Trends in Miniaturization of Self-Powered Sensor Devices

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Miniaturization Evolution and Objectives

The miniaturization of self-powered sensor devices represents one of the most significant technological evolutions in recent decades. This trend began in the late 1990s with relatively bulky self-powered systems that were primarily limited to industrial applications. The trajectory has since accelerated dramatically, with device sizes decreasing by approximately 80% every decade while simultaneously increasing in functionality and efficiency.

The evolution of miniaturization in this field has been driven by several converging technological advancements. Semiconductor manufacturing processes have progressed from 90nm to sub-5nm nodes, enabling dramatically smaller integrated circuits with lower power requirements. Concurrently, energy harvesting technologies have evolved from rudimentary mechanical systems to sophisticated multi-source harvesters capable of capturing energy from ambient light, vibration, thermal gradients, and RF signals at previously unattainable efficiencies.

Material science breakthroughs have been equally crucial, particularly the development of high-energy-density storage components and flexible substrates. The introduction of graphene, carbon nanotubes, and other two-dimensional materials has revolutionized both energy harvesting and storage capabilities at the microscale. These materials have enabled the creation of supercapacitors and thin-film batteries with energy densities orders of magnitude greater than their predecessors while maintaining minimal footprints.

The primary objectives driving miniaturization efforts include achieving true autonomous operation in increasingly constrained environments. Current research aims to develop self-powered sensors measuring less than 1mm³ that can operate indefinitely without external power sources. This represents a critical threshold for many biomedical applications, environmental monitoring systems, and IoT deployments where device size directly impacts deployment feasibility.

Another key objective is the integration of multiple sensing modalities within single miniaturized platforms. Modern research focuses on developing systems that can simultaneously monitor temperature, pressure, chemical composition, and acceleration while maintaining minimal form factors. This multi-parameter sensing capability is essential for applications in healthcare monitoring, structural health assessment, and environmental surveillance.

Energy autonomy remains perhaps the most challenging objective in the miniaturization roadmap. The goal is to achieve perpetual operation through optimized energy harvesting and ultra-efficient power management. Current benchmarks target power consumption below 10 nanowatts for sensing and data transmission functions, representing a 100-fold improvement over systems from just a decade ago.

Looking forward, the technological trajectory points toward sub-millimeter, fully autonomous sensor systems capable of deployment in previously inaccessible environments, from deep tissue monitoring to distributed environmental sensing networks comprising thousands of nearly invisible nodes.

The evolution of miniaturization in this field has been driven by several converging technological advancements. Semiconductor manufacturing processes have progressed from 90nm to sub-5nm nodes, enabling dramatically smaller integrated circuits with lower power requirements. Concurrently, energy harvesting technologies have evolved from rudimentary mechanical systems to sophisticated multi-source harvesters capable of capturing energy from ambient light, vibration, thermal gradients, and RF signals at previously unattainable efficiencies.

Material science breakthroughs have been equally crucial, particularly the development of high-energy-density storage components and flexible substrates. The introduction of graphene, carbon nanotubes, and other two-dimensional materials has revolutionized both energy harvesting and storage capabilities at the microscale. These materials have enabled the creation of supercapacitors and thin-film batteries with energy densities orders of magnitude greater than their predecessors while maintaining minimal footprints.

The primary objectives driving miniaturization efforts include achieving true autonomous operation in increasingly constrained environments. Current research aims to develop self-powered sensors measuring less than 1mm³ that can operate indefinitely without external power sources. This represents a critical threshold for many biomedical applications, environmental monitoring systems, and IoT deployments where device size directly impacts deployment feasibility.

Another key objective is the integration of multiple sensing modalities within single miniaturized platforms. Modern research focuses on developing systems that can simultaneously monitor temperature, pressure, chemical composition, and acceleration while maintaining minimal form factors. This multi-parameter sensing capability is essential for applications in healthcare monitoring, structural health assessment, and environmental surveillance.

Energy autonomy remains perhaps the most challenging objective in the miniaturization roadmap. The goal is to achieve perpetual operation through optimized energy harvesting and ultra-efficient power management. Current benchmarks target power consumption below 10 nanowatts for sensing and data transmission functions, representing a 100-fold improvement over systems from just a decade ago.

Looking forward, the technological trajectory points toward sub-millimeter, fully autonomous sensor systems capable of deployment in previously inaccessible environments, from deep tissue monitoring to distributed environmental sensing networks comprising thousands of nearly invisible nodes.

