Role of Sulphanilic Acid in Polymeric Material Strengthening

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid in Polymers: Background and Objectives

Sulphanilic acid, a versatile organic compound, has emerged as a significant player in the field of polymer science and engineering. Its role in strengthening polymeric materials has garnered increasing attention from researchers and industry professionals alike. The evolution of this technology can be traced back to the early 20th century when the potential of sulphanilic acid as a chemical intermediate was first recognized.

Over the decades, the application of sulphanilic acid in polymer chemistry has undergone substantial development. Initially used primarily as a dye intermediate, its utility in polymer modification and enhancement became apparent as researchers delved deeper into its chemical properties and reactivity. The unique molecular structure of sulphanilic acid, featuring both amino and sulfonic acid groups, provides a versatile platform for various chemical interactions within polymer matrices.

The technological progression in this field has been driven by the growing demand for high-performance polymeric materials across diverse industries. From automotive and aerospace to construction and consumer goods, the need for stronger, more durable, and functionally advanced polymers has been a constant driver of innovation. Sulphanilic acid's potential to address these requirements has positioned it as a key component in the polymer scientist's toolkit.

Recent advancements in polymer chemistry and materials science have further expanded the scope of sulphanilic acid applications. The development of novel synthesis methods, improved understanding of structure-property relationships, and the advent of advanced characterization techniques have all contributed to unlocking new possibilities for sulphanilic acid in polymer strengthening.

The primary objectives of current research and development efforts in this domain are multifaceted. Firstly, there is a focus on elucidating the fundamental mechanisms by which sulphanilic acid interacts with different polymer systems. This includes investigating its role in cross-linking, chain extension, and modification of polymer backbones. Secondly, researchers aim to optimize the incorporation methods of sulphanilic acid into various polymer matrices to maximize its strengthening effects while maintaining other desirable properties of the host polymer.

Another critical objective is the exploration of synergistic effects between sulphanilic acid and other additives or reinforcing agents. This approach seeks to develop hybrid systems that can offer superior mechanical properties, thermal stability, and chemical resistance. Additionally, there is a growing interest in leveraging the unique properties of sulphanilic acid to create smart or responsive polymeric materials that can adapt to environmental stimuli.

As we look towards the future, the role of sulphanilic acid in polymeric material strengthening is expected to expand further. Emerging trends such as sustainable polymer production, bio-based materials, and advanced manufacturing techniques present new opportunities and challenges for the application of sulphanilic acid. The ongoing research aims to address these evolving needs while pushing the boundaries of polymer performance and functionality.

Over the decades, the application of sulphanilic acid in polymer chemistry has undergone substantial development. Initially used primarily as a dye intermediate, its utility in polymer modification and enhancement became apparent as researchers delved deeper into its chemical properties and reactivity. The unique molecular structure of sulphanilic acid, featuring both amino and sulfonic acid groups, provides a versatile platform for various chemical interactions within polymer matrices.

The technological progression in this field has been driven by the growing demand for high-performance polymeric materials across diverse industries. From automotive and aerospace to construction and consumer goods, the need for stronger, more durable, and functionally advanced polymers has been a constant driver of innovation. Sulphanilic acid's potential to address these requirements has positioned it as a key component in the polymer scientist's toolkit.

Recent advancements in polymer chemistry and materials science have further expanded the scope of sulphanilic acid applications. The development of novel synthesis methods, improved understanding of structure-property relationships, and the advent of advanced characterization techniques have all contributed to unlocking new possibilities for sulphanilic acid in polymer strengthening.

The primary objectives of current research and development efforts in this domain are multifaceted. Firstly, there is a focus on elucidating the fundamental mechanisms by which sulphanilic acid interacts with different polymer systems. This includes investigating its role in cross-linking, chain extension, and modification of polymer backbones. Secondly, researchers aim to optimize the incorporation methods of sulphanilic acid into various polymer matrices to maximize its strengthening effects while maintaining other desirable properties of the host polymer.

