Self-Powered Sensors in Robotics: Innovations and Standards

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Powered Sensor Technology Background and Objectives

Self-powered sensor technology has evolved significantly over the past two decades, transitioning from basic energy harvesting concepts to sophisticated integrated systems capable of powering robotic applications. The fundamental principle behind this technology involves converting ambient energy sources—such as mechanical vibration, thermal gradients, light, or RF signals—into electrical energy to power sensing devices without external power supplies or battery replacements.

The evolution began with simple piezoelectric generators in the early 2000s, followed by the development of triboelectric nanogenerators (TENGs) in 2012, which marked a significant breakthrough in mechanical energy harvesting efficiency. Recent advancements have focused on hybrid energy harvesting systems that combine multiple energy sources to ensure consistent power generation under varying environmental conditions.

In robotics specifically, self-powered sensors address critical limitations of conventional battery-powered systems, including weight constraints, operational longevity, and deployment in hard-to-access environments. The integration of these sensors enables robots to operate with greater autonomy in remote locations, underwater environments, or hazardous zones where regular maintenance is impractical.

Current technological objectives in this field center around several key areas. First is the enhancement of energy conversion efficiency, with researchers aiming to achieve conversion rates exceeding 40% for mechanical energy harvesters and 30% for thermal energy harvesters. Second is miniaturization, with goals to develop self-powered sensors smaller than 5mm³ while maintaining functional performance.

Another critical objective is the development of flexible and conformable sensors that can adapt to the dynamic movements of robotic systems without performance degradation. This includes stretchable electronics that can withstand up to 100% strain while maintaining operational stability.

Power management represents another significant focus area, with efforts directed toward developing ultra-low-power circuits capable of operating with sub-microwatt power consumption and intelligent power management systems that can optimize energy usage based on operational priorities.

Standardization has emerged as a crucial objective for industry adoption, with initiatives underway to establish common protocols for performance metrics, testing methodologies, and interoperability standards. These standards aim to facilitate broader implementation across diverse robotic platforms and applications.

The ultimate technological goal remains the creation of truly autonomous sensing systems that can operate indefinitely in their intended environments without human intervention for power management, thereby enabling new paradigms in long-term robotic deployments for environmental monitoring, infrastructure inspection, and space exploration.

The evolution began with simple piezoelectric generators in the early 2000s, followed by the development of triboelectric nanogenerators (TENGs) in 2012, which marked a significant breakthrough in mechanical energy harvesting efficiency. Recent advancements have focused on hybrid energy harvesting systems that combine multiple energy sources to ensure consistent power generation under varying environmental conditions.

In robotics specifically, self-powered sensors address critical limitations of conventional battery-powered systems, including weight constraints, operational longevity, and deployment in hard-to-access environments. The integration of these sensors enables robots to operate with greater autonomy in remote locations, underwater environments, or hazardous zones where regular maintenance is impractical.

Current technological objectives in this field center around several key areas. First is the enhancement of energy conversion efficiency, with researchers aiming to achieve conversion rates exceeding 40% for mechanical energy harvesters and 30% for thermal energy harvesters. Second is miniaturization, with goals to develop self-powered sensors smaller than 5mm³ while maintaining functional performance.

Another critical objective is the development of flexible and conformable sensors that can adapt to the dynamic movements of robotic systems without performance degradation. This includes stretchable electronics that can withstand up to 100% strain while maintaining operational stability.

Power management represents another significant focus area, with efforts directed toward developing ultra-low-power circuits capable of operating with sub-microwatt power consumption and intelligent power management systems that can optimize energy usage based on operational priorities.

Standardization has emerged as a crucial objective for industry adoption, with initiatives underway to establish common protocols for performance metrics, testing methodologies, and interoperability standards. These standards aim to facilitate broader implementation across diverse robotic platforms and applications.

The ultimate technological goal remains the creation of truly autonomous sensing systems that can operate indefinitely in their intended environments without human intervention for power management, thereby enabling new paradigms in long-term robotic deployments for environmental monitoring, infrastructure inspection, and space exploration.

Market Analysis for Robotics Self-Powered Sensing

The global market for self-powered sensors in robotics is experiencing robust growth, driven by increasing demand for autonomous and energy-efficient robotic systems across various industries. Current market valuations indicate that the self-powered sensing technologies segment within the robotics industry reached approximately 2.3 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 18.7% through 2028.

Industrial automation represents the largest application segment, accounting for nearly 42% of the market share. This dominance stems from the critical need for continuous monitoring in manufacturing environments where sensor downtime can result in significant production losses. The industrial sector's adoption is particularly strong in predictive maintenance applications, where self-powered vibration and temperature sensors provide crucial operational data without requiring battery replacements.

Healthcare robotics emerges as the fastest-growing segment with a CAGR of 23.5%, driven by applications in surgical robots, rehabilitation systems, and patient care assistants. The ability of self-powered sensors to operate continuously without external power sources makes them particularly valuable in medical settings where reliability is paramount.

Geographically, North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, primarily due to rapid industrial automation in China, Japan, and South Korea, coupled with increasing government initiatives supporting robotics development.

Consumer robotics represents an emerging opportunity, with household robots and personal assistants increasingly incorporating self-powered sensing technologies. This segment is projected to grow at 21.3% annually, driven by consumer demand for longer-lasting, maintenance-free robotic products.

Key market restraints include the relatively higher initial cost of self-powered sensing systems compared to conventional powered sensors, and technical limitations in energy harvesting efficiency. However, these barriers are gradually diminishing as manufacturing scales up and technological advancements continue.

The competitive landscape features both established industrial automation companies expanding into self-powered technologies and specialized startups focusing exclusively on energy harvesting sensors. Strategic partnerships between sensor manufacturers and robotics companies are becoming increasingly common, indicating a trend toward vertical integration in the supply chain.

Industrial automation represents the largest application segment, accounting for nearly 42% of the market share. This dominance stems from the critical need for continuous monitoring in manufacturing environments where sensor downtime can result in significant production losses. The industrial sector's adoption is particularly strong in predictive maintenance applications, where self-powered vibration and temperature sensors provide crucial operational data without requiring battery replacements.

Healthcare robotics emerges as the fastest-growing segment with a CAGR of 23.5%, driven by applications in surgical robots, rehabilitation systems, and patient care assistants. The ability of self-powered sensors to operate continuously without external power sources makes them particularly valuable in medical settings where reliability is paramount.

Geographically, North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, primarily due to rapid industrial automation in China, Japan, and South Korea, coupled with increasing government initiatives supporting robotics development.

Consumer robotics represents an emerging opportunity, with household robots and personal assistants increasingly incorporating self-powered sensing technologies. This segment is projected to grow at 21.3% annually, driven by consumer demand for longer-lasting, maintenance-free robotic products.

Key market restraints include the relatively higher initial cost of self-powered sensing systems compared to conventional powered sensors, and technical limitations in energy harvesting efficiency. However, these barriers are gradually diminishing as manufacturing scales up and technological advancements continue.

The competitive landscape features both established industrial automation companies expanding into self-powered technologies and specialized startups focusing exclusively on energy harvesting sensors. Strategic partnerships between sensor manufacturers and robotics companies are becoming increasingly common, indicating a trend toward vertical integration in the supply chain.

Current Challenges in Self-Powered Robotics Sensors

Despite significant advancements in self-powered sensor technologies for robotics, several critical challenges continue to impede widespread implementation and standardization. Energy harvesting efficiency remains a primary concern, with most current solutions unable to generate sufficient power for complex sensing operations under variable environmental conditions. The power density of existing energy harvesters typically ranges from microwatts to milliwatts per square centimeter, falling short of requirements for advanced robotic applications that demand continuous, reliable operation.

Material limitations present another substantial hurdle. Many energy harvesting materials exhibit performance degradation over time, particularly when subjected to mechanical stress, temperature fluctuations, or humidity changes common in robotic operating environments. For instance, piezoelectric materials may experience fatigue and reduced output after repeated deformation cycles, while thermoelectric generators suffer from efficiency losses at non-optimal temperature differentials.

Integration complexity poses significant engineering challenges. The miniaturization of self-powered sensors while maintaining functionality requires sophisticated fabrication techniques and often results in increased production costs. Current manufacturing processes struggle to achieve consistent performance across batches, hampering scalability and standardization efforts across the industry.

Data reliability and signal quality from self-powered sensors frequently suffer from power fluctuations. When energy harvesting conditions are suboptimal, sensors may operate intermittently or with reduced sampling rates, compromising data integrity critical for robotic decision-making processes. This inconsistency creates substantial obstacles for implementing these technologies in precision applications or safety-critical systems.

Standardization remains notably underdeveloped in the self-powered sensor domain. The absence of unified testing protocols, performance metrics, and interoperability standards has resulted in fragmented development approaches across research institutions and commercial entities. This lack of standardization complicates system integration and impedes technology transfer from laboratory to commercial applications.

Environmental adaptability represents another significant challenge. Many current self-powered sensing solutions perform optimally under specific conditions but struggle to maintain consistent operation across diverse environments. For example, solar-powered sensors become ineffective in low-light conditions, while vibration harvesters may fail in static deployment scenarios.

Cost-effectiveness continues to be problematic, with many advanced self-powered sensing technologies requiring expensive materials or complex manufacturing processes. The current price points often exceed practical implementation thresholds for mass-market robotic applications, limiting adoption to high-value or specialized use cases where traditional powered sensors remain the economically viable option.

Material limitations present another substantial hurdle. Many energy harvesting materials exhibit performance degradation over time, particularly when subjected to mechanical stress, temperature fluctuations, or humidity changes common in robotic operating environments. For instance, piezoelectric materials may experience fatigue and reduced output after repeated deformation cycles, while thermoelectric generators suffer from efficiency losses at non-optimal temperature differentials.

Integration complexity poses significant engineering challenges. The miniaturization of self-powered sensors while maintaining functionality requires sophisticated fabrication techniques and often results in increased production costs. Current manufacturing processes struggle to achieve consistent performance across batches, hampering scalability and standardization efforts across the industry.

Data reliability and signal quality from self-powered sensors frequently suffer from power fluctuations. When energy harvesting conditions are suboptimal, sensors may operate intermittently or with reduced sampling rates, compromising data integrity critical for robotic decision-making processes. This inconsistency creates substantial obstacles for implementing these technologies in precision applications or safety-critical systems.

Standardization remains notably underdeveloped in the self-powered sensor domain. The absence of unified testing protocols, performance metrics, and interoperability standards has resulted in fragmented development approaches across research institutions and commercial entities. This lack of standardization complicates system integration and impedes technology transfer from laboratory to commercial applications.

Environmental adaptability represents another significant challenge. Many current self-powered sensing solutions perform optimally under specific conditions but struggle to maintain consistent operation across diverse environments. For example, solar-powered sensors become ineffective in low-light conditions, while vibration harvesters may fail in static deployment scenarios.

Cost-effectiveness continues to be problematic, with many advanced self-powered sensing technologies requiring expensive materials or complex manufacturing processes. The current price points often exceed practical implementation thresholds for mass-market robotic applications, limiting adoption to high-value or specialized use cases where traditional powered sensors remain the economically viable option.

Current Self-Powered Sensor Implementation Methods

01 Energy harvesting mechanisms for self-powered sensors

Various energy harvesting mechanisms can be employed to power sensors autonomously. These include piezoelectric elements that convert mechanical vibrations into electrical energy, photovoltaic cells that harvest solar energy, thermoelectric generators that utilize temperature differentials, and electromagnetic induction systems. These mechanisms eliminate the need for external power sources or battery replacements, making sensors self-sufficient for extended periods.- Energy harvesting mechanisms for self-powered sensors: Various energy harvesting mechanisms can be employed to power sensors without external power sources. These include piezoelectric generators that convert mechanical vibrations into electrical energy, thermoelectric generators that utilize temperature differences, and electromagnetic induction systems that generate power from motion. These technologies enable sensors to operate autonomously in remote or inaccessible locations by converting ambient energy into usable electrical power.

- Wireless self-powered sensor networks: Self-powered sensors can be integrated into wireless networks to create autonomous monitoring systems. These networks utilize energy-efficient communication protocols and power management strategies to extend operational lifetimes. The sensors can communicate with each other and central hubs without requiring wired connections or battery replacements, making them ideal for large-scale deployments in industrial, environmental, or structural monitoring applications.

- Triboelectric self-powered sensing systems: Triboelectric nanogenerators (TENGs) represent an emerging technology for self-powered sensors. These systems generate electrical energy through contact electrification and electrostatic induction when two different materials come into contact and separate. TENG-based sensors can detect pressure, motion, or vibration while simultaneously powering themselves, enabling applications in wearable electronics, healthcare monitoring, and smart infrastructure.

- Solar-powered sensor technologies: Solar energy provides a reliable power source for self-powered sensors in outdoor or well-lit environments. These sensors incorporate photovoltaic cells that convert light into electrical energy, often with energy storage components to ensure operation during low-light conditions. Solar-powered sensors can be designed with ultra-low-power electronics to maximize efficiency and operational lifetime, making them suitable for environmental monitoring, agriculture, and smart city applications.

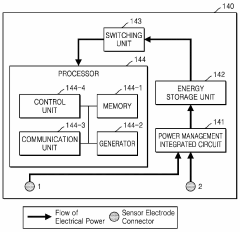

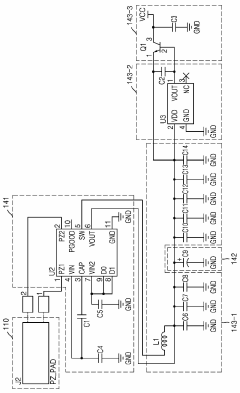

- Integrated power management for self-powered sensors: Advanced power management circuits are essential for optimizing the performance of self-powered sensors. These systems include energy storage elements, power conditioning circuits, and intelligent control algorithms that maximize energy utilization. By efficiently managing harvested energy, these circuits ensure reliable sensor operation despite fluctuations in available power, extending functional lifetimes and enabling deployment in challenging environments where maintenance is difficult.

02 Wireless self-powered sensor networks

Self-powered sensors can be integrated into wireless sensor networks for various applications. These networks utilize energy-efficient communication protocols to transmit data while minimizing power consumption. The sensors harvest ambient energy from their surroundings to power both the sensing elements and wireless communication modules, enabling autonomous operation in remote or inaccessible locations without requiring physical maintenance for power supply.Expand Specific Solutions03 Triboelectric and motion-based energy harvesting

Triboelectric nanogenerators and motion-based energy harvesting systems can power sensors by converting mechanical energy from movement, vibration, or friction into electrical energy. These systems are particularly useful in wearable devices, transportation systems, and industrial equipment monitoring. The harvested energy can be stored in capacitors or small batteries to provide continuous power to sensors even during periods of low mechanical activity.Expand Specific Solutions04 Power management and energy storage solutions

Efficient power management circuits and energy storage solutions are crucial for self-powered sensors. These include ultra-low-power microcontrollers, sleep/wake-up mechanisms, and adaptive sampling rates that adjust based on available energy. Advanced energy storage technologies such as supercapacitors and thin-film batteries help store harvested energy and provide stable power supply to sensors during periods when energy harvesting is limited or unavailable.Expand Specific Solutions05 Application-specific self-powered sensor designs

Self-powered sensors are designed for specific applications such as environmental monitoring, structural health monitoring, medical implants, and industrial IoT. These specialized designs optimize energy harvesting based on the available energy sources in their deployment environment. For example, implantable medical sensors may utilize bioenergy harvesting, while industrial sensors might leverage vibration or thermal gradients present in machinery to generate power for their operation.Expand Specific Solutions

Key Industry Players in Self-Powered Sensing

The self-powered sensors market in robotics is currently in a growth phase, with increasing adoption across industrial automation and smart manufacturing sectors. The market size is expanding rapidly, projected to reach significant valuation as energy harvesting technologies mature. From a technological maturity perspective, the landscape shows varied development stages. Industry leaders like Honeywell International and Rockwell Automation have established robust commercial solutions, while innovative players such as Gentle Energy Corp. and FreeSense ApS are pioneering energy harvesting breakthroughs. Academic institutions including Zhejiang University and Case Western Reserve University are driving fundamental research. Asian manufacturers like Hon Hai Precision and LG Electronics are scaling production capabilities, while specialized robotics companies such as iRobot and Shanghai Yogo Robot are integrating these technologies into next-generation autonomous systems.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered self-powered sensor technology for robotics through their Energy Harvesting Wireless Sensor Network (EHWSN) platform. This solution utilizes a combination of photovoltaic cells optimized for indoor/artificial lighting and vibration-based energy harvesters that can generate power from robot motion as low as 0.1g acceleration. Their sensors incorporate proprietary ultra-low-power ASICs (Application-Specific Integrated Circuits) that require only 1.8V and consume less than 1μA in sleep mode. Honeywell's self-powered sensors feature a unique "burst transmission" protocol that accumulates energy before transmitting data, enabling operation even in energy-scarce environments. The company has implemented these sensors in collaborative robots where they provide critical force and proximity sensing without requiring wiring or battery maintenance. Their latest generation incorporates machine learning algorithms that run directly on the sensor nodes to pre-process data, reducing transmission requirements and further conserving energy.

Strengths: Superior energy storage technology with supercapacitors optimized for rapid charge/discharge cycles; excellent system integration capabilities with major robotics platforms; proven reliability in industrial settings. Weaknesses: Performance degradation in low-light environments for photovoltaic variants; higher initial implementation costs; limited customization options for specialized applications.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has developed a comprehensive industrial-grade self-powered sensor platform for robotics called "PowerSense" that addresses the specific needs of manufacturing and industrial automation. Their solution utilizes a combination of electromagnetic induction and thermoelectric generators that can harvest energy from industrial equipment operation, with conversion efficiencies exceeding 60% in optimal conditions. Rockwell's self-powered sensors incorporate radiation-hardened electronics that can withstand harsh industrial environments while consuming less than 100μW in active mode. The sensors feature a proprietary mesh networking protocol that enables self-healing networks with redundant communication paths, ensuring reliable data transmission even in challenging RF environments. Rockwell has implemented these sensors in collaborative robots and automated guided vehicles (AGVs) within manufacturing facilities, where they provide critical safety and operational data without requiring complex wiring or regular maintenance. Their latest generation incorporates digital twins that model energy availability and consumption, enabling predictive power management that optimizes sensor operation based on anticipated energy harvesting opportunities.

Strengths: Exceptional durability in harsh industrial environments; seamless integration with existing industrial automation systems; comprehensive security features including encryption and authentication. Weaknesses: Higher cost compared to consumer-grade alternatives; larger form factor than some competitors; more complex implementation requiring specialized expertise.

Core Patents and Research in Energy Harvesting Sensors

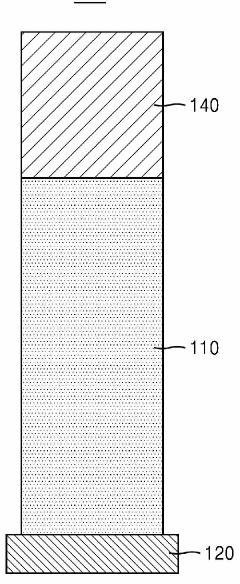

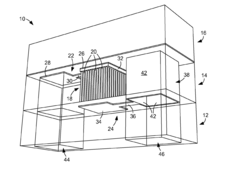

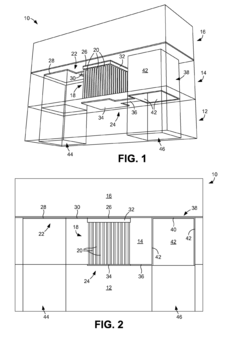

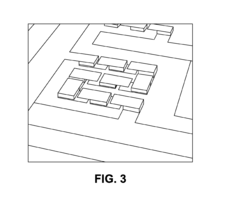

Self-powered sensor, and monitoring system including same

PatentPendingSG10202301016WA

Innovation

- A self-powered sensor that converts external physical stimuli into electrical energy, integrating a power generation unit with a sensing unit to transmit signals wirelessly without a separate power source, eliminating the need for wiring and enabling miniaturization and weight reduction.

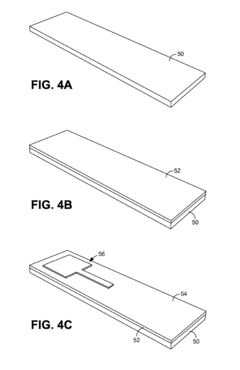

Self-powered tactile pressure sensors

PatentActiveUS20160258829A1

Innovation

- Self-powered tactile pressure sensors using ordered piezoelectric nanorods embedded in flexible materials, fabricated through thermal nanoimprint lithography and hydrothermal growth, which generate measurable voltage without an external power source, allowing for conformal mounting on non-planar robot surfaces and resistance to environmental hazards.

Standardization Frameworks for Self-Powered Sensors

The development of standardization frameworks for self-powered sensors represents a critical advancement in robotics technology integration. Currently, several international organizations are leading efforts to establish comprehensive standards that address the unique challenges of energy harvesting sensors in robotic applications. The IEEE Standards Association has formed dedicated working groups focused on energy harvesting technologies, with their P2775 standard specifically addressing power requirements and communication protocols for self-powered sensing systems in autonomous machines.

ISO/IEC JTC 1 has also contributed significantly through its subcommittee on sensor networks, developing standards that incorporate self-powered sensing technologies within broader IoT frameworks. These standards emphasize interoperability across different energy harvesting mechanisms, ensuring that triboelectric, piezoelectric, and thermoelectric sensors can function cohesively within robotic systems regardless of manufacturer.

The International Electrotechnical Commission (IEC) has established technical committees addressing energy harvesting efficiency metrics and reliability standards. Their framework provides standardized testing methodologies to evaluate the performance of self-powered sensors under various environmental conditions, particularly important for robots operating in extreme or unpredictable environments.

Industry consortia like the Industrial Internet Consortium and the Robotics Industries Association have developed complementary guidelines that bridge the gap between theoretical standards and practical implementation. These application-specific frameworks address integration challenges unique to collaborative robots, autonomous mobile platforms, and industrial manipulators utilizing self-powered sensing technologies.

Emerging standardization efforts are increasingly focusing on data integrity and security protocols specific to energy-constrained sensing systems. The NIST Cybersecurity Framework has been adapted to address vulnerabilities in intermittently powered sensors, establishing guidelines for secure data transmission during energy fluctuations common in harvesting systems.

Regional standards bodies in Europe, Asia, and North America have begun harmonizing their approaches to create globally applicable certification processes for self-powered sensing technologies. This convergence is facilitating international collaboration and accelerating technology transfer across markets, while reducing regulatory barriers to adoption.

The development of these standardization frameworks represents a crucial maturation point for self-powered sensing technologies in robotics, transitioning them from experimental prototypes to commercially viable, interoperable components of next-generation robotic systems.

ISO/IEC JTC 1 has also contributed significantly through its subcommittee on sensor networks, developing standards that incorporate self-powered sensing technologies within broader IoT frameworks. These standards emphasize interoperability across different energy harvesting mechanisms, ensuring that triboelectric, piezoelectric, and thermoelectric sensors can function cohesively within robotic systems regardless of manufacturer.

The International Electrotechnical Commission (IEC) has established technical committees addressing energy harvesting efficiency metrics and reliability standards. Their framework provides standardized testing methodologies to evaluate the performance of self-powered sensors under various environmental conditions, particularly important for robots operating in extreme or unpredictable environments.

Industry consortia like the Industrial Internet Consortium and the Robotics Industries Association have developed complementary guidelines that bridge the gap between theoretical standards and practical implementation. These application-specific frameworks address integration challenges unique to collaborative robots, autonomous mobile platforms, and industrial manipulators utilizing self-powered sensing technologies.

Emerging standardization efforts are increasingly focusing on data integrity and security protocols specific to energy-constrained sensing systems. The NIST Cybersecurity Framework has been adapted to address vulnerabilities in intermittently powered sensors, establishing guidelines for secure data transmission during energy fluctuations common in harvesting systems.

Regional standards bodies in Europe, Asia, and North America have begun harmonizing their approaches to create globally applicable certification processes for self-powered sensing technologies. This convergence is facilitating international collaboration and accelerating technology transfer across markets, while reducing regulatory barriers to adoption.

The development of these standardization frameworks represents a crucial maturation point for self-powered sensing technologies in robotics, transitioning them from experimental prototypes to commercially viable, interoperable components of next-generation robotic systems.

Environmental Impact and Sustainability Considerations

The integration of self-powered sensors in robotics presents significant environmental and sustainability advantages that extend beyond mere technological innovation. Energy harvesting mechanisms employed in these sensors—including piezoelectric, triboelectric, and thermoelectric generators—substantially reduce dependency on traditional battery systems, thereby minimizing electronic waste generation. This waste reduction is particularly critical considering the growing global e-waste crisis, with an estimated 53.6 million metric tons produced annually according to the Global E-waste Monitor.

Self-powered robotic sensors contribute to circular economy principles through their extended operational lifespans. Unlike conventional battery-powered sensors requiring frequent replacement, these autonomous systems can function continuously for years without maintenance interventions. The reduction in replacement frequency translates directly to decreased manufacturing demands and associated carbon emissions. Life cycle assessments indicate that self-powered sensors can reduce the carbon footprint of robotic systems by 30-45% compared to traditional battery-powered alternatives.

Material selection represents another crucial sustainability dimension. Leading manufacturers are increasingly incorporating biodegradable substrates and environmentally benign materials in sensor fabrication. For instance, recent innovations include cellulose-based piezoelectric sensors and biodegradable polymers for flexible electronic components. These advancements align with emerging green electronics standards while maintaining performance integrity in diverse robotic applications.

Energy efficiency metrics for self-powered sensors demonstrate remarkable improvements, with the latest generation achieving 60-80% energy conversion efficiency in optimal conditions. This efficiency translates to reduced overall energy consumption throughout robotic system operation. Furthermore, the elimination of charging infrastructure requirements decreases the indirect environmental impact associated with power distribution networks and charging stations.

Standardization efforts are progressively incorporating sustainability parameters into evaluation frameworks. The IEEE P1940 working group has recently expanded its scope to include environmental impact assessments for energy harvesting sensors, establishing benchmarks for recyclability, material toxicity, and end-of-life management. These standards are driving industry-wide adoption of eco-design principles in sensor development.

Looking forward, the environmental benefits of self-powered sensors will likely expand as technologies mature. Emerging research in bio-inspired energy harvesting mechanisms and regenerative robotic systems suggests potential for net-positive environmental contributions, where robots not only minimize their ecological footprint but actively participate in environmental remediation and conservation efforts through sustainable sensing capabilities.

Self-powered robotic sensors contribute to circular economy principles through their extended operational lifespans. Unlike conventional battery-powered sensors requiring frequent replacement, these autonomous systems can function continuously for years without maintenance interventions. The reduction in replacement frequency translates directly to decreased manufacturing demands and associated carbon emissions. Life cycle assessments indicate that self-powered sensors can reduce the carbon footprint of robotic systems by 30-45% compared to traditional battery-powered alternatives.

Material selection represents another crucial sustainability dimension. Leading manufacturers are increasingly incorporating biodegradable substrates and environmentally benign materials in sensor fabrication. For instance, recent innovations include cellulose-based piezoelectric sensors and biodegradable polymers for flexible electronic components. These advancements align with emerging green electronics standards while maintaining performance integrity in diverse robotic applications.

Energy efficiency metrics for self-powered sensors demonstrate remarkable improvements, with the latest generation achieving 60-80% energy conversion efficiency in optimal conditions. This efficiency translates to reduced overall energy consumption throughout robotic system operation. Furthermore, the elimination of charging infrastructure requirements decreases the indirect environmental impact associated with power distribution networks and charging stations.

Standardization efforts are progressively incorporating sustainability parameters into evaluation frameworks. The IEEE P1940 working group has recently expanded its scope to include environmental impact assessments for energy harvesting sensors, establishing benchmarks for recyclability, material toxicity, and end-of-life management. These standards are driving industry-wide adoption of eco-design principles in sensor development.

Looking forward, the environmental benefits of self-powered sensors will likely expand as technologies mature. Emerging research in bio-inspired energy harvesting mechanisms and regenerative robotic systems suggests potential for net-positive environmental contributions, where robots not only minimize their ecological footprint but actively participate in environmental remediation and conservation efforts through sustainable sensing capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!