Sodium Ion Batteries in Water Purification Technology

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Background and Objectives

Sodium-ion batteries have emerged as a promising technology in recent years, attracting significant attention from researchers and industry professionals. The development of these batteries can be traced back to the 1980s, but it is only in the past decade that they have gained momentum as a potential alternative to lithium-ion batteries. The evolution of sodium-ion batteries has been driven by the need for more sustainable and cost-effective energy storage solutions, particularly in applications where high energy density is not the primary concern.

The technology behind sodium-ion batteries is based on the principle of ion intercalation, similar to lithium-ion batteries. However, sodium-ion batteries utilize abundant and widely distributed sodium resources, making them potentially more economical and environmentally friendly. The progression of this technology has been marked by advancements in electrode materials, electrolytes, and cell designs, all aimed at improving performance and stability.

In the context of water purification technology, sodium-ion batteries present an intriguing opportunity for innovation. The integration of these batteries into water treatment systems could potentially address several challenges in the field, including energy efficiency, remote operation, and the need for sustainable power sources in off-grid locations. As water scarcity becomes an increasingly pressing global issue, the development of energy-efficient and cost-effective purification technologies is crucial.

The primary objectives of researching sodium-ion batteries in water purification technology are multifaceted. Firstly, there is a need to explore the feasibility of using these batteries as a reliable power source for various water treatment processes, such as reverse osmosis, electrodialysis, and advanced oxidation. Secondly, researchers aim to optimize the battery design and chemistry to withstand the unique environmental conditions often encountered in water treatment facilities, including high humidity and potential exposure to corrosive elements.

Another key goal is to investigate the potential for sodium-ion batteries to enable more efficient and flexible water purification systems. This includes exploring their use in portable or mobile water treatment units, which could be crucial for disaster relief efforts or in areas with limited infrastructure. Additionally, researchers are interested in leveraging the inherent properties of sodium-ion batteries, such as their ability to operate effectively at a wide range of temperatures, to enhance the overall robustness and versatility of water purification systems.

As the research progresses, there is also a focus on addressing the specific challenges associated with integrating sodium-ion batteries into existing water treatment technologies. This involves studying the long-term performance and durability of these batteries in water purification applications, as well as developing strategies to mitigate any potential environmental impacts associated with their production and disposal.

The technology behind sodium-ion batteries is based on the principle of ion intercalation, similar to lithium-ion batteries. However, sodium-ion batteries utilize abundant and widely distributed sodium resources, making them potentially more economical and environmentally friendly. The progression of this technology has been marked by advancements in electrode materials, electrolytes, and cell designs, all aimed at improving performance and stability.

In the context of water purification technology, sodium-ion batteries present an intriguing opportunity for innovation. The integration of these batteries into water treatment systems could potentially address several challenges in the field, including energy efficiency, remote operation, and the need for sustainable power sources in off-grid locations. As water scarcity becomes an increasingly pressing global issue, the development of energy-efficient and cost-effective purification technologies is crucial.

The primary objectives of researching sodium-ion batteries in water purification technology are multifaceted. Firstly, there is a need to explore the feasibility of using these batteries as a reliable power source for various water treatment processes, such as reverse osmosis, electrodialysis, and advanced oxidation. Secondly, researchers aim to optimize the battery design and chemistry to withstand the unique environmental conditions often encountered in water treatment facilities, including high humidity and potential exposure to corrosive elements.

Another key goal is to investigate the potential for sodium-ion batteries to enable more efficient and flexible water purification systems. This includes exploring their use in portable or mobile water treatment units, which could be crucial for disaster relief efforts or in areas with limited infrastructure. Additionally, researchers are interested in leveraging the inherent properties of sodium-ion batteries, such as their ability to operate effectively at a wide range of temperatures, to enhance the overall robustness and versatility of water purification systems.

As the research progresses, there is also a focus on addressing the specific challenges associated with integrating sodium-ion batteries into existing water treatment technologies. This involves studying the long-term performance and durability of these batteries in water purification applications, as well as developing strategies to mitigate any potential environmental impacts associated with their production and disposal.

Water Purification Market Analysis

The water purification market has been experiencing significant growth in recent years, driven by increasing global concerns over water scarcity and quality. The market is expected to continue its upward trajectory, with a particular focus on innovative technologies such as sodium ion batteries in water purification systems.

The global water purification market is segmented into various categories, including residential, commercial, and industrial applications. Among these, the industrial sector holds a substantial market share due to stringent regulations on wastewater treatment and the need for high-quality process water in manufacturing.

Geographically, North America and Europe have traditionally dominated the water purification market, owing to their advanced infrastructure and stringent environmental regulations. However, the Asia-Pacific region is emerging as a key growth area, fueled by rapid industrialization, urbanization, and increasing awareness of water quality issues.