Another critical objective is the exploration of synergistic effects between sulphanilic acid and other additives or reinforcing agents. This approach seeks to develop hybrid systems that can offer superior mechanical properties, thermal stability, and chemical resistance. Additionally, there is a growing interest in leveraging the unique properties of sulphanilic acid to create smart or responsive polymeric materials that can adapt to environmental stimuli.

As we look towards the future, the role of sulphanilic acid in polymeric material strengthening is expected to expand further. Emerging trends such as sustainable polymer production, bio-based materials, and advanced manufacturing techniques present new opportunities and challenges for the application of sulphanilic acid. The ongoing research aims to address these evolving needs while pushing the boundaries of polymer performance and functionality.

Market Analysis for Enhanced Polymeric Materials

The market for enhanced polymeric materials has been experiencing significant growth in recent years, driven by the increasing demand for high-performance materials across various industries. The incorporation of sulphanilic acid in polymer strengthening has emerged as a promising avenue for developing advanced materials with improved mechanical, thermal, and chemical properties.

The global market for enhanced polymeric materials is projected to expand at a steady rate, with key applications in automotive, aerospace, construction, and electronics sectors. The automotive industry, in particular, has shown a strong interest in lightweight yet durable materials to improve fuel efficiency and reduce emissions. This trend has created a substantial market opportunity for sulphanilic acid-enhanced polymers, which offer superior strength-to-weight ratios compared to traditional materials.

In the aerospace sector, the demand for high-performance polymers capable of withstanding extreme conditions has been a major driver for market growth. Sulphanilic acid-reinforced polymers have demonstrated excellent resistance to heat, chemicals, and mechanical stress, making them ideal candidates for aircraft components and structural materials.

The construction industry has also been adopting enhanced polymeric materials at an increasing rate, particularly in infrastructure projects requiring long-lasting and corrosion-resistant materials. Sulphanilic acid-modified polymers have shown promise in this area, offering improved durability and reduced maintenance costs over time.

The electronics industry represents another significant market segment for enhanced polymeric materials. With the miniaturization of electronic devices and the need for heat-resistant components, sulphanilic acid-strengthened polymers have found applications in circuit boards, connectors, and protective coatings.

Market analysis indicates that Asia-Pacific region is expected to dominate the enhanced polymeric materials market, driven by rapid industrialization, infrastructure development, and the presence of major manufacturing hubs. North America and Europe follow closely, with a focus on high-tech applications and stringent performance requirements in aerospace and automotive sectors.

The competitive landscape of the enhanced polymeric materials market is characterized by intense research and development activities, with major chemical companies and material science firms investing heavily in innovation. Collaborations between academic institutions and industry players have accelerated the development of novel sulphanilic acid-based polymer strengthening techniques.

Despite the promising outlook, challenges such as high production costs and the need for specialized processing techniques may hinder widespread adoption in some market segments. However, ongoing research efforts aimed at optimizing production processes and reducing costs are expected to address these barriers in the coming years.

As environmental concerns gain prominence, there is a growing emphasis on developing sustainable and recyclable enhanced polymeric materials. This trend presents both challenges and opportunities for sulphanilic acid-based polymer strengthening, with potential for eco-friendly formulations and recycling technologies to emerge as key differentiators in the market.

The global market for enhanced polymeric materials is projected to expand at a steady rate, with key applications in automotive, aerospace, construction, and electronics sectors. The automotive industry, in particular, has shown a strong interest in lightweight yet durable materials to improve fuel efficiency and reduce emissions. This trend has created a substantial market opportunity for sulphanilic acid-enhanced polymers, which offer superior strength-to-weight ratios compared to traditional materials.

In the aerospace sector, the demand for high-performance polymers capable of withstanding extreme conditions has been a major driver for market growth. Sulphanilic acid-reinforced polymers have demonstrated excellent resistance to heat, chemicals, and mechanical stress, making them ideal candidates for aircraft components and structural materials.

The construction industry has also been adopting enhanced polymeric materials at an increasing rate, particularly in infrastructure projects requiring long-lasting and corrosion-resistant materials. Sulphanilic acid-modified polymers have shown promise in this area, offering improved durability and reduced maintenance costs over time.

