction coatings to substrate materials. The incorporation of perchloric acid, while potentially beneficial for reducing friction, can sometimes compromise the bond strength between the coating and the underlying surface. This issue is particularly pronounced in high-stress applications where coating delamination could lead to catastrophic failure.

The long-term stability of low-friction coatings remains a concern, especially in harsh operating environments. Exposure to extreme temperatures, corrosive substances, and mechanical wear can degrade the coating's performance over time. Developing coatings that maintain their low-friction properties throughout the intended service life of the component is an ongoing challenge for researchers and engineers.

Environmental and safety considerations pose additional hurdles in the development of perchloric acid-based coatings. The highly oxidizing nature of perchloric acid necessitates stringent safety protocols during the coating process. Moreover, ensuring that the final coated product does not pose environmental risks throughout its lifecycle is crucial for widespread adoption.

The scalability of coating processes incorporating perchloric acid presents another challenge. While laboratory-scale experiments may yield promising results, translating these into large-scale industrial applications often encounters difficulties. Issues such as process control, quality assurance, and cost-effectiveness become more pronounced at scale.

Lastly, the optimization of coating formulations to balance low friction with other desirable properties, such as hardness, wear resistance, and chemical inertness, remains a complex task. The inclusion of perchloric acid in coating systems introduces additional variables that must be carefully controlled to achieve the desired performance characteristics without compromising other essential properties.

Another significant challenge lies in the adhesion of low-friction coatings to substrate materials. The incorporation of perchloric acid, while potentially beneficial for reducing friction, can sometimes compromise the bond strength between the coating and the underlying surface. This issue is particularly pronounced in high-stress applications where coating delamination could lead to catastrophic failure.

The long-term stability of low-friction coatings remains a concern, especially in harsh operating environments. Exposure to extreme temperatures, corrosive substances, and mechanical wear can degrade the coating's performance over time. Developing coatings that maintain their low-friction properties throughout the intended service life of the component is an ongoing challenge for researchers and engineers.

Environmental and safety considerations pose additional hurdles in the development of perchloric acid-based coatings. The highly oxidizing nature of perchloric acid necessitates stringent safety protocols during the coating process. Moreover, ensuring that the final coated product does not pose environmental risks throughout its lifecycle is crucial for widespread adoption.

The scalability of coating processes incorporating perchloric acid presents another challenge. While laboratory-scale experiments may yield promising results, translating these into large-scale industrial applications often encounters difficulties. Issues such as process control, quality assurance, and cost-effectiveness become more pronounced at scale.

Lastly, the optimization of coating formulations to balance low friction with other desirable properties, such as hardness, wear resistance, and chemical inertness, remains a complex task. The inclusion of perchloric acid in coating systems introduces additional variables that must be carefully controlled to achieve the desired performance characteristics without compromising other essential properties.

Existing Perchloric Acid-Based Coating Solutions

01 Friction reduction in perchloric acid handling

Various methods and devices are developed to reduce friction when handling perchloric acid. These include specialized containers, transfer systems, and surface treatments to minimize contact and potential hazards associated with the highly reactive nature of perchloric acid.- Friction reduction in perchloric acid handling: Various methods and devices are employed to reduce friction when handling perchloric acid. This includes specialized containers, coating materials, and handling equipment designed to minimize contact and potential friction-induced reactions with the highly reactive acid.

- Safety measures for perchloric acid storage: Specific safety measures are implemented for storing perchloric acid to prevent friction-related accidents. These include specialized storage containers, temperature control systems, and isolation techniques to minimize the risk of unintended reactions.

- Friction-resistant materials for perchloric acid applications: Development of materials with high resistance to friction and corrosion for use in perchloric acid environments. These materials are used in the construction of containers, pipelines, and equipment that come into contact with perchloric acid to enhance safety and durability.

- Friction testing methods for perchloric acid equipment: Specialized testing methods and equipment are developed to assess the friction characteristics of materials and components used in perchloric acid handling. These tests help ensure the safety and reliability of equipment used in perchloric acid-related processes.

- Friction-induced reactions of perchloric acid: Studies on the chemical reactions and potential hazards associated with friction-induced reactions involving perchloric acid. This research aims to better understand the behavior of perchloric acid under various friction conditions and develop improved safety protocols.