Market Demand for Self-Powered Microsensors

The global market for self-powered microsensors is experiencing unprecedented growth, driven by the convergence of IoT expansion, industrial automation, and healthcare innovation. Current market valuations indicate that the self-powered sensor market reached approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate of 18-20% through 2030, potentially reaching $12-15 billion by the end of the decade.

Healthcare applications represent the fastest-growing segment, with demand for implantable and wearable self-powered sensors increasing by nearly 25% annually. This surge is primarily fueled by the aging global population and the rising prevalence of chronic conditions requiring continuous monitoring. Medical device manufacturers are specifically seeking miniaturized sensors that can operate autonomously for extended periods without battery replacement.

Industrial IoT applications constitute another significant market driver, with manufacturing, logistics, and infrastructure sectors collectively accounting for approximately 40% of current demand. These industries require robust, maintenance-free sensing solutions that can be deployed in hard-to-reach or hazardous environments where regular battery replacement is impractical or costly.

Consumer electronics manufacturers are increasingly incorporating self-powered microsensors into next-generation devices, with particular emphasis on energy harvesting capabilities that align with sustainability initiatives. Market research indicates that consumers are willing to pay a 15-20% premium for devices with extended operational lifespans that require minimal maintenance.

Regional analysis reveals that North America currently leads market consumption at 38%, followed by Europe (29%) and Asia-Pacific (26%), though the latter is demonstrating the highest growth rate at 22% annually. This geographic distribution reflects varying levels of industrial automation and healthcare infrastructure development.

Key market requirements consistently emphasize four critical parameters: further size reduction (with target dimensions below 1mm³), increased energy harvesting efficiency (particularly in low-light or low-vibration environments), improved power management capabilities, and enhanced wireless communication range despite reduced form factors. Industry surveys indicate that 78% of potential adopters consider size reduction the most critical factor for widespread implementation.

The economic value proposition of self-powered microsensors is compelling, with potential cost savings in maintenance and battery replacement estimated at 30-40% over device lifetime compared to traditional powered sensors. This economic advantage, combined with the technical benefits of continuous operation and deployment flexibility, is accelerating market adoption across multiple sectors.

Healthcare applications represent the fastest-growing segment, with demand for implantable and wearable self-powered sensors increasing by nearly 25% annually. This surge is primarily fueled by the aging global population and the rising prevalence of chronic conditions requiring continuous monitoring. Medical device manufacturers are specifically seeking miniaturized sensors that can operate autonomously for extended periods without battery replacement.

Industrial IoT applications constitute another significant market driver, with manufacturing, logistics, and infrastructure sectors collectively accounting for approximately 40% of current demand. These industries require robust, maintenance-free sensing solutions that can be deployed in hard-to-reach or hazardous environments where regular battery replacement is impractical or costly.

Consumer electronics manufacturers are increasingly incorporating self-powered microsensors into next-generation devices, with particular emphasis on energy harvesting capabilities that align with sustainability initiatives. Market research indicates that consumers are willing to pay a 15-20% premium for devices with extended operational lifespans that require minimal maintenance.

Regional analysis reveals that North America currently leads market consumption at 38%, followed by Europe (29%) and Asia-Pacific (26%), though the latter is demonstrating the highest growth rate at 22% annually. This geographic distribution reflects varying levels of industrial automation and healthcare infrastructure development.

Key market requirements consistently emphasize four critical parameters: further size reduction (with target dimensions below 1mm³), increased energy harvesting efficiency (particularly in low-light or low-vibration environments), improved power management capabilities, and enhanced wireless communication range despite reduced form factors. Industry surveys indicate that 78% of potential adopters consider size reduction the most critical factor for widespread implementation.

The economic value proposition of self-powered microsensors is compelling, with potential cost savings in maintenance and battery replacement estimated at 30-40% over device lifetime compared to traditional powered sensors. This economic advantage, combined with the technical benefits of continuous operation and deployment flexibility, is accelerating market adoption across multiple sectors.

Technical Barriers and Global Development Status

Despite significant advancements in self-powered sensor miniaturization, several technical barriers continue to impede progress in this field. Energy harvesting at microscale remains a fundamental challenge, as the power generation capacity diminishes dramatically with size reduction. Current micro-energy harvesters struggle to maintain efficiency when scaled down below certain thresholds, particularly for piezoelectric, triboelectric, and thermoelectric generators where material properties and physical constraints become limiting factors.

