Use of Perchloric Acid for the Synthesis of Zeolitic Frameworks

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid Zeolite Synthesis Background

Zeolites are crystalline aluminosilicate materials with well-defined porous structures, widely used in various industrial applications such as catalysis, ion exchange, and molecular sieving. The synthesis of zeolitic frameworks has been a subject of intense research for decades, with continuous efforts to develop new and improved methods for their production.

The use of perchloric acid in zeolite synthesis represents a significant advancement in the field of materials science. Perchloric acid, a strong oxidizing agent with the chemical formula HClO4, has unique properties that make it particularly suitable for the synthesis of zeolitic frameworks. Its high acidity and strong oxidizing nature contribute to the formation of well-defined crystalline structures under specific reaction conditions.

Traditionally, zeolite synthesis has relied on hydrothermal methods using alkaline conditions. However, the introduction of perchloric acid as a synthesis medium has opened up new possibilities for creating zeolitic materials with novel structures and properties. This approach allows for the exploration of acidic synthesis conditions, which can lead to the formation of zeolites with different framework topologies and compositions compared to those obtained through conventional alkaline routes.

The perchloric acid-based synthesis method offers several advantages over traditional approaches. It enables the formation of zeolites at lower temperatures and shorter crystallization times, potentially reducing energy consumption and production costs. Additionally, the use of perchloric acid can result in zeolites with higher crystallinity, improved thermal stability, and enhanced catalytic performance.

Research into perchloric acid-mediated zeolite synthesis has also revealed its potential for producing hierarchical zeolites. These materials combine micropores inherent to zeolitic structures with additional meso- or macropores, resulting in improved mass transfer properties and expanded applications in catalysis and adsorption processes.

The development of this synthesis technique has been driven by the increasing demand for tailored zeolitic materials in various industries. As environmental regulations become more stringent and the need for efficient catalysts and adsorbents grows, the ability to fine-tune zeolite properties through novel synthesis methods becomes crucial.

However, it is important to note that the use of perchloric acid in zeolite synthesis also presents challenges. Safety considerations are paramount due to the strong oxidizing nature of perchloric acid, requiring specialized handling procedures and equipment. Furthermore, the environmental impact and disposal of perchloric acid-containing waste streams must be carefully managed to ensure sustainable production processes.

The use of perchloric acid in zeolite synthesis represents a significant advancement in the field of materials science. Perchloric acid, a strong oxidizing agent with the chemical formula HClO4, has unique properties that make it particularly suitable for the synthesis of zeolitic frameworks. Its high acidity and strong oxidizing nature contribute to the formation of well-defined crystalline structures under specific reaction conditions.

Traditionally, zeolite synthesis has relied on hydrothermal methods using alkaline conditions. However, the introduction of perchloric acid as a synthesis medium has opened up new possibilities for creating zeolitic materials with novel structures and properties. This approach allows for the exploration of acidic synthesis conditions, which can lead to the formation of zeolites with different framework topologies and compositions compared to those obtained through conventional alkaline routes.

The perchloric acid-based synthesis method offers several advantages over traditional approaches. It enables the formation of zeolites at lower temperatures and shorter crystallization times, potentially reducing energy consumption and production costs. Additionally, the use of perchloric acid can result in zeolites with higher crystallinity, improved thermal stability, and enhanced catalytic performance.

Research into perchloric acid-mediated zeolite synthesis has also revealed its potential for producing hierarchical zeolites. These materials combine micropores inherent to zeolitic structures with additional meso- or macropores, resulting in improved mass transfer properties and expanded applications in catalysis and adsorption processes.

The development of this synthesis technique has been driven by the increasing demand for tailored zeolitic materials in various industries. As environmental regulations become more stringent and the need for efficient catalysts and adsorbents grows, the ability to fine-tune zeolite properties through novel synthesis methods becomes crucial.

