Role of 2-Methylpentane in Nanomaterial Dispersion Technologies

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane in Nanomaterial Dispersion: Background and Objectives

The field of nanomaterial dispersion has seen significant advancements in recent years, with 2-methylpentane emerging as a key player in this technological landscape. This branched alkane, also known as isohexane, has garnered attention for its unique properties that make it particularly suitable for dispersing nanomaterials.

Historically, the dispersion of nanomaterials has been a challenging aspect of nanotechnology, often limiting the practical applications of these materials. The need for effective dispersion techniques has driven research towards finding solvents that can maintain the stability and uniformity of nanomaterial suspensions while preserving their unique properties.

2-Methylpentane, with its low boiling point and non-polar nature, has shown promise in addressing many of the challenges associated with nanomaterial dispersion. Its molecular structure allows for efficient interaction with various nanomaterials, particularly carbon-based ones such as carbon nanotubes and graphene.

The evolution of 2-methylpentane's role in nanomaterial dispersion can be traced back to the early 2000s when researchers began exploring alternative solvents for improving dispersion quality. Initial studies focused on its use in conjunction with other dispersion techniques, such as sonication and surfactant addition.

As research progressed, the unique benefits of 2-methylpentane became increasingly apparent. Its low surface tension and ability to form stable suspensions without significantly altering the nanomaterial properties made it an attractive option for various applications, ranging from electronics to biomedical devices.

The primary objective of current research in this field is to fully understand and optimize the mechanisms by which 2-methylpentane facilitates nanomaterial dispersion. This includes investigating its interactions with different types of nanomaterials, exploring its potential in creating hybrid nanomaterial systems, and developing standardized protocols for its use in industrial applications.

Furthermore, researchers aim to address environmental and safety concerns associated with the use of 2-methylpentane, given its volatile nature. This involves developing methods for its safe handling and exploring potential recycling strategies to minimize waste and environmental impact.

Another key goal is to expand the application scope of 2-methylpentane-based nanomaterial dispersions. This includes exploring its potential in emerging fields such as flexible electronics, energy storage devices, and advanced composite materials. By leveraging the unique properties of both 2-methylpentane and nanomaterials, researchers hope to unlock new possibilities in material science and engineering.

Historically, the dispersion of nanomaterials has been a challenging aspect of nanotechnology, often limiting the practical applications of these materials. The need for effective dispersion techniques has driven research towards finding solvents that can maintain the stability and uniformity of nanomaterial suspensions while preserving their unique properties.

2-Methylpentane, with its low boiling point and non-polar nature, has shown promise in addressing many of the challenges associated with nanomaterial dispersion. Its molecular structure allows for efficient interaction with various nanomaterials, particularly carbon-based ones such as carbon nanotubes and graphene.

The evolution of 2-methylpentane's role in nanomaterial dispersion can be traced back to the early 2000s when researchers began exploring alternative solvents for improving dispersion quality. Initial studies focused on its use in conjunction with other dispersion techniques, such as sonication and surfactant addition.

As research progressed, the unique benefits of 2-methylpentane became increasingly apparent. Its low surface tension and ability to form stable suspensions without significantly altering the nanomaterial properties made it an attractive option for various applications, ranging from electronics to biomedical devices.

The primary objective of current research in this field is to fully understand and optimize the mechanisms by which 2-methylpentane facilitates nanomaterial dispersion. This includes investigating its interactions with different types of nanomaterials, exploring its potential in creating hybrid nanomaterial systems, and developing standardized protocols for its use in industrial applications.

Furthermore, researchers aim to address environmental and safety concerns associated with the use of 2-methylpentane, given its volatile nature. This involves developing methods for its safe handling and exploring potential recycling strategies to minimize waste and environmental impact.

Another key goal is to expand the application scope of 2-methylpentane-based nanomaterial dispersions. This includes exploring its potential in emerging fields such as flexible electronics, energy storage devices, and advanced composite materials. By leveraging the unique properties of both 2-methylpentane and nanomaterials, researchers hope to unlock new possibilities in material science and engineering.

Market Analysis for Nanomaterial Dispersion Technologies

The market for nanomaterial dispersion technologies has been experiencing significant growth in recent years, driven by the increasing demand for advanced materials across various industries. The global nanomaterial market size was valued at approximately $8.5 billion in 2020 and is projected to reach $22.3 billion by 2025, growing at a CAGR of 21.1% during the forecast period.