The market for sodium ion battery-based water purification technologies is still in its nascent stages but shows promising potential. This technology offers several advantages over conventional water treatment methods, including energy efficiency, cost-effectiveness, and environmental sustainability. As research and development in this field progress, it is expected to carve out a significant niche within the broader water purification market.

Key market drivers for sodium ion battery-based water purification systems include the growing demand for sustainable and energy-efficient water treatment solutions, increasing water stress in many regions, and the push for circular economy practices in water management. Additionally, the rising adoption of smart water technologies and the integration of IoT in water treatment systems are creating new opportunities for innovative solutions like sodium ion batteries.

However, the market also faces challenges, such as the need for further technological advancements to improve efficiency and scalability, as well as competition from established water purification technologies. Overcoming these hurdles will be crucial for the widespread adoption of sodium ion battery-based water purification systems.

In terms of market dynamics, there is a growing trend towards decentralized water treatment solutions, which could potentially benefit sodium ion battery technologies due to their compact size and energy efficiency. Furthermore, the increasing focus on removing emerging contaminants, such as pharmaceuticals and microplastics, from water sources presents an opportunity for advanced technologies like sodium ion batteries to demonstrate their effectiveness.

As the water purification market continues to evolve, collaborations between technology providers, water utilities, and research institutions are likely to play a crucial role in driving innovation and market growth for sodium ion battery-based water purification systems.

The global water purification market is segmented into various categories, including residential, commercial, and industrial applications. Among these, the industrial sector holds a substantial market share due to stringent regulations on wastewater treatment and the need for high-quality process water in manufacturing.

Geographically, North America and Europe have traditionally dominated the water purification market, owing to their advanced infrastructure and stringent environmental regulations. However, the Asia-Pacific region is emerging as a key growth area, fueled by rapid industrialization, urbanization, and increasing awareness of water quality issues.

The market for sodium ion battery-based water purification technologies is still in its nascent stages but shows promising potential. This technology offers several advantages over conventional water treatment methods, including energy efficiency, cost-effectiveness, and environmental sustainability. As research and development in this field progress, it is expected to carve out a significant niche within the broader water purification market.

Key market drivers for sodium ion battery-based water purification systems include the growing demand for sustainable and energy-efficient water treatment solutions, increasing water stress in many regions, and the push for circular economy practices in water management. Additionally, the rising adoption of smart water technologies and the integration of IoT in water treatment systems are creating new opportunities for innovative solutions like sodium ion batteries.

However, the market also faces challenges, such as the need for further technological advancements to improve efficiency and scalability, as well as competition from established water purification technologies. Overcoming these hurdles will be crucial for the widespread adoption of sodium ion battery-based water purification systems.

In terms of market dynamics, there is a growing trend towards decentralized water treatment solutions, which could potentially benefit sodium ion battery technologies due to their compact size and energy efficiency. Furthermore, the increasing focus on removing emerging contaminants, such as pharmaceuticals and microplastics, from water sources presents an opportunity for advanced technologies like sodium ion batteries to demonstrate their effectiveness.

As the water purification market continues to evolve, collaborations between technology providers, water utilities, and research institutions are likely to play a crucial role in driving innovation and market growth for sodium ion battery-based water purification systems.

Sodium Ion Battery Challenges in Water Treatment

The integration of sodium-ion batteries into water purification technology presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the limited energy density of sodium-ion batteries compared to their lithium-ion counterparts. This constraint necessitates larger battery sizes to achieve equivalent power outputs, potentially increasing the overall footprint of water treatment systems and limiting their portability.

Another critical challenge lies in the stability and longevity of sodium-ion batteries in water treatment applications. The harsh environmental conditions often present in water purification processes, including high humidity and potential exposure to corrosive substances, can accelerate battery degradation. This issue demands the development of robust encapsulation techniques and materials that can withstand these challenging conditions while maintaining battery performance over extended periods.

The cycling stability of sodium-ion batteries also poses a significant hurdle in water treatment contexts. The repeated charge and discharge cycles, coupled with potential intermittent usage patterns in water purification systems, can lead to capacity fading and reduced battery lifespan. Addressing this challenge requires innovative electrode materials and electrolyte formulations that can maintain stable performance over thousands of cycles.

Furthermore, the integration of sodium-ion batteries with existing water treatment technologies presents compatibility issues. Adapting current purification systems to accommodate these batteries may require significant redesigns, potentially increasing costs and complexity. Engineers must develop seamless integration strategies that optimize the synergy between battery systems and water treatment processes without compromising efficiency or reliability.

Safety considerations also play a crucial role in the application of sodium-ion batteries in water purification. While generally considered safer than lithium-ion batteries due to lower reactivity, sodium-ion batteries still pose potential risks in water-rich environments. Developing fail-safe mechanisms and protective measures to prevent short circuits or thermal runaway events is essential for widespread adoption in water treatment facilities.