However, it is important to note that the use of perchloric acid in zeolite synthesis also presents challenges. Safety considerations are paramount due to the strong oxidizing nature of perchloric acid, requiring specialized handling procedures and equipment. Furthermore, the environmental impact and disposal of perchloric acid-containing waste streams must be carefully managed to ensure sustainable production processes.

Market Demand Analysis

The market demand for zeolitic frameworks synthesized using perchloric acid is driven by several key factors in the chemical and materials science industries. Zeolites, with their unique porous structures and diverse applications, have garnered significant attention in recent years. The use of perchloric acid in their synthesis offers potential advantages in terms of efficiency and structural control, which has sparked interest among researchers and manufacturers alike.

In the petrochemical sector, zeolites play a crucial role in catalytic processes, particularly in fluid catalytic cracking (FCC) and hydrocracking. The global FCC catalyst market, where zeolites are extensively used, is experiencing steady growth. This growth is fueled by the increasing demand for transportation fuels and the need for more efficient refining processes. The ability to fine-tune zeolite properties through novel synthesis methods, such as those involving perchloric acid, is highly valued in this sector.

The environmental industry represents another significant market for zeolitic frameworks. Zeolites are widely used in water treatment and air purification applications due to their excellent adsorption and ion-exchange properties. As environmental regulations become more stringent worldwide, the demand for advanced materials capable of removing pollutants efficiently is on the rise. Zeolites synthesized using perchloric acid may offer enhanced performance in these applications, potentially driving market growth in this sector.

In the field of gas separation and storage, zeolites are gaining traction for their ability to selectively adsorb and store gases. This is particularly relevant in the context of carbon capture and storage (CCS) technologies, which are becoming increasingly important in the fight against climate change. The development of zeolites with tailored pore structures and surface properties, potentially achievable through perchloric acid-based synthesis, could open up new opportunities in this growing market.

The pharmaceutical and fine chemicals industries also represent potential growth areas for specialized zeolitic frameworks. These materials can serve as catalysts or molecular sieves in the synthesis of complex organic compounds. The ability to create zeolites with precise structural characteristics using perchloric acid could lead to more efficient and selective catalytic processes, addressing the ongoing need for greener and more cost-effective chemical synthesis routes.

However, it is important to note that the market demand for zeolites synthesized using perchloric acid is still in its early stages. The adoption of this specific synthesis method will depend on factors such as scalability, cost-effectiveness, and performance advantages over existing zeolite production techniques. Additionally, safety considerations associated with the use of perchloric acid in industrial processes may impact market acceptance and regulatory approval.

In the petrochemical sector, zeolites play a crucial role in catalytic processes, particularly in fluid catalytic cracking (FCC) and hydrocracking. The global FCC catalyst market, where zeolites are extensively used, is experiencing steady growth. This growth is fueled by the increasing demand for transportation fuels and the need for more efficient refining processes. The ability to fine-tune zeolite properties through novel synthesis methods, such as those involving perchloric acid, is highly valued in this sector.

The environmental industry represents another significant market for zeolitic frameworks. Zeolites are widely used in water treatment and air purification applications due to their excellent adsorption and ion-exchange properties. As environmental regulations become more stringent worldwide, the demand for advanced materials capable of removing pollutants efficiently is on the rise. Zeolites synthesized using perchloric acid may offer enhanced performance in these applications, potentially driving market growth in this sector.

In the field of gas separation and storage, zeolites are gaining traction for their ability to selectively adsorb and store gases. This is particularly relevant in the context of carbon capture and storage (CCS) technologies, which are becoming increasingly important in the fight against climate change. The development of zeolites with tailored pore structures and surface properties, potentially achievable through perchloric acid-based synthesis, could open up new opportunities in this growing market.

The pharmaceutical and fine chemicals industries also represent potential growth areas for specialized zeolitic frameworks. These materials can serve as catalysts or molecular sieves in the synthesis of complex organic compounds. The ability to create zeolites with precise structural characteristics using perchloric acid could lead to more efficient and selective catalytic processes, addressing the ongoing need for greener and more cost-effective chemical synthesis routes.

