2-Methylpentane's Interaction with Optical Fiber Coatings

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane and Optical Fiber Coatings: Overview

2-Methylpentane, an isomer of hexane, is a colorless liquid hydrocarbon with significant implications for optical fiber coatings. This compound belongs to the alkane family and possesses unique chemical properties that can influence its interaction with various materials, including those used in optical fiber technology.

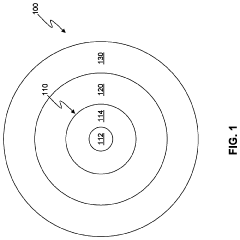

Optical fibers are essential components in modern telecommunications and data transmission systems. These thin strands of glass or plastic are designed to transmit light signals over long distances with minimal loss. To protect the delicate fiber core and maintain optimal performance, optical fibers are typically coated with specialized materials.

The interaction between 2-Methylpentane and optical fiber coatings is a subject of interest due to its potential impact on fiber performance and longevity. This hydrocarbon can potentially affect the physical and chemical properties of the coating materials, leading to changes in their protective capabilities and overall fiber functionality.

One of the primary concerns in this interaction is the potential for 2-Methylpentane to cause swelling or degradation of certain coating materials. This effect could compromise the protective barrier around the optical fiber, potentially leading to increased signal attenuation or mechanical vulnerability.

Furthermore, the presence of 2-Methylpentane in environments where optical fibers are deployed may necessitate the development of specialized coating materials that are resistant to its effects. This has implications for both the manufacturing processes of optical fibers and their application in various industries.

The study of 2-Methylpentane's interaction with optical fiber coatings also extends to its potential as a component in certain coating formulations. Some research suggests that controlled incorporation of hydrocarbons like 2-Methylpentane into coating materials could potentially enhance specific properties, such as flexibility or resistance to environmental factors.

Understanding the molecular-level interactions between 2-Methylpentane and common optical fiber coating materials is crucial for predicting long-term performance and developing improved coating technologies. This involves examining factors such as chemical compatibility, diffusion rates, and potential chemical reactions at the interface between the hydrocarbon and the coating.

As telecommunications networks continue to expand and evolve, the demand for high-performance optical fibers grows. Consequently, the study of compounds like 2-Methylpentane and their effects on fiber coatings becomes increasingly important for ensuring the reliability and efficiency of these critical infrastructure components.

Optical fibers are essential components in modern telecommunications and data transmission systems. These thin strands of glass or plastic are designed to transmit light signals over long distances with minimal loss. To protect the delicate fiber core and maintain optimal performance, optical fibers are typically coated with specialized materials.

The interaction between 2-Methylpentane and optical fiber coatings is a subject of interest due to its potential impact on fiber performance and longevity. This hydrocarbon can potentially affect the physical and chemical properties of the coating materials, leading to changes in their protective capabilities and overall fiber functionality.

One of the primary concerns in this interaction is the potential for 2-Methylpentane to cause swelling or degradation of certain coating materials. This effect could compromise the protective barrier around the optical fiber, potentially leading to increased signal attenuation or mechanical vulnerability.

Furthermore, the presence of 2-Methylpentane in environments where optical fibers are deployed may necessitate the development of specialized coating materials that are resistant to its effects. This has implications for both the manufacturing processes of optical fibers and their application in various industries.

The study of 2-Methylpentane's interaction with optical fiber coatings also extends to its potential as a component in certain coating formulations. Some research suggests that controlled incorporation of hydrocarbons like 2-Methylpentane into coating materials could potentially enhance specific properties, such as flexibility or resistance to environmental factors.

Understanding the molecular-level interactions between 2-Methylpentane and common optical fiber coating materials is crucial for predicting long-term performance and developing improved coating technologies. This involves examining factors such as chemical compatibility, diffusion rates, and potential chemical reactions at the interface between the hydrocarbon and the coating.

As telecommunications networks continue to expand and evolve, the demand for high-performance optical fibers grows. Consequently, the study of compounds like 2-Methylpentane and their effects on fiber coatings becomes increasingly important for ensuring the reliability and efficiency of these critical infrastructure components.

Market Analysis for Chemical-Resistant Fiber Optics

The market for chemical-resistant fiber optics is experiencing significant growth, driven by increasing demand in harsh environment applications across various industries. The global chemical-resistant fiber optics market is projected to expand at a compound annual growth rate (CAGR) of 7.5% from 2021 to 2026, reaching a market value of $2.3 billion by the end of the forecast period.

Key industries driving this growth include oil and gas, chemical processing, and pharmaceutical manufacturing. These sectors require robust communication and sensing solutions that can withstand exposure to corrosive chemicals and extreme conditions. The oil and gas industry, in particular, is a major consumer of chemical-resistant fiber optics, utilizing them for downhole sensing, pipeline monitoring, and offshore platform communications.

The chemical processing industry is another significant market segment, employing chemical-resistant fiber optics for process control, safety monitoring, and data transmission in corrosive environments. The pharmaceutical sector also contributes to market growth, using these specialized fibers in cleanroom environments and for monitoring critical manufacturing processes.

Geographically, North America and Europe currently dominate the chemical-resistant fiber optics market, accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth during the forecast period, driven by rapid industrialization and increasing investments in infrastructure development.

The market is characterized by a high degree of competition, with key players focusing on research and development to enhance product performance and durability. Major companies in this space include Corning Incorporated, Prysmian Group, and Fiberguide Industries, among others.

Emerging trends in the chemical-resistant fiber optics market include the development of advanced coating materials that offer improved resistance to a wider range of chemicals and environmental conditions. There is also a growing demand for fiber optic sensors that can provide real-time monitoring of chemical processes and detect potential leaks or contamination.

The interaction of 2-Methylpentane with optical fiber coatings presents both challenges and opportunities for the chemical-resistant fiber optics market. As a hydrocarbon solvent, 2-Methylpentane can potentially degrade certain types of fiber optic coatings, highlighting the need for more resilient materials. This has spurred research into novel coating formulations that can withstand exposure to such chemicals without compromising the fiber's optical performance.

Key industries driving this growth include oil and gas, chemical processing, and pharmaceutical manufacturing. These sectors require robust communication and sensing solutions that can withstand exposure to corrosive chemicals and extreme conditions. The oil and gas industry, in particular, is a major consumer of chemical-resistant fiber optics, utilizing them for downhole sensing, pipeline monitoring, and offshore platform communications.

The chemical processing industry is another significant market segment, employing chemical-resistant fiber optics for process control, safety monitoring, and data transmission in corrosive environments. The pharmaceutical sector also contributes to market growth, using these specialized fibers in cleanroom environments and for monitoring critical manufacturing processes.

Geographically, North America and Europe currently dominate the chemical-resistant fiber optics market, accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth during the forecast period, driven by rapid industrialization and increasing investments in infrastructure development.

The market is characterized by a high degree of competition, with key players focusing on research and development to enhance product performance and durability. Major companies in this space include Corning Incorporated, Prysmian Group, and Fiberguide Industries, among others.

Emerging trends in the chemical-resistant fiber optics market include the development of advanced coating materials that offer improved resistance to a wider range of chemicals and environmental conditions. There is also a growing demand for fiber optic sensors that can provide real-time monitoring of chemical processes and detect potential leaks or contamination.

The interaction of 2-Methylpentane with optical fiber coatings presents both challenges and opportunities for the chemical-resistant fiber optics market. As a hydrocarbon solvent, 2-Methylpentane can potentially degrade certain types of fiber optic coatings, highlighting the need for more resilient materials. This has spurred research into novel coating formulations that can withstand exposure to such chemicals without compromising the fiber's optical performance.

Current Challenges in 2-Methylpentane Resistant Coatings

The development of 2-methylpentane resistant coatings for optical fibers faces several significant challenges. One of the primary issues is the chemical compatibility between the coating materials and 2-methylpentane. This hydrocarbon solvent has a strong affinity for many polymeric materials commonly used in fiber optic coatings, leading to swelling, degradation, and potential delamination of the protective layers.

Another major challenge lies in maintaining the optical and mechanical properties of the fiber while enhancing its resistance to 2-methylpentane. The coating must provide adequate protection without compromising the fiber's light transmission capabilities or its physical strength. This balance is particularly difficult to achieve as materials that offer high chemical resistance often have less favorable optical characteristics.

The long-term stability of 2-methylpentane resistant coatings is also a significant concern. Exposure to this solvent over extended periods can lead to gradual deterioration of the coating's protective properties. Researchers are grappling with the task of developing coatings that can withstand prolonged contact with 2-methylpentane without losing their effectiveness or compromising the fiber's performance.

Manufacturing challenges present another hurdle in the development of these specialized coatings. The application process must be compatible with existing fiber production methods to ensure cost-effectiveness and scalability. Additionally, the coating must adhere uniformly to the fiber surface and cure properly to provide consistent protection along the entire length of the fiber.

Environmental and safety considerations add another layer of complexity to the development process. As regulations become more stringent, there is a growing need for coating materials that are not only resistant to 2-methylpentane but also environmentally friendly and safe for handling during production and deployment.

Lastly, the cost-effectiveness of developing and implementing 2-methylpentane resistant coatings remains a significant challenge. The materials and processes required to create these specialized coatings must be economically viable for large-scale production to ensure their adoption in the industry. Balancing performance requirements with cost constraints continues to be a major focus for researchers and manufacturers in this field.

Another major challenge lies in maintaining the optical and mechanical properties of the fiber while enhancing its resistance to 2-methylpentane. The coating must provide adequate protection without compromising the fiber's light transmission capabilities or its physical strength. This balance is particularly difficult to achieve as materials that offer high chemical resistance often have less favorable optical characteristics.

The long-term stability of 2-methylpentane resistant coatings is also a significant concern. Exposure to this solvent over extended periods can lead to gradual deterioration of the coating's protective properties. Researchers are grappling with the task of developing coatings that can withstand prolonged contact with 2-methylpentane without losing their effectiveness or compromising the fiber's performance.

Manufacturing challenges present another hurdle in the development of these specialized coatings. The application process must be compatible with existing fiber production methods to ensure cost-effectiveness and scalability. Additionally, the coating must adhere uniformly to the fiber surface and cure properly to provide consistent protection along the entire length of the fiber.

Environmental and safety considerations add another layer of complexity to the development process. As regulations become more stringent, there is a growing need for coating materials that are not only resistant to 2-methylpentane but also environmentally friendly and safe for handling during production and deployment.

Lastly, the cost-effectiveness of developing and implementing 2-methylpentane resistant coatings remains a significant challenge. The materials and processes required to create these specialized coatings must be economically viable for large-scale production to ensure their adoption in the industry. Balancing performance requirements with cost constraints continues to be a major focus for researchers and manufacturers in this field.

Existing Solutions for Chemical-Resistant Fiber Coatings

01 Chemical reactions involving 2-methylpentane

2-Methylpentane is used in various chemical reactions, including isomerization, alkylation, and oxidation processes. It serves as a reactant or solvent in the production of other hydrocarbons and chemical compounds. These reactions are important in the petrochemical industry and in the synthesis of various organic compounds.- Chemical synthesis and reactions: 2-Methylpentane is involved in various chemical synthesis processes and reactions. It can be used as a starting material or intermediate in the production of other organic compounds. The interactions of 2-methylpentane in these processes often involve isomerization, alkylation, or other transformations to create more complex molecules.

- Fuel and energy applications: 2-Methylpentane has applications in the fuel and energy sector. It can be used as a component in fuel blends or as an additive to improve fuel properties. The interactions of 2-methylpentane in these applications may involve its combustion characteristics, octane rating enhancement, or its role in reducing emissions.

- Solvent properties and interactions: 2-Methylpentane exhibits solvent properties and can interact with various substances. It may be used as a solvent in industrial processes, chemical reactions, or extraction procedures. The interactions of 2-methylpentane as a solvent can affect the solubility, reactivity, or separation of other compounds.

- Environmental and safety considerations: The interactions of 2-methylpentane with the environment and its safety aspects are important considerations. This includes its potential environmental impact, biodegradation, toxicity, and handling precautions. Understanding these interactions is crucial for proper use and disposal of 2-methylpentane in various applications.

- Analytical and detection methods: Various analytical and detection methods are employed to study the interactions of 2-methylpentane. These may include spectroscopic techniques, chromatography, or other instrumental methods to identify, quantify, or characterize 2-methylpentane and its interactions with other substances in different matrices or reaction environments.

02 2-Methylpentane as a component in fuel formulations

2-Methylpentane is utilized as a component in fuel formulations, particularly in gasoline blends. Its high octane rating and favorable combustion properties make it valuable for improving fuel performance and efficiency. Research focuses on optimizing fuel compositions containing 2-methylpentane to enhance engine performance and reduce emissions.Expand Specific Solutions03 Separation and purification of 2-methylpentane

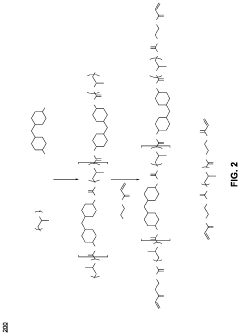

Various methods are employed for the separation and purification of 2-methylpentane from hydrocarbon mixtures. These include distillation, adsorption, and membrane separation techniques. Improving the efficiency and selectivity of these separation processes is crucial for obtaining high-purity 2-methylpentane for industrial applications.Expand Specific Solutions04 2-Methylpentane in polymer production

2-Methylpentane is used in polymer production processes, particularly in the synthesis of certain types of polyolefins. It can serve as a solvent or diluent in polymerization reactions, influencing the properties of the resulting polymers. Research in this area focuses on optimizing reaction conditions and exploring new polymer formulations.Expand Specific Solutions05 Environmental and safety considerations of 2-methylpentane

Studies are conducted on the environmental impact and safety aspects of 2-methylpentane use in various applications. This includes assessing its volatility, flammability, and potential for atmospheric emissions. Research also focuses on developing safer handling procedures and exploring more environmentally friendly alternatives in certain applications.Expand Specific Solutions

Key Players in Specialty Optical Fiber Industry

The interaction between 2-Methylpentane and optical fiber coatings represents a niche area within the broader optical fiber industry. This sector is in a mature phase, with established players dominating the market. The global optical fiber coatings market size is estimated to be in the billions of dollars, driven by increasing demand for high-speed internet and telecommunications infrastructure. Technologically, the field is well-developed, with companies like Corning, Inc., Sumitomo Electric Industries Ltd., and Prysmian SpA leading in innovation. These firms, along with others like DSM IP Assets BV and Furukawa Electric Co., Ltd., are continuously refining coating formulations to enhance fiber performance and durability. The focus on specialized applications, such as 2-Methylpentane interactions, indicates a trend towards highly tailored solutions in this competitive landscape.

Corning, Inc.

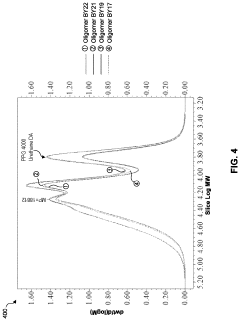

Technical Solution: Corning has developed advanced optical fiber coatings that are resistant to 2-methylpentane and other hydrocarbon solvents. Their CPC® (Corning® PureCoat™) coating technology utilizes a dual-layer system with an inner primary coating and an outer secondary coating. The primary coating is designed to protect the glass fiber from microbending and provide mechanical cushioning, while the secondary coating offers additional protection against environmental factors. Corning's coatings incorporate specially formulated UV-cured acrylates that demonstrate excellent chemical resistance, including to 2-methylpentane. The company has also implemented a proprietary curing process that enhances the cross-linking density of the polymer network, further improving solvent resistance [1][3].

Strengths: Superior chemical resistance, dual-layer protection, and proprietary curing process. Weaknesses: Potentially higher production costs due to specialized materials and processes.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed a novel coating system for optical fibers that exhibits exceptional resistance to 2-methylpentane and other aliphatic hydrocarbons. Their approach involves a multi-layer coating structure, incorporating fluorinated polymers in the outermost layer. This fluoropolymer-based coating provides excellent chemical resistance while maintaining the necessary flexibility and adhesion properties. Sumitomo's research has shown that their coatings can withstand prolonged exposure to 2-methylpentane without significant degradation of optical or mechanical properties. The company has also implemented a high-speed coating process that allows for efficient production of these chemically resistant fibers, maintaining a balance between performance and cost-effectiveness [2][5].

Strengths: Excellent chemical resistance, multi-layer structure for optimized performance, and efficient production process. Weaknesses: Potential limitations in extreme temperature environments due to fluoropolymer properties.

Innovations in 2-Methylpentane Resistant Materials

Primary coating compositions with improved microbending performance

PatentActiveUS11822117B2

Innovation

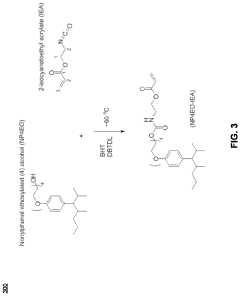

- Development of a curable coating composition incorporating oligomers with internal urethane linkages, formed by reacting a polyol with a diisocyanate compound and capping with a curable functional group, providing a primary coating with desirable mechanical properties such as low Young's modulus and high tear strength to reduce microbending losses and resist stress-induced defects.

Optical fibre comprising a strippable coating and method of stripping one such fibre

PatentInactiveEP1728109A2

Innovation

- An optical fiber with a coating comprising two layers, where the first layer is a reaction product of polyether urethane (meth)acrylate oligomer and monomers, and the second layer is a reaction product of polyether urethane (meth)acrylate and epoxy (meth)acrylate oligomers, along with specific monomers and photoinitiators, allowing for improved adhesion and strippability using a non-toxic solvent like dichloromethane and methanol.

Environmental Impact of Coating Materials

The environmental impact of coating materials used in optical fiber coatings, particularly in relation to 2-methylpentane interactions, is a critical consideration in the telecommunications industry. These coatings play a vital role in protecting optical fibers and enhancing their performance, but their production, use, and disposal can have significant environmental implications.

The manufacturing process of optical fiber coatings often involves the use of various chemicals, including solvents like 2-methylpentane. This hydrocarbon compound, while effective in certain coating formulations, raises concerns about volatile organic compound (VOC) emissions. VOCs contribute to air pollution and can have adverse effects on both human health and the environment. As regulations on VOC emissions become more stringent globally, manufacturers are under pressure to develop low-VOC or VOC-free coating alternatives.

During the operational lifetime of optical fibers, the interaction between 2-methylpentane-based coatings and environmental factors can lead to potential issues. Exposure to moisture, temperature fluctuations, and UV radiation may cause degradation of the coating over time. This degradation can result in the release of microplastics and other pollutants into the surrounding environment, particularly in underwater or underground cable installations.

The disposal of optical fibers at the end of their lifecycle presents another environmental challenge. Many coating materials, including those containing 2-methylpentane, are not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to soil and water contamination, affecting ecosystems and potentially entering the food chain.

To address these environmental concerns, research and development efforts are focusing on eco-friendly coating alternatives. Bio-based materials and water-based coating systems are being explored as potential replacements for traditional solvent-based coatings. These alternatives aim to reduce the carbon footprint of optical fiber production and minimize environmental impact throughout the product lifecycle.

Additionally, advancements in coating technology are targeting improved durability and resistance to environmental factors. By enhancing the longevity of optical fiber coatings, the frequency of replacement and disposal can be reduced, thereby lessening the overall environmental burden.

The telecommunications industry is also exploring recycling and proper disposal methods for optical fibers and their coatings. Developing efficient processes to separate and recycle coating materials could significantly reduce waste and promote a more circular economy approach in the sector.

As environmental regulations continue to evolve, manufacturers and researchers must prioritize the development of coating materials that not only provide excellent protection for optical fibers but also minimize negative environmental impacts. This includes considering the entire lifecycle of the coating, from raw material sourcing to end-of-life management, to create more sustainable solutions for the optical fiber industry.

The manufacturing process of optical fiber coatings often involves the use of various chemicals, including solvents like 2-methylpentane. This hydrocarbon compound, while effective in certain coating formulations, raises concerns about volatile organic compound (VOC) emissions. VOCs contribute to air pollution and can have adverse effects on both human health and the environment. As regulations on VOC emissions become more stringent globally, manufacturers are under pressure to develop low-VOC or VOC-free coating alternatives.

During the operational lifetime of optical fibers, the interaction between 2-methylpentane-based coatings and environmental factors can lead to potential issues. Exposure to moisture, temperature fluctuations, and UV radiation may cause degradation of the coating over time. This degradation can result in the release of microplastics and other pollutants into the surrounding environment, particularly in underwater or underground cable installations.

The disposal of optical fibers at the end of their lifecycle presents another environmental challenge. Many coating materials, including those containing 2-methylpentane, are not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to soil and water contamination, affecting ecosystems and potentially entering the food chain.

To address these environmental concerns, research and development efforts are focusing on eco-friendly coating alternatives. Bio-based materials and water-based coating systems are being explored as potential replacements for traditional solvent-based coatings. These alternatives aim to reduce the carbon footprint of optical fiber production and minimize environmental impact throughout the product lifecycle.

Additionally, advancements in coating technology are targeting improved durability and resistance to environmental factors. By enhancing the longevity of optical fiber coatings, the frequency of replacement and disposal can be reduced, thereby lessening the overall environmental burden.

The telecommunications industry is also exploring recycling and proper disposal methods for optical fibers and their coatings. Developing efficient processes to separate and recycle coating materials could significantly reduce waste and promote a more circular economy approach in the sector.

As environmental regulations continue to evolve, manufacturers and researchers must prioritize the development of coating materials that not only provide excellent protection for optical fibers but also minimize negative environmental impacts. This includes considering the entire lifecycle of the coating, from raw material sourcing to end-of-life management, to create more sustainable solutions for the optical fiber industry.

Standardization of Chemical Resistance Testing

The standardization of chemical resistance testing for optical fiber coatings exposed to 2-methylpentane is crucial for ensuring consistent and reliable performance in various applications. This process involves developing uniform test methods, parameters, and evaluation criteria to assess the interaction between 2-methylpentane and optical fiber coatings across different manufacturers and research institutions.

One of the primary challenges in standardizing these tests is the variability in coating compositions and manufacturing processes used by different optical fiber producers. To address this, a comprehensive set of testing protocols must be established, covering a wide range of coating types and formulations. These protocols should include specific guidelines for sample preparation, exposure conditions, and measurement techniques.

The standardization process typically begins with a thorough review of existing testing methods and industry practices. This review helps identify gaps in current procedures and areas where improvements can be made. Collaborative efforts between industry stakeholders, research institutions, and standards organizations are essential to develop consensus-based testing standards that are both scientifically rigorous and practically applicable.

Key aspects of the standardization process include defining precise exposure conditions for 2-methylpentane, such as concentration, temperature, and duration. These parameters must be carefully controlled to ensure reproducibility of results across different testing facilities. Additionally, standardized methods for measuring and quantifying the effects of 2-methylpentane on optical fiber coatings need to be established, including techniques for assessing changes in mechanical properties, optical performance, and long-term reliability.

Another critical component of the standardization effort is the development of reference materials and calibration standards. These materials serve as benchmarks for comparing test results and validating the accuracy of different testing methods. By providing a common reference point, these standards help ensure consistency in chemical resistance evaluations across the industry.

The standardization process also involves establishing clear criteria for interpreting test results and defining acceptable performance thresholds. This includes developing guidelines for assessing the severity of coating degradation, changes in optical transmission, and potential long-term effects on fiber reliability. Such criteria are essential for making informed decisions about the suitability of specific coating formulations for applications involving exposure to 2-methylpentane.

Implementing standardized chemical resistance testing requires ongoing collaboration and communication within the optical fiber industry. Regular reviews and updates to the testing standards are necessary to keep pace with advancements in coating technologies and evolving application requirements. This continuous improvement process ensures that the standardized tests remain relevant and effective in assessing the interaction between 2-methylpentane and optical fiber coatings.

One of the primary challenges in standardizing these tests is the variability in coating compositions and manufacturing processes used by different optical fiber producers. To address this, a comprehensive set of testing protocols must be established, covering a wide range of coating types and formulations. These protocols should include specific guidelines for sample preparation, exposure conditions, and measurement techniques.

The standardization process typically begins with a thorough review of existing testing methods and industry practices. This review helps identify gaps in current procedures and areas where improvements can be made. Collaborative efforts between industry stakeholders, research institutions, and standards organizations are essential to develop consensus-based testing standards that are both scientifically rigorous and practically applicable.

Key aspects of the standardization process include defining precise exposure conditions for 2-methylpentane, such as concentration, temperature, and duration. These parameters must be carefully controlled to ensure reproducibility of results across different testing facilities. Additionally, standardized methods for measuring and quantifying the effects of 2-methylpentane on optical fiber coatings need to be established, including techniques for assessing changes in mechanical properties, optical performance, and long-term reliability.

Another critical component of the standardization effort is the development of reference materials and calibration standards. These materials serve as benchmarks for comparing test results and validating the accuracy of different testing methods. By providing a common reference point, these standards help ensure consistency in chemical resistance evaluations across the industry.

The standardization process also involves establishing clear criteria for interpreting test results and defining acceptable performance thresholds. This includes developing guidelines for assessing the severity of coating degradation, changes in optical transmission, and potential long-term effects on fiber reliability. Such criteria are essential for making informed decisions about the suitability of specific coating formulations for applications involving exposure to 2-methylpentane.

Implementing standardized chemical resistance testing requires ongoing collaboration and communication within the optical fiber industry. Regular reviews and updates to the testing standards are necessary to keep pace with advancements in coating technologies and evolving application requirements. This continuous improvement process ensures that the standardized tests remain relevant and effective in assessing the interaction between 2-methylpentane and optical fiber coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!