Research on Self-Powered Sensors for Biomedical Applications

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomedical Self-Powered Sensing: Background and Objectives

Self-powered sensing technologies have emerged as a revolutionary approach in biomedical applications, representing a significant paradigm shift from conventional battery-dependent devices. The evolution of this technology can be traced back to early energy harvesting concepts in the 1990s, which gradually converged with sensing technologies in the early 2000s. The past decade has witnessed exponential growth in research publications and patents related to self-powered biomedical sensors, indicating the field's increasing maturity and potential.

The technological trajectory has been shaped by advancements in materials science, particularly nanomaterials and flexible electronics, alongside miniaturization techniques that have enabled unprecedented form factors suitable for biomedical applications. Concurrently, developments in low-power electronics and energy harvesting mechanisms have addressed the fundamental challenge of operating sophisticated sensing systems with minimal energy input.

Current research focuses on harnessing various energy sources available in the human body and its immediate environment, including mechanical energy from body movements, thermal gradients, biochemical energy from bodily fluids, and ambient electromagnetic radiation. These energy sources, when effectively captured and converted, can power sensors for continuous health monitoring without the limitations imposed by traditional power sources.

The primary objective of self-powered biomedical sensing research is to develop autonomous, maintenance-free monitoring systems that can function reliably within or on the human body for extended periods. This includes creating sensors capable of detecting physiological parameters, biomarkers, and environmental factors relevant to health status, while simultaneously harvesting sufficient energy to power their operation and data transmission capabilities.

Secondary objectives encompass improving biocompatibility and addressing bioethical considerations, enhancing energy conversion efficiency to support more complex sensing and computing functions, and developing standardized protocols for performance evaluation and clinical validation. Additionally, there is a growing emphasis on creating systems that can adapt to the variable and often unpredictable nature of biological energy sources.

The ultimate goal extends beyond mere technical feasibility to practical clinical utility, aiming for seamless integration into healthcare systems. This necessitates addressing challenges related to data security, reliability in diverse physiological conditions, and compatibility with existing medical infrastructure. The field is progressing toward creating a new generation of medical devices that could transform patient monitoring, drug delivery, and therapeutic interventions through continuous, unobtrusive health surveillance without the constraints of external power sources.

The technological trajectory has been shaped by advancements in materials science, particularly nanomaterials and flexible electronics, alongside miniaturization techniques that have enabled unprecedented form factors suitable for biomedical applications. Concurrently, developments in low-power electronics and energy harvesting mechanisms have addressed the fundamental challenge of operating sophisticated sensing systems with minimal energy input.

Current research focuses on harnessing various energy sources available in the human body and its immediate environment, including mechanical energy from body movements, thermal gradients, biochemical energy from bodily fluids, and ambient electromagnetic radiation. These energy sources, when effectively captured and converted, can power sensors for continuous health monitoring without the limitations imposed by traditional power sources.

The primary objective of self-powered biomedical sensing research is to develop autonomous, maintenance-free monitoring systems that can function reliably within or on the human body for extended periods. This includes creating sensors capable of detecting physiological parameters, biomarkers, and environmental factors relevant to health status, while simultaneously harvesting sufficient energy to power their operation and data transmission capabilities.

Secondary objectives encompass improving biocompatibility and addressing bioethical considerations, enhancing energy conversion efficiency to support more complex sensing and computing functions, and developing standardized protocols for performance evaluation and clinical validation. Additionally, there is a growing emphasis on creating systems that can adapt to the variable and often unpredictable nature of biological energy sources.

The ultimate goal extends beyond mere technical feasibility to practical clinical utility, aiming for seamless integration into healthcare systems. This necessitates addressing challenges related to data security, reliability in diverse physiological conditions, and compatibility with existing medical infrastructure. The field is progressing toward creating a new generation of medical devices that could transform patient monitoring, drug delivery, and therapeutic interventions through continuous, unobtrusive health surveillance without the constraints of external power sources.

Market Analysis for Self-Powered Biomedical Sensors

The global market for self-powered biomedical sensors is experiencing robust growth, driven by increasing healthcare demands and technological advancements. Current market valuations indicate that the self-powered sensor market for biomedical applications reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 12.7% through 2028.

Healthcare industry trends significantly influence this market segment. The shift toward remote patient monitoring and telemedicine, accelerated by the COVID-19 pandemic, has created substantial demand for autonomous sensing solutions that can operate continuously without battery replacement. This trend aligns perfectly with self-powered sensor capabilities, particularly for long-term implantable and wearable medical devices.

Demographic factors further strengthen market potential, with aging populations in developed regions requiring more continuous health monitoring solutions. By 2030, over 20% of the population in North America, Europe, and East Asia will be over 65 years old, creating a substantial user base for biomedical monitoring technologies that minimize maintenance requirements.

Regional market analysis reveals varying adoption patterns. North America currently leads with approximately 38% market share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the fastest growth rate at 15.3% annually, driven by increasing healthcare infrastructure investments in China and India.