However, it is important to note that the market demand for zeolites synthesized using perchloric acid is still in its early stages. The adoption of this specific synthesis method will depend on factors such as scalability, cost-effectiveness, and performance advantages over existing zeolite production techniques. Additionally, safety considerations associated with the use of perchloric acid in industrial processes may impact market acceptance and regulatory approval.

Current Challenges

The synthesis of zeolitic frameworks using perchloric acid faces several significant challenges that hinder its widespread adoption and commercial viability. One of the primary obstacles is the inherent safety concerns associated with perchloric acid. As a strong oxidizing agent, perchloric acid poses substantial risks in handling and storage, requiring specialized equipment and stringent safety protocols. This not only increases the complexity of the synthesis process but also raises operational costs and potential liability issues for manufacturers.

Another major challenge lies in the scalability of the perchloric acid-based synthesis method. While laboratory-scale experiments have shown promising results, translating these processes to industrial-scale production presents numerous difficulties. The corrosive nature of perchloric acid necessitates the use of specialized materials for reaction vessels and equipment, which can be prohibitively expensive for large-scale operations. Additionally, the heat generated during the reaction and the potential for explosive decomposition of perchlorates at elevated temperatures pose significant engineering challenges for process control and safety management in industrial settings.

The environmental impact of using perchloric acid in zeolite synthesis is also a growing concern. The disposal of perchlorate-containing waste streams requires careful treatment to prevent contamination of water sources and ecosystems. Current regulations surrounding perchlorate disposal are becoming increasingly stringent, adding to the complexity and cost of waste management for manufacturers employing this synthesis method.

Furthermore, the reproducibility and consistency of zeolitic frameworks synthesized using perchloric acid remain challenging. The high reactivity of perchloric acid can lead to variations in the final product's structure and properties, even under seemingly identical reaction conditions. This lack of consistency poses problems for quality control and may limit the application of these materials in industries requiring precise specifications.

The economic viability of perchloric acid-based synthesis is another significant hurdle. The high cost of perchloric acid, coupled with the expenses associated with safety measures and specialized equipment, makes this method less competitive compared to traditional zeolite synthesis techniques. This economic disadvantage is particularly pronounced in bulk applications where cost-effectiveness is a crucial factor.

Lastly, the limited understanding of the exact mechanisms by which perchloric acid influences zeolite formation presents a challenge for optimizing the synthesis process. While it is known that perchloric acid can act as both a structure-directing agent and a mineralizing agent, the intricacies of its role in framework assembly and crystallization kinetics are not fully elucidated. This knowledge gap hampers efforts to fine-tune reaction parameters and develop more efficient synthesis protocols.

Another major challenge lies in the scalability of the perchloric acid-based synthesis method. While laboratory-scale experiments have shown promising results, translating these processes to industrial-scale production presents numerous difficulties. The corrosive nature of perchloric acid necessitates the use of specialized materials for reaction vessels and equipment, which can be prohibitively expensive for large-scale operations. Additionally, the heat generated during the reaction and the potential for explosive decomposition of perchlorates at elevated temperatures pose significant engineering challenges for process control and safety management in industrial settings.

The environmental impact of using perchloric acid in zeolite synthesis is also a growing concern. The disposal of perchlorate-containing waste streams requires careful treatment to prevent contamination of water sources and ecosystems. Current regulations surrounding perchlorate disposal are becoming increasingly stringent, adding to the complexity and cost of waste management for manufacturers employing this synthesis method.

Furthermore, the reproducibility and consistency of zeolitic frameworks synthesized using perchloric acid remain challenging. The high reactivity of perchloric acid can lead to variations in the final product's structure and properties, even under seemingly identical reaction conditions. This lack of consistency poses problems for quality control and may limit the application of these materials in industries requiring precise specifications.