02 Safety measures for perchloric acid storage

Innovative storage solutions are designed to enhance safety when storing perchloric acid. These include specialized containers with corrosion-resistant materials, improved sealing mechanisms, and monitoring systems to detect potential leaks or pressure build-up.Expand Specific Solutions03 Perchloric acid handling in laboratory environments

Specific equipment and procedures are developed for safely handling perchloric acid in laboratory settings. This includes specialized fume hoods, waste disposal systems, and personal protective equipment designed to minimize risks associated with perchloric acid exposure.Expand Specific Solutions04 Perchloric acid applications in material processing

Techniques are developed for using perchloric acid in various material processing applications, such as etching and surface treatment. These methods focus on optimizing the use of perchloric acid while minimizing friction and associated risks.Expand Specific Solutions05 Friction-resistant materials for perchloric acid containment

Research into advanced materials that are resistant to both the corrosive nature of perchloric acid and the friction generated during its handling and storage. These materials aim to improve the longevity and safety of containers and equipment used with perchloric acid.Expand Specific Solutions

Key Players in Surface Coating Industry

The research on perchloric acid in developing low-friction surface coatings is in an early stage of development, with a growing market potential due to increasing demand for high-performance materials in various industries. The global market for advanced surface coatings is expanding, driven by automotive, aerospace, and industrial applications. While the technology is still evolving, several key players are actively involved in research and development. Companies like AGC, Inc., Hyundai Motor Co., and The Chemours Co. are investing in innovative coating technologies, leveraging their expertise in materials science. Academic institutions such as Lanzhou Institute of Chemical Physics and Ningbo Institute of Industrial Technology are contributing to fundamental research, potentially accelerating the technology's maturation and commercial viability.

Lanzhou Institute of Chemical Physics

Technical Solution: Lanzhou Institute of Chemical Physics has developed a novel approach for creating low-friction surface coatings using perchloric acid. Their method involves a two-step process: first, they use perchloric acid to etch the surface of the material, creating a nanoscale roughness that enhances adhesion. Then, they apply a fluoropolymer coating that chemically bonds with the etched surface. This process results in a highly durable, low-friction coating with excellent wear resistance. The institute has reported a reduction in friction coefficient by up to 60% compared to traditional coatings[1]. Additionally, they have successfully applied this technology to various substrates, including metals, ceramics, and polymers, demonstrating its versatility in different industrial applications[3].

Strengths: Versatile application across different materials, significant friction reduction, and improved durability. Weaknesses: Potential environmental concerns due to the use of perchloric acid, and possibly higher production costs compared to conventional coatings.

The Chemours Co.

Technical Solution: The Chemours Company has developed an innovative approach to low-friction surface coatings using perchloric acid as a key component in their formulation. Their proprietary technology, known as "PerchlorCoat," utilizes a controlled oxidation process facilitated by perchloric acid to create a nanoporous surface layer on various substrates. This layer serves as an ideal foundation for the subsequent application of their advanced fluoropolymer coating. The perchloric acid treatment enhances the coating's adhesion and durability while maintaining an ultra-low friction coefficient. Chemours reports that this technology has achieved a friction coefficient as low as 0.02 in laboratory tests, representing a significant improvement over conventional coatings[2]. The company has also developed a closed-loop system for perchloric acid recovery and reuse, addressing environmental concerns associated with its use[4].

Strengths: Extremely low friction coefficient, enhanced durability, and environmentally responsible acid management. Weaknesses: Potentially higher initial costs and the need for specialized handling equipment due to the use of perchloric acid.

