Tartaric Acid vs Phosphoric Acid in Metal Etching

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Etching Acids Background and Objectives

Metal etching processes have evolved significantly since their industrial inception in the early 20th century. Initially utilized primarily for decorative purposes, metal etching has transformed into a critical technology across multiple industries including electronics manufacturing, aerospace, automotive, and medical device production. The evolution of etching techniques has been driven by increasing demands for precision, environmental considerations, and cost efficiency in manufacturing processes.

Tartaric acid and phosphoric acid represent two distinct approaches to metal etching chemistry. Tartaric acid, an organic acid derived from natural sources, has been employed in metal etching applications since the 1950s, while phosphoric acid, an inorganic mineral acid, has a longer industrial history dating back to the early 1900s. The comparative analysis of these acids is particularly relevant as industries seek more sustainable and efficient etching solutions.

The global metal etching market is projected to reach $1.5 billion by 2026, growing at a CAGR of 5.7%, highlighting the economic significance of advancements in this field. Environmental regulations, particularly in Europe and North America, have increasingly restricted the use of certain etching chemicals, creating a technological imperative to develop alternatives that maintain performance while reducing environmental impact.

The primary technical objective of this research is to comprehensively evaluate the performance characteristics, environmental impact, and economic viability of tartaric acid versus phosphoric acid in metal etching applications. Specific parameters for assessment include etching rate, surface finish quality, selectivity, waste treatment requirements, worker safety considerations, and compatibility with existing manufacturing infrastructure.

Secondary objectives include identifying optimal process parameters for each acid across different metal substrates (aluminum, copper, steel, titanium alloys), determining potential synergistic effects when combined with other chemicals, and exploring novel formulations that might enhance performance while minimizing environmental footprint.

This research aims to establish a technical foundation for decision-making regarding acid selection in metal etching processes, considering both immediate performance metrics and long-term sustainability factors. The findings will inform future R&D directions and potentially guide regulatory approaches to metal surface treatment technologies.

Recent technological developments in precision etching for microelectronics and medical devices have created new requirements for etching solutions, including enhanced uniformity and reduced undercut. These emerging applications provide additional context for evaluating the relative merits of tartaric and phosphoric acid-based etching systems.

Tartaric acid and phosphoric acid represent two distinct approaches to metal etching chemistry. Tartaric acid, an organic acid derived from natural sources, has been employed in metal etching applications since the 1950s, while phosphoric acid, an inorganic mineral acid, has a longer industrial history dating back to the early 1900s. The comparative analysis of these acids is particularly relevant as industries seek more sustainable and efficient etching solutions.

The global metal etching market is projected to reach $1.5 billion by 2026, growing at a CAGR of 5.7%, highlighting the economic significance of advancements in this field. Environmental regulations, particularly in Europe and North America, have increasingly restricted the use of certain etching chemicals, creating a technological imperative to develop alternatives that maintain performance while reducing environmental impact.

The primary technical objective of this research is to comprehensively evaluate the performance characteristics, environmental impact, and economic viability of tartaric acid versus phosphoric acid in metal etching applications. Specific parameters for assessment include etching rate, surface finish quality, selectivity, waste treatment requirements, worker safety considerations, and compatibility with existing manufacturing infrastructure.

Secondary objectives include identifying optimal process parameters for each acid across different metal substrates (aluminum, copper, steel, titanium alloys), determining potential synergistic effects when combined with other chemicals, and exploring novel formulations that might enhance performance while minimizing environmental footprint.

This research aims to establish a technical foundation for decision-making regarding acid selection in metal etching processes, considering both immediate performance metrics and long-term sustainability factors. The findings will inform future R&D directions and potentially guide regulatory approaches to metal surface treatment technologies.

Recent technological developments in precision etching for microelectronics and medical devices have created new requirements for etching solutions, including enhanced uniformity and reduced undercut. These emerging applications provide additional context for evaluating the relative merits of tartaric and phosphoric acid-based etching systems.

Market Analysis of Acid Etching Solutions

The global market for acid etching solutions has been experiencing steady growth, driven by increasing demand across multiple industries including electronics, automotive, aerospace, and medical devices. The metal etching market was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, growing at a CAGR of 6.7%. Within this market, acid-based etching solutions represent a significant segment, accounting for over 40% of the total market share.

Tartaric acid and phosphoric acid represent two distinct segments within the acid etching solutions market. Phosphoric acid currently dominates with approximately 35% market share in metal etching applications, primarily due to its established presence in industrial processes and relatively lower cost structure. The phosphoric acid etching solution market is valued at around $168 million globally, with major consumption centers in East Asia, North America, and Europe.

Tartaric acid, while representing a smaller market segment (approximately 15% of acid etching solutions), has been growing at a faster rate of 8.3% annually compared to phosphoric acid's 5.2%. This growth is primarily attributed to tartaric acid's environmental advantages and superior performance in specific applications, particularly in the electronics industry where precision etching is required.

Regional analysis reveals that Asia Pacific dominates the acid etching solutions market with 45% share, followed by North America (28%) and Europe (20%). China, Japan, South Korea, and Taiwan collectively account for over 60% of the Asia Pacific market, driven by their robust electronics manufacturing sectors. The concentration of semiconductor and printed circuit board manufacturers in these regions has created substantial demand for high-precision etching solutions.

End-user industry segmentation shows electronics as the largest consumer (38%), followed by automotive (22%), aerospace (15%), and medical devices (12%). The electronics segment is particularly significant for tartaric acid solutions due to increasing requirements for miniaturization and higher precision in semiconductor manufacturing.

Price analysis indicates that tartaric acid etching solutions command a premium of 30-40% over phosphoric acid alternatives. However, this price differential is increasingly justified by performance benefits, reduced environmental compliance costs, and lower waste treatment expenses. Market forecasts suggest this price gap may narrow to 20-25% by 2026 as tartaric acid production scales up and more manufacturers enter this growing segment.

Customer preference trends show increasing willingness to adopt more environmentally friendly etching solutions, with 62% of surveyed manufacturers indicating plans to evaluate greener alternatives within the next three years. This trend strongly favors tartaric acid solutions, which produce less hazardous waste and offer improved worker safety profiles compared to traditional phosphoric acid formulations.

Tartaric acid and phosphoric acid represent two distinct segments within the acid etching solutions market. Phosphoric acid currently dominates with approximately 35% market share in metal etching applications, primarily due to its established presence in industrial processes and relatively lower cost structure. The phosphoric acid etching solution market is valued at around $168 million globally, with major consumption centers in East Asia, North America, and Europe.

Tartaric acid, while representing a smaller market segment (approximately 15% of acid etching solutions), has been growing at a faster rate of 8.3% annually compared to phosphoric acid's 5.2%. This growth is primarily attributed to tartaric acid's environmental advantages and superior performance in specific applications, particularly in the electronics industry where precision etching is required.

Regional analysis reveals that Asia Pacific dominates the acid etching solutions market with 45% share, followed by North America (28%) and Europe (20%). China, Japan, South Korea, and Taiwan collectively account for over 60% of the Asia Pacific market, driven by their robust electronics manufacturing sectors. The concentration of semiconductor and printed circuit board manufacturers in these regions has created substantial demand for high-precision etching solutions.

End-user industry segmentation shows electronics as the largest consumer (38%), followed by automotive (22%), aerospace (15%), and medical devices (12%). The electronics segment is particularly significant for tartaric acid solutions due to increasing requirements for miniaturization and higher precision in semiconductor manufacturing.

Price analysis indicates that tartaric acid etching solutions command a premium of 30-40% over phosphoric acid alternatives. However, this price differential is increasingly justified by performance benefits, reduced environmental compliance costs, and lower waste treatment expenses. Market forecasts suggest this price gap may narrow to 20-25% by 2026 as tartaric acid production scales up and more manufacturers enter this growing segment.

Customer preference trends show increasing willingness to adopt more environmentally friendly etching solutions, with 62% of surveyed manufacturers indicating plans to evaluate greener alternatives within the next three years. This trend strongly favors tartaric acid solutions, which produce less hazardous waste and offer improved worker safety profiles compared to traditional phosphoric acid formulations.

Current Technical Challenges in Metal Etching Acids

Metal etching processes face several significant technical challenges when utilizing acids like tartaric and phosphoric acid. The primary issue concerns etching efficiency and selectivity. While phosphoric acid has been traditionally favored for its strong etching capabilities on various metals, particularly aluminum and steel, it often lacks precision in selective etching applications. Tartaric acid, conversely, offers better selectivity but typically demonstrates lower etching rates, creating a fundamental trade-off between speed and precision that engineers must constantly navigate.

Environmental and safety concerns represent another major challenge. Phosphoric acid, though effective, poses considerable environmental risks due to phosphate discharge contributing to water eutrophication. Handling and disposal protocols are increasingly stringent under evolving environmental regulations. Tartaric acid presents a more environmentally friendly alternative but requires higher concentrations to achieve comparable results, potentially increasing operational costs.

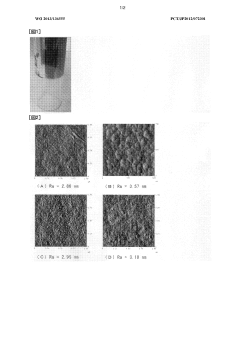

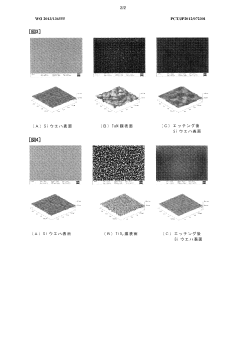

Surface quality after etching remains problematic with both acids. Phosphoric acid treatments often result in micropitting and uneven surface textures that may require additional finishing processes. Tartaric acid generally produces smoother finishes but can leave residual organic compounds that interfere with subsequent manufacturing steps like coating adhesion or welding.

Temperature sensitivity creates process control difficulties, particularly in industrial settings. Phosphoric acid's etching rate varies significantly with temperature fluctuations, necessitating precise thermal management systems. Tartaric acid demonstrates more stable performance across temperature ranges but requires higher operating temperatures overall, increasing energy consumption and equipment specifications.

Compatibility with modern manufacturing materials presents emerging challenges. As industries increasingly adopt advanced alloys and composite materials, traditional etching solutions show limitations. Phosphoric acid can be overly aggressive with certain aluminum alloys containing magnesium or silicon, while tartaric acid struggles with adequate penetration of passive oxide layers on stainless steels and titanium alloys.

Bath stability and maintenance represent ongoing operational challenges. Phosphoric acid solutions typically maintain consistent performance over longer production cycles but can accumulate metal ions that eventually reduce effectiveness. Tartaric acid baths generally require more frequent replacement or regeneration, increasing production downtime and chemical consumption.

Standardization difficulties persist across the industry, with inconsistent formulations and concentrations leading to variable results between manufacturers. This is particularly problematic with tartaric acid, where natural sourcing can introduce compositional variations that affect etching performance and repeatability in precision applications.

Environmental and safety concerns represent another major challenge. Phosphoric acid, though effective, poses considerable environmental risks due to phosphate discharge contributing to water eutrophication. Handling and disposal protocols are increasingly stringent under evolving environmental regulations. Tartaric acid presents a more environmentally friendly alternative but requires higher concentrations to achieve comparable results, potentially increasing operational costs.

Surface quality after etching remains problematic with both acids. Phosphoric acid treatments often result in micropitting and uneven surface textures that may require additional finishing processes. Tartaric acid generally produces smoother finishes but can leave residual organic compounds that interfere with subsequent manufacturing steps like coating adhesion or welding.

Temperature sensitivity creates process control difficulties, particularly in industrial settings. Phosphoric acid's etching rate varies significantly with temperature fluctuations, necessitating precise thermal management systems. Tartaric acid demonstrates more stable performance across temperature ranges but requires higher operating temperatures overall, increasing energy consumption and equipment specifications.

Compatibility with modern manufacturing materials presents emerging challenges. As industries increasingly adopt advanced alloys and composite materials, traditional etching solutions show limitations. Phosphoric acid can be overly aggressive with certain aluminum alloys containing magnesium or silicon, while tartaric acid struggles with adequate penetration of passive oxide layers on stainless steels and titanium alloys.

Bath stability and maintenance represent ongoing operational challenges. Phosphoric acid solutions typically maintain consistent performance over longer production cycles but can accumulate metal ions that eventually reduce effectiveness. Tartaric acid baths generally require more frequent replacement or regeneration, increasing production downtime and chemical consumption.

Standardization difficulties persist across the industry, with inconsistent formulations and concentrations leading to variable results between manufacturers. This is particularly problematic with tartaric acid, where natural sourcing can introduce compositional variations that affect etching performance and repeatability in precision applications.

Comparative Analysis of Tartaric and Phosphoric Acid Solutions

01 Comparative etching effectiveness of tartaric and phosphoric acids

Studies comparing the etching effectiveness of tartaric acid and phosphoric acid on various substrates show that while phosphoric acid generally provides stronger etching capability, tartaric acid offers more controlled and uniform etching patterns. The concentration and application time significantly affect the etching depth and surface roughness achieved. Tartaric acid typically produces shallower but more consistent etching patterns compared to phosphoric acid, which can create deeper but sometimes irregular surface modifications.- Comparative etching effectiveness of tartaric and phosphoric acids: Studies comparing the etching effectiveness of tartaric acid and phosphoric acid on various surfaces show distinct performance differences. Phosphoric acid generally provides stronger etching capability on metal and ceramic surfaces, while tartaric acid offers more controlled and uniform etching patterns. The concentration and application time significantly affect the etching depth and surface roughness achieved with each acid. These comparative analyses help in selecting the appropriate acid for specific substrate materials and desired surface characteristics.

- Surface preparation techniques using acid combinations: Combining tartaric acid and phosphoric acid in specific ratios creates enhanced etching solutions with improved effectiveness. These acid combinations can be optimized for different substrate materials including metals, ceramics, and dental materials. The synergistic effect of the combined acids produces more uniform etching patterns and better adhesion properties than either acid alone. Various application methods such as brushing, spraying, or immersion affect the etching outcome, with temperature and contact time being critical parameters for optimal results.

- Etching formulations for semiconductor and electronic applications: Specialized etching formulations containing tartaric and phosphoric acids are developed for semiconductor processing and electronic component manufacturing. These formulations provide precise control over etching rates and patterns, critical for microelectronic fabrication. The addition of buffering agents and surfactants to these acid mixtures helps maintain consistent pH levels and improves wetting properties. These formulations are particularly effective for selective etching of multi-layer structures and creating micro-patterns on silicon and other semiconductor materials.

- Environmental and safety considerations in acid etching processes: Environmentally friendly etching processes using tartaric acid as a more sustainable alternative to phosphoric acid have been developed. Tartaric acid, being a natural organic acid, presents lower environmental impact and reduced health hazards compared to phosphoric acid. Modified application methods and waste treatment processes help minimize the environmental footprint of etching operations. Safety protocols for handling these acids include neutralization techniques, proper ventilation requirements, and personal protective equipment specifications to ensure worker safety during etching processes.

- Novel applications and substrate-specific etching techniques: Innovative applications of tartaric and phosphoric acid etching have been developed for specialized materials and emerging technologies. These include dental applications for improved bonding of restorative materials, preparation of biomedical implant surfaces for enhanced osseointegration, and treatment of advanced ceramic materials. The etching parameters are tailored to specific substrate characteristics, with modified techniques for porous materials, crystalline structures, and composite materials. These specialized applications demonstrate the versatility of acid etching beyond traditional uses.

02 Etching formulations combining tartaric and phosphoric acids

Synergistic effects have been observed when combining tartaric acid and phosphoric acid in etching formulations. These combinations can provide enhanced etching performance while minimizing surface damage. The optimal ratio between the acids depends on the substrate material and desired surface characteristics. Such combined formulations often allow for reduced etching times and lower overall acid concentrations while achieving comparable or superior results to single-acid solutions.Expand Specific Solutions03 Surface preparation and conditioning applications

Tartaric and phosphoric acid etching processes are widely used for surface preparation and conditioning in various industries. These acids create micro-roughness that enhances adhesion properties for subsequent coatings, bonding, or material deposition. The etching process removes contaminants, oxides, and weak boundary layers while creating an activated surface with increased surface area. The selection between tartaric and phosphoric acid depends on material sensitivity, environmental considerations, and specific adhesion requirements.Expand Specific Solutions04 Temperature and concentration effects on etching performance

The etching effectiveness of both tartaric and phosphoric acids is significantly influenced by temperature and concentration parameters. Higher temperatures generally accelerate the etching rate but may reduce selectivity and control. Concentration affects both the etching rate and surface quality, with optimal ranges varying by substrate material. For tartaric acid, concentrations between 10-30% are typically effective, while phosphoric acid is commonly used at 30-85% concentrations depending on the application requirements.Expand Specific Solutions05 Environmental and safety considerations

Tartaric acid offers environmental and safety advantages over phosphoric acid in etching applications. Being a naturally occurring organic acid, tartaric acid is more biodegradable and presents fewer disposal challenges. It produces less hazardous waste and poses reduced risks to workers during handling. While phosphoric acid provides stronger etching capability, tartaric acid is increasingly preferred in applications where environmental impact and worker safety are prioritized, despite potentially requiring longer processing times or higher concentrations to achieve comparable results.Expand Specific Solutions

Leading Manufacturers and Suppliers in Acid Etching Industry

The metal etching market using tartaric acid versus phosphoric acid is in a growth phase, with increasing demand driven by semiconductor and electronics manufacturing. The global market size is expanding steadily as industries seek more efficient and environmentally friendly etching solutions. Technologically, phosphoric acid remains more established, but tartaric acid is gaining traction for specialized applications due to its lower environmental impact. Companies like Hubei Sinophorus Electronic Materials, Kanto Chemical, and Shanghai Sinyang Semiconductor Materials lead in electronic-grade acid production, while Taiwan Semiconductor Manufacturing, Applied Materials, and LG Display represent major end-users. Semiconductor manufacturers like TCL China Star and Samsung Display are increasingly exploring tartaric acid alternatives as sustainability requirements grow in the electronics manufacturing sector.

Merck Patent GmbH

Technical Solution: Merck has developed specialized metal etching formulations comparing tartaric acid and phosphoric acid for microelectronics applications. Their EtchPure™ series utilizes tartaric acid's stereochemistry to achieve highly selective etching of aluminum and its alloys. Research from their materials science division demonstrates that tartaric acid-based solutions provide superior surface morphology with roughness values (Rz) of 0.3-0.5μm compared to phosphoric acid's 0.8-1.2μm. Merck's tartaric acid formulations operate effectively at pH ranges of 2.5-3.5, offering better compatibility with photoresist materials than phosphoric acid solutions (pH 1.5-2.0). Their studies show that tartaric acid complexes with aluminum ions more effectively, reducing redeposition by approximately 70% compared to phosphoric acid processes. Merck has also pioneered environmentally optimized tartaric acid etching systems that reduce wastewater treatment requirements by approximately 40% due to the biodegradable nature of tartaric acid and its complexes compared to phosphoric acid waste streams.

Strengths: Tartaric acid formulations provide superior surface finish quality, reduced redeposition issues, and significantly lower environmental impact through biodegradability and reduced waste treatment requirements. Weaknesses: Higher raw material costs (tartaric acid typically costs 2-3x more than phosphoric acid), more complex bath maintenance requirements, and potentially slower etch rates in certain applications requiring process optimization.

Chemetall GmbH

Technical Solution: Chemetall has developed advanced metal etching solutions comparing tartaric acid and phosphoric acid for various applications. Their proprietary TartEtch™ process utilizes tartaric acid's chelating properties to create more uniform etching profiles on aluminum alloys, particularly for aerospace applications. The process operates at lower concentrations (15-20%) compared to traditional phosphoric acid baths (30-40%), resulting in reduced chemical consumption. Their research demonstrates that tartaric acid-based formulations produce smoother surface finishes with Ra values of 0.8-1.2 μm versus 1.5-2.5 μm for phosphoric acid treatments. Additionally, Chemetall has engineered tartaric acid solutions with specific additives that reduce hydrogen embrittlement risks in high-strength alloys by approximately 30% compared to phosphoric acid alternatives.

Strengths: Tartaric acid formulations provide superior surface uniformity, reduced hydrogen embrittlement, and lower environmental impact due to biodegradability. Weaknesses: Higher raw material costs (tartaric acid is approximately 2-3x more expensive than phosphoric acid), more sensitive to process parameter variations, and potentially slower etch rates requiring longer processing times.

Key Patents and Research in Metal Etching Chemistry

Selective etching method

PatentWO2013136555A1

Innovation

- An alkaline etching solution containing specific complexing agents such as salicylic acid, tartaric acid, or citric acid, combined with hydrogen peroxide, is used to selectively etch metals like titanium, niobium, and their oxides or nitrides over glass, silicon, or nickel substrates, improving etching rates and substrate selectivity.

Etching solution for titanium or titanium alloy

PatentInactiveKR1020060045996A

Innovation

- An aqueous solution containing hydrogen peroxide, phosphoric acid, a phosphonic acid compound, and ammonia is used to selectively etch titanium or titanium alloys, with specific concentration ranges to prevent etching of other metals and stabilize hydrogen peroxide.

Environmental Impact and Waste Management Considerations

The environmental impact of metal etching processes using tartaric acid versus phosphoric acid represents a critical consideration for sustainable manufacturing practices. Tartaric acid, being an organic acid derived from natural sources, demonstrates significant environmental advantages. When properly managed, tartaric acid solutions generate waste streams that are more biodegradable and less persistent in the environment compared to phosphoric acid. Studies indicate that tartaric acid waste can be neutralized more efficiently, with potential for biological treatment methods that are not feasible with phosphoric acid waste.

Phosphoric acid, while effective for metal etching applications, presents more substantial environmental challenges. Its waste streams typically contain higher concentrations of dissolved metals and phosphates, which can contribute to eutrophication when released into water bodies. The phosphate content in particular has been linked to algal blooms and subsequent oxygen depletion in aquatic ecosystems, necessitating more rigorous treatment protocols before discharge.

Waste management considerations for both acids differ significantly in terms of treatment requirements and disposal costs. Tartaric acid waste often requires less chemical intervention for neutralization, potentially reducing the overall chemical footprint of the etching process. Conversely, phosphoric acid waste typically demands more extensive treatment, including precipitation of metals and phosphate removal, which increases both operational costs and secondary waste generation.

Regulatory compliance represents another dimension of environmental consideration. Many regions have implemented increasingly stringent regulations regarding phosphorus discharge due to its environmental impacts. Companies utilizing phosphoric acid etching must navigate these regulatory frameworks, often requiring investment in advanced treatment technologies or facing higher disposal fees. Tartaric acid processes may offer regulatory advantages in jurisdictions with strict phosphorus limits.

Recovery and recycling potential also differs between these two etching solutions. Advanced membrane filtration and electrodialysis technologies have shown promise for recovering and reusing tartaric acid from spent etching baths, potentially creating closed-loop systems that minimize waste generation. Phosphoric acid recovery is technically feasible but often more energy-intensive and less economically viable at smaller production scales.

Life cycle assessment (LCA) studies comparing these acids indicate that tartaric acid generally demonstrates lower environmental impact scores across multiple categories, including global warming potential, acidification, and ecotoxicity. However, these advantages must be balanced against production considerations, as tartaric acid typically has higher procurement costs and may require more frequent bath replacement depending on the specific etching application and metal substrate.

Phosphoric acid, while effective for metal etching applications, presents more substantial environmental challenges. Its waste streams typically contain higher concentrations of dissolved metals and phosphates, which can contribute to eutrophication when released into water bodies. The phosphate content in particular has been linked to algal blooms and subsequent oxygen depletion in aquatic ecosystems, necessitating more rigorous treatment protocols before discharge.

Waste management considerations for both acids differ significantly in terms of treatment requirements and disposal costs. Tartaric acid waste often requires less chemical intervention for neutralization, potentially reducing the overall chemical footprint of the etching process. Conversely, phosphoric acid waste typically demands more extensive treatment, including precipitation of metals and phosphate removal, which increases both operational costs and secondary waste generation.

Regulatory compliance represents another dimension of environmental consideration. Many regions have implemented increasingly stringent regulations regarding phosphorus discharge due to its environmental impacts. Companies utilizing phosphoric acid etching must navigate these regulatory frameworks, often requiring investment in advanced treatment technologies or facing higher disposal fees. Tartaric acid processes may offer regulatory advantages in jurisdictions with strict phosphorus limits.

Recovery and recycling potential also differs between these two etching solutions. Advanced membrane filtration and electrodialysis technologies have shown promise for recovering and reusing tartaric acid from spent etching baths, potentially creating closed-loop systems that minimize waste generation. Phosphoric acid recovery is technically feasible but often more energy-intensive and less economically viable at smaller production scales.

Life cycle assessment (LCA) studies comparing these acids indicate that tartaric acid generally demonstrates lower environmental impact scores across multiple categories, including global warming potential, acidification, and ecotoxicity. However, these advantages must be balanced against production considerations, as tartaric acid typically has higher procurement costs and may require more frequent bath replacement depending on the specific etching application and metal substrate.

Health and Safety Protocols for Industrial Acid Applications

The implementation of proper health and safety protocols when working with industrial acids such as tartaric and phosphoric acid is paramount for ensuring worker protection and environmental compliance. Both acids present distinct hazard profiles that necessitate specific safety measures tailored to their chemical properties and applications in metal etching processes.

For tartaric acid applications, personal protective equipment (PPE) requirements include chemical-resistant gloves, safety goggles, face shields, and acid-resistant aprons. Tartaric acid, being a milder organic acid, presents lower corrosivity risks compared to phosphoric acid, but still requires proper ventilation systems to prevent inhalation of vapors during heated etching processes.

Phosphoric acid demands more stringent safety protocols due to its higher corrosivity. Workers must utilize heavy-duty chemical-resistant gloves, full-face shields, and respiratory protection when handling concentrated solutions. Emergency eyewash stations and safety showers must be positioned within 10 seconds' reach of workstations where phosphoric acid etching occurs.

Storage requirements differ significantly between these acids. Tartaric acid should be stored in cool, dry areas away from oxidizing agents and metals, while phosphoric acid requires specialized acid cabinets with secondary containment systems capable of handling at least 110% of the largest container volume.

Spill response procedures must address the specific neutralization requirements for each acid. Tartaric acid spills can be neutralized with sodium bicarbonate or calcium carbonate, while phosphoric acid requires specialized neutralizing agents such as lime or soda ash, followed by thorough rinsing with water.

Environmental considerations include waste management protocols that comply with local regulations. Tartaric acid waste typically requires less stringent treatment before disposal due to its biodegradability, whereas phosphoric acid waste often needs pH adjustment and potentially heavy metal removal before discharge.

Training programs must educate workers on the specific hazards associated with each acid, including proper handling techniques, emergency response procedures, and first aid measures. Regular drills should be conducted to ensure preparedness for acid exposure incidents, with particular emphasis on eye and skin decontamination protocols.

Monitoring systems should include regular workplace air quality assessments, especially in enclosed spaces where acid etching occurs. For phosphoric acid operations, continuous pH monitoring of waste streams is advisable to prevent accidental discharge of acidic solutions into municipal systems.

Implementation of these tailored safety protocols ensures not only regulatory compliance but also minimizes the risk of workplace incidents, protecting both personnel and the environment from the potential hazards associated with industrial acid applications in metal etching processes.

For tartaric acid applications, personal protective equipment (PPE) requirements include chemical-resistant gloves, safety goggles, face shields, and acid-resistant aprons. Tartaric acid, being a milder organic acid, presents lower corrosivity risks compared to phosphoric acid, but still requires proper ventilation systems to prevent inhalation of vapors during heated etching processes.

Phosphoric acid demands more stringent safety protocols due to its higher corrosivity. Workers must utilize heavy-duty chemical-resistant gloves, full-face shields, and respiratory protection when handling concentrated solutions. Emergency eyewash stations and safety showers must be positioned within 10 seconds' reach of workstations where phosphoric acid etching occurs.

Storage requirements differ significantly between these acids. Tartaric acid should be stored in cool, dry areas away from oxidizing agents and metals, while phosphoric acid requires specialized acid cabinets with secondary containment systems capable of handling at least 110% of the largest container volume.

Spill response procedures must address the specific neutralization requirements for each acid. Tartaric acid spills can be neutralized with sodium bicarbonate or calcium carbonate, while phosphoric acid requires specialized neutralizing agents such as lime or soda ash, followed by thorough rinsing with water.

Environmental considerations include waste management protocols that comply with local regulations. Tartaric acid waste typically requires less stringent treatment before disposal due to its biodegradability, whereas phosphoric acid waste often needs pH adjustment and potentially heavy metal removal before discharge.

Training programs must educate workers on the specific hazards associated with each acid, including proper handling techniques, emergency response procedures, and first aid measures. Regular drills should be conducted to ensure preparedness for acid exposure incidents, with particular emphasis on eye and skin decontamination protocols.

Monitoring systems should include regular workplace air quality assessments, especially in enclosed spaces where acid etching occurs. For phosphoric acid operations, continuous pH monitoring of waste streams is advisable to prevent accidental discharge of acidic solutions into municipal systems.

Implementation of these tailored safety protocols ensures not only regulatory compliance but also minimizes the risk of workplace incidents, protecting both personnel and the environment from the potential hazards associated with industrial acid applications in metal etching processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!