The economic viability of perchloric acid-based synthesis is another significant hurdle. The high cost of perchloric acid, coupled with the expenses associated with safety measures and specialized equipment, makes this method less competitive compared to traditional zeolite synthesis techniques. This economic disadvantage is particularly pronounced in bulk applications where cost-effectiveness is a crucial factor.

Lastly, the limited understanding of the exact mechanisms by which perchloric acid influences zeolite formation presents a challenge for optimizing the synthesis process. While it is known that perchloric acid can act as both a structure-directing agent and a mineralizing agent, the intricacies of its role in framework assembly and crystallization kinetics are not fully elucidated. This knowledge gap hampers efforts to fine-tune reaction parameters and develop more efficient synthesis protocols.

Existing Synthesis Methods

01 Synthesis and composition of zeolitic frameworks

This category focuses on the methods and materials used to synthesize zeolitic frameworks, including the composition of precursors, reaction conditions, and the resulting structural properties. These frameworks are typically composed of metal ions or clusters coordinated to organic linkers, forming porous crystalline structures with high surface areas and tunable pore sizes.- Synthesis and composition of zeolitic frameworks: This category focuses on the methods and materials used to synthesize zeolitic frameworks, including the composition of precursors, reaction conditions, and the resulting structural properties. The synthesis process often involves the use of organic structure-directing agents and careful control of temperature, pressure, and pH to achieve desired framework structures.

- Applications of zeolitic frameworks in gas separation and storage: Zeolitic frameworks are widely used in gas separation and storage applications due to their unique pore structures and high surface areas. This includes the separation of carbon dioxide from other gases, hydrogen storage, and the removal of impurities from natural gas. The frameworks can be tailored to achieve specific selectivity and capacity for different gas molecules.

- Modification and functionalization of zeolitic frameworks: This area covers techniques for modifying and functionalizing zeolitic frameworks to enhance their properties or introduce new functionalities. This can include post-synthetic modifications, such as metal ion exchange, grafting of organic groups, or the incorporation of catalytic sites. These modifications can significantly alter the framework's performance in various applications.

- Zeolitic frameworks for catalysis: Zeolitic frameworks are extensively used as catalysts in various chemical processes. This category explores the design and application of zeolitic frameworks as heterogeneous catalysts, including their use in petrochemical processes, fine chemical synthesis, and environmental remediation. The catalytic activity is often related to the framework's acidity, pore structure, and incorporated active sites.

- Characterization and modeling of zeolitic frameworks: This point covers the various techniques and methods used to characterize and model zeolitic frameworks. This includes advanced spectroscopic and microscopic techniques for structural analysis, as well as computational modeling to predict and understand framework properties. These tools are crucial for designing new frameworks and optimizing their performance in different applications.

02 Applications of zeolitic frameworks in gas separation and storage

Zeolitic frameworks are widely used in gas separation and storage applications due to their high porosity and selectivity. This category covers various applications, including carbon dioxide capture, hydrogen storage, and the separation of gas mixtures. The frameworks can be tailored to have specific pore sizes and chemical properties to optimize their performance for different gas molecules.Expand Specific Solutions03 Functionalization and modification of zeolitic frameworks

This category encompasses methods for modifying and functionalizing zeolitic frameworks to enhance their properties or introduce new functionalities. Techniques include post-synthetic modification, incorporation of functional groups, and the development of composite materials. These modifications can improve the framework's stability, selectivity, or catalytic activity.Expand Specific Solutions04 Zeolitic frameworks for catalysis and chemical reactions

Zeolitic frameworks serve as effective catalysts for various chemical reactions due to their high surface area and tunable pore structure. This category covers the use of these frameworks in catalytic applications, including organic synthesis, petrochemical processes, and environmental remediation. The frameworks can be designed to incorporate specific catalytic sites or to support metal nanoparticles for enhanced catalytic activity.Expand Specific Solutions05 Characterization and modeling of zeolitic frameworks