Material limitations present another significant obstacle. The development of multifunctional materials that can simultaneously harvest energy, sense parameters, and maintain structural integrity at microscale dimensions requires breakthrough innovations in material science. Current materials often exhibit performance degradation when fabricated at extremely small dimensions, affecting both energy generation and sensing capabilities.

Integration density poses substantial challenges for miniaturized self-powered sensors. As devices shrink, the proximity of different functional components creates interference issues, thermal management problems, and reliability concerns. The integration of energy harvesting, energy storage, sensing, and communication modules within increasingly confined spaces demands novel architectural approaches and fabrication techniques.

Power management circuitry miniaturization represents another critical barrier. Conventional power conditioning circuits consume relatively high power and occupy significant space, creating a paradoxical situation where the power management system itself becomes a limiting factor in further miniaturization. Ultra-low-power circuit designs that can operate efficiently at sub-microwatt levels are essential yet technically challenging to implement.

Globally, research and development in miniaturized self-powered sensors shows distinct geographical patterns. North America, particularly the United States, leads in fundamental research and innovative startups focusing on novel energy harvesting mechanisms and system integration. Academic institutions like MIT, Stanford, and Georgia Tech have established specialized research centers dedicated to self-powered microsystems.

East Asia, especially Japan, South Korea, and China, demonstrates strength in manufacturing innovation and commercial applications. Companies like Murata (Japan), Samsung (South Korea), and research institutions such as the Chinese Academy of Sciences have made significant contributions to miniaturization techniques and mass production capabilities for self-powered sensors.

Europe excels in precision engineering and specialized applications, with countries like Germany, Switzerland, and the Netherlands focusing on high-reliability self-powered sensors for industrial and medical applications. Research clusters around institutions like ETH Zurich, Fraunhofer Society, and Delft University of Technology are advancing novel fabrication techniques for microscale energy harvesters.

Emerging economies, particularly India and Brazil, are increasingly investing in this technology domain, focusing on cost-effective solutions and applications tailored to local needs, though they currently lag behind in fundamental research capabilities and advanced manufacturing infrastructure.

Material limitations present another significant obstacle. The development of multifunctional materials that can simultaneously harvest energy, sense parameters, and maintain structural integrity at microscale dimensions requires breakthrough innovations in material science. Current materials often exhibit performance degradation when fabricated at extremely small dimensions, affecting both energy generation and sensing capabilities.

Integration density poses substantial challenges for miniaturized self-powered sensors. As devices shrink, the proximity of different functional components creates interference issues, thermal management problems, and reliability concerns. The integration of energy harvesting, energy storage, sensing, and communication modules within increasingly confined spaces demands novel architectural approaches and fabrication techniques.

Power management circuitry miniaturization represents another critical barrier. Conventional power conditioning circuits consume relatively high power and occupy significant space, creating a paradoxical situation where the power management system itself becomes a limiting factor in further miniaturization. Ultra-low-power circuit designs that can operate efficiently at sub-microwatt levels are essential yet technically challenging to implement.

Globally, research and development in miniaturized self-powered sensors shows distinct geographical patterns. North America, particularly the United States, leads in fundamental research and innovative startups focusing on novel energy harvesting mechanisms and system integration. Academic institutions like MIT, Stanford, and Georgia Tech have established specialized research centers dedicated to self-powered microsystems.

East Asia, especially Japan, South Korea, and China, demonstrates strength in manufacturing innovation and commercial applications. Companies like Murata (Japan), Samsung (South Korea), and research institutions such as the Chinese Academy of Sciences have made significant contributions to miniaturization techniques and mass production capabilities for self-powered sensors.

Europe excels in precision engineering and specialized applications, with countries like Germany, Switzerland, and the Netherlands focusing on high-reliability self-powered sensors for industrial and medical applications. Research clusters around institutions like ETH Zurich, Fraunhofer Society, and Delft University of Technology are advancing novel fabrication techniques for microscale energy harvesters.

Emerging economies, particularly India and Brazil, are increasingly investing in this technology domain, focusing on cost-effective solutions and applications tailored to local needs, though they currently lag behind in fundamental research capabilities and advanced manufacturing infrastructure.

