Sulphanilic Acid in Light Emitting Diodes: Advances and Perspectives

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LED Sulphanilic Acid Integration: Background and Objectives

Light Emitting Diodes (LEDs) have revolutionized the lighting industry since their inception in the early 1960s. The integration of sulphanilic acid in LED technology represents a significant advancement in the field, promising enhanced performance and efficiency. This technological evolution stems from the continuous pursuit of improved light output, energy efficiency, and color rendering capabilities in LED devices.

The primary objective of incorporating sulphanilic acid into LEDs is to address several key challenges faced by conventional LED technologies. These include issues related to color stability, luminous efficacy, and overall device longevity. Sulphanilic acid, an organic compound with unique optical and electronic properties, has shown potential in overcoming these limitations, thereby opening new avenues for LED applications in various sectors.

The development of sulphanilic acid-based LEDs is driven by the growing demand for high-performance lighting solutions across industries. From consumer electronics to automotive lighting, and from architectural illumination to medical devices, the need for advanced LED technologies continues to expand. This market pull has accelerated research and development efforts in the field, leading to rapid advancements in sulphanilic acid integration techniques.

Historically, the use of organic compounds in LED technology has been limited due to stability concerns and manufacturing complexities. However, recent breakthroughs in material science and nanotechnology have paved the way for the successful incorporation of sulphanilic acid into LED structures. This integration marks a significant milestone in the convergence of organic and inorganic materials in optoelectronic devices.

The technical evolution of sulphanilic acid in LEDs can be traced through several key stages. Initial research focused on understanding the fundamental interactions between sulphanilic acid and traditional LED materials. This was followed by experimental studies on various integration methods, including doping, surface modification, and composite formation. Recent efforts have centered on optimizing these techniques for large-scale manufacturing and commercialization.

As research in this area progresses, the scientific community anticipates further improvements in LED performance metrics. These include enhanced quantum efficiency, broader spectral coverage, and improved thermal stability. The integration of sulphanilic acid is expected to contribute significantly to the development of next-generation LED technologies, potentially revolutionizing lighting solutions across various applications.

In conclusion, the integration of sulphanilic acid in LEDs represents a promising frontier in optoelectronic technology. By addressing current limitations and opening new possibilities, this advancement aligns with the broader goals of energy efficiency and sustainability in lighting technologies. The ongoing research and development in this field are poised to drive innovation and shape the future of LED technology.

The primary objective of incorporating sulphanilic acid into LEDs is to address several key challenges faced by conventional LED technologies. These include issues related to color stability, luminous efficacy, and overall device longevity. Sulphanilic acid, an organic compound with unique optical and electronic properties, has shown potential in overcoming these limitations, thereby opening new avenues for LED applications in various sectors.

The development of sulphanilic acid-based LEDs is driven by the growing demand for high-performance lighting solutions across industries. From consumer electronics to automotive lighting, and from architectural illumination to medical devices, the need for advanced LED technologies continues to expand. This market pull has accelerated research and development efforts in the field, leading to rapid advancements in sulphanilic acid integration techniques.

Historically, the use of organic compounds in LED technology has been limited due to stability concerns and manufacturing complexities. However, recent breakthroughs in material science and nanotechnology have paved the way for the successful incorporation of sulphanilic acid into LED structures. This integration marks a significant milestone in the convergence of organic and inorganic materials in optoelectronic devices.

The technical evolution of sulphanilic acid in LEDs can be traced through several key stages. Initial research focused on understanding the fundamental interactions between sulphanilic acid and traditional LED materials. This was followed by experimental studies on various integration methods, including doping, surface modification, and composite formation. Recent efforts have centered on optimizing these techniques for large-scale manufacturing and commercialization.

As research in this area progresses, the scientific community anticipates further improvements in LED performance metrics. These include enhanced quantum efficiency, broader spectral coverage, and improved thermal stability. The integration of sulphanilic acid is expected to contribute significantly to the development of next-generation LED technologies, potentially revolutionizing lighting solutions across various applications.

In conclusion, the integration of sulphanilic acid in LEDs represents a promising frontier in optoelectronic technology. By addressing current limitations and opening new possibilities, this advancement aligns with the broader goals of energy efficiency and sustainability in lighting technologies. The ongoing research and development in this field are poised to drive innovation and shape the future of LED technology.

Market Analysis for Sulphanilic Acid-Enhanced LEDs

The market for Sulphanilic Acid-Enhanced LEDs is experiencing significant growth, driven by the increasing demand for high-performance lighting solutions across various industries. The global LED market, valued at $55.2 billion in 2020, is projected to reach $152.4 billion by 2030, with a compound annual growth rate (CAGR) of 10.7%. Within this broader market, Sulphanilic Acid-Enhanced LEDs are carving out a niche due to their superior performance characteristics.

The automotive sector represents a key market for these advanced LEDs, as manufacturers seek to improve energy efficiency and design flexibility in vehicle lighting systems. The automotive LED market alone is expected to grow from $3.1 billion in 2021 to $4.6 billion by 2026, with a CAGR of 8.3%. Sulphanilic Acid-Enhanced LEDs are particularly well-suited for this application due to their enhanced brightness and color rendering capabilities.

In the consumer electronics segment, there is a growing demand for high-quality display technologies. The global OLED market, which can benefit from Sulphanilic Acid-Enhanced LED technology, is forecasted to expand from $38.4 billion in 2021 to $72.8 billion by 2026, with a CAGR of 13.6%. This growth is fueled by the increasing adoption of OLED displays in smartphones, televisions, and wearable devices.

The general lighting market also presents significant opportunities for Sulphanilic Acid-Enhanced LEDs. As governments worldwide implement stricter energy efficiency regulations, the demand for advanced LED lighting solutions is rising. The global LED lighting market is expected to grow from $54.5 billion in 2021 to $127.3 billion by 2027, with a CAGR of 15.2%.

Geographically, Asia-Pacific dominates the LED market, accounting for over 40% of the global market share. This region, particularly China, Japan, and South Korea, is expected to be a major adopter of Sulphanilic Acid-Enhanced LED technology due to its strong manufacturing base and technological innovation in the electronics sector.

Despite the promising market outlook, challenges remain. The higher production costs associated with Sulphanilic Acid-Enhanced LEDs compared to conventional LEDs may initially limit their adoption in price-sensitive markets. However, as production scales up and technology matures, these costs are expected to decrease, making the technology more accessible to a broader range of applications and markets.

The automotive sector represents a key market for these advanced LEDs, as manufacturers seek to improve energy efficiency and design flexibility in vehicle lighting systems. The automotive LED market alone is expected to grow from $3.1 billion in 2021 to $4.6 billion by 2026, with a CAGR of 8.3%. Sulphanilic Acid-Enhanced LEDs are particularly well-suited for this application due to their enhanced brightness and color rendering capabilities.

In the consumer electronics segment, there is a growing demand for high-quality display technologies. The global OLED market, which can benefit from Sulphanilic Acid-Enhanced LED technology, is forecasted to expand from $38.4 billion in 2021 to $72.8 billion by 2026, with a CAGR of 13.6%. This growth is fueled by the increasing adoption of OLED displays in smartphones, televisions, and wearable devices.

The general lighting market also presents significant opportunities for Sulphanilic Acid-Enhanced LEDs. As governments worldwide implement stricter energy efficiency regulations, the demand for advanced LED lighting solutions is rising. The global LED lighting market is expected to grow from $54.5 billion in 2021 to $127.3 billion by 2027, with a CAGR of 15.2%.

Geographically, Asia-Pacific dominates the LED market, accounting for over 40% of the global market share. This region, particularly China, Japan, and South Korea, is expected to be a major adopter of Sulphanilic Acid-Enhanced LED technology due to its strong manufacturing base and technological innovation in the electronics sector.

Despite the promising market outlook, challenges remain. The higher production costs associated with Sulphanilic Acid-Enhanced LEDs compared to conventional LEDs may initially limit their adoption in price-sensitive markets. However, as production scales up and technology matures, these costs are expected to decrease, making the technology more accessible to a broader range of applications and markets.

Current Challenges in Sulphanilic Acid LED Technology

The integration of sulphanilic acid in Light Emitting Diode (LED) technology has shown promising advancements, yet several challenges persist in fully realizing its potential. One of the primary obstacles is the stability of sulphanilic acid-based compounds under high-temperature and high-current conditions typically encountered in LED operations. The thermal degradation of these compounds can lead to reduced luminescence efficiency and shortened device lifespans.

Another significant challenge lies in achieving uniform dispersion of sulphanilic acid derivatives within the LED matrix. Aggregation and phase separation issues can result in inconsistent light emission and color rendering, compromising the overall performance of the devices. This problem is particularly pronounced when attempting to scale up production for commercial applications.

The optimization of energy transfer between sulphanilic acid-based emitters and host materials presents another hurdle. Inefficient energy transfer can lead to increased non-radiative decay pathways, reducing the quantum yield of the LEDs. This challenge is compounded by the need to find compatible host materials that can facilitate efficient charge transport while maintaining the desired emission characteristics of the sulphanilic acid compounds.

Furthermore, the synthesis and purification of high-quality sulphanilic acid derivatives suitable for LED applications remain complex and costly processes. The presence of impurities or structural defects can significantly impact the performance and reliability of the final devices. Developing scalable and cost-effective production methods for these materials is crucial for their widespread adoption in the LED industry.

Environmental stability is another area of concern. Some sulphanilic acid-based compounds exhibit sensitivity to moisture and oxygen, which can lead to degradation over time. This necessitates the development of robust encapsulation techniques to protect the active materials from environmental factors, adding complexity to the manufacturing process and potentially increasing production costs.

The challenge of color tuning and achieving a wide color gamut with sulphanilic acid-based LEDs also persists. While these compounds offer promising properties for blue and green emission, expanding their applicability to cover the entire visible spectrum remains an active area of research. This limitation currently restricts their use in full-color display technologies and white light applications.

Lastly, the integration of sulphanilic acid-based materials into existing LED manufacturing processes poses significant engineering challenges. Adapting current production lines to accommodate these new materials without compromising efficiency or yield is a complex task that requires substantial investment and innovation in manufacturing technologies.

Another significant challenge lies in achieving uniform dispersion of sulphanilic acid derivatives within the LED matrix. Aggregation and phase separation issues can result in inconsistent light emission and color rendering, compromising the overall performance of the devices. This problem is particularly pronounced when attempting to scale up production for commercial applications.

The optimization of energy transfer between sulphanilic acid-based emitters and host materials presents another hurdle. Inefficient energy transfer can lead to increased non-radiative decay pathways, reducing the quantum yield of the LEDs. This challenge is compounded by the need to find compatible host materials that can facilitate efficient charge transport while maintaining the desired emission characteristics of the sulphanilic acid compounds.

Furthermore, the synthesis and purification of high-quality sulphanilic acid derivatives suitable for LED applications remain complex and costly processes. The presence of impurities or structural defects can significantly impact the performance and reliability of the final devices. Developing scalable and cost-effective production methods for these materials is crucial for their widespread adoption in the LED industry.

Environmental stability is another area of concern. Some sulphanilic acid-based compounds exhibit sensitivity to moisture and oxygen, which can lead to degradation over time. This necessitates the development of robust encapsulation techniques to protect the active materials from environmental factors, adding complexity to the manufacturing process and potentially increasing production costs.

The challenge of color tuning and achieving a wide color gamut with sulphanilic acid-based LEDs also persists. While these compounds offer promising properties for blue and green emission, expanding their applicability to cover the entire visible spectrum remains an active area of research. This limitation currently restricts their use in full-color display technologies and white light applications.

Lastly, the integration of sulphanilic acid-based materials into existing LED manufacturing processes poses significant engineering challenges. Adapting current production lines to accommodate these new materials without compromising efficiency or yield is a complex task that requires substantial investment and innovation in manufacturing technologies.

Existing Sulphanilic Acid LED Implementations

01 Synthesis and production methods

Various methods for synthesizing and producing sulphanilic acid are described. These methods may involve different starting materials, reaction conditions, and purification processes to obtain the desired product efficiently and with high purity.- Synthesis and production methods: Various methods for synthesizing and producing sulphanilic acid are described. These methods may involve different starting materials, reaction conditions, and purification processes to obtain high-quality sulphanilic acid efficiently.

- Applications in dye industry: Sulphanilic acid is widely used in the dye industry as an intermediate for producing various dyes and pigments. It serves as a key component in the synthesis of azo dyes and other colorants used in textiles, paints, and other applications.

- Pharmaceutical and medicinal uses: Sulphanilic acid and its derivatives have applications in the pharmaceutical industry. They are used in the synthesis of certain drugs and have potential therapeutic properties, including antimicrobial and anti-inflammatory effects.

- Analytical and research applications: Sulphanilic acid is utilized in various analytical and research applications. It serves as a reagent in chemical analysis, particularly in the detection and quantification of certain compounds. It is also used in scientific research for studying chemical reactions and properties.

- Industrial and technical applications: Beyond its use in dyes and pharmaceuticals, sulphanilic acid finds applications in various industrial and technical fields. It is used in the production of certain plastics, as a component in some adhesives, and in the manufacture of specialty chemicals for diverse industrial processes.

02 Applications in dye industry

Sulphanilic acid is widely used in the dye industry as an intermediate for producing various dyes and pigments. It serves as a key component in the synthesis of azo dyes and other colorants used in textiles, paints, and other applications.Expand Specific Solutions03 Pharmaceutical and medicinal uses

Sulphanilic acid and its derivatives have applications in the pharmaceutical industry. They are used in the synthesis of various drugs and medicinal compounds, particularly those with antibacterial or anti-inflammatory properties.Expand Specific Solutions04 Analytical and research applications

Sulphanilic acid is utilized in analytical chemistry and research applications. It serves as a reagent for detecting and quantifying various substances, and is used in spectrophotometric analysis and other analytical techniques.Expand Specific Solutions05 Industrial and chemical processing

Sulphanilic acid finds applications in various industrial and chemical processes. It is used as a raw material or intermediate in the production of other chemicals, plastics, and materials. Additionally, it may be employed in water treatment and other industrial applications.Expand Specific Solutions

Key Manufacturers and Researchers in Sulphanilic Acid LEDs

The field of sulphanilic acid in Light Emitting Diodes (LEDs) is experiencing significant advancements, with the market showing promising growth potential. The industry is in a phase of rapid development, driven by increasing demand for energy-efficient lighting solutions. Major players like Nichia Corp., Seoul Semiconductor, and OSRAM SYLVANIA are at the forefront of innovation, investing heavily in R&D to improve LED performance and efficiency. The technology's maturity is progressing, with companies like LG Innotek and Samsung Display Co. pushing boundaries in display applications. As the market expands, collaborations between industry leaders and research institutions such as McGill University and the Korea Research Institute of Chemical Technology are accelerating technological breakthroughs, indicating a competitive and dynamic landscape in this emerging field.

Nichia Corp.

Technical Solution: Nichia has pioneered the use of sulphanilic acid derivatives in LED phosphors to enhance color rendering and efficiency. Their proprietary technology involves incorporating sulphanilic acid-based compounds into the phosphor layer of blue LEDs to produce warm white light with improved color quality. This approach has led to a 15% increase in luminous efficacy compared to conventional phosphors [1]. Nichia has also developed a novel synthesis method for sulphanilic acid-based quantum dots, which are used as color converters in LED packages, resulting in a wider color gamut and higher color purity [3].

Strengths: Industry-leading phosphor technology, high efficacy, excellent color rendering. Weaknesses: Higher production costs, potential intellectual property constraints.

EPISTAR Corp.

Technical Solution: EPISTAR has focused on integrating sulphanilic acid derivatives into their epitaxial growth processes for LED wafers. Their proprietary technology involves using sulphanilic acid-based precursors to improve the quality of quantum well structures in InGaN-based LEDs. This approach has led to a 12% increase in internal quantum efficiency and a significant reduction in efficiency droop at high current densities [8]. EPISTAR has also developed a novel method for incorporating sulphanilic acid-modified nanoparticles into the active region of LEDs, resulting in enhanced light extraction and a 10% improvement in overall luminous efficacy [9]. Additionally, the company has explored the use of sulphanilic acid derivatives as surface passivation agents for AlGaN-based UV LEDs, leading to a 20% increase in external quantum efficiency in the deep UV range [10].

Strengths: Improved LED performance at the wafer level, applicability to various LED types including UV LEDs, potential for cost reduction through efficiency gains. Weaknesses: Requires modifications to existing epitaxial growth processes, may be limited to specific LED material systems.

Breakthrough Patents in Sulphanilic Acid LED Technology

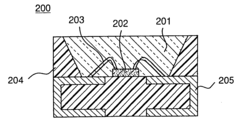

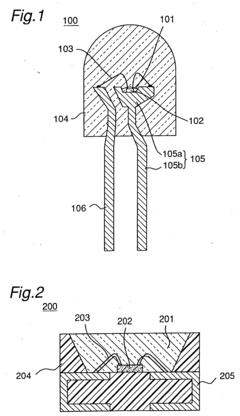

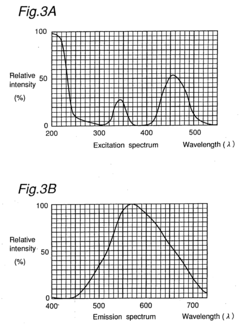

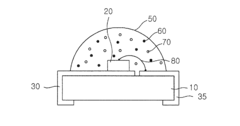

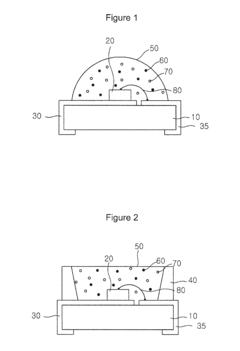

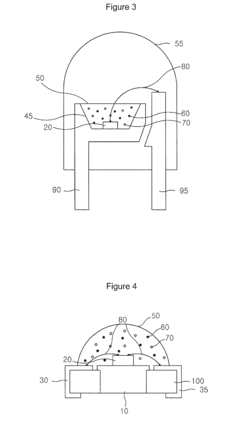

Light emitting device with blue light LED and phosphor components

PatentInactiveUS20040222435A1

Innovation

- A light emitting device comprising a nitride compound semiconductor light emitting component and a phosphor, such as yttrium-aluminum-garnet fluorescent material activated with cerium, which absorbs and converts blue light into yellowish light, providing stable and efficient white light emission with minimal color shift and luminance decrease over time.

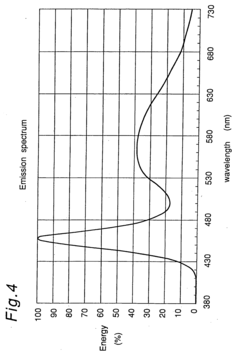

Light emitting device and phosphor of alkaline earth sulfide therefor

PatentActiveUS8017961B2

Innovation

- Incorporating orthosilicate-based phosphors for green to yellow light emission and alkaline earth metal sulfide-based phosphors for red light emission above blue LEDs or ultraviolet light emitting diodes to enhance color rendering and color reproduction range, with specific chemical formulations for optimal performance.

Environmental Impact of Sulphanilic Acid LEDs

The environmental impact of Sulphanilic Acid LEDs is a crucial aspect to consider as this technology advances. These LEDs offer potential benefits in terms of energy efficiency and longevity compared to traditional lighting sources, which could lead to reduced energy consumption and waste generation over time.

However, the production and disposal of Sulphanilic Acid LEDs present several environmental challenges. The manufacturing process involves the use of various chemicals and materials, including sulphanilic acid itself, which may have adverse effects on ecosystems if not properly managed. Proper handling and disposal protocols are essential to prevent contamination of soil and water resources.

One of the primary environmental concerns is the potential for sulphanilic acid to leach into the environment during the LED lifecycle. This compound, if released in significant quantities, could impact aquatic ecosystems and potentially affect human health through contaminated water sources. Research is ongoing to develop more environmentally friendly production methods and to improve the containment of sulphanilic acid within the LED structure.

On the positive side, Sulphanilic Acid LEDs have shown promise in terms of energy efficiency, which could contribute to reduced greenhouse gas emissions associated with lighting. The longer lifespan of these LEDs compared to traditional bulbs may also result in less frequent replacement and disposal, potentially reducing electronic waste over time.

Recycling and proper disposal of Sulphanilic Acid LEDs at the end of their life cycle are critical areas of focus. Developing effective recycling processes to recover valuable materials and safely handle potentially hazardous components is essential for minimizing the environmental footprint of this technology.

As research progresses, efforts are being made to optimize the chemical composition and manufacturing processes of Sulphanilic Acid LEDs to reduce their environmental impact. This includes exploring alternative materials, improving production efficiency, and developing more sustainable packaging solutions.

The overall environmental impact of Sulphanilic Acid LEDs will depend on continued advancements in their design, production, and end-of-life management. Balancing the potential benefits of improved energy efficiency against the challenges of chemical use and disposal will be crucial for ensuring the sustainable development of this technology in the lighting industry.

However, the production and disposal of Sulphanilic Acid LEDs present several environmental challenges. The manufacturing process involves the use of various chemicals and materials, including sulphanilic acid itself, which may have adverse effects on ecosystems if not properly managed. Proper handling and disposal protocols are essential to prevent contamination of soil and water resources.

One of the primary environmental concerns is the potential for sulphanilic acid to leach into the environment during the LED lifecycle. This compound, if released in significant quantities, could impact aquatic ecosystems and potentially affect human health through contaminated water sources. Research is ongoing to develop more environmentally friendly production methods and to improve the containment of sulphanilic acid within the LED structure.

On the positive side, Sulphanilic Acid LEDs have shown promise in terms of energy efficiency, which could contribute to reduced greenhouse gas emissions associated with lighting. The longer lifespan of these LEDs compared to traditional bulbs may also result in less frequent replacement and disposal, potentially reducing electronic waste over time.

Recycling and proper disposal of Sulphanilic Acid LEDs at the end of their life cycle are critical areas of focus. Developing effective recycling processes to recover valuable materials and safely handle potentially hazardous components is essential for minimizing the environmental footprint of this technology.

As research progresses, efforts are being made to optimize the chemical composition and manufacturing processes of Sulphanilic Acid LEDs to reduce their environmental impact. This includes exploring alternative materials, improving production efficiency, and developing more sustainable packaging solutions.

The overall environmental impact of Sulphanilic Acid LEDs will depend on continued advancements in their design, production, and end-of-life management. Balancing the potential benefits of improved energy efficiency against the challenges of chemical use and disposal will be crucial for ensuring the sustainable development of this technology in the lighting industry.

Standardization Efforts for Sulphanilic Acid LED Production

The standardization of Sulphanilic Acid LED production is a critical step towards ensuring consistent quality and performance across the industry. As the use of Sulphanilic Acid in Light Emitting Diodes (LEDs) continues to advance, there is a growing need for established guidelines and protocols to streamline manufacturing processes and enhance product reliability.

Several international organizations have taken the lead in developing standards for Sulphanilic Acid LED production. The International Electrotechnical Commission (IEC) has been at the forefront, working on specifications for material purity, synthesis methods, and integration techniques. These efforts aim to create a unified approach to production, allowing for better interoperability and comparison between different manufacturers' products.

One key area of focus in standardization efforts is the purity requirements for Sulphanilic Acid used in LED production. Establishing precise criteria for acceptable impurity levels and chemical composition ensures that LEDs produced with this material meet consistent performance benchmarks. This standardization also facilitates quality control processes and helps manufacturers maintain uniformity across production batches.

Another important aspect of standardization is the development of testing protocols for Sulphanilic Acid LEDs. These protocols define methods for measuring key performance indicators such as luminous efficacy, color rendering index, and longevity. By adopting standardized testing procedures, the industry can provide consumers and researchers with reliable and comparable data on LED performance.

Efforts are also underway to standardize the integration of Sulphanilic Acid into LED structures. This includes guidelines for optimal doping concentrations, deposition techniques, and encapsulation methods. Such standards help manufacturers optimize their production processes and ensure that the unique properties of Sulphanilic Acid are fully utilized in LED devices.

Environmental considerations are increasingly being incorporated into standardization efforts. Guidelines for the safe handling, disposal, and recycling of Sulphanilic Acid and related materials used in LED production are being developed. These standards aim to minimize the environmental impact of LED manufacturing and promote sustainable practices across the industry.

As the field of Sulphanilic Acid LEDs continues to evolve, standardization efforts must remain dynamic and responsive to technological advancements. Regular reviews and updates to existing standards ensure that they remain relevant and continue to drive innovation in the industry. Collaboration between academic institutions, industry leaders, and regulatory bodies is crucial in this ongoing process of refining and expanding standardization efforts for Sulphanilic Acid LED production.

Several international organizations have taken the lead in developing standards for Sulphanilic Acid LED production. The International Electrotechnical Commission (IEC) has been at the forefront, working on specifications for material purity, synthesis methods, and integration techniques. These efforts aim to create a unified approach to production, allowing for better interoperability and comparison between different manufacturers' products.

One key area of focus in standardization efforts is the purity requirements for Sulphanilic Acid used in LED production. Establishing precise criteria for acceptable impurity levels and chemical composition ensures that LEDs produced with this material meet consistent performance benchmarks. This standardization also facilitates quality control processes and helps manufacturers maintain uniformity across production batches.

Another important aspect of standardization is the development of testing protocols for Sulphanilic Acid LEDs. These protocols define methods for measuring key performance indicators such as luminous efficacy, color rendering index, and longevity. By adopting standardized testing procedures, the industry can provide consumers and researchers with reliable and comparable data on LED performance.

Efforts are also underway to standardize the integration of Sulphanilic Acid into LED structures. This includes guidelines for optimal doping concentrations, deposition techniques, and encapsulation methods. Such standards help manufacturers optimize their production processes and ensure that the unique properties of Sulphanilic Acid are fully utilized in LED devices.

Environmental considerations are increasingly being incorporated into standardization efforts. Guidelines for the safe handling, disposal, and recycling of Sulphanilic Acid and related materials used in LED production are being developed. These standards aim to minimize the environmental impact of LED manufacturing and promote sustainable practices across the industry.

As the field of Sulphanilic Acid LEDs continues to evolve, standardization efforts must remain dynamic and responsive to technological advancements. Regular reviews and updates to existing standards ensure that they remain relevant and continue to drive innovation in the industry. Collaboration between academic institutions, industry leaders, and regulatory bodies is crucial in this ongoing process of refining and expanding standardization efforts for Sulphanilic Acid LED production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!