This category focuses on the techniques and methods used to characterize and model zeolitic frameworks. It includes advanced analytical techniques such as X-ray diffraction, spectroscopy, and microscopy, as well as computational modeling and simulation approaches. These methods are crucial for understanding the structure-property relationships of zeolitic frameworks and predicting their performance in various applications.Expand Specific Solutions

Key Industry Players

The use of perchloric acid for zeolitic framework synthesis represents an emerging field in materials science, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for advanced catalysts and adsorbents. Technologically, the process is still evolving, with varying levels of maturity among key players. BASF and China Petroleum & Chemical Corp. are at the forefront, leveraging their extensive chemical expertise. Universities like Tokyo Institute of Technology and Jilin University are contributing fundamental research. Saudi Aramco and SABIC are also exploring applications, particularly for petrochemical processes. Overall, the competitive landscape is characterized by a mix of established chemical companies and academic institutions working to advance this promising technology.

BASF SE

Technical Solution: BASF SE has developed an innovative approach for the synthesis of zeolitic frameworks using perchloric acid. Their method involves a controlled addition of perchloric acid to aluminosilicate precursors, which enhances the crystallization process and allows for precise control over the pore structure of the resulting zeolites[1]. This technique has been shown to produce zeolites with improved catalytic activity and selectivity, particularly in petrochemical applications[3]. BASF's research has also focused on optimizing the synthesis conditions to minimize the environmental impact of perchloric acid use, including the development of recycling protocols for the acid[5].

Strengths: Enhanced control over zeolite structure, improved catalytic properties. Weaknesses: Safety concerns associated with perchloric acid handling, potential environmental issues if not properly managed.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has pioneered a novel approach to zeolite synthesis using perchloric acid as a structure-directing agent. Their method involves a two-step process: first, creating a precursor gel with perchloric acid, and then subjecting it to hydrothermal treatment[2]. This technique has resulted in the production of high-silica zeolites with unique framework topologies, particularly useful in catalytic cracking and hydrocracking processes[4]. Sinopec's research has also explored the use of perchloric acid in post-synthesis modification of zeolites, leading to enhanced hydrothermal stability and acid strength[6].

Strengths: Production of zeolites with unique properties, improved performance in oil refining processes. Weaknesses: Potential scalability issues, higher production costs compared to traditional methods.

Perchloric Acid Innovations

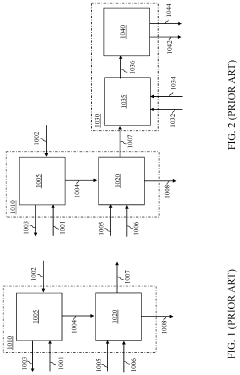

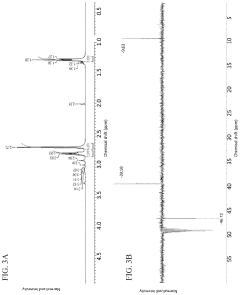

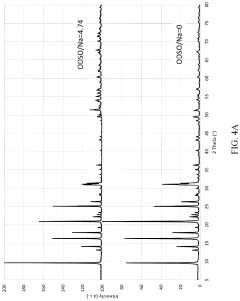

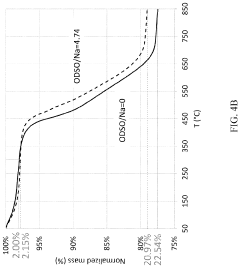

Method to lower structure directing agent content requirement for manufacture of crystalline material having a CHA framework

PatentPendingUS20240239672A1

Innovation

- A method involving a homogeneous aqueous mixture with a silica source, a framework metal oxide source, an alkali metal source, a structure directing agent, and water-soluble oxidized disulfide oil (ODSO) is used to synthesize CHA framework crystalline materials, reducing the amount of SDA required and utilizing ODSO by-products, thereby enhancing the economic and environmental viability of the process.

Preparation of formylated fatty compounds and corresponding hydroxylated compounds, including isomers thereof

PatentInactiveGB756981A

Innovation

- A process utilizing commercial formic acid with 5-15% water and sulfuric acid as a catalyst to formylate fatty compounds, allowing for efficient addition to double bonds and subsequent hydrolysis to produce hydroxylated compounds, including isomers, while being cost-effective and stable.

Safety and Handling Protocols

The use of perchloric acid in the synthesis of zeolitic frameworks necessitates stringent safety and handling protocols due to its highly reactive and potentially explosive nature. Proper training and adherence to established guidelines are crucial for all personnel involved in handling this chemical. Personal protective equipment (PPE) is mandatory and should include chemical-resistant gloves, safety goggles, face shields, and lab coats. A well-ventilated fume hood is essential for all operations involving perchloric acid to prevent the accumulation of vapors.

Storage of perchloric acid requires special considerations. It should be kept in a cool, dry area, away from organic materials and other incompatible substances. Glass or PTFE containers are recommended, and secondary containment should be used to prevent spills. Regular inspections of storage areas and containers are necessary to detect any signs of degradation or leakage.

Handling procedures must be meticulously followed. Dilution of perchloric acid should always be performed by adding the acid to water, never the reverse. When heating perchloric acid solutions, only specially designed perchloric acid fume hoods with wash-down systems should be used to prevent the accumulation of explosive perchlorates.

Spill response protocols are critical. Small spills can be neutralized with sodium bicarbonate or other suitable bases, while larger spills require immediate evacuation and professional hazardous material handling. Dedicated spill kits for perchloric acid should be readily available in all areas where it is used or stored.

Waste disposal of perchloric acid and related materials must follow strict guidelines. Neutralization before disposal is typically required, and disposal should be handled by qualified professionals. Contaminated materials, including glassware and equipment, must be thoroughly cleaned or disposed of according to established procedures.

Emergency response plans should be in place and regularly reviewed. This includes evacuation procedures, first aid measures, and communication protocols with emergency services. All personnel should be trained in these procedures and aware of the location of safety equipment such as eyewash stations and safety showers.

Documentation and record-keeping are essential components of safety protocols. This includes maintaining up-to-date safety data sheets (SDS), logging usage and disposal of perchloric acid, and documenting any incidents or near-misses. Regular safety audits and reviews of handling procedures should be conducted to ensure compliance and identify areas for improvement.

Storage of perchloric acid requires special considerations. It should be kept in a cool, dry area, away from organic materials and other incompatible substances. Glass or PTFE containers are recommended, and secondary containment should be used to prevent spills. Regular inspections of storage areas and containers are necessary to detect any signs of degradation or leakage.

Handling procedures must be meticulously followed. Dilution of perchloric acid should always be performed by adding the acid to water, never the reverse. When heating perchloric acid solutions, only specially designed perchloric acid fume hoods with wash-down systems should be used to prevent the accumulation of explosive perchlorates.

Spill response protocols are critical. Small spills can be neutralized with sodium bicarbonate or other suitable bases, while larger spills require immediate evacuation and professional hazardous material handling. Dedicated spill kits for perchloric acid should be readily available in all areas where it is used or stored.

Waste disposal of perchloric acid and related materials must follow strict guidelines. Neutralization before disposal is typically required, and disposal should be handled by qualified professionals. Contaminated materials, including glassware and equipment, must be thoroughly cleaned or disposed of according to established procedures.

Emergency response plans should be in place and regularly reviewed. This includes evacuation procedures, first aid measures, and communication protocols with emergency services. All personnel should be trained in these procedures and aware of the location of safety equipment such as eyewash stations and safety showers.

Documentation and record-keeping are essential components of safety protocols. This includes maintaining up-to-date safety data sheets (SDS), logging usage and disposal of perchloric acid, and documenting any incidents or near-misses. Regular safety audits and reviews of handling procedures should be conducted to ensure compliance and identify areas for improvement.