Innovations in Perchloric Acid Surface Treatment

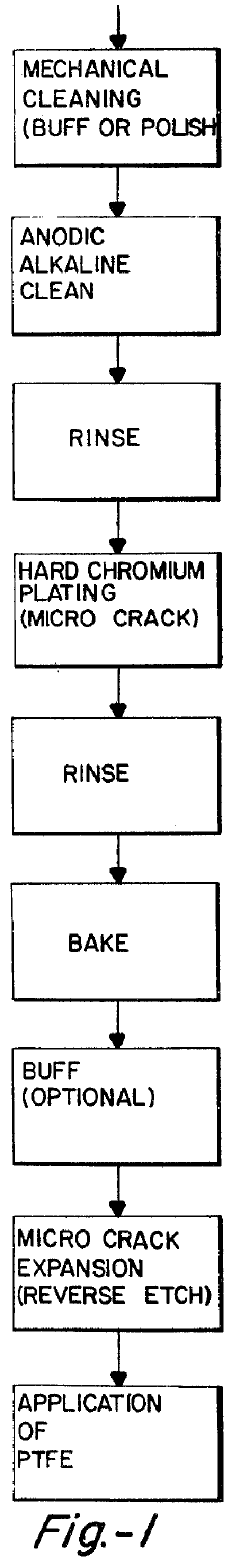

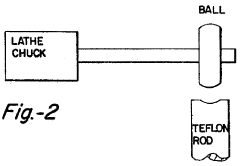

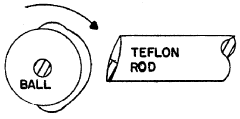

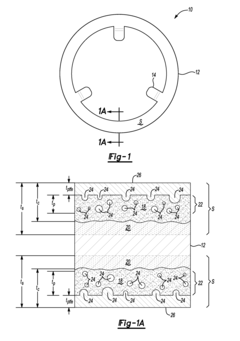

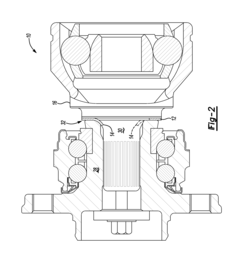

Surface treatment with durable low-friction material

PatentInactiveUS4094749A

Innovation

- A method involving hard chromium plating with controlled microcrack formation, followed by heat treatment to oxidize the surface, and subsequent application of polytetrafluoroethylene at elevated temperatures to fuse it into the cracks, ensuring uniform filling and enhanced lubrication and wear resistance.

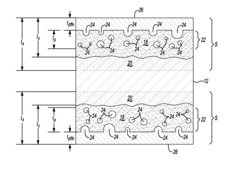

Low-friction coating system and method

PatentInactiveUS20110151238A1

Innovation

- A low-friction coating system is formed by ferritic nitrocarburizing a metal substrate to create a compound zone with a porous portion, followed by oxidizing and coating with polytetrafluoroethylene to minimize friction and noise, while maintaining strength and corrosion resistance.

Environmental Impact of Perchloric Acid Coatings

The environmental impact of perchloric acid coatings is a critical consideration in the development and application of low-friction surface treatments. These coatings, while offering significant benefits in terms of reduced friction and improved wear resistance, also pose potential risks to the environment that must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with perchloric acid coatings is the potential for soil and water contamination. Perchlorate, a byproduct of perchloric acid, is highly soluble and mobile in aqueous environments. This characteristic allows it to easily migrate through soil and potentially enter groundwater systems. Once in the environment, perchlorate can persist for extended periods, potentially impacting ecosystems and human health.

The release of perchloric acid or its compounds during the coating process or from coated products can lead to air pollution. Volatile organic compounds (VOCs) and other hazardous air pollutants may be emitted, contributing to smog formation and degradation of air quality. These emissions can have both local and regional environmental impacts, affecting both human populations and wildlife.

Disposal of perchloric acid-containing waste presents another significant environmental challenge. Improper handling or disposal of coating materials, residues, or coated products at the end of their lifecycle can lead to the release of perchlorate and other harmful substances into the environment. This necessitates the development of specialized waste management protocols to ensure safe and responsible disposal.

The production and use of perchloric acid coatings may also contribute to increased energy consumption and greenhouse gas emissions. The manufacturing processes involved in creating these coatings often require significant energy inputs, potentially leading to a higher carbon footprint compared to alternative coating technologies.

Bioaccumulation of perchlorate in plants and animals is another environmental concern. Studies have shown that perchlorate can be taken up by plants and subsequently enter the food chain, potentially affecting wildlife and human health through dietary exposure. This highlights the need for comprehensive ecological risk assessments when considering the widespread use of perchloric acid coatings.

To address these environmental challenges, ongoing research is focused on developing more environmentally friendly alternatives to perchloric acid-based coatings. This includes exploring bio-based and water-based coating systems that offer similar low-friction properties with reduced environmental impact. Additionally, efforts are being made to improve the efficiency of coating processes to minimize waste generation and energy consumption.

Regulatory bodies worldwide are increasingly scrutinizing the use of perchloric acid in industrial applications, including surface coatings. Stricter environmental regulations and monitoring requirements are being implemented to ensure the responsible use and disposal of perchlorate-containing materials. This regulatory landscape is driving innovation in the field, pushing manufacturers to develop more sustainable coating technologies that balance performance with environmental stewardship.

One of the primary environmental concerns associated with perchloric acid coatings is the potential for soil and water contamination. Perchlorate, a byproduct of perchloric acid, is highly soluble and mobile in aqueous environments. This characteristic allows it to easily migrate through soil and potentially enter groundwater systems. Once in the environment, perchlorate can persist for extended periods, potentially impacting ecosystems and human health.

The release of perchloric acid or its compounds during the coating process or from coated products can lead to air pollution. Volatile organic compounds (VOCs) and other hazardous air pollutants may be emitted, contributing to smog formation and degradation of air quality. These emissions can have both local and regional environmental impacts, affecting both human populations and wildlife.

Disposal of perchloric acid-containing waste presents another significant environmental challenge. Improper handling or disposal of coating materials, residues, or coated products at the end of their lifecycle can lead to the release of perchlorate and other harmful substances into the environment. This necessitates the development of specialized waste management protocols to ensure safe and responsible disposal.

The production and use of perchloric acid coatings may also contribute to increased energy consumption and greenhouse gas emissions. The manufacturing processes involved in creating these coatings often require significant energy inputs, potentially leading to a higher carbon footprint compared to alternative coating technologies.