Application segmentation shows wearable health monitors as the dominant category, accounting for 42% of market revenue. Implantable medical devices represent 31%, while environmental and contextual health sensors comprise 18%. The remaining market share belongs to specialized applications including drug delivery systems and rehabilitation devices.

Consumer willingness to adopt these technologies appears strong, with recent surveys indicating that 67% of patients would prefer medical devices that require minimal maintenance or battery changes. Healthcare providers similarly express interest, with 72% of surveyed clinicians indicating that battery-free operation would significantly influence their device selection decisions.

Key market restraints include concerns about data reliability, initial implementation costs, and regulatory approval timelines. Despite these challenges, the convergence of energy harvesting technologies with miniaturized sensors creates a compelling value proposition that addresses critical healthcare needs for continuous, maintenance-free monitoring solutions.

Healthcare industry trends significantly influence this market segment. The shift toward remote patient monitoring and telemedicine, accelerated by the COVID-19 pandemic, has created substantial demand for autonomous sensing solutions that can operate continuously without battery replacement. This trend aligns perfectly with self-powered sensor capabilities, particularly for long-term implantable and wearable medical devices.

Demographic factors further strengthen market potential, with aging populations in developed regions requiring more continuous health monitoring solutions. By 2030, over 20% of the population in North America, Europe, and East Asia will be over 65 years old, creating a substantial user base for biomedical monitoring technologies that minimize maintenance requirements.

Regional market analysis reveals varying adoption patterns. North America currently leads with approximately 38% market share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the fastest growth rate at 15.3% annually, driven by increasing healthcare infrastructure investments in China and India.

Application segmentation shows wearable health monitors as the dominant category, accounting for 42% of market revenue. Implantable medical devices represent 31%, while environmental and contextual health sensors comprise 18%. The remaining market share belongs to specialized applications including drug delivery systems and rehabilitation devices.

Consumer willingness to adopt these technologies appears strong, with recent surveys indicating that 67% of patients would prefer medical devices that require minimal maintenance or battery changes. Healthcare providers similarly express interest, with 72% of surveyed clinicians indicating that battery-free operation would significantly influence their device selection decisions.

Key market restraints include concerns about data reliability, initial implementation costs, and regulatory approval timelines. Despite these challenges, the convergence of energy harvesting technologies with miniaturized sensors creates a compelling value proposition that addresses critical healthcare needs for continuous, maintenance-free monitoring solutions.

Technical Challenges in Self-Powered Sensing Technologies

Despite significant advancements in self-powered sensing technologies for biomedical applications, several critical technical challenges persist that impede widespread adoption and optimal performance. Energy harvesting mechanisms remain a fundamental challenge, as current technologies struggle to generate sufficient power from limited biological energy sources such as body heat, movement, or biochemical reactions. The power density of existing harvesters typically ranges from nanowatts to microwatts per square centimeter, which falls short of the requirements for continuous operation of advanced sensing systems.

Miniaturization presents another significant hurdle, particularly for implantable and wearable biomedical sensors. Reducing the size of energy harvesting components while maintaining adequate power output creates complex engineering trade-offs. Current energy harvesting technologies often require relatively large surface areas or volumes to generate meaningful power, conflicting with the need for minimally invasive medical devices.

Biocompatibility and long-term stability constitute critical challenges for self-powered sensors intended for in-vivo applications. Materials used in energy harvesters must not trigger immune responses or tissue inflammation while maintaining functionality in the corrosive and dynamic biological environment. Current materials often degrade over time, leading to diminished performance and potential safety concerns for long-term implantation scenarios.

Power management and energy storage systems face substantial technical barriers. The intermittent nature of harvested energy necessitates efficient power conditioning circuits and energy storage solutions. However, existing power management integrated circuits (PMICs) typically consume significant portions of the harvested energy, reducing overall system efficiency. Additionally, conventional batteries and supercapacitors have limited charge cycles and may contain toxic materials unsuitable for biomedical applications.

Signal processing and data transmission represent another layer of technical complexity. Self-powered sensors must balance the energy demands of sensing, processing, and wireless communication against limited available power. Current low-power communication protocols still consume relatively high energy during data transmission, creating bottlenecks in system design and operational longevity.

Manufacturing scalability and cost-effectiveness remain significant obstacles to commercialization. Many self-powered sensing technologies rely on specialized fabrication processes or exotic materials that are difficult to mass-produce. The integration of multiple components—energy harvesters, storage elements, sensors, and communication modules—into a single functional system presents complex manufacturing challenges that increase production costs and limit market penetration.

Miniaturization presents another significant hurdle, particularly for implantable and wearable biomedical sensors. Reducing the size of energy harvesting components while maintaining adequate power output creates complex engineering trade-offs. Current energy harvesting technologies often require relatively large surface areas or volumes to generate meaningful power, conflicting with the need for minimally invasive medical devices.

Biocompatibility and long-term stability constitute critical challenges for self-powered sensors intended for in-vivo applications. Materials used in energy harvesters must not trigger immune responses or tissue inflammation while maintaining functionality in the corrosive and dynamic biological environment. Current materials often degrade over time, leading to diminished performance and potential safety concerns for long-term implantation scenarios.