Lastly, the cost-effectiveness of sodium-ion batteries in water purification applications remains a challenge. Although sodium is more abundant and potentially cheaper than lithium, the current production scales and technological maturity of sodium-ion batteries result in higher costs compared to established alternatives. Achieving economic viability requires further research into cost-effective manufacturing processes and materials, as well as demonstrating clear long-term benefits in water treatment applications to justify initial investments.

Another critical challenge lies in the stability and longevity of sodium-ion batteries in water treatment applications. The harsh environmental conditions often present in water purification processes, including high humidity and potential exposure to corrosive substances, can accelerate battery degradation. This issue demands the development of robust encapsulation techniques and materials that can withstand these challenging conditions while maintaining battery performance over extended periods.

The cycling stability of sodium-ion batteries also poses a significant hurdle in water treatment contexts. The repeated charge and discharge cycles, coupled with potential intermittent usage patterns in water purification systems, can lead to capacity fading and reduced battery lifespan. Addressing this challenge requires innovative electrode materials and electrolyte formulations that can maintain stable performance over thousands of cycles.

Furthermore, the integration of sodium-ion batteries with existing water treatment technologies presents compatibility issues. Adapting current purification systems to accommodate these batteries may require significant redesigns, potentially increasing costs and complexity. Engineers must develop seamless integration strategies that optimize the synergy between battery systems and water treatment processes without compromising efficiency or reliability.

Safety considerations also play a crucial role in the application of sodium-ion batteries in water purification. While generally considered safer than lithium-ion batteries due to lower reactivity, sodium-ion batteries still pose potential risks in water-rich environments. Developing fail-safe mechanisms and protective measures to prevent short circuits or thermal runaway events is essential for widespread adoption in water treatment facilities.

Lastly, the cost-effectiveness of sodium-ion batteries in water purification applications remains a challenge. Although sodium is more abundant and potentially cheaper than lithium, the current production scales and technological maturity of sodium-ion batteries result in higher costs compared to established alternatives. Achieving economic viability requires further research into cost-effective manufacturing processes and materials, as well as demonstrating clear long-term benefits in water treatment applications to justify initial investments.

Current Sodium Ion Battery Water Purification Solutions

01 Electrode materials for sodium-ion batteries

Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials can include various compounds and composites designed to enhance energy density, cycling stability, and rate capability. Research focuses on optimizing the structure and composition of both anode and cathode materials to facilitate efficient sodium ion insertion and extraction.- Electrode materials for sodium-ion batteries: Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials focus on enhancing energy density, cycling stability, and rate capability. Research includes exploring various compounds and nanostructures to optimize sodium storage and transport properties.

- Electrolyte compositions for sodium-ion batteries: Innovative electrolyte formulations are being developed to enhance the performance and safety of sodium-ion batteries. These include novel solvents, additives, and salt combinations designed to improve ionic conductivity, electrochemical stability, and interfacial properties between the electrolyte and electrodes.

- Battery cell design and manufacturing processes: Advancements in cell design and manufacturing techniques are being made to optimize sodium-ion battery performance and scalability. This includes innovations in electrode preparation, cell assembly, and packaging to improve energy density, reduce costs, and enhance overall battery efficiency.

- Sodium-ion battery management systems: Development of sophisticated battery management systems tailored for sodium-ion batteries is ongoing. These systems aim to optimize charging/discharging protocols, monitor battery health, and improve overall performance and lifespan of sodium-ion battery packs in various applications.

- Applications and integration of sodium-ion batteries: Research is focused on integrating sodium-ion batteries into various applications, including grid energy storage, electric vehicles, and portable electronics. This involves developing battery pack designs, thermal management systems, and integration strategies to leverage the unique characteristics of sodium-ion technology in different use cases.

02 Electrolyte formulations for sodium-ion batteries

Electrolyte composition plays a vital role in the performance and safety of sodium-ion batteries. Researchers are exploring various electrolyte formulations, including liquid, solid, and gel electrolytes, to improve ionic conductivity, electrochemical stability, and interfacial properties. Additives and solvents are being investigated to enhance the overall battery performance and mitigate issues such as dendrite formation.Expand Specific Solutions03 Battery cell design and manufacturing processes

Innovations in cell design and manufacturing processes are essential for commercializing sodium-ion batteries. This includes developing efficient assembly techniques, optimizing electrode coating and stacking methods, and designing battery packs suitable for various applications. Efforts are also focused on scaling up production while maintaining quality and reducing costs.Expand Specific Solutions04 Battery management systems for sodium-ion batteries