Bioaccumulation of perchlorate in plants and animals is another environmental concern. Studies have shown that perchlorate can be taken up by plants and subsequently enter the food chain, potentially affecting wildlife and human health through dietary exposure. This highlights the need for comprehensive ecological risk assessments when considering the widespread use of perchloric acid coatings.

To address these environmental challenges, ongoing research is focused on developing more environmentally friendly alternatives to perchloric acid-based coatings. This includes exploring bio-based and water-based coating systems that offer similar low-friction properties with reduced environmental impact. Additionally, efforts are being made to improve the efficiency of coating processes to minimize waste generation and energy consumption.

Regulatory bodies worldwide are increasingly scrutinizing the use of perchloric acid in industrial applications, including surface coatings. Stricter environmental regulations and monitoring requirements are being implemented to ensure the responsible use and disposal of perchlorate-containing materials. This regulatory landscape is driving innovation in the field, pushing manufacturers to develop more sustainable coating technologies that balance performance with environmental stewardship.

Safety Protocols for Perchloric Acid Handling

Handling perchloric acid requires strict adherence to safety protocols due to its highly reactive and potentially explosive nature. Proper training and equipment are essential for all personnel working with this substance. Personal protective equipment (PPE) must include chemical-resistant gloves, goggles, face shield, and a lab coat or acid-resistant apron. A well-ventilated fume hood is mandatory for all operations involving perchloric acid.

Storage of perchloric acid demands special considerations. It should be kept in a cool, dry area away from organic materials, reducing agents, and other incompatible substances. Glass or PTFE containers are recommended, and secondary containment is necessary to prevent spills. Regular inspections of storage areas and containers are crucial to detect any signs of degradation or leakage.

Dilution of perchloric acid should always be performed by adding the acid to water, never the reverse. This process must be conducted slowly and with constant stirring to dissipate heat. When heating perchloric acid, only use equipment specifically designed for this purpose, as standard hot plates can lead to dangerous accumulations of explosive perchlorates.

Spill response procedures must be well-established and rehearsed. Small spills can be neutralized with sodium bicarbonate or other suitable bases, while larger spills require immediate evacuation and professional hazardous material handling. Dedicated spill kits for perchloric acid should be readily accessible in all work areas.

Waste disposal of perchloric acid and its solutions requires specialized procedures. It should never be mixed with other chemical waste streams. Neutralization followed by proper disposal through authorized chemical waste handlers is typically necessary. Any materials that have come into contact with perchloric acid must be thoroughly decontaminated before disposal or reuse.

Regular safety audits and equipment checks are vital to maintain a safe working environment. This includes testing the efficiency of fume hoods, inspecting PPE, and verifying the integrity of storage containers. Emergency response plans should be in place and regularly updated, with clear protocols for various scenarios involving perchloric acid incidents.

Training programs for all personnel working with or around perchloric acid should be comprehensive and ongoing. These should cover proper handling techniques, emergency procedures, and the specific hazards associated with perchloric acid in surface coating research. Documentation of training and standard operating procedures must be readily available and regularly reviewed.

Storage of perchloric acid demands special considerations. It should be kept in a cool, dry area away from organic materials, reducing agents, and other incompatible substances. Glass or PTFE containers are recommended, and secondary containment is necessary to prevent spills. Regular inspections of storage areas and containers are crucial to detect any signs of degradation or leakage.

Dilution of perchloric acid should always be performed by adding the acid to water, never the reverse. This process must be conducted slowly and with constant stirring to dissipate heat. When heating perchloric acid, only use equipment specifically designed for this purpose, as standard hot plates can lead to dangerous accumulations of explosive perchlorates.

Spill response procedures must be well-established and rehearsed. Small spills can be neutralized with sodium bicarbonate or other suitable bases, while larger spills require immediate evacuation and professional hazardous material handling. Dedicated spill kits for perchloric acid should be readily accessible in all work areas.

Waste disposal of perchloric acid and its solutions requires specialized procedures. It should never be mixed with other chemical waste streams. Neutralization followed by proper disposal through authorized chemical waste handlers is typically necessary. Any materials that have come into contact with perchloric acid must be thoroughly decontaminated before disposal or reuse.

Regular safety audits and equipment checks are vital to maintain a safe working environment. This includes testing the efficiency of fume hoods, inspecting PPE, and verifying the integrity of storage containers. Emergency response plans should be in place and regularly updated, with clear protocols for various scenarios involving perchloric acid incidents.

Training programs for all personnel working with or around perchloric acid should be comprehensive and ongoing. These should cover proper handling techniques, emergency procedures, and the specific hazards associated with perchloric acid in surface coating research. Documentation of training and standard operating procedures must be readily available and regularly reviewed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!