Power management and energy storage systems face substantial technical barriers. The intermittent nature of harvested energy necessitates efficient power conditioning circuits and energy storage solutions. However, existing power management integrated circuits (PMICs) typically consume significant portions of the harvested energy, reducing overall system efficiency. Additionally, conventional batteries and supercapacitors have limited charge cycles and may contain toxic materials unsuitable for biomedical applications.

Signal processing and data transmission represent another layer of technical complexity. Self-powered sensors must balance the energy demands of sensing, processing, and wireless communication against limited available power. Current low-power communication protocols still consume relatively high energy during data transmission, creating bottlenecks in system design and operational longevity.

Manufacturing scalability and cost-effectiveness remain significant obstacles to commercialization. Many self-powered sensing technologies rely on specialized fabrication processes or exotic materials that are difficult to mass-produce. The integration of multiple components—energy harvesters, storage elements, sensors, and communication modules—into a single functional system presents complex manufacturing challenges that increase production costs and limit market penetration.

Current Self-Powered Sensing Solutions

01 Energy harvesting mechanisms for self-powered sensors

Various energy harvesting mechanisms can be employed to power sensors autonomously. These include piezoelectric elements that convert mechanical vibrations into electrical energy, solar cells that harness light energy, and thermoelectric generators that utilize temperature differentials. These energy harvesting technologies enable sensors to operate without external power sources, making them suitable for remote or inaccessible locations where battery replacement is challenging.- Energy harvesting mechanisms for self-powered sensors: Various energy harvesting mechanisms can be employed to power sensors autonomously. These include piezoelectric elements that convert mechanical vibrations into electrical energy, thermoelectric generators that utilize temperature differentials, and photovoltaic cells that convert light into electricity. These harvesting technologies enable sensors to operate without external power sources, making them suitable for remote or inaccessible locations.

- Wireless self-powered sensor networks: Self-powered sensors can be integrated into wireless networks to enable distributed sensing applications. These networks utilize energy-efficient communication protocols and power management strategies to extend operational lifetimes. The sensors can communicate with each other or with central hubs while operating solely on harvested energy, enabling applications in environmental monitoring, structural health monitoring, and industrial automation.

- Triboelectric nanogenerators for sensor power: Triboelectric nanogenerators (TENGs) represent an emerging technology for powering sensors. These devices generate electricity through contact electrification and electrostatic induction when two materials with different electron affinities come into contact and separate. TENGs can harvest energy from various mechanical motions including human movement, vibrations, or fluid flow, making them versatile power sources for self-powered sensing systems.

- Integrated power management circuits: Specialized power management circuits are essential components of self-powered sensors. These circuits efficiently collect, store, and distribute the harvested energy to sensor components. They typically include voltage regulators, energy storage elements like supercapacitors, and intelligent power distribution systems that prioritize critical functions during low-energy periods. Advanced designs incorporate adaptive duty cycling to optimize power consumption based on available energy.

- Motion-based energy harvesting for sensors: Motion-based energy harvesting techniques specifically target kinetic energy from movement to power sensors. These systems can utilize inertial generators, electromagnetic induction, or mechanical strain to generate electricity. Applications include wearable health monitors powered by body movement, vehicle sensors powered by vibration, and industrial monitors powered by machinery motion. This approach is particularly valuable for sensors deployed in dynamic environments with regular movement patterns.

02 Wireless self-powered sensor networks

Self-powered sensors can be integrated into wireless sensor networks for various applications. These networks utilize energy-efficient communication protocols to transmit data while minimizing power consumption. The sensors harvest ambient energy from their surroundings to power both the sensing elements and wireless communication modules, enabling long-term deployment without maintenance. Such networks are particularly valuable for environmental monitoring, structural health monitoring, and industrial automation applications.Expand Specific Solutions03 Triboelectric and mechanical motion-based energy harvesting

Triboelectric and mechanical motion-based energy harvesting techniques convert kinetic energy from movement into electrical power for sensors. These systems utilize friction, vibration, or rotational motion to generate electricity. Applications include wearable devices that harvest energy from human movement, vehicle-mounted sensors powered by vibrations, and industrial sensors that utilize machinery motion. This approach is particularly effective in environments with consistent mechanical activity.Expand Specific Solutions04 Power management and energy storage solutions

Efficient power management circuits and energy storage solutions are critical for self-powered sensor systems. These include ultra-low-power microcontrollers, energy-efficient sensing algorithms, and optimized duty cycling to minimize power consumption. Advanced energy storage technologies such as supercapacitors and thin-film batteries store harvested energy for use during periods when ambient energy is unavailable. These systems often incorporate intelligent power management to prioritize critical functions when energy is limited.Expand Specific Solutions05 Application-specific self-powered sensor designs

Self-powered sensors are designed for specific applications with unique energy harvesting and sensing requirements. These include environmental sensors that monitor parameters like temperature, humidity, and air quality; biomedical sensors for health monitoring; structural health monitoring sensors for infrastructure; and industrial sensors for equipment monitoring. Each application requires tailored energy harvesting mechanisms, sensing technologies, and power management strategies to ensure reliable operation without external power sources.Expand Specific Solutions