The adoption of nanomaterial dispersion technologies is particularly prominent in sectors such as electronics, healthcare, energy, and automotive. In the electronics industry, nanomaterials are used to enhance the performance of semiconductors, displays, and energy storage devices. The healthcare sector utilizes nanomaterials for drug delivery systems, diagnostic tools, and medical imaging. The energy sector benefits from nanomaterials in solar cells, fuel cells, and energy storage applications.

2-Methylpentane, as a dispersing agent for nanomaterials, plays a crucial role in improving the stability and uniformity of nanoparticle dispersions. This compound has gained traction in the market due to its ability to enhance the performance of nanomaterials in various applications. The demand for 2-methylpentane in nanomaterial dispersion technologies is expected to grow in parallel with the overall nanomaterial market.

Key market drivers for nanomaterial dispersion technologies include the increasing focus on miniaturization in electronics, the growing need for efficient drug delivery systems in healthcare, and the push for improved energy storage solutions. Additionally, the automotive industry's shift towards lightweight materials and electric vehicles is creating new opportunities for nanomaterial applications.

However, the market also faces challenges such as high production costs, regulatory hurdles, and concerns about the environmental and health impacts of nanomaterials. These factors may hinder the growth of the market to some extent. Nevertheless, ongoing research and development efforts are addressing these challenges, potentially opening up new avenues for market expansion.

Geographically, North America and Europe are the leading markets for nanomaterial dispersion technologies, owing to their advanced research infrastructure and strong presence of key industry players. Asia-Pacific is emerging as a rapidly growing market, driven by increasing industrialization, government initiatives, and rising investments in nanotechnology research.

In conclusion, the market for nanomaterial dispersion technologies, including those utilizing 2-methylpentane, shows promising growth potential. As industries continue to seek innovative solutions for improved performance and efficiency, the demand for advanced nanomaterial dispersion technologies is expected to rise, creating opportunities for both established players and new entrants in the market.

The adoption of nanomaterial dispersion technologies is particularly prominent in sectors such as electronics, healthcare, energy, and automotive. In the electronics industry, nanomaterials are used to enhance the performance of semiconductors, displays, and energy storage devices. The healthcare sector utilizes nanomaterials for drug delivery systems, diagnostic tools, and medical imaging. The energy sector benefits from nanomaterials in solar cells, fuel cells, and energy storage applications.

2-Methylpentane, as a dispersing agent for nanomaterials, plays a crucial role in improving the stability and uniformity of nanoparticle dispersions. This compound has gained traction in the market due to its ability to enhance the performance of nanomaterials in various applications. The demand for 2-methylpentane in nanomaterial dispersion technologies is expected to grow in parallel with the overall nanomaterial market.

Key market drivers for nanomaterial dispersion technologies include the increasing focus on miniaturization in electronics, the growing need for efficient drug delivery systems in healthcare, and the push for improved energy storage solutions. Additionally, the automotive industry's shift towards lightweight materials and electric vehicles is creating new opportunities for nanomaterial applications.

However, the market also faces challenges such as high production costs, regulatory hurdles, and concerns about the environmental and health impacts of nanomaterials. These factors may hinder the growth of the market to some extent. Nevertheless, ongoing research and development efforts are addressing these challenges, potentially opening up new avenues for market expansion.

Geographically, North America and Europe are the leading markets for nanomaterial dispersion technologies, owing to their advanced research infrastructure and strong presence of key industry players. Asia-Pacific is emerging as a rapidly growing market, driven by increasing industrialization, government initiatives, and rising investments in nanotechnology research.

In conclusion, the market for nanomaterial dispersion technologies, including those utilizing 2-methylpentane, shows promising growth potential. As industries continue to seek innovative solutions for improved performance and efficiency, the demand for advanced nanomaterial dispersion technologies is expected to rise, creating opportunities for both established players and new entrants in the market.

Current Challenges in Nanomaterial Dispersion

Despite significant advancements in nanomaterial dispersion technologies, several challenges persist in achieving stable and uniform dispersions of nanoparticles in various media. One of the primary obstacles is the strong tendency of nanoparticles to agglomerate due to their high surface energy and van der Waals forces. This agglomeration can significantly alter the unique properties of nanomaterials, reducing their effectiveness in applications ranging from electronics to biomedicine.

Another major challenge is the lack of universal dispersion methods applicable across different types of nanomaterials and dispersion media. The diversity of nanomaterial compositions, shapes, and sizes necessitates tailored approaches, making it difficult to develop standardized protocols. This variability also complicates the scaling up of laboratory-level dispersions to industrial production volumes.