Developing advanced battery management systems (BMS) tailored for sodium-ion batteries is crucial for optimizing performance and ensuring safety. These systems monitor and control various parameters such as voltage, current, and temperature, and implement algorithms for state-of-charge and state-of-health estimation. Intelligent BMS can also enhance the longevity and reliability of sodium-ion battery packs.Expand Specific Solutions05 Applications and integration of sodium-ion batteries

Research is ongoing to explore and expand the applications of sodium-ion batteries in various sectors. This includes their integration into renewable energy storage systems, electric vehicles, and portable electronics. Studies focus on optimizing battery performance for specific use cases, addressing challenges related to energy density, cycle life, and operating conditions in different applications.Expand Specific Solutions

Key Players in Sodium Ion Battery Water Treatment

The research on sodium-ion batteries in water purification technology is in an early developmental stage, with the market still emerging. The global market for this technology is expected to grow significantly in the coming years, driven by increasing water scarcity concerns and the need for sustainable purification solutions. While the technology is promising, it is not yet fully mature, with ongoing research to improve efficiency and scalability. Companies like Contemporary Amperex Technology Co., Ltd. (CATL) and Faradion Ltd. are leading the charge in sodium-ion battery development, while research institutions such as Nankai University and CNRS are contributing to advancements in water purification applications. The competitive landscape is evolving, with both established players and startups vying for market share in this innovative field.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed advanced sodium-ion batteries with potential applications in water purification technology. Their sodium-ion cells feature a hard carbon anode and a Prussian white cathode, achieving energy densities of up to 160 Wh/kg [1]. CATL's batteries utilize a novel electrolyte formulation that enhances ion transport and stability in aqueous environments, making them suitable for water treatment applications. The company has also implemented a porous separator design that allows for efficient ion exchange while preventing electrode contamination [2]. CATL's sodium-ion technology demonstrates excellent cycling stability, with capacity retention of over 90% after 1000 cycles, crucial for long-term water purification operations [3].

Strengths: High energy density, excellent cycling stability, and compatibility with aqueous environments. Weaknesses: Potential higher initial costs compared to traditional water treatment methods and limited large-scale deployment experience in water purification applications.

Faradion Ltd.

Technical Solution: Faradion Ltd. has pioneered sodium-ion battery technology with potential applications in water purification. Their proprietary Na-ion cells utilize a layered oxide cathode and hard carbon anode, achieving energy densities comparable to lithium-ion batteries [4]. Faradion's technology incorporates a unique electrolyte formulation that enhances ion mobility and stability in aqueous environments, making it suitable for water treatment systems. The company has developed a modular battery design that allows for scalable integration into various water purification setups. Faradion's sodium-ion batteries demonstrate exceptional low-temperature performance, maintaining over 80% capacity at -20°C, which is advantageous for water treatment in cold climates [5]. Their batteries also exhibit rapid charging capabilities, reaching 80% capacity in less than 30 minutes, enabling quick deployment in emergency water purification scenarios.

Strengths: High energy density, excellent low-temperature performance, and rapid charging capabilities. Weaknesses: Limited large-scale production experience and potential higher costs compared to established water treatment technologies.

Core Innovations in Sodium Ion Battery Water Treatment

Sodium ion secondary battery

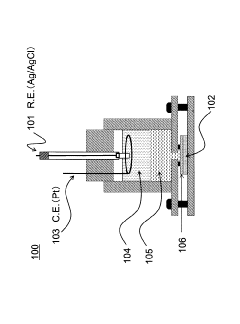

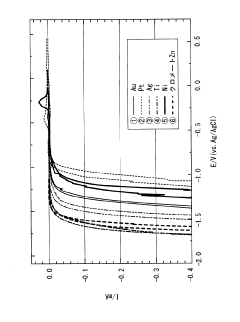

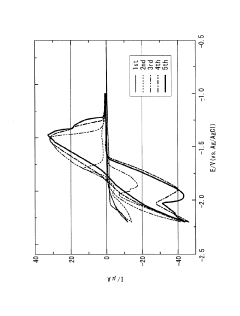

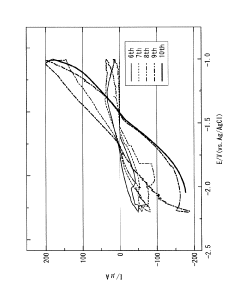

PatentInactiveJP2019153378A

Innovation

- A sodium ion secondary battery design incorporating a negative electrode with a hydrophobic organic cation ionic liquid and a solid electrolyte layer with sodium ion conductivity, which suppresses water electrolysis by shielding the negative electrode with a hydrophobic environment.