Current Miniaturization Approaches and Solutions

01 Energy harvesting technologies for self-powered sensors

Various energy harvesting technologies can be integrated into miniaturized sensor devices to enable self-powering capabilities. These include piezoelectric, thermoelectric, and photovoltaic mechanisms that convert ambient energy (mechanical vibrations, temperature gradients, light) into electrical power. By eliminating the need for external power sources or bulky batteries, these technologies contribute significantly to device miniaturization while maintaining operational functionality.- Energy harvesting technologies for self-powered sensors: Various energy harvesting technologies can be integrated into sensor devices to make them self-powered, eliminating the need for external power sources or battery replacement. These technologies include piezoelectric, thermoelectric, and photovoltaic systems that convert ambient energy (mechanical vibrations, temperature gradients, light) into electrical energy to power miniaturized sensors. This approach enables long-term operation in remote or inaccessible locations while reducing the overall device size.

- Miniaturization techniques for sensor components: Advanced miniaturization techniques focus on reducing the size of sensor components while maintaining or improving functionality. These include MEMS (Micro-Electro-Mechanical Systems) fabrication, nanomaterial integration, and system-on-chip designs that combine sensing elements, signal processing, and communication capabilities on a single chip. Such techniques enable the development of ultra-compact sensor devices with reduced power consumption and enhanced performance for various applications.

- Power management systems for efficient energy utilization: Sophisticated power management systems are crucial for miniaturized self-powered sensors to optimize energy utilization. These systems include low-power microcontrollers, adaptive duty cycling, and intelligent sleep modes that activate sensors only when needed. Advanced power conditioning circuits ensure efficient energy storage and distribution, while energy-aware algorithms dynamically adjust sensor operation based on available power, extending device lifetime and enabling smaller form factors.

- Wireless communication optimization for miniaturized sensors: Optimizing wireless communication is essential for miniaturized self-powered sensors to reduce energy consumption while maintaining connectivity. Low-power communication protocols like BLE, ZigBee, and LoRa are implemented alongside efficient data compression algorithms to minimize transmission energy requirements. Adaptive transmission power control and event-driven communication strategies further reduce energy needs, allowing for smaller energy harvesting components and overall device miniaturization.

- Integrated packaging solutions for compact sensor systems: Advanced packaging technologies enable the integration of multiple components into compact, self-powered sensor systems. 3D integration techniques, flexible substrates, and system-in-package approaches allow for stacking of sensing elements, energy harvesters, and processing units in minimal space. Multifunctional materials that serve both structural and functional purposes (such as energy storage and sensing) further contribute to size reduction while maintaining environmental protection and reliability.

02 MEMS-based miniaturization techniques

Micro-Electro-Mechanical Systems (MEMS) technology enables the fabrication of extremely small sensor devices with integrated sensing, processing, and communication capabilities. These techniques allow for the creation of miniaturized self-powered sensors through microfabrication processes that combine mechanical elements, sensors, actuators, and electronics on a common silicon substrate. The resulting devices feature reduced size, weight, and power consumption while maintaining high performance.Expand Specific Solutions03 Low-power circuit design for sensor miniaturization

Advanced low-power circuit designs are crucial for miniaturizing self-powered sensor devices. These designs incorporate power management techniques such as duty cycling, sleep modes, and adaptive sampling rates to minimize energy consumption. By optimizing the power requirements of sensing, processing, and communication components, these circuit designs enable smaller form factors and extended operational lifetimes for self-powered sensors.Expand Specific Solutions04 Wireless communication optimization for miniaturized sensors

Optimizing wireless communication protocols and hardware is essential for miniaturizing self-powered sensor devices. Techniques include implementing low-power communication standards, reducing transmission frequency, and optimizing antenna designs for smaller form factors. These optimizations minimize the energy required for data transmission, allowing for smaller energy storage components and overall device miniaturization while maintaining reliable connectivity.Expand Specific Solutions05 Advanced packaging and integration techniques

Innovative packaging and integration techniques enable further miniaturization of self-powered sensor devices. These include 3D stacking, system-in-package approaches, and flexible substrate technologies that allow for more compact arrangements of components. By efficiently integrating sensors, energy harvesters, processing units, and communication modules into smaller packages, these techniques significantly reduce the overall device footprint while maintaining functionality.Expand Specific Solutions