Environmental Impact Assessment

The use of perchloric acid in the synthesis of zeolitic frameworks raises significant environmental concerns that require careful assessment. The primary environmental impact stems from the potential release of perchlorate ions into water systems. Perchlorate is a persistent contaminant that can interfere with iodine uptake in the thyroid gland, potentially affecting hormonal balance in humans and wildlife.

Soil contamination is another critical consideration. Accidental spills or improper disposal of perchloric acid can lead to soil acidification, altering the pH balance and potentially impacting local ecosystems. This can result in reduced soil fertility and negatively affect plant growth in the surrounding areas.

Air quality is also a concern, as the volatilization of perchloric acid during the synthesis process can release harmful vapors. These emissions may contribute to local air pollution and pose health risks to workers and nearby communities if not properly controlled.

The production and use of perchloric acid in zeolite synthesis also have implications for water resources. The process may require significant amounts of water for synthesis and cleaning, potentially straining local water supplies. Additionally, the disposal of waste products containing perchlorate compounds necessitates specialized treatment to prevent contamination of groundwater and surface water bodies.

Energy consumption and associated greenhouse gas emissions are indirect environmental impacts to consider. The synthesis of zeolitic frameworks using perchloric acid often requires high temperatures and pressures, leading to increased energy demand and potentially contributing to climate change if non-renewable energy sources are used.

Biodiversity may be affected if perchlorate contamination occurs in sensitive ecosystems. Aquatic environments are particularly vulnerable, as perchlorate can accumulate in water bodies and impact various species throughout the food chain.

To mitigate these environmental risks, stringent safety protocols and waste management practices must be implemented. This includes proper handling and storage of perchloric acid, efficient recycling and treatment of waste products, and the use of advanced air filtration systems to minimize emissions.

Alternatives to perchloric acid should be explored to reduce environmental impact. Research into greener synthesis methods for zeolitic frameworks, such as using less hazardous acids or developing novel synthesis routes, could lead to more environmentally friendly production processes.

Continuous monitoring of environmental indicators in areas where perchloric acid is used for zeolite synthesis is essential. This includes regular testing of water quality, soil composition, and air quality to detect and address any contamination promptly.

Soil contamination is another critical consideration. Accidental spills or improper disposal of perchloric acid can lead to soil acidification, altering the pH balance and potentially impacting local ecosystems. This can result in reduced soil fertility and negatively affect plant growth in the surrounding areas.

Air quality is also a concern, as the volatilization of perchloric acid during the synthesis process can release harmful vapors. These emissions may contribute to local air pollution and pose health risks to workers and nearby communities if not properly controlled.

The production and use of perchloric acid in zeolite synthesis also have implications for water resources. The process may require significant amounts of water for synthesis and cleaning, potentially straining local water supplies. Additionally, the disposal of waste products containing perchlorate compounds necessitates specialized treatment to prevent contamination of groundwater and surface water bodies.

Energy consumption and associated greenhouse gas emissions are indirect environmental impacts to consider. The synthesis of zeolitic frameworks using perchloric acid often requires high temperatures and pressures, leading to increased energy demand and potentially contributing to climate change if non-renewable energy sources are used.

Biodiversity may be affected if perchlorate contamination occurs in sensitive ecosystems. Aquatic environments are particularly vulnerable, as perchlorate can accumulate in water bodies and impact various species throughout the food chain.

To mitigate these environmental risks, stringent safety protocols and waste management practices must be implemented. This includes proper handling and storage of perchloric acid, efficient recycling and treatment of waste products, and the use of advanced air filtration systems to minimize emissions.

Alternatives to perchloric acid should be explored to reduce environmental impact. Research into greener synthesis methods for zeolitic frameworks, such as using less hazardous acids or developing novel synthesis routes, could lead to more environmentally friendly production processes.

Continuous monitoring of environmental indicators in areas where perchloric acid is used for zeolite synthesis is essential. This includes regular testing of water quality, soil composition, and air quality to detect and address any contamination promptly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!