Sodium Ion Batteries

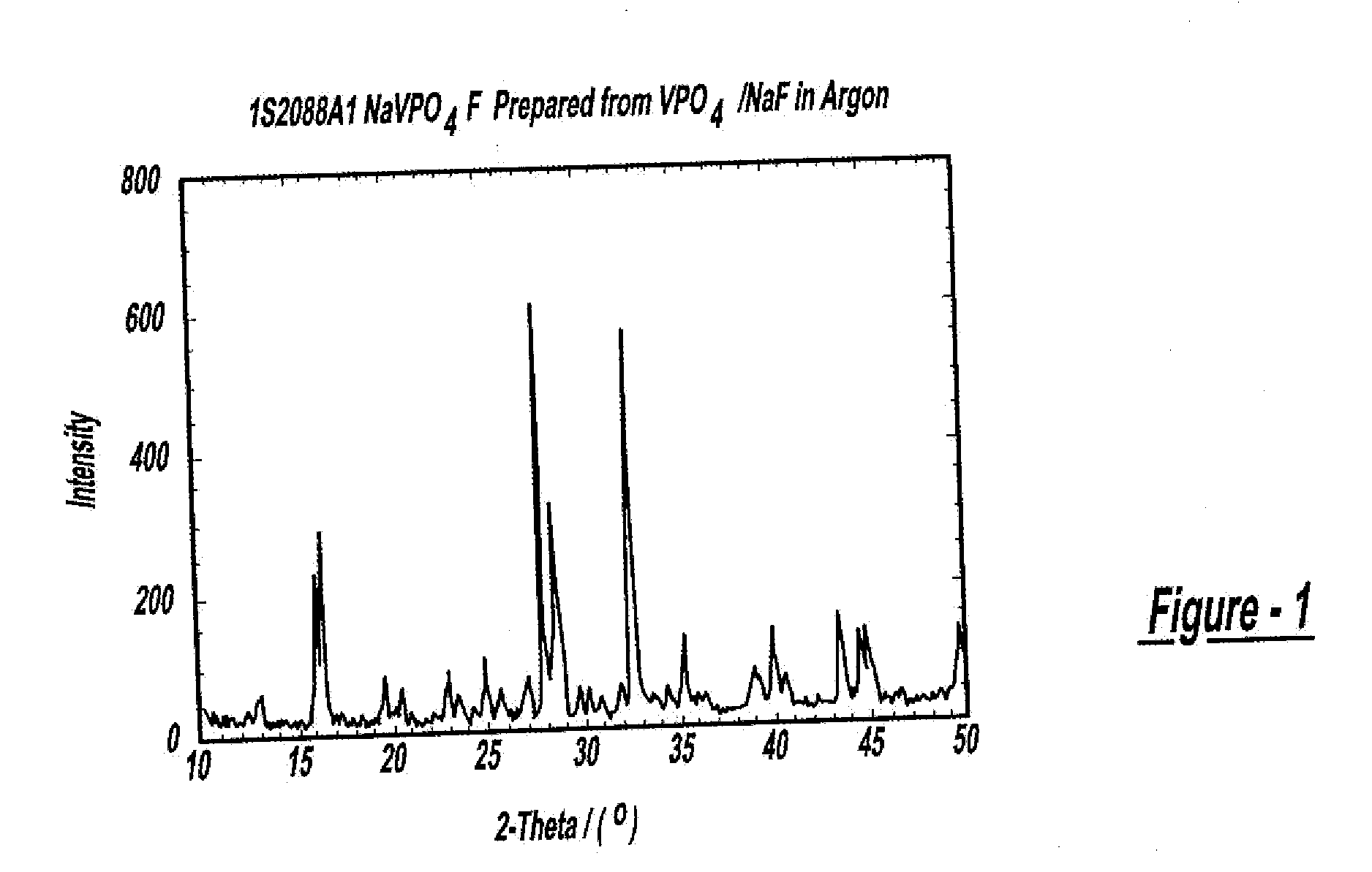

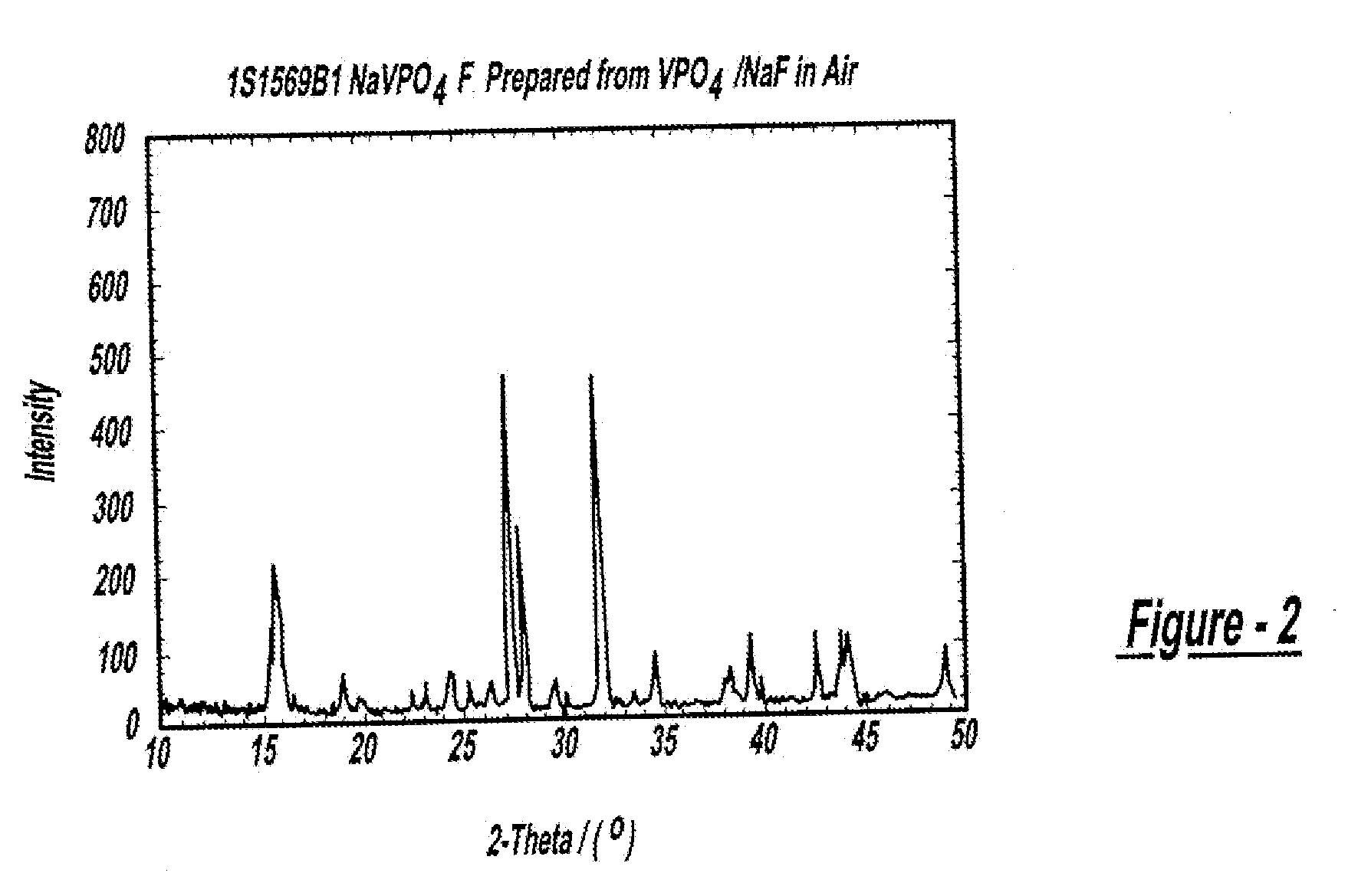

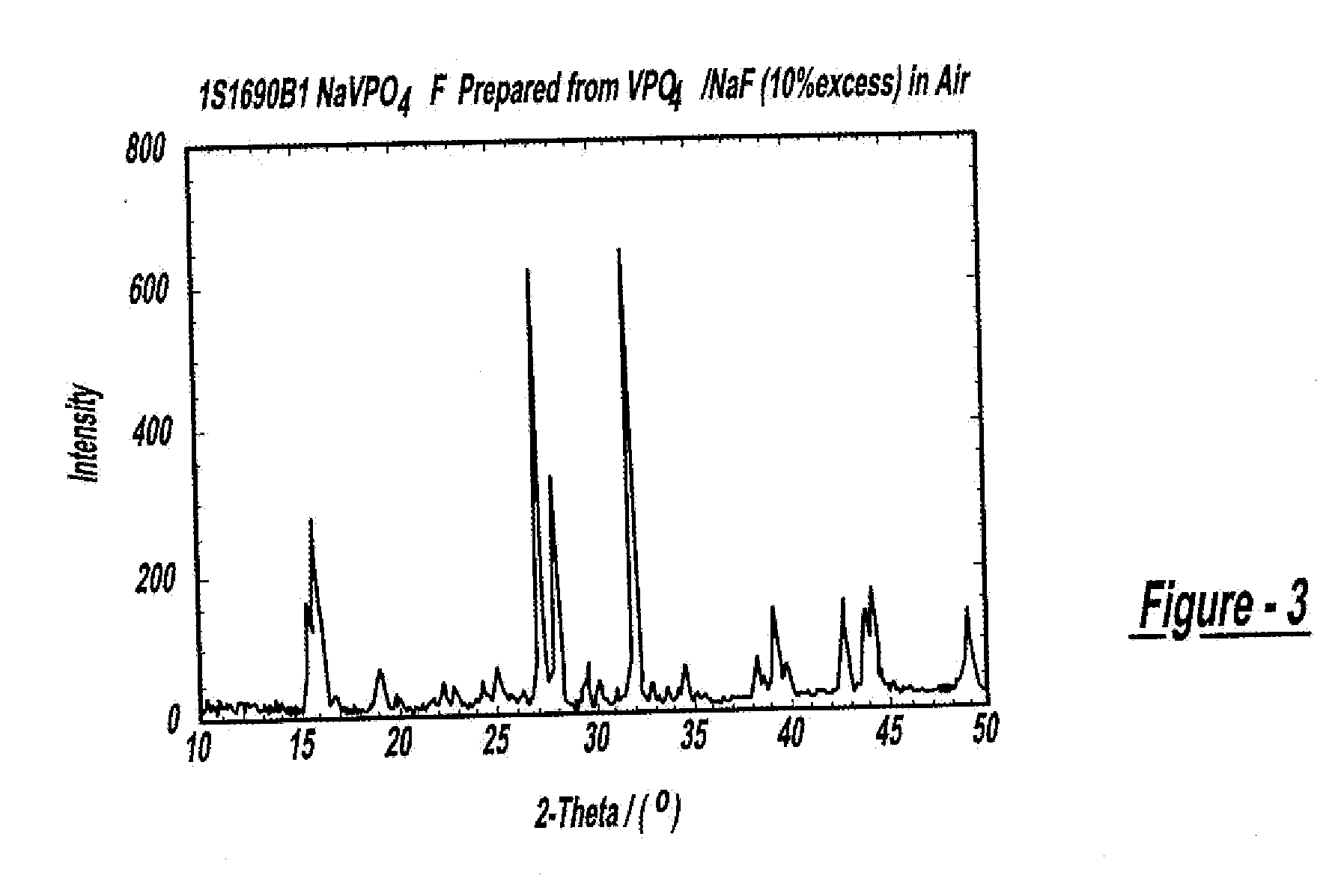

PatentInactiveUS20110052986A1

Innovation

- Development of sodium transition metal compounds, specifically sodium metal phosphates and fluorophosphates, as cathode active materials, and the use of hard carbon as an anode capable of inserting and releasing sodium ions, enabling reversible cycling and enhancing the electrochemical performance of sodium ion batteries.

Environmental Impact Assessment

The integration of sodium ion batteries in water purification technology presents both opportunities and challenges from an environmental perspective. These batteries offer a promising alternative to traditional lithium-ion batteries, potentially reducing the environmental impact associated with lithium mining and processing. Sodium, being more abundant and widely distributed than lithium, can be sourced more sustainably and with less ecological disruption.

In the context of water purification, the use of sodium ion batteries can contribute to the development of more energy-efficient and environmentally friendly systems. These batteries can store energy from renewable sources, enabling off-grid or remote water purification operations with a lower carbon footprint. This is particularly beneficial in areas where access to clean water and reliable electricity is limited, potentially reducing reliance on fossil fuel-powered generators.