Key Industry Players and Research Institutions

The self-powered sensors for biomedical applications market is in an early growth phase, with significant research momentum but limited commercial deployment. The global market is projected to expand rapidly as healthcare IoT and wearable medical devices gain traction. Academic institutions dominate the research landscape, with University of Electronic Science & Technology of China, California Institute of Technology, and Xi'an Jiaotong University leading fundamental innovations. Commercial players like Medtronic, Abbott Diabetes Care, and Inspire Medical Systems are beginning to translate research into practical applications, focusing on implantable and wearable self-powered monitoring solutions. The technology remains in early-to-mid maturity, with significant challenges in biocompatibility, power density, and long-term reliability still being addressed through collaborative industry-academic partnerships.

California Institute of Technology

Technical Solution: Caltech has developed groundbreaking self-powered biomedical sensors based on their proprietary flexible bioelectronic systems. Their approach combines novel nanomaterials with innovative energy harvesting mechanisms to create multifunctional sensing platforms. Caltech researchers have pioneered the use of graphene-based thermoelectric generators that convert small temperature differences between skin and ambient environment into electrical power, achieving conversion efficiencies of up to 2% with power densities of 3-4 μW/cm² at temperature differentials of just 5°C. These sensors incorporate ultrathin (< 5 μm) flexible substrates that conform perfectly to skin contours, maximizing thermal contact and energy transfer. Their technology also features hybrid energy harvesting systems that combine thermoelectric, piezoelectric, and photovoltaic elements to ensure continuous power generation under varying physiological conditions. Caltech's sensors employ advanced signal processing algorithms implemented in ultra-low-power ASIC chips (operating at < 500 nW) that enable continuous monitoring of multiple physiological parameters simultaneously. Recent developments include self-healing materials that extend device lifetime and improve reliability in dynamic biological environments.

Strengths: Cutting-edge materials science expertise; highly interdisciplinary approach combining multiple energy harvesting modalities; strong academic research capabilities driving continuous innovation. Weaknesses: Less developed commercialization pathway compared to industry players; potential challenges in scaling laboratory prototypes to mass production; academic focus may prioritize novelty over practical implementation considerations.

Abbott Diabetes Care, Inc.

Technical Solution: Abbott Diabetes Care has pioneered self-powered glucose monitoring sensors that utilize biofuel cell technology to generate power from bodily fluids. Their innovative approach employs specialized enzymes (glucose oxidase and laccase) immobilized on carbon nanotube electrodes that catalyze glucose oxidation in interstitial fluid, generating electrical current proportional to glucose concentration. This dual-function design simultaneously powers the sensor and provides glucose measurements without external power sources. Abbott's FreeStyle Libre system incorporates elements of this technology, achieving power densities of approximately 1-2 μW/cm² under physiological conditions. The sensors feature specialized membranes that control glucose diffusion and prevent enzyme degradation, extending operational lifetimes to 14+ days. Their proprietary signal processing algorithms compensate for variations in biofuel cell output, maintaining measurement accuracy throughout the sensor lifetime. Recent developments include integration with flexible, stretchable electronics that conform to body contours, improving user comfort and sensor contact stability.

Strengths: Direct correlation between analyte concentration and power generation creates an elegant self-calibrating system; extensive commercial experience in glucose monitoring; strong intellectual property portfolio. Weaknesses: Limited power output restricts functionality beyond basic sensing; enzyme stability issues can affect long-term reliability; performance variations based on physiological conditions like oxygen availability.

Critical Patents and Literature in Energy Harvesting Biosensors

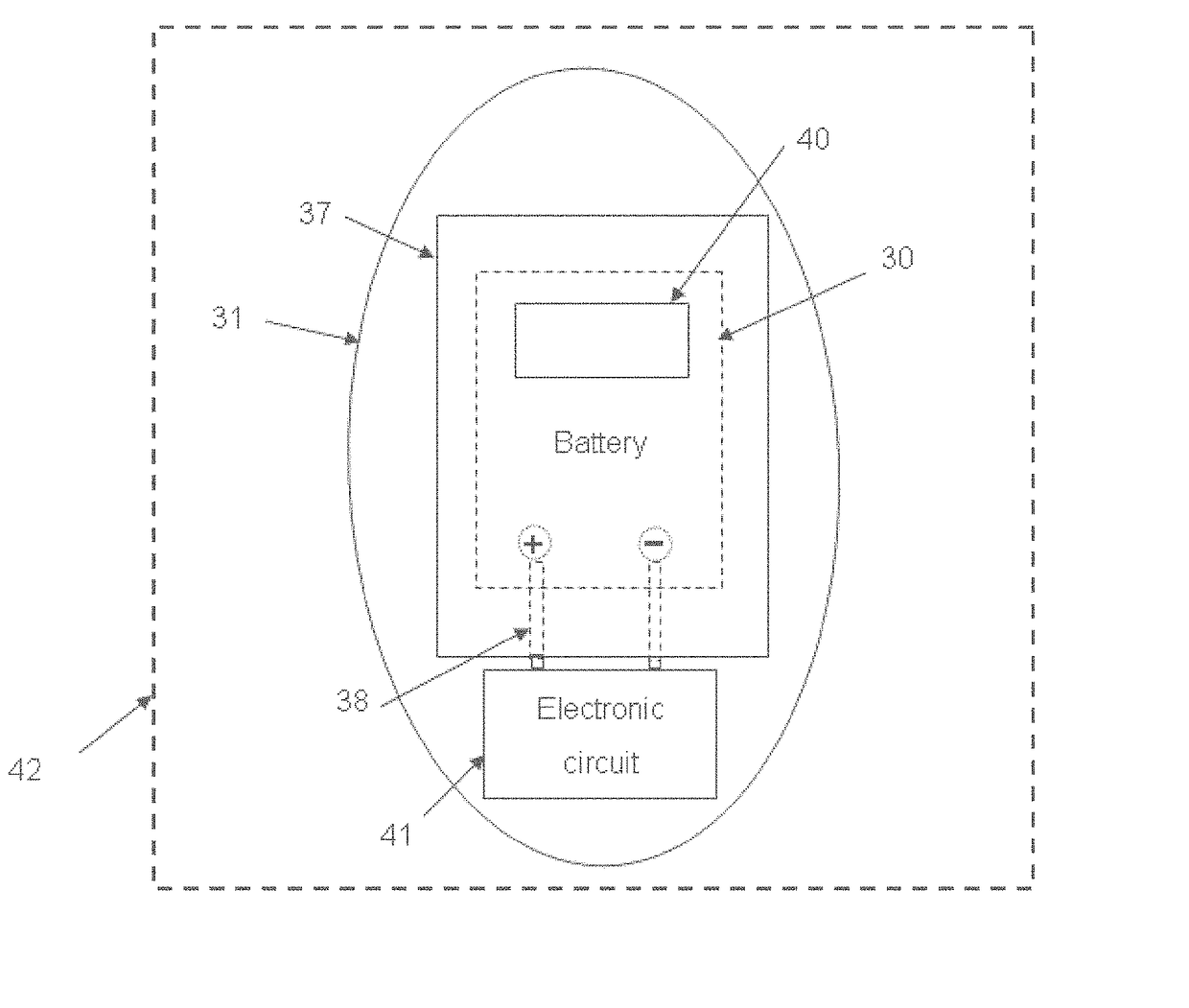

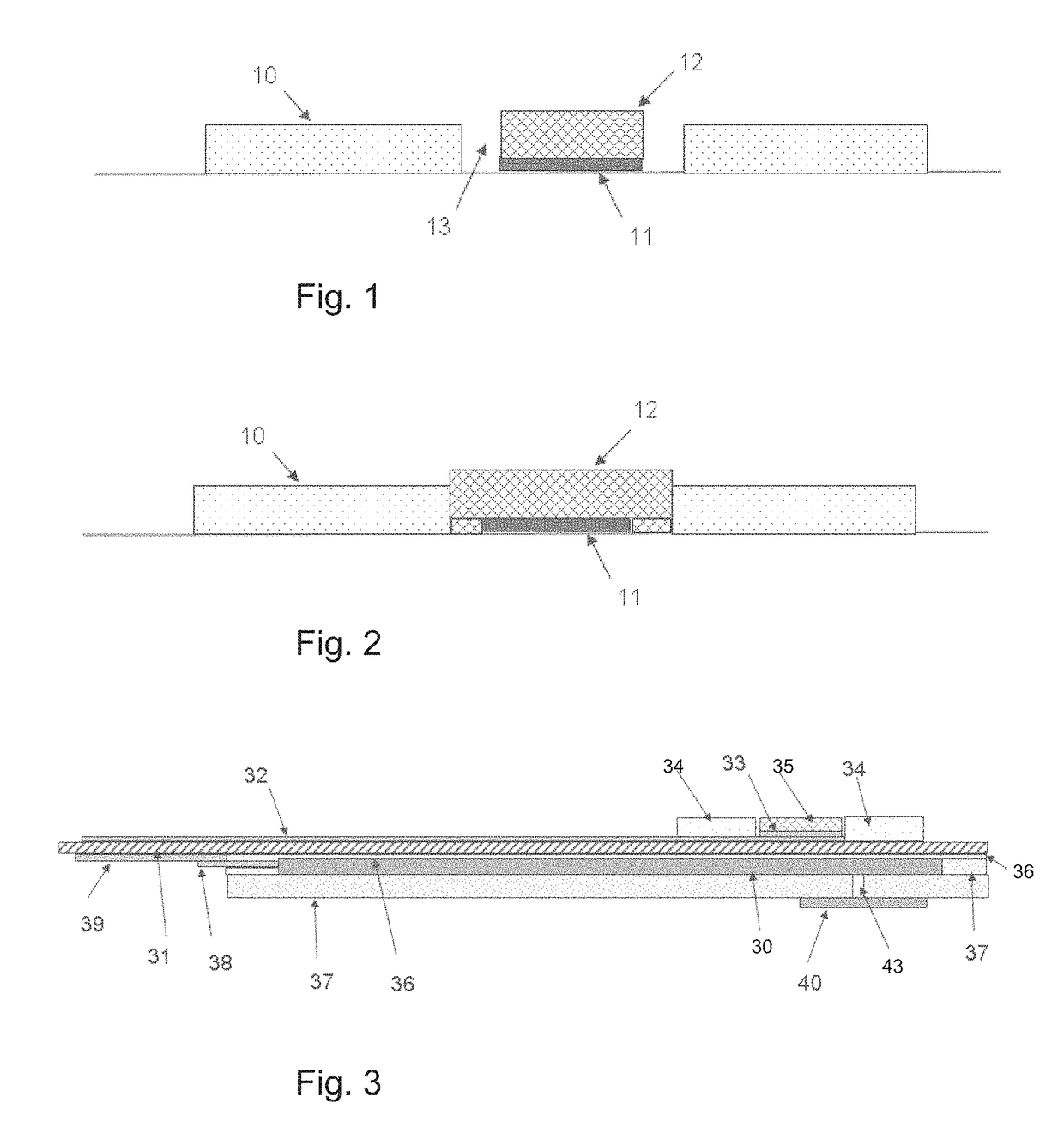

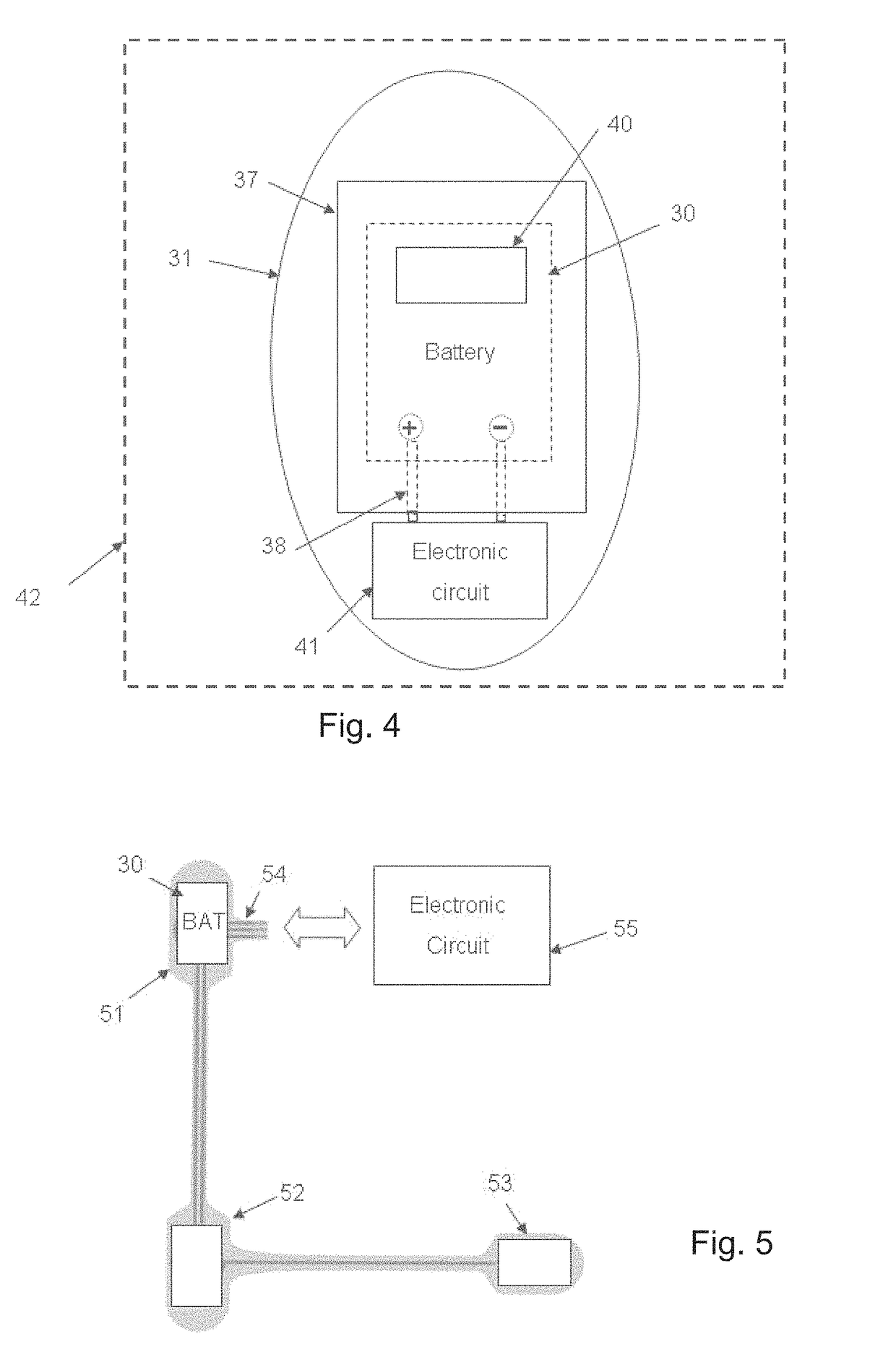

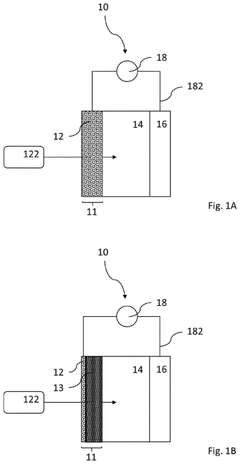

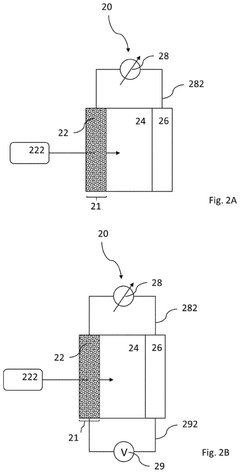

Single-use biomedical sensors

PatentActiveUS9782095B2

Innovation

- A self-powered biomedical sensor with a hermetically sealed compartment containing a printed battery and electrolyte, protected by humidity-resistant materials, allowing for long-term storage in high humidity and saline conditions without special handling.

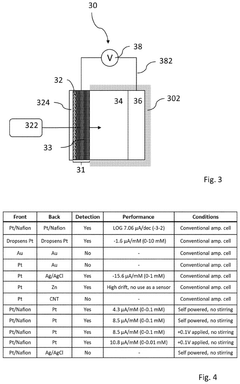

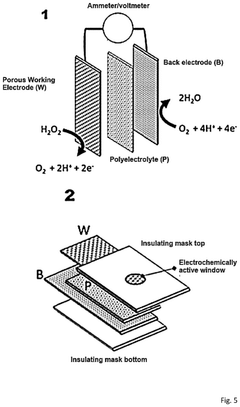

Electrochemical sensor in configuration thereof

PatentPendingUS20240353368A1

Innovation

- An electrochemical sensor configuration where the working electrode is porous, allowing the aqueous solution to percolate through and reach a counter electrode via an electrolytic conductor bridge, enabling full utilization of the exposed area for current generation and minimizing interference from redox-active species without the need for additional reference solutions.

Biocompatibility and Implantation Considerations

Biocompatibility represents a critical consideration in the development of self-powered sensors for biomedical applications. These devices must maintain functionality while avoiding adverse biological responses when implanted in the human body. The materials used in sensor construction must be carefully selected to prevent immune rejection, inflammation, or toxicity. Common biocompatible materials include medical-grade silicone, titanium alloys, certain ceramics, and specialized polymers that demonstrate minimal biological reactivity while maintaining necessary mechanical and electrical properties.

Long-term implantation introduces additional challenges beyond initial biocompatibility. Sensors must resist degradation from bodily fluids, maintain stable performance despite protein adsorption, and avoid mechanical failure due to micromotion or tissue growth. The encapsulation strategy becomes particularly important, requiring hermetic sealing that prevents moisture ingress while allowing for necessary sensing functions. Recent advances in flexible electronics have enabled the development of conformal sensors that better accommodate tissue movement, reducing mechanical stress at the tissue-device interface.

Power generation mechanisms for self-powered sensors introduce unique biocompatibility considerations. Piezoelectric materials must be selected or engineered to avoid leaching toxic elements while maintaining energy harvesting capabilities. Triboelectric generators require careful surface engineering to optimize charge generation while preventing adverse tissue reactions. Biofuel cells utilizing enzymatic reactions must ensure enzyme stability without triggering immunological responses.

Surgical implantation procedures and sensor form factors significantly impact clinical viability. Minimally invasive delivery methods are increasingly prioritized, requiring sensors to be compact, potentially foldable or injectable, and capable of self-deployment. The sensor's shape, size, and surface topography must be optimized to minimize tissue trauma during implantation while promoting appropriate tissue integration post-implantation. Edge smoothing, rounded corners, and gradient-stiffness designs have shown promise in reducing foreign body responses.

Regulatory pathways for implantable self-powered sensors remain challenging, with requirements varying by jurisdiction. ISO 10993 standards provide a framework for biological evaluation, including cytotoxicity, sensitization, and genotoxicity testing. Long-term animal studies are typically required to demonstrate safety before human trials can commence. The FDA's regulatory pathway for combination devices (incorporating sensing, power generation, and potentially drug delivery) adds complexity to the approval process, necessitating comprehensive safety and efficacy data.

Long-term implantation introduces additional challenges beyond initial biocompatibility. Sensors must resist degradation from bodily fluids, maintain stable performance despite protein adsorption, and avoid mechanical failure due to micromotion or tissue growth. The encapsulation strategy becomes particularly important, requiring hermetic sealing that prevents moisture ingress while allowing for necessary sensing functions. Recent advances in flexible electronics have enabled the development of conformal sensors that better accommodate tissue movement, reducing mechanical stress at the tissue-device interface.

Power generation mechanisms for self-powered sensors introduce unique biocompatibility considerations. Piezoelectric materials must be selected or engineered to avoid leaching toxic elements while maintaining energy harvesting capabilities. Triboelectric generators require careful surface engineering to optimize charge generation while preventing adverse tissue reactions. Biofuel cells utilizing enzymatic reactions must ensure enzyme stability without triggering immunological responses.

Surgical implantation procedures and sensor form factors significantly impact clinical viability. Minimally invasive delivery methods are increasingly prioritized, requiring sensors to be compact, potentially foldable or injectable, and capable of self-deployment. The sensor's shape, size, and surface topography must be optimized to minimize tissue trauma during implantation while promoting appropriate tissue integration post-implantation. Edge smoothing, rounded corners, and gradient-stiffness designs have shown promise in reducing foreign body responses.

Regulatory pathways for implantable self-powered sensors remain challenging, with requirements varying by jurisdiction. ISO 10993 standards provide a framework for biological evaluation, including cytotoxicity, sensitization, and genotoxicity testing. Long-term animal studies are typically required to demonstrate safety before human trials can commence. The FDA's regulatory pathway for combination devices (incorporating sensing, power generation, and potentially drug delivery) adds complexity to the approval process, necessitating comprehensive safety and efficacy data.

Regulatory Framework for Medical Sensing Devices

The regulatory landscape for self-powered biomedical sensors presents a complex framework that manufacturers, researchers, and healthcare providers must navigate. In the United States, the Food and Drug Administration (FDA) classifies most biomedical sensors as medical devices, with self-powered sensors typically falling under Class II or Class III categories depending on their invasiveness and risk profile. The regulatory pathway often requires premarket notification (510(k)) or premarket approval (PMA), with increasing scrutiny for implantable or long-term monitoring devices.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which introduced more stringent requirements for clinical evidence, post-market surveillance, and unique device identification. Self-powered sensors must comply with these regulations, demonstrating safety, performance, and clinical benefit through comprehensive technical documentation and conformity assessment procedures.

In Asia, Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA) have established their own regulatory frameworks, often requiring country-specific testing and documentation. This regional variation creates significant challenges for global deployment of innovative sensing technologies.

International standards play a crucial role in regulatory compliance. ISO 13485 for quality management systems, IEC 60601 for electrical medical equipment safety, and ISO 14971 for risk management are fundamental standards that self-powered sensor developers must adhere to. Additionally, specific standards for biocompatibility (ISO 10993) and software validation (IEC 62304) are particularly relevant for implantable or wearable self-powered sensing devices.

Data privacy regulations add another layer of complexity. The Health Insurance Portability and Accountability Act (HIPAA) in the US, General Data Protection Regulation (GDPR) in Europe, and similar frameworks worldwide impose strict requirements on the collection, storage, and transmission of health data generated by biomedical sensors. Manufacturers must implement robust data protection measures and transparent consent mechanisms.

Emerging regulatory considerations include cybersecurity requirements, as connected biomedical sensors become potential targets for malicious attacks. Regulatory bodies are increasingly demanding comprehensive cybersecurity risk assessments and mitigation strategies throughout the device lifecycle. Additionally, the environmental impact of disposable sensors is drawing regulatory attention, with some jurisdictions implementing extended producer responsibility requirements.

The pathway to regulatory approval for novel self-powered sensors often requires early engagement with regulatory authorities through pre-submission consultations and careful strategic planning to navigate the evolving regulatory landscape efficiently while ensuring patient safety and device effectiveness.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which introduced more stringent requirements for clinical evidence, post-market surveillance, and unique device identification. Self-powered sensors must comply with these regulations, demonstrating safety, performance, and clinical benefit through comprehensive technical documentation and conformity assessment procedures.

In Asia, Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA) have established their own regulatory frameworks, often requiring country-specific testing and documentation. This regional variation creates significant challenges for global deployment of innovative sensing technologies.

International standards play a crucial role in regulatory compliance. ISO 13485 for quality management systems, IEC 60601 for electrical medical equipment safety, and ISO 14971 for risk management are fundamental standards that self-powered sensor developers must adhere to. Additionally, specific standards for biocompatibility (ISO 10993) and software validation (IEC 62304) are particularly relevant for implantable or wearable self-powered sensing devices.

Data privacy regulations add another layer of complexity. The Health Insurance Portability and Accountability Act (HIPAA) in the US, General Data Protection Regulation (GDPR) in Europe, and similar frameworks worldwide impose strict requirements on the collection, storage, and transmission of health data generated by biomedical sensors. Manufacturers must implement robust data protection measures and transparent consent mechanisms.

Emerging regulatory considerations include cybersecurity requirements, as connected biomedical sensors become potential targets for malicious attacks. Regulatory bodies are increasingly demanding comprehensive cybersecurity risk assessments and mitigation strategies throughout the device lifecycle. Additionally, the environmental impact of disposable sensors is drawing regulatory attention, with some jurisdictions implementing extended producer responsibility requirements.

The pathway to regulatory approval for novel self-powered sensors often requires early engagement with regulatory authorities through pre-submission consultations and careful strategic planning to navigate the evolving regulatory landscape efficiently while ensuring patient safety and device effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!