The stability of nanomaterial dispersions over time remains a critical issue. Many dispersions exhibit sedimentation, flocculation, or phase separation during storage or under varying environmental conditions. This instability not only affects the shelf life of nanomaterial-based products but also raises concerns about their long-term performance and reliability in various applications.

Environmental and health concerns pose additional challenges in nanomaterial dispersion technologies. The potential release of nanoparticles during processing or application raises questions about their environmental impact and human health risks. Developing eco-friendly dispersion methods and ensuring the safe handling of nanomaterials throughout their lifecycle are ongoing challenges that require interdisciplinary approaches.

The characterization of nanomaterial dispersions presents its own set of difficulties. Accurate measurement of particle size distribution, zeta potential, and dispersion quality in complex media often requires sophisticated analytical techniques. The dynamic nature of dispersions and the potential for artifacts during sample preparation further complicate reliable characterization.

In the context of 2-methylpentane's role in nanomaterial dispersion, specific challenges arise related to its effectiveness as a dispersing agent across different nanomaterial types. While it shows promise for certain applications, its limited solubility in water and potential volatility may restrict its use in aqueous systems or high-temperature processes. Balancing the dispersing efficiency of 2-methylpentane with environmental and safety considerations remains an area of active research and development.

Another major challenge is the lack of universal dispersion methods applicable across different types of nanomaterials and dispersion media. The diversity of nanomaterial compositions, shapes, and sizes necessitates tailored approaches, making it difficult to develop standardized protocols. This variability also complicates the scaling up of laboratory-level dispersions to industrial production volumes.

The stability of nanomaterial dispersions over time remains a critical issue. Many dispersions exhibit sedimentation, flocculation, or phase separation during storage or under varying environmental conditions. This instability not only affects the shelf life of nanomaterial-based products but also raises concerns about their long-term performance and reliability in various applications.

Environmental and health concerns pose additional challenges in nanomaterial dispersion technologies. The potential release of nanoparticles during processing or application raises questions about their environmental impact and human health risks. Developing eco-friendly dispersion methods and ensuring the safe handling of nanomaterials throughout their lifecycle are ongoing challenges that require interdisciplinary approaches.

The characterization of nanomaterial dispersions presents its own set of difficulties. Accurate measurement of particle size distribution, zeta potential, and dispersion quality in complex media often requires sophisticated analytical techniques. The dynamic nature of dispersions and the potential for artifacts during sample preparation further complicate reliable characterization.

In the context of 2-methylpentane's role in nanomaterial dispersion, specific challenges arise related to its effectiveness as a dispersing agent across different nanomaterial types. While it shows promise for certain applications, its limited solubility in water and potential volatility may restrict its use in aqueous systems or high-temperature processes. Balancing the dispersing efficiency of 2-methylpentane with environmental and safety considerations remains an area of active research and development.

Existing 2-Methylpentane-based Dispersion Solutions

01 Synthesis and purification of 2-methylpentane

Methods for synthesizing and purifying 2-methylpentane, including various chemical reactions and separation techniques. These processes aim to produce high-purity 2-methylpentane for use in dispersions and other applications.- Synthesis and purification of 2-methylpentane: Methods for synthesizing and purifying 2-methylpentane, including various chemical reactions and separation techniques. These processes aim to produce high-purity 2-methylpentane for use in dispersions and other applications.

- 2-Methylpentane as a solvent in dispersions: Utilization of 2-methylpentane as a solvent in various dispersion formulations. Its properties make it suitable for dispersing different materials, including polymers, pigments, and other substances, enhancing the stability and performance of the dispersions.

- 2-Methylpentane in polymer processing: Applications of 2-methylpentane in polymer processing, including its use as a dispersing agent or solvent in polymer production, modification, and formulation. It can improve the dispersion of additives and enhance the properties of polymer products.

- 2-Methylpentane in chemical reactions and catalysis: Use of 2-methylpentane as a reactant or solvent in various chemical reactions and catalytic processes. Its involvement in these processes can lead to the formation of valuable chemical products or improve reaction efficiency.

- Environmental and safety considerations for 2-methylpentane dispersions: Addressing environmental and safety aspects related to the use of 2-methylpentane in dispersions. This includes developing eco-friendly formulations, reducing volatile organic compound (VOC) emissions, and ensuring safe handling and storage practices.

02 2-Methylpentane as a solvent in dispersions

Utilization of 2-methylpentane as a solvent in various dispersion formulations. Its properties make it suitable for dispersing different materials, including polymers, pigments, and other substances, enhancing the stