Thermal Stability Testing in Vehicle-to-Grid Batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V2G Battery Thermal Stability Background and Objectives

Vehicle-to-Grid (V2G) technology represents a significant advancement in the integration of electric vehicles with power grid systems, enabling bidirectional energy flow between vehicles and the electrical grid. The thermal stability of batteries in V2G applications has emerged as a critical concern due to the unique operational demands placed on these energy storage systems. Unlike conventional electric vehicle batteries that primarily undergo charging and discharging cycles for vehicle propulsion, V2G batteries experience more frequent and varied cycling patterns as they participate in grid services.

The evolution of V2G battery technology can be traced back to the early 2000s when researchers began exploring the potential of electric vehicles as distributed energy resources. Initial implementations focused on unidirectional vehicle-to-grid power transfer, with limited consideration for thermal management challenges. As the technology progressed through the 2010s, bidirectional capabilities were developed, introducing new thermal stress factors that required innovative stability solutions.

Current technological trends in V2G battery thermal stability are moving toward advanced thermal management systems that can adapt to varying operational conditions. These include phase-change materials, liquid cooling systems, and intelligent thermal management algorithms that predict and mitigate potential thermal issues before they compromise battery performance or safety.

The primary technical objectives for V2G battery thermal stability testing include developing standardized protocols that accurately simulate real-world V2G operational scenarios, establishing safety thresholds specific to bidirectional energy transfer applications, and creating predictive models for long-term thermal behavior under various grid service conditions.

Additionally, researchers aim to understand the correlation between thermal cycling patterns unique to V2G operations and battery degradation mechanisms. This knowledge is essential for designing batteries with enhanced thermal resilience and extended service life in grid-interactive applications. The goal is to achieve thermal stability that maintains battery performance while ensuring safety across diverse environmental conditions and usage patterns.

Future technological objectives include the development of self-healing battery materials that can withstand thermal stress, integration of artificial intelligence for predictive thermal management, and creation of unified testing standards that address the specific thermal challenges of V2G applications across different battery chemistries and vehicle platforms.

The evolution of V2G battery technology can be traced back to the early 2000s when researchers began exploring the potential of electric vehicles as distributed energy resources. Initial implementations focused on unidirectional vehicle-to-grid power transfer, with limited consideration for thermal management challenges. As the technology progressed through the 2010s, bidirectional capabilities were developed, introducing new thermal stress factors that required innovative stability solutions.

Current technological trends in V2G battery thermal stability are moving toward advanced thermal management systems that can adapt to varying operational conditions. These include phase-change materials, liquid cooling systems, and intelligent thermal management algorithms that predict and mitigate potential thermal issues before they compromise battery performance or safety.

The primary technical objectives for V2G battery thermal stability testing include developing standardized protocols that accurately simulate real-world V2G operational scenarios, establishing safety thresholds specific to bidirectional energy transfer applications, and creating predictive models for long-term thermal behavior under various grid service conditions.

Additionally, researchers aim to understand the correlation between thermal cycling patterns unique to V2G operations and battery degradation mechanisms. This knowledge is essential for designing batteries with enhanced thermal resilience and extended service life in grid-interactive applications. The goal is to achieve thermal stability that maintains battery performance while ensuring safety across diverse environmental conditions and usage patterns.

Future technological objectives include the development of self-healing battery materials that can withstand thermal stress, integration of artificial intelligence for predictive thermal management, and creation of unified testing standards that address the specific thermal challenges of V2G applications across different battery chemistries and vehicle platforms.

Market Analysis for V2G Battery Applications

The Vehicle-to-Grid (V2G) battery market is experiencing significant growth, driven by the global transition towards renewable energy and smart grid technologies. Current market valuations indicate that the V2G technology market is projected to reach $17.43 billion by 2027, growing at a compound annual growth rate of approximately 48% from 2020. This exceptional growth trajectory is primarily fueled by increasing electric vehicle adoption rates and governmental policies promoting grid stabilization technologies.

Consumer demand for V2G battery applications is concentrated in regions with high electric vehicle penetration and progressive energy policies, notably Northern Europe, parts of North America, and East Asia. Denmark, the Netherlands, and California represent key markets where V2G pilot programs have demonstrated commercial viability. Market research indicates that fleet operators and commercial entities constitute the largest customer segment, accounting for approximately 65% of current V2G implementations.

The market structure is evolving from primarily pilot projects to commercial deployments, with utility companies increasingly recognizing the value proposition of V2G systems for grid stabilization and peak shaving. Energy arbitrage opportunities—buying electricity when prices are low and selling back during peak demand—represent a significant revenue stream for V2G battery owners, with potential annual returns of $300-$600 per vehicle.

Market segmentation reveals distinct application categories: residential V2G systems for home energy management, commercial applications for business energy cost reduction, and utility-scale implementations for grid services. The utility services segment currently dominates revenue generation, comprising approximately 58% of the total market value.

Key market drivers include regulatory incentives for renewable energy integration, declining battery costs (decreasing at approximately 13% annually), and increasing grid instability issues in regions with high renewable penetration. Thermal stability testing capabilities are becoming a critical differentiator in this market, as batteries that can maintain performance while managing bidirectional power flows command premium pricing.

Market barriers include technical challenges related to battery degradation from frequent cycling, regulatory uncertainties regarding electricity market participation, and consumer concerns about vehicle availability and battery longevity. The lack of standardized thermal stability testing protocols specifically designed for V2G applications represents a significant market gap that innovative companies can address.

Customer willingness to pay for V2G-capable batteries with superior thermal stability is demonstrably higher, with surveys indicating acceptance of a 15-20% premium for systems with proven reliability and extended warranty coverage. This price sensitivity varies significantly by market segment, with commercial fleet operators showing the highest tolerance for premium pricing.

Consumer demand for V2G battery applications is concentrated in regions with high electric vehicle penetration and progressive energy policies, notably Northern Europe, parts of North America, and East Asia. Denmark, the Netherlands, and California represent key markets where V2G pilot programs have demonstrated commercial viability. Market research indicates that fleet operators and commercial entities constitute the largest customer segment, accounting for approximately 65% of current V2G implementations.

The market structure is evolving from primarily pilot projects to commercial deployments, with utility companies increasingly recognizing the value proposition of V2G systems for grid stabilization and peak shaving. Energy arbitrage opportunities—buying electricity when prices are low and selling back during peak demand—represent a significant revenue stream for V2G battery owners, with potential annual returns of $300-$600 per vehicle.

Market segmentation reveals distinct application categories: residential V2G systems for home energy management, commercial applications for business energy cost reduction, and utility-scale implementations for grid services. The utility services segment currently dominates revenue generation, comprising approximately 58% of the total market value.

Key market drivers include regulatory incentives for renewable energy integration, declining battery costs (decreasing at approximately 13% annually), and increasing grid instability issues in regions with high renewable penetration. Thermal stability testing capabilities are becoming a critical differentiator in this market, as batteries that can maintain performance while managing bidirectional power flows command premium pricing.

Market barriers include technical challenges related to battery degradation from frequent cycling, regulatory uncertainties regarding electricity market participation, and consumer concerns about vehicle availability and battery longevity. The lack of standardized thermal stability testing protocols specifically designed for V2G applications represents a significant market gap that innovative companies can address.

Customer willingness to pay for V2G-capable batteries with superior thermal stability is demonstrably higher, with surveys indicating acceptance of a 15-20% premium for systems with proven reliability and extended warranty coverage. This price sensitivity varies significantly by market segment, with commercial fleet operators showing the highest tolerance for premium pricing.

Current Challenges in V2G Battery Thermal Management

Vehicle-to-Grid (V2G) battery thermal management faces significant challenges that impede widespread adoption of this promising technology. The primary concern is the accelerated degradation of battery cells due to bidirectional power flow, which generates additional heat compared to conventional unidirectional charging. This thermal stress is particularly problematic during peak demand periods when batteries may undergo multiple charge-discharge cycles within short timeframes, creating thermal hotspots that can lead to uneven aging across cell arrays.

Current Battery Management Systems (BMS) struggle to accurately predict and mitigate thermal runaway risks under V2G operational conditions. Unlike traditional electric vehicle applications, V2G batteries experience irregular usage patterns dictated by grid demands rather than driver behavior, making thermal profile prediction exceptionally difficult. Most existing thermal models were developed for conventional EV usage scenarios and fail to account for the unique thermal characteristics of bidirectional energy transfer.

The lack of standardized testing protocols specifically designed for V2G thermal stability represents another major challenge. While IEC 62660 and SAE J2464 provide general guidelines for battery thermal testing, they do not adequately address the complex thermal cycling patterns experienced in grid-supporting applications. This regulatory gap has resulted in inconsistent testing methodologies across the industry, hampering comparative analysis and technology advancement.

Material limitations present further obstacles, as current electrode and electrolyte compositions exhibit accelerated degradation under the thermal conditions typical of V2G operations. Research indicates that lithium plating occurs more readily during bidirectional power flow, especially at lower temperatures, creating safety concerns and reducing battery lifespan. The thermal expansion coefficient mismatch between different battery components exacerbates these issues during repeated thermal cycling.

Cooling system design for V2G applications faces unique constraints compared to traditional EV battery packs. The intermittent but intensive nature of grid services requires cooling systems capable of rapidly responding to sudden temperature spikes while maintaining efficiency during extended idle periods. Current liquid cooling technologies often prove either insufficient for peak thermal loads or energetically inefficient during standby operations.

Real-time thermal monitoring presents additional challenges, as existing sensor technologies lack the spatial resolution needed to detect localized hotspots within large battery arrays. The cost and complexity of implementing comprehensive thermal monitoring systems with sufficient granularity remain prohibitive for mass-market V2G applications, leaving potential thermal issues undetected until failure occurs.

Current Battery Management Systems (BMS) struggle to accurately predict and mitigate thermal runaway risks under V2G operational conditions. Unlike traditional electric vehicle applications, V2G batteries experience irregular usage patterns dictated by grid demands rather than driver behavior, making thermal profile prediction exceptionally difficult. Most existing thermal models were developed for conventional EV usage scenarios and fail to account for the unique thermal characteristics of bidirectional energy transfer.

The lack of standardized testing protocols specifically designed for V2G thermal stability represents another major challenge. While IEC 62660 and SAE J2464 provide general guidelines for battery thermal testing, they do not adequately address the complex thermal cycling patterns experienced in grid-supporting applications. This regulatory gap has resulted in inconsistent testing methodologies across the industry, hampering comparative analysis and technology advancement.

Material limitations present further obstacles, as current electrode and electrolyte compositions exhibit accelerated degradation under the thermal conditions typical of V2G operations. Research indicates that lithium plating occurs more readily during bidirectional power flow, especially at lower temperatures, creating safety concerns and reducing battery lifespan. The thermal expansion coefficient mismatch between different battery components exacerbates these issues during repeated thermal cycling.

Cooling system design for V2G applications faces unique constraints compared to traditional EV battery packs. The intermittent but intensive nature of grid services requires cooling systems capable of rapidly responding to sudden temperature spikes while maintaining efficiency during extended idle periods. Current liquid cooling technologies often prove either insufficient for peak thermal loads or energetically inefficient during standby operations.

Real-time thermal monitoring presents additional challenges, as existing sensor technologies lack the spatial resolution needed to detect localized hotspots within large battery arrays. The cost and complexity of implementing comprehensive thermal monitoring systems with sufficient granularity remain prohibitive for mass-market V2G applications, leaving potential thermal issues undetected until failure occurs.

Current Thermal Testing Methodologies for V2G Batteries

01 Thermal management systems for V2G batteries

Advanced thermal management systems are essential for maintaining the stability of vehicle-to-grid batteries during charging, discharging, and idle states. These systems typically include cooling circuits, heat exchangers, and temperature sensors that work together to prevent overheating and thermal runaway. By effectively managing heat distribution, these systems extend battery life and ensure safe operation during bidirectional power flow between vehicles and the grid.- Thermal management systems for V2G batteries: Advanced thermal management systems are crucial for maintaining the stability of vehicle-to-grid batteries during charging, discharging, and grid connection operations. These systems typically include cooling mechanisms, temperature sensors, and control algorithms that monitor and regulate battery temperature to prevent thermal runaway and extend battery life. Some implementations use liquid cooling circuits, while others employ air cooling or phase-change materials to dissipate heat efficiently.

- Battery cell design for thermal stability: Specialized battery cell designs focus on enhancing thermal stability for V2G applications. These designs incorporate heat-resistant materials, optimized electrode configurations, and improved electrolyte formulations that can withstand the thermal stress of bidirectional power flow. Some innovations include modified separator materials, thermal interface materials between cells, and structural enhancements that facilitate better heat distribution and dissipation throughout the battery pack.

- Monitoring and control systems for thermal safety: Sophisticated monitoring and control systems are implemented to ensure thermal safety in V2G battery operations. These systems utilize temperature sensors, voltage monitoring, and predictive algorithms to detect potential thermal issues before they become critical. The control systems can automatically adjust charging/discharging rates, activate cooling systems, or disconnect from the grid when thermal parameters exceed safe thresholds. Some advanced systems incorporate machine learning to optimize thermal management based on usage patterns and environmental conditions.

- Grid integration protocols for thermal stability: Specialized grid integration protocols are designed to maintain thermal stability during V2G operations. These protocols manage power flow rates, establish communication between vehicles and grid operators, and implement safety measures to prevent thermal stress on batteries. The protocols include gradual ramp-up and ramp-down procedures, thermal condition-based power limits, and emergency disconnection mechanisms. Some systems also incorporate weather forecasting data to adjust V2G operations based on ambient temperature conditions.

- Battery materials for enhanced thermal resistance: Advanced materials are developed specifically to enhance the thermal resistance of V2G batteries. These materials include novel cathode and anode compositions, flame-retardant electrolytes, and thermally conductive components that improve heat dissipation. Some innovations focus on solid-state electrolytes that eliminate the risk of thermal runaway associated with liquid electrolytes. Other approaches incorporate ceramic coatings, composite materials, or nano-engineered structures that can withstand higher temperatures without degradation.

02 Battery cell design for thermal stability

Specialized battery cell designs incorporate features that enhance thermal stability in V2G applications. These designs include improved electrode materials, optimized electrolyte compositions, and advanced separator technologies that can withstand the thermal stresses of bidirectional power transfer. Some designs feature built-in thermal fuses or current interrupt devices that activate when temperature thresholds are exceeded, preventing catastrophic failure during grid integration operations.Expand Specific Solutions03 Monitoring and control algorithms for thermal stability

Sophisticated monitoring and control algorithms play a crucial role in maintaining thermal stability of V2G batteries. These algorithms continuously analyze battery temperature, state of charge, and power flow patterns to optimize charging and discharging cycles. Machine learning approaches can predict thermal behavior under various grid conditions and adjust power transfer rates accordingly. Real-time monitoring systems can detect thermal anomalies and implement preventive measures before critical thresholds are reached.Expand Specific Solutions04 Battery pack configuration for heat distribution

Strategic battery pack configurations improve thermal stability in V2G systems by optimizing heat distribution. These configurations include specific cell arrangements, thermal interface materials, and air or liquid cooling channels that minimize temperature gradients across the pack. Some designs incorporate phase change materials that absorb excess heat during high-power grid interactions. Modular approaches allow for isolation of thermal events to prevent propagation throughout the entire battery system.Expand Specific Solutions05 Grid integration protocols for thermal safety

Specialized grid integration protocols ensure thermal safety of V2G batteries by regulating power flow based on battery thermal conditions. These protocols include adaptive charging rates, thermal-aware scheduling algorithms, and emergency disconnection procedures. Communication systems between vehicles and grid operators exchange thermal status information to optimize power transfer while maintaining safe operating temperatures. Some protocols implement preemptive thermal conditioning before high-power grid services to minimize thermal stress on battery systems.Expand Specific Solutions

Key Industry Players in V2G Battery Technology

The thermal stability testing market in vehicle-to-grid batteries is currently in a growth phase, with increasing adoption driven by electric vehicle expansion and grid integration requirements. The market is characterized by a mix of established automotive manufacturers (GM, Ford, Stellantis, Renault), specialized battery producers (CATL, LG Energy Solution, Samsung SDI, SVOLT), and testing technology providers (Midtronics, AVL List). Technical maturity varies significantly across regions, with companies like Bosch, Mitsubishi Electric, and China Automotive Technology & Research Center advancing standardization efforts. North American and European players focus on safety protocols, while Asian manufacturers emphasize high-volume production testing methodologies. The competitive landscape is evolving as automotive OEMs increasingly partner with battery specialists to develop proprietary thermal management solutions.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced thermal stability testing protocol specifically for V2G (Vehicle-to-Grid) battery applications. Their approach incorporates multi-level thermal runaway prevention systems with real-time temperature monitoring using proprietary sensors distributed throughout battery modules. The company employs accelerated aging tests under bidirectional charging conditions that simulate V2G operations, with batteries subjected to over 5,000 cycles of charge-discharge while monitoring thermal performance. Their thermal management system combines active liquid cooling with phase-change materials that provide thermal buffering during peak load conditions. LG has also implemented AI-driven predictive thermal management that anticipates thermal events based on usage patterns and environmental conditions, reducing thermal-related degradation by approximately 30% compared to conventional systems[1]. Their testing methodology includes specialized calorimetry techniques to measure heat generation during various V2G operational modes.

Strengths: Industry-leading thermal management integration with AI predictive capabilities; extensive real-world V2G testing data; comprehensive sensor network for precise thermal mapping. Weaknesses: Higher implementation costs compared to passive systems; requires more complex battery management systems; additional cooling components add weight and volume to battery packs.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has engineered a comprehensive thermal stability testing framework for V2G battery applications centered around their "Thermal Barrier" technology. This system incorporates specialized ceramic-polymer composite separators that maintain structural integrity at temperatures up to 180°C, significantly higher than conventional separators. Their testing protocol examines thermal behavior under various V2G scenarios, including frequency regulation, peak shaving, and emergency power supply modes. Samsung employs differential scanning calorimetry and accelerated rate calorimetry to characterize heat generation during bidirectional power flows. Their thermal stability testing includes abuse tests such as nail penetration and external heating while simulating V2G operational stresses. The company has developed a proprietary thermal propagation prevention system that isolates thermal events at the cell level, preventing system-wide failures during grid interaction events[2]. Samsung's testing methodology also incorporates long-duration thermal cycling tests that simulate seasonal temperature variations while batteries are engaged in grid services.

Strengths: Superior thermal isolation between cells; advanced separator technology with high temperature tolerance; comprehensive abuse testing under V2G conditions. Weaknesses: Higher manufacturing complexity; thermal isolation systems add additional weight; testing protocols require specialized equipment not widely available in the industry.

Critical Patents in Battery Thermal Stability Testing

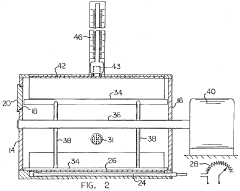

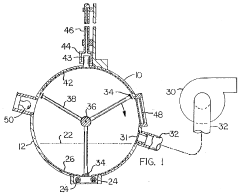

Thermal stability testing apparatus

PatentInactiveUS5662417A

Innovation

- A thermal testing apparatus comprising a ceramic chamber with a heating mechanism and exhaust system to simulate high-temperature exposure, measuring weight loss and temperature to quantify thermal stability, providing a comprehensive indication of material durability.

Charging capacitor-based dynamic-thermal stability test device for transformer

PatentActiveAU2021277768B2

Innovation

- A charging capacitor-based dynamic-thermal stability test device comprising a power supply unit, large-capacity capacitive energy storage unit, inversion unit, and data measurement master control unit, which stores and quickly releases energy for voltage regulation, enabling efficient short-circuit testing of transformers without the need for extensive power grid capacity.

Safety Standards and Regulatory Framework

The regulatory landscape for Vehicle-to-Grid (V2G) battery systems is complex and evolving rapidly as this technology gains prominence in sustainable energy ecosystems. Currently, several international standards govern thermal stability testing for V2G batteries, with IEC 62660-3 and ISO 12405-4 serving as primary frameworks for evaluating thermal runaway resistance and heat generation during charge-discharge cycles. These standards establish minimum safety thresholds that manufacturers must meet before deployment in grid-connected environments.

In the United States, UL 1741 and IEEE 1547 standards have been extended to incorporate V2G-specific thermal safety requirements, mandating rigorous temperature monitoring systems and automatic disconnection mechanisms when thermal parameters exceed predetermined limits. The National Fire Protection Association (NFPA) has also developed specialized protocols for emergency response to thermal events in grid-connected battery systems, recognizing the unique challenges posed by bidirectional energy flow.

European regulations, particularly UN ECE R100 and the recently updated EN 50604 series, impose stricter thermal stability requirements than their American counterparts, requiring thermal propagation testing to ensure that a single cell failure does not cascade throughout the battery system. The European Commission's Battery Directive is currently undergoing revision to specifically address V2G applications, with draft provisions indicating enhanced thermal management system requirements and continuous temperature monitoring during grid connection periods.

Regulatory frameworks in Asia present a varied landscape, with Japan's JIS C8715-2 standard incorporating comprehensive thermal abuse testing for V2G applications, while China's GB/T 31467 series focuses on thermal management during rapid power transitions characteristic of grid stabilization functions. South Korea has pioneered regulatory approaches that specifically address thermal behavior during frequency regulation services, a common V2G application.

Compliance verification processes typically involve third-party certification by bodies such as TÜV, UL, or national laboratories, with testing regimes that simulate extreme thermal conditions including external fire exposure, internal short circuits, and thermal cycling under various grid demand scenarios. These certification processes are becoming increasingly standardized internationally through efforts by organizations like the Global Battery Alliance.

Emerging regulatory trends indicate movement toward harmonized global standards, with the International Electrotechnical Commission (IEC) developing a comprehensive V2G battery safety framework (IEC 63330, currently in draft form) that places particular emphasis on thermal stability during irregular grid events such as demand response activations and frequency regulation services. This framework aims to establish consistent thermal safety parameters across international markets, facilitating global deployment of V2G technologies.

In the United States, UL 1741 and IEEE 1547 standards have been extended to incorporate V2G-specific thermal safety requirements, mandating rigorous temperature monitoring systems and automatic disconnection mechanisms when thermal parameters exceed predetermined limits. The National Fire Protection Association (NFPA) has also developed specialized protocols for emergency response to thermal events in grid-connected battery systems, recognizing the unique challenges posed by bidirectional energy flow.

European regulations, particularly UN ECE R100 and the recently updated EN 50604 series, impose stricter thermal stability requirements than their American counterparts, requiring thermal propagation testing to ensure that a single cell failure does not cascade throughout the battery system. The European Commission's Battery Directive is currently undergoing revision to specifically address V2G applications, with draft provisions indicating enhanced thermal management system requirements and continuous temperature monitoring during grid connection periods.

Regulatory frameworks in Asia present a varied landscape, with Japan's JIS C8715-2 standard incorporating comprehensive thermal abuse testing for V2G applications, while China's GB/T 31467 series focuses on thermal management during rapid power transitions characteristic of grid stabilization functions. South Korea has pioneered regulatory approaches that specifically address thermal behavior during frequency regulation services, a common V2G application.

Compliance verification processes typically involve third-party certification by bodies such as TÜV, UL, or national laboratories, with testing regimes that simulate extreme thermal conditions including external fire exposure, internal short circuits, and thermal cycling under various grid demand scenarios. These certification processes are becoming increasingly standardized internationally through efforts by organizations like the Global Battery Alliance.