Leading Companies in Micro Energy Harvesting

The miniaturization of self-powered sensor devices is currently in a growth phase, with the market expected to reach significant expansion due to increasing IoT applications. Texas Instruments and TSMC lead the semiconductor manufacturing aspect, providing essential components for miniaturized sensors. Universities like Tsinghua, Zhejiang, and Chongqing are advancing fundamental research in energy harvesting technologies. Companies such as Broadcom, Robert Bosch, and Alps Alpine are developing application-specific integrated solutions. The technology is approaching maturity in certain segments (wearables, industrial monitoring) while still evolving in others (implantable devices, environmental sensing). Collaboration between academic institutions and industry players is accelerating commercialization, with significant innovations emerging in materials science and power management techniques.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced ultra-low-power microcontrollers (MCUs) specifically designed for self-powered sensor applications. Their MSP430 series features power consumption as low as 100 nA in standby mode and can operate at voltages down to 1.8V, making them ideal for energy harvesting applications. TI has integrated these MCUs with their nano-power management ICs that can harvest energy from multiple sources including solar, thermal, and vibration. Their BQ25570 power management IC can start harvesting energy at inputs as low as 100 mV, achieving up to 90% efficiency in energy conversion. TI has also pioneered miniaturized wireless connectivity solutions like SimpleLink that consume minimal power while enabling sensor data transmission. Their integrated approach combines sensing, processing, power management, and connectivity in packages as small as 2.0 × 2.5 mm, representing a significant advancement in miniaturization of self-powered sensor devices.

Strengths: Industry-leading ultra-low power consumption, comprehensive ecosystem of compatible components, and extensive experience in power management. Their solutions offer exceptional energy harvesting efficiency and versatility across multiple energy sources. Weakness: Higher cost compared to some competitors, and relatively complex implementation requiring significant engineering expertise.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed specialized semiconductor manufacturing processes critical for miniaturization of self-powered sensor devices. Their ultra-low power (ULP) technology platform enables the production of chips with power consumption in the nanowatt range, essential for energy harvesting applications. TSMC's 22nm ULP process technology delivers 30% power reduction compared to their 28nm process while maintaining performance, making it ideal for IoT sensor applications. The company has also pioneered advanced packaging technologies like Integrated Fan-Out (InFO) and System-on-Integrated-Chips (SoIC) that allow for stacking multiple dies in a single package, dramatically reducing the footprint of sensor systems. Their 3D IC integration technology enables the combination of sensors, processors, and power management circuits in packages smaller than 1mm³. TSMC has collaborated with research institutions to develop specialized processes for MEMS sensors that can operate with sub-microwatt power consumption, representing a significant breakthrough for self-powered applications.

Strengths: World-leading semiconductor fabrication capabilities, cutting-edge process nodes optimized for ultra-low power, and advanced packaging technologies enabling extreme miniaturization. Weakness: As a foundry, TSMC depends on customers' designs and doesn't directly create end products, limiting their control over final device implementation and optimization.

Key Patents in Microscale Energy Harvesting

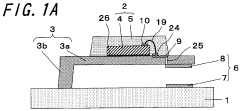

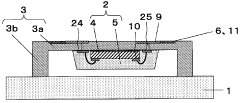

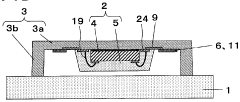

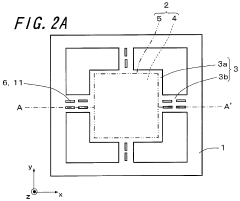

Sensor device

PatentWO2008149821A1

Innovation

- The sensor device integrates the IC within the weight portion, eliminating the need for a separate IC mounting area and allowing the IC to function as both the processing unit and weight, thereby reducing the overall size and volume.