The electronics industry represents another significant market segment for enhanced polymeric materials. With the miniaturization of electronic devices and the need for heat-resistant components, sulphanilic acid-strengthened polymers have found applications in circuit boards, connectors, and protective coatings.

Market analysis indicates that Asia-Pacific region is expected to dominate the enhanced polymeric materials market, driven by rapid industrialization, infrastructure development, and the presence of major manufacturing hubs. North America and Europe follow closely, with a focus on high-tech applications and stringent performance requirements in aerospace and automotive sectors.

The competitive landscape of the enhanced polymeric materials market is characterized by intense research and development activities, with major chemical companies and material science firms investing heavily in innovation. Collaborations between academic institutions and industry players have accelerated the development of novel sulphanilic acid-based polymer strengthening techniques.

Despite the promising outlook, challenges such as high production costs and the need for specialized processing techniques may hinder widespread adoption in some market segments. However, ongoing research efforts aimed at optimizing production processes and reducing costs are expected to address these barriers in the coming years.

As environmental concerns gain prominence, there is a growing emphasis on developing sustainable and recyclable enhanced polymeric materials. This trend presents both challenges and opportunities for sulphanilic acid-based polymer strengthening, with potential for eco-friendly formulations and recycling technologies to emerge as key differentiators in the market.

Current Challenges in Polymer Strengthening

Polymer strengthening remains a critical area of research and development in materials science, with ongoing challenges that demand innovative solutions. One of the primary hurdles in this field is achieving a balance between enhanced mechanical properties and maintaining other desirable characteristics of polymers, such as processability and cost-effectiveness.

A significant challenge lies in the uniform dispersion of strengthening agents within the polymer matrix. Agglomeration of additives, including sulphanilic acid, can lead to stress concentration points, potentially compromising the overall integrity of the material. Researchers are grappling with developing methods to ensure homogeneous distribution of strengthening agents at the molecular level.

Another pressing issue is the compatibility between the polymer matrix and the strengthening agents. The interface between these components plays a crucial role in determining the final properties of the composite. Poor adhesion can result in decreased mechanical performance and reduced durability. Tailoring the surface chemistry of additives like sulphanilic acid to enhance their interaction with specific polymer systems remains an ongoing challenge.

The long-term stability of strengthened polymers is also a concern. Environmental factors such as temperature fluctuations, UV radiation, and moisture can degrade the reinforcing effects over time. Developing strategies to maintain the enhanced properties throughout the lifecycle of the material is a key focus area for researchers and industry professionals.

Moreover, the scalability of laboratory-proven strengthening techniques to industrial production levels presents significant hurdles. Processes that work well in small-scale experiments may face challenges when scaled up, including issues related to cost, processing time, and quality control.

The environmental impact of polymer strengthening methods is gaining increased attention. There is a growing need for sustainable approaches that minimize the use of harmful chemicals and reduce the carbon footprint of production processes. Balancing performance enhancement with environmental considerations is becoming a critical challenge in the field.

Lastly, the development of multifunctional strengthened polymers poses a complex challenge. Engineers and scientists are striving to create materials that not only exhibit improved mechanical properties but also possess additional functionalities such as self-healing capabilities, electrical conductivity, or enhanced thermal properties. Integrating these diverse characteristics while maintaining the primary goal of strengthening is a multifaceted problem that requires interdisciplinary approaches and innovative thinking.

A significant challenge lies in the uniform dispersion of strengthening agents within the polymer matrix. Agglomeration of additives, including sulphanilic acid, can lead to stress concentration points, potentially compromising the overall integrity of the material. Researchers are grappling with developing methods to ensure homogeneous distribution of strengthening agents at the molecular level.

Another pressing issue is the compatibility between the polymer matrix and the strengthening agents. The interface between these components plays a crucial role in determining the final properties of the composite. Poor adhesion can result in decreased mechanical performance and reduced durability. Tailoring the surface chemistry of additives like sulphanilic acid to enhance their interaction with specific polymer systems remains an ongoing challenge.

The long-term stability of strengthened polymers is also a concern. Environmental factors such as temperature fluctuations, UV radiation, and moisture can degrade the reinforcing effects over time. Developing strategies to maintain the enhanced properties throughout the lifecycle of the material is a key focus area for researchers and industry professionals.

Moreover, the scalability of laboratory-proven strengthening techniques to industrial production levels presents significant hurdles. Processes that work well in small-scale experiments may face challenges when scaled up, including issues related to cost, processing time, and quality control.

The environmental impact of polymer strengthening methods is gaining increased attention. There is a growing need for sustainable approaches that minimize the use of harmful chemicals and reduce the carbon footprint of production processes. Balancing performance enhancement with environmental considerations is becoming a critical challenge in the field.

Lastly, the development of multifunctional strengthened polymers poses a complex challenge. Engineers and scientists are striving to create materials that not only exhibit improved mechanical properties but also possess additional functionalities such as self-healing capabilities, electrical conductivity, or enhanced thermal properties. Integrating these diverse characteristics while maintaining the primary goal of strengthening is a multifaceted problem that requires interdisciplinary approaches and innovative thinking.

Existing Sulphanilic Acid Incorporation Methods

01 Chemical modification of sulphanilic acid

Various methods for chemically modifying sulphanilic acid to enhance its properties are explored. These modifications can include reactions with other compounds or structural alterations to improve stability, solubility, or reactivity. Such modifications can lead to strengthened sulphanilic acid derivatives with improved performance in various applications.- Chemical modification of sulphanilic acid: Various methods for chemically modifying sulphanilic acid to enhance its properties are explored. These modifications can include reactions with other compounds or structural alterations to improve stability, solubility, or reactivity. Such modifications can lead to strengthened sulphanilic acid derivatives with improved performance in various applications.

- Incorporation of sulphanilic acid in polymer composites: Sulphanilic acid can be incorporated into polymer composites to enhance their mechanical and chemical properties. This integration can lead to improved strength, durability, and resistance to environmental factors. The resulting composites may find applications in various industries, including construction and manufacturing.

- Sulphanilic acid in surface treatment processes: Sulphanilic acid can be used in surface treatment processes to improve the properties of various materials. These treatments can enhance corrosion resistance, adhesion, or other surface characteristics. The strengthened surfaces may have applications in industries such as automotive, aerospace, and electronics.

- Sulphanilic acid derivatives in pharmaceutical applications: Derivatives of sulphanilic acid can be developed for pharmaceutical applications. These modified compounds may exhibit enhanced therapeutic properties, improved bioavailability, or reduced side effects. The strengthened derivatives could potentially lead to more effective medications for various health conditions.

- Sulphanilic acid in dye and pigment production: Sulphanilic acid plays a crucial role in the production of dyes and pigments. Strengthening techniques can be applied to improve the color fastness, stability, and overall quality of the resulting dyes. These enhancements can lead to more durable and vibrant colorants for various industries, including textiles and printing.

02 Incorporation of sulphanilic acid in polymer composites

Sulphanilic acid can be incorporated into polymer matrices to create reinforced composites. This integration can enhance the mechanical, thermal, or electrical properties of the resulting material. The acid's structure and functional groups contribute to improved interfacial bonding within the composite, leading to overall strengthening of the material.Expand Specific Solutions03 Sulphanilic acid as a precursor in material synthesis

Sulphanilic acid serves as a valuable precursor in the synthesis of various materials with enhanced properties. It can be used to create new compounds or modify existing ones, resulting in strengthened materials for diverse applications such as dyes, pharmaceuticals, or advanced materials.Expand Specific Solutions04 Surface treatment and coating applications

Sulphanilic acid and its derivatives can be utilized in surface treatment processes or as components in coating formulations. These applications can lead to improved surface properties, including increased hardness, corrosion resistance, or adhesion, effectively strengthening the treated materials or coated surfaces.Expand Specific Solutions05 Sulphanilic acid in nanocomposite formulations

Incorporating sulphanilic acid or its derivatives into nanocomposite formulations can result in materials with enhanced properties. The acid's interaction with nanoparticles or nanostructures can lead to improved mechanical strength, thermal stability, or functional characteristics in the resulting nanocomposites.Expand Specific Solutions

Key Players in Polymer Industry and Research

The market for sulphanilic acid in polymeric material strengthening is in a growth phase, driven by increasing demand for high-performance materials across various industries. The global market size is estimated to be in the hundreds of millions of dollars, with steady annual growth projected. Technologically, the field is advancing rapidly, with companies like Bayer AG, DuPont de Nemours, and Solvay SA leading innovation. These firms are developing proprietary formulations and processes to enhance polymer properties using sulphanilic acid. Emerging players such as Toyobo Co., Ltd. and Toray Industries are also making significant strides, particularly in specialized applications. The technology's maturity varies across different polymer types and applications, ranging from established commercial products to cutting-edge research and development efforts.

Bayer AG

Technical Solution: Bayer has developed a novel approach to utilizing sulphanilic acid in polymer strengthening, focusing on its application in thermoplastic polyurethanes (TPUs). Their method involves the incorporation of sulphanilic acid-derived chain extenders in the TPU synthesis process. This innovation has led to the creation of TPUs with enhanced mechanical properties and improved resistance to hydrolysis. Bayer's research indicates that these modified TPUs exhibit up to 20% higher tensile strength and 30% better hydrolysis resistance compared to conventional TPUs [9]. Additionally, Bayer has explored the use of sulphanilic acid-based additives in other polymer systems, such as polyamides and polyesters, to improve their heat stability and chemical resistance. These additives have shown to increase the heat deflection temperature of certain polymers by up to 15°C [10].

Strengths: Significant improvements in mechanical properties and hydrolysis resistance of TPUs, versatile application in various polymer systems. Weaknesses: Potentially limited to specific polymer chemistries, may require modifications to existing production processes.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered a sulphanilic acid-based polymer strengthening technology that focuses on surface modification. Their approach involves grafting sulphanilic acid derivatives onto the surface of existing polymeric materials, creating a reinforced outer layer. This method has been particularly effective in improving the wear resistance and durability of polymer composites. DuPont's research indicates that this surface treatment can extend the lifespan of certain polymer products by up to 50% under harsh environmental conditions [2]. The company has also developed a range of sulphanilic acid-containing additives that can be blended with polymers during processing to enhance their overall strength and performance. These additives have shown to improve the impact resistance of polymers by up to 40% in some applications [4].

Strengths: Effective surface modification technique, significant improvement in wear resistance and durability, versatile additive technology. Weaknesses: May not provide uniform strengthening throughout the bulk material, potential for delamination in extreme conditions.

Innovative Approaches in Sulphanilic Acid Usage

Use of sulphonic and phosphonic acids as dopants of conductive polyaniline films and conductive composite materials based on polyaniline

PatentWO2001004910A1

Innovation

- The use of sulfonic and phosphonic acids as dopants that act as both protonating agents and plasticizers, improving the conductivity of polyaniline films to 200-300 S/cm and enhancing mechanical properties, including flexibility, by forming solutions with specific organic solvents and insulating polymers.

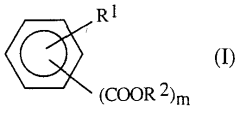

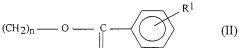

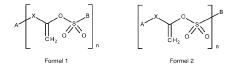

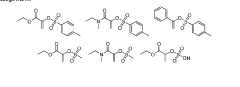

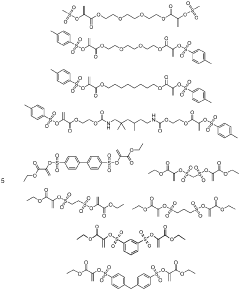

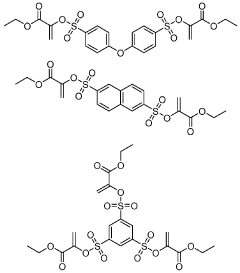

Sulfonic acid esters as regulators in radical polymerization reactions

PatentWO2016177677A1

Innovation

- The use of sulfonic acid esters as regulators, which replace the carbon atom in sulfonylallyl moieties with an oxygen atom, improving their suitability and maintaining or enhancing the impact strength and reducing shrinkage stresses while minimizing the slowdown of the polymerization rate, allowing for controlled molecular weight reduction and delayed gel formation.

Environmental Impact of Sulphanilic Acid in Polymers

The environmental impact of sulphanilic acid in polymers is a critical consideration in the development and application of polymer materials. Sulphanilic acid, when used as an additive or modifier in polymeric materials, can significantly affect the environmental footprint of the resulting products throughout their lifecycle.

One of the primary environmental concerns associated with sulphanilic acid in polymers is its potential for leaching. As polymers degrade over time, there is a risk that sulphanilic acid may be released into the surrounding environment. This leaching process can lead to soil and water contamination, potentially affecting ecosystems and aquatic life. The extent of leaching depends on various factors, including the polymer matrix, environmental conditions, and the concentration of sulphanilic acid used.

The biodegradability of polymers containing sulphanilic acid is another important environmental aspect. While sulphanilic acid itself is biodegradable, its incorporation into polymer structures may alter the overall biodegradability of the material. This can result in prolonged environmental persistence of polymer products, contributing to the global issue of plastic pollution.

During the production phase, the synthesis and incorporation of sulphanilic acid into polymers may involve chemical processes that generate waste and emissions. These byproducts can contribute to air and water pollution if not properly managed. Additionally, the energy requirements for these processes may indirectly contribute to greenhouse gas emissions, depending on the energy sources used.

The end-of-life disposal of polymers containing sulphanilic acid presents further environmental challenges. Incineration of these materials may release harmful compounds into the atmosphere, while landfill disposal can lead to long-term soil and groundwater contamination. Recycling processes must also be carefully designed to handle the presence of sulphanilic acid and prevent its release during material recovery.

On the positive side, the use of sulphanilic acid in polymers can potentially enhance the durability and lifespan of certain products. This increased longevity may reduce the need for frequent replacements, thereby decreasing overall material consumption and waste generation. However, this benefit must be weighed against the potential environmental risks associated with the material's persistence.

To mitigate these environmental impacts, researchers and manufacturers are exploring alternative additives and developing more environmentally friendly polymer formulations. Efforts are also being made to improve the recyclability and biodegradability of polymers containing sulphanilic acid, as well as to optimize production processes to minimize waste and emissions.

One of the primary environmental concerns associated with sulphanilic acid in polymers is its potential for leaching. As polymers degrade over time, there is a risk that sulphanilic acid may be released into the surrounding environment. This leaching process can lead to soil and water contamination, potentially affecting ecosystems and aquatic life. The extent of leaching depends on various factors, including the polymer matrix, environmental conditions, and the concentration of sulphanilic acid used.

The biodegradability of polymers containing sulphanilic acid is another important environmental aspect. While sulphanilic acid itself is biodegradable, its incorporation into polymer structures may alter the overall biodegradability of the material. This can result in prolonged environmental persistence of polymer products, contributing to the global issue of plastic pollution.

During the production phase, the synthesis and incorporation of sulphanilic acid into polymers may involve chemical processes that generate waste and emissions. These byproducts can contribute to air and water pollution if not properly managed. Additionally, the energy requirements for these processes may indirectly contribute to greenhouse gas emissions, depending on the energy sources used.

The end-of-life disposal of polymers containing sulphanilic acid presents further environmental challenges. Incineration of these materials may release harmful compounds into the atmosphere, while landfill disposal can lead to long-term soil and groundwater contamination. Recycling processes must also be carefully designed to handle the presence of sulphanilic acid and prevent its release during material recovery.

On the positive side, the use of sulphanilic acid in polymers can potentially enhance the durability and lifespan of certain products. This increased longevity may reduce the need for frequent replacements, thereby decreasing overall material consumption and waste generation. However, this benefit must be weighed against the potential environmental risks associated with the material's persistence.

To mitigate these environmental impacts, researchers and manufacturers are exploring alternative additives and developing more environmentally friendly polymer formulations. Efforts are also being made to improve the recyclability and biodegradability of polymers containing sulphanilic acid, as well as to optimize production processes to minimize waste and emissions.

Scalability and Industrial Application Prospects

The scalability and industrial application prospects of sulphanilic acid in polymeric material strengthening are promising, with significant potential for widespread adoption across various sectors. The use of sulphanilic acid as a strengthening agent in polymers offers several advantages that make it attractive for large-scale industrial applications.

One of the key factors contributing to the scalability of this technology is the relatively low cost and widespread availability of sulphanilic acid. As a derivative of aniline, which is produced on a large scale for various industrial applications, sulphanilic acid can be readily obtained in sufficient quantities to meet the demands of polymer manufacturing processes. This ensures a stable supply chain and reduces the risk of production bottlenecks.

The incorporation of sulphanilic acid into polymeric materials can be achieved through existing manufacturing processes with minimal modifications. This compatibility with current production methods significantly lowers the barriers to adoption and allows for seamless integration into existing manufacturing facilities. The ability to use conventional polymer processing techniques, such as extrusion, injection molding, and compression molding, further enhances the scalability of this technology.

From an industrial application perspective, the strengthening effects of sulphanilic acid on polymeric materials open up new possibilities across multiple sectors. In the automotive industry, for instance, stronger and lighter polymeric components can contribute to improved fuel efficiency and reduced emissions. The construction sector can benefit from enhanced durability and weather resistance in polymer-based building materials, leading to longer-lasting structures and reduced maintenance costs.

The electronics industry stands to gain from the improved mechanical properties of polymeric materials strengthened with sulphanilic acid. This could lead to more robust and reliable electronic components, particularly in applications where structural integrity is crucial, such as in wearable devices or automotive electronics.

Moreover, the potential for customization and fine-tuning of material properties through varying concentrations of sulphanilic acid offers versatility in industrial applications. This adaptability allows manufacturers to tailor the strengthening effect to meet specific requirements across different products and industries, further expanding its potential market reach.

As environmental concerns continue to drive innovation in materials science, the use of sulphanilic acid in polymer strengthening aligns well with sustainability goals. By enhancing the performance of polymeric materials, it may be possible to reduce the overall material consumption in certain applications, contributing to resource efficiency and waste reduction.

One of the key factors contributing to the scalability of this technology is the relatively low cost and widespread availability of sulphanilic acid. As a derivative of aniline, which is produced on a large scale for various industrial applications, sulphanilic acid can be readily obtained in sufficient quantities to meet the demands of polymer manufacturing processes. This ensures a stable supply chain and reduces the risk of production bottlenecks.

The incorporation of sulphanilic acid into polymeric materials can be achieved through existing manufacturing processes with minimal modifications. This compatibility with current production methods significantly lowers the barriers to adoption and allows for seamless integration into existing manufacturing facilities. The ability to use conventional polymer processing techniques, such as extrusion, injection molding, and compression molding, further enhances the scalability of this technology.

From an industrial application perspective, the strengthening effects of sulphanilic acid on polymeric materials open up new possibilities across multiple sectors. In the automotive industry, for instance, stronger and lighter polymeric components can contribute to improved fuel efficiency and reduced emissions. The construction sector can benefit from enhanced durability and weather resistance in polymer-based building materials, leading to longer-lasting structures and reduced maintenance costs.

The electronics industry stands to gain from the improved mechanical properties of polymeric materials strengthened with sulphanilic acid. This could lead to more robust and reliable electronic components, particularly in applications where structural integrity is crucial, such as in wearable devices or automotive electronics.

Moreover, the potential for customization and fine-tuning of material properties through varying concentrations of sulphanilic acid offers versatility in industrial applications. This adaptability allows manufacturers to tailor the strengthening effect to meet specific requirements across different products and industries, further expanding its potential market reach.

As environmental concerns continue to drive innovation in materials science, the use of sulphanilic acid in polymer strengthening aligns well with sustainability goals. By enhancing the performance of polymeric materials, it may be possible to reduce the overall material consumption in certain applications, contributing to resource efficiency and waste reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!