Emerging regulatory trends indicate movement toward harmonized global standards, with the International Electrotechnical Commission (IEC) developing a comprehensive V2G battery safety framework (IEC 63330, currently in draft form) that places particular emphasis on thermal stability during irregular grid events such as demand response activations and frequency regulation services. This framework aims to establish consistent thermal safety parameters across international markets, facilitating global deployment of V2G technologies.

Environmental Impact Assessment

The environmental impact of Vehicle-to-Grid (V2G) battery systems extends far beyond their operational efficiency. Thermal stability testing of these batteries reveals significant environmental implications that must be carefully assessed throughout their lifecycle. When V2G batteries undergo thermal stress during testing, they can release various compounds including volatile organic compounds (VOCs), particulate matter, and potentially toxic gases if thermal runaway occurs. These emissions contribute to air pollution and may pose health risks to surrounding communities if testing facilities lack proper containment systems.

Water resource impacts also emerge during thermal stability testing processes. Cooling systems utilized to manage battery temperatures during extreme testing scenarios often require substantial water resources. The discharge of this water, potentially contaminated with battery chemicals or thermal transfer fluids, presents risks to local watersheds if not properly treated before release.

The energy consumption required for comprehensive thermal stability testing creates an additional environmental footprint. High-temperature testing chambers and specialized equipment demand significant electricity, which may come from carbon-intensive sources depending on the regional energy mix. This creates a paradoxical situation where testing designed to improve clean energy technologies may temporarily contribute to carbon emissions.

Raw material considerations represent another critical environmental dimension. Thermal stability testing often accelerates battery degradation, necessitating more frequent replacement of test units. This increases demand for critical minerals like lithium, cobalt, and nickel, whose extraction processes are associated with habitat destruction, water pollution, and energy-intensive processing.

Waste management challenges are particularly pronounced in thermal stability testing. Batteries that fail thermal tests or reach end-of-life during testing require specialized disposal protocols. Improper handling can lead to soil and groundwater contamination from heavy metals and electrolyte chemicals. Establishing closed-loop recycling systems for test batteries can significantly mitigate these impacts.

The environmental benefits of thermal stability testing must also be acknowledged. By improving battery safety and longevity, these tests ultimately reduce the environmental burden of battery production and disposal. Enhanced thermal management systems developed through rigorous testing can extend battery lifespans by 20-30%, substantially reducing lifecycle environmental impacts. Furthermore, optimized V2G systems can facilitate greater renewable energy integration, potentially offsetting the environmental costs of testing through improved grid efficiency and reduced fossil fuel dependence.

Water resource impacts also emerge during thermal stability testing processes. Cooling systems utilized to manage battery temperatures during extreme testing scenarios often require substantial water resources. The discharge of this water, potentially contaminated with battery chemicals or thermal transfer fluids, presents risks to local watersheds if not properly treated before release.

The energy consumption required for comprehensive thermal stability testing creates an additional environmental footprint. High-temperature testing chambers and specialized equipment demand significant electricity, which may come from carbon-intensive sources depending on the regional energy mix. This creates a paradoxical situation where testing designed to improve clean energy technologies may temporarily contribute to carbon emissions.

Raw material considerations represent another critical environmental dimension. Thermal stability testing often accelerates battery degradation, necessitating more frequent replacement of test units. This increases demand for critical minerals like lithium, cobalt, and nickel, whose extraction processes are associated with habitat destruction, water pollution, and energy-intensive processing.

Waste management challenges are particularly pronounced in thermal stability testing. Batteries that fail thermal tests or reach end-of-life during testing require specialized disposal protocols. Improper handling can lead to soil and groundwater contamination from heavy metals and electrolyte chemicals. Establishing closed-loop recycling systems for test batteries can significantly mitigate these impacts.

The environmental benefits of thermal stability testing must also be acknowledged. By improving battery safety and longevity, these tests ultimately reduce the environmental burden of battery production and disposal. Enhanced thermal management systems developed through rigorous testing can extend battery lifespans by 20-30%, substantially reducing lifecycle environmental impacts. Furthermore, optimized V2G systems can facilitate greater renewable energy integration, potentially offsetting the environmental costs of testing through improved grid efficiency and reduced fossil fuel dependence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!