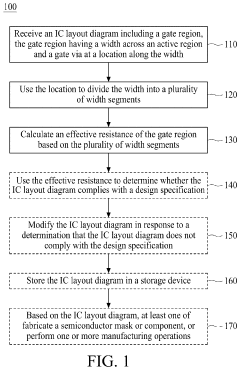

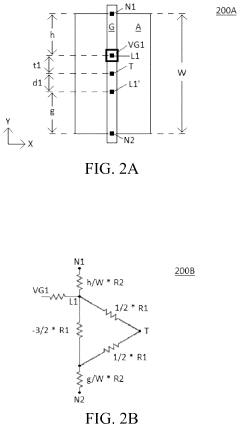

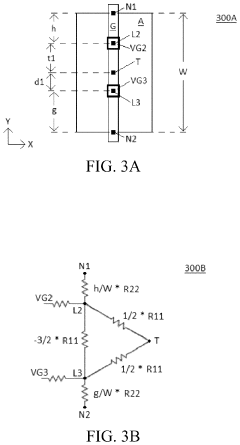

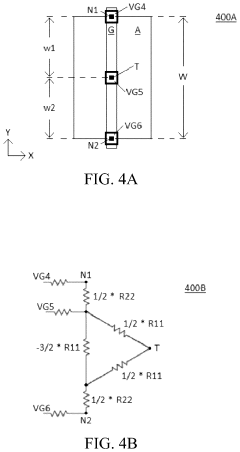

Integrated circuit layout generation method and system

PatentActiveUS11842135B2

Innovation

- Dividing the gate width into segments based on gate via locations and applying a distributed resistance model to each segment, along with effective resistance values to delta resistance networks, improves accuracy in modeling the effective gate resistance.

Materials Innovation for Miniaturized Sensors

Materials innovation represents a cornerstone in the advancement of miniaturized self-powered sensor devices. Recent breakthroughs in nanomaterials have significantly contributed to reducing sensor dimensions while enhancing performance characteristics. Carbon-based materials, particularly graphene and carbon nanotubes, have emerged as frontrunners due to their exceptional electrical conductivity, mechanical flexibility, and minimal spatial requirements. These materials enable the development of sensors with dimensions in the nanometer range while maintaining high sensitivity and response times.

Piezoelectric materials have undergone substantial evolution, with lead-free alternatives such as zinc oxide nanowires and barium titanate nanostructures gaining prominence. These materials efficiently convert mechanical energy into electrical signals at the microscale, facilitating the creation of self-powered motion and pressure sensors with dramatically reduced footprints. The integration of these materials into flexible substrates has further expanded application possibilities in wearable technology and biomedical monitoring.

Thermoelectric materials innovation has focused on enhancing the Seebeck coefficient while reducing thermal conductivity at smaller scales. Bismuth telluride-based nanocomposites and silicon nanowires have demonstrated improved energy conversion efficiency, enabling temperature-differential sensors that can operate autonomously at dimensions below one cubic millimeter. These advancements are particularly valuable for environmental monitoring and industrial process control applications.

Hybrid material systems represent another significant trend, combining different material classes to overcome individual limitations. For instance, the integration of triboelectric layers with piezoelectric elements creates multi-modal energy harvesting capabilities within compact form factors. Similarly, the combination of quantum dots with conventional semiconductor materials has yielded photodetectors with enhanced sensitivity at reduced dimensions.

Biodegradable and biocompatible materials have gained traction for implantable and environmental sensing applications. Magnesium-based alloys, silk fibroin, and polylactic acid derivatives offer transient electronics capabilities, where sensors can perform their function for a predetermined period before harmlessly dissolving. This approach eliminates the need for retrieval procedures in medical applications and reduces electronic waste in environmental monitoring scenarios.

Manufacturing techniques have evolved in parallel with materials innovation, with atomic layer deposition and directed self-assembly enabling precise material placement at nanoscale dimensions. These processes allow for the creation of complex three-dimensional architectures that maximize surface area within minimal volumes, enhancing energy harvesting capabilities and sensor response characteristics.

Piezoelectric materials have undergone substantial evolution, with lead-free alternatives such as zinc oxide nanowires and barium titanate nanostructures gaining prominence. These materials efficiently convert mechanical energy into electrical signals at the microscale, facilitating the creation of self-powered motion and pressure sensors with dramatically reduced footprints. The integration of these materials into flexible substrates has further expanded application possibilities in wearable technology and biomedical monitoring.

Thermoelectric materials innovation has focused on enhancing the Seebeck coefficient while reducing thermal conductivity at smaller scales. Bismuth telluride-based nanocomposites and silicon nanowires have demonstrated improved energy conversion efficiency, enabling temperature-differential sensors that can operate autonomously at dimensions below one cubic millimeter. These advancements are particularly valuable for environmental monitoring and industrial process control applications.

Hybrid material systems represent another significant trend, combining different material classes to overcome individual limitations. For instance, the integration of triboelectric layers with piezoelectric elements creates multi-modal energy harvesting capabilities within compact form factors. Similarly, the combination of quantum dots with conventional semiconductor materials has yielded photodetectors with enhanced sensitivity at reduced dimensions.

Biodegradable and biocompatible materials have gained traction for implantable and environmental sensing applications. Magnesium-based alloys, silk fibroin, and polylactic acid derivatives offer transient electronics capabilities, where sensors can perform their function for a predetermined period before harmlessly dissolving. This approach eliminates the need for retrieval procedures in medical applications and reduces electronic waste in environmental monitoring scenarios.

Manufacturing techniques have evolved in parallel with materials innovation, with atomic layer deposition and directed self-assembly enabling precise material placement at nanoscale dimensions. These processes allow for the creation of complex three-dimensional architectures that maximize surface area within minimal volumes, enhancing energy harvesting capabilities and sensor response characteristics.

Energy Efficiency and Power Management Strategies

Energy efficiency represents a critical challenge in the miniaturization of self-powered sensor devices. As dimensions decrease, power constraints become increasingly stringent, necessitating innovative approaches to energy management. Current self-powered microsensors typically operate with power budgets in the microwatt to milliwatt range, requiring careful optimization of every component in the power chain.

Power management strategies have evolved significantly over the past decade, with particular emphasis on dynamic power scaling techniques. These approaches enable devices to adjust their power consumption based on operational requirements, effectively extending battery life or harvested energy utilization. Advanced power gating mechanisms can now isolate unused circuit blocks with leakage currents reduced to nano-ampere levels, representing a 100-fold improvement compared to earlier implementations.

Energy harvesting integration presents another frontier in power management for miniaturized sensors. Recent developments in piezoelectric, thermoelectric, and photovoltaic materials have yielded energy densities approaching 10-100 μW/cm², sufficient for intermittent sensing applications. Multi-source energy harvesting architectures are emerging as particularly promising, with hybrid systems demonstrating 30-40% higher energy yield compared to single-source alternatives.

Ultra-low-power circuit design techniques have become essential in this domain. Sub-threshold operation of transistors, though challenging to implement reliably, can reduce dynamic power consumption by 70-80% in certain applications. Similarly, approximate computing methodologies selectively reduce computational precision to conserve energy while maintaining acceptable performance for specific sensing tasks.

Energy storage remains a significant bottleneck in miniaturized self-powered systems. While traditional lithium-based microbatteries offer energy densities of 200-300 Wh/L, their cycle life limitations and form factor constraints have driven interest in alternatives. Solid-state thin-film batteries and microsupercapacitors are emerging as viable options, with the latter offering power densities exceeding 1000 W/L and cycle lifetimes approaching 100,000 cycles.

Intelligent power management algorithms represent the integration layer for these various technologies. Machine learning approaches that predict energy availability and optimize device duty cycles have demonstrated energy savings of 25-45% compared to static scheduling approaches. These systems increasingly incorporate contextual awareness, allowing devices to adapt their operation based on environmental conditions and application requirements.

Power management strategies have evolved significantly over the past decade, with particular emphasis on dynamic power scaling techniques. These approaches enable devices to adjust their power consumption based on operational requirements, effectively extending battery life or harvested energy utilization. Advanced power gating mechanisms can now isolate unused circuit blocks with leakage currents reduced to nano-ampere levels, representing a 100-fold improvement compared to earlier implementations.

Energy harvesting integration presents another frontier in power management for miniaturized sensors. Recent developments in piezoelectric, thermoelectric, and photovoltaic materials have yielded energy densities approaching 10-100 μW/cm², sufficient for intermittent sensing applications. Multi-source energy harvesting architectures are emerging as particularly promising, with hybrid systems demonstrating 30-40% higher energy yield compared to single-source alternatives.

Ultra-low-power circuit design techniques have become essential in this domain. Sub-threshold operation of transistors, though challenging to implement reliably, can reduce dynamic power consumption by 70-80% in certain applications. Similarly, approximate computing methodologies selectively reduce computational precision to conserve energy while maintaining acceptable performance for specific sensing tasks.

Energy storage remains a significant bottleneck in miniaturized self-powered systems. While traditional lithium-based microbatteries offer energy densities of 200-300 Wh/L, their cycle life limitations and form factor constraints have driven interest in alternatives. Solid-state thin-film batteries and microsupercapacitors are emerging as viable options, with the latter offering power densities exceeding 1000 W/L and cycle lifetimes approaching 100,000 cycles.

Intelligent power management algorithms represent the integration layer for these various technologies. Machine learning approaches that predict energy availability and optimize device duty cycles have demonstrated energy savings of 25-45% compared to static scheduling approaches. These systems increasingly incorporate contextual awareness, allowing devices to adapt their operation based on environmental conditions and application requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!