However, the environmental impact of sodium ion batteries in water purification technology is not without concerns. The production process of these batteries still requires energy and resources, albeit potentially less than lithium-ion batteries. The extraction and processing of sodium and other materials used in the batteries may have localized environmental effects, including land use changes and potential water pollution if not properly managed.

The end-of-life management of sodium ion batteries is an important consideration. While sodium is less toxic than lithium, proper recycling and disposal mechanisms need to be established to prevent environmental contamination. The development of efficient recycling processes for these batteries could significantly reduce their overall environmental impact and contribute to a circular economy approach in water purification technology.

Water purification systems powered by sodium ion batteries may also have indirect environmental benefits. By providing more reliable and sustainable access to clean water, these systems can reduce the need for bottled water, thereby decreasing plastic waste and the carbon emissions associated with bottled water production and transportation.

The long-term environmental impact of widespread adoption of sodium ion batteries in water purification technology remains to be fully assessed. Ongoing research is needed to evaluate the life cycle impacts, including raw material extraction, manufacturing processes, operational efficiency, and end-of-life management. This comprehensive assessment will be crucial in determining the true environmental sustainability of this technology compared to existing alternatives.

In the context of water purification, the use of sodium ion batteries can contribute to the development of more energy-efficient and environmentally friendly systems. These batteries can store energy from renewable sources, enabling off-grid or remote water purification operations with a lower carbon footprint. This is particularly beneficial in areas where access to clean water and reliable electricity is limited, potentially reducing reliance on fossil fuel-powered generators.

However, the environmental impact of sodium ion batteries in water purification technology is not without concerns. The production process of these batteries still requires energy and resources, albeit potentially less than lithium-ion batteries. The extraction and processing of sodium and other materials used in the batteries may have localized environmental effects, including land use changes and potential water pollution if not properly managed.

The end-of-life management of sodium ion batteries is an important consideration. While sodium is less toxic than lithium, proper recycling and disposal mechanisms need to be established to prevent environmental contamination. The development of efficient recycling processes for these batteries could significantly reduce their overall environmental impact and contribute to a circular economy approach in water purification technology.

Water purification systems powered by sodium ion batteries may also have indirect environmental benefits. By providing more reliable and sustainable access to clean water, these systems can reduce the need for bottled water, thereby decreasing plastic waste and the carbon emissions associated with bottled water production and transportation.

The long-term environmental impact of widespread adoption of sodium ion batteries in water purification technology remains to be fully assessed. Ongoing research is needed to evaluate the life cycle impacts, including raw material extraction, manufacturing processes, operational efficiency, and end-of-life management. This comprehensive assessment will be crucial in determining the true environmental sustainability of this technology compared to existing alternatives.

Regulatory Framework for Water Treatment Technologies

The regulatory framework for water treatment technologies, including sodium ion batteries in water purification, is a complex and evolving landscape. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in setting standards and regulations for water quality and treatment technologies. The Safe Drinking Water Act (SDWA) and the Clean Water Act (CWA) form the foundation of these regulations, establishing guidelines for contaminant levels and treatment processes.

For emerging technologies like sodium ion batteries in water purification, the EPA's Office of Water is responsible for evaluating and approving new treatment methods. This process involves rigorous testing and validation to ensure the technology meets safety and efficacy standards. The National Sanitation Foundation (NSF) also plays a significant role in certifying water treatment technologies, including those incorporating sodium ion batteries.

At the state level, regulations may vary, with some states imposing stricter standards than federal requirements. State environmental agencies often work in conjunction with the EPA to enforce and implement water treatment regulations. Local municipalities may also have additional requirements or restrictions on water treatment technologies.

Internationally, organizations such as the World Health Organization (WHO) provide guidelines for water quality and treatment that influence regulatory frameworks in many countries. The European Union, for instance, has its own set of directives, including the Drinking Water Directive, which establishes standards for water quality and treatment technologies.

For sodium ion batteries in water purification, specific regulations may not yet exist due to the novelty of the technology. However, they would likely fall under broader categories of electrochemical water treatment or ion exchange technologies. As research progresses, regulatory bodies may develop more specific guidelines to address the unique aspects of sodium ion battery-based water purification systems.

Compliance with these regulations often requires extensive documentation, regular testing, and reporting. Manufacturers and operators of water treatment systems must demonstrate ongoing compliance with water quality standards and operational safety requirements. This may involve periodic inspections, water quality testing, and maintenance of detailed records.

As environmental concerns grow and water scarcity becomes more prevalent, regulations are likely to become more stringent. Future regulatory frameworks may place greater emphasis on energy efficiency, sustainability, and the ability to remove emerging contaminants. This could potentially benefit sodium ion battery technology in water purification, given its potential for energy efficiency and effectiveness against a wide range of pollutants.

For emerging technologies like sodium ion batteries in water purification, the EPA's Office of Water is responsible for evaluating and approving new treatment methods. This process involves rigorous testing and validation to ensure the technology meets safety and efficacy standards. The National Sanitation Foundation (NSF) also plays a significant role in certifying water treatment technologies, including those incorporating sodium ion batteries.

At the state level, regulations may vary, with some states imposing stricter standards than federal requirements. State environmental agencies often work in conjunction with the EPA to enforce and implement water treatment regulations. Local municipalities may also have additional requirements or restrictions on water treatment technologies.

Internationally, organizations such as the World Health Organization (WHO) provide guidelines for water quality and treatment that influence regulatory frameworks in many countries. The European Union, for instance, has its own set of directives, including the Drinking Water Directive, which establishes standards for water quality and treatment technologies.

For sodium ion batteries in water purification, specific regulations may not yet exist due to the novelty of the technology. However, they would likely fall under broader categories of electrochemical water treatment or ion exchange technologies. As research progresses, regulatory bodies may develop more specific guidelines to address the unique aspects of sodium ion battery-based water purification systems.

Compliance with these regulations often requires extensive documentation, regular testing, and reporting. Manufacturers and operators of water treatment systems must demonstrate ongoing compliance with water quality standards and operational safety requirements. This may involve periodic inspections, water quality testing, and maintenance of detailed records.

As environmental concerns grow and water scarcity becomes more prevalent, regulations are likely to become more stringent. Future regulatory frameworks may place greater emphasis on energy efficiency, sustainability, and the ability to remove emerging contaminants. This could potentially benefit sodium ion battery technology in water purification, given its potential for energy efficiency and effectiveness against a wide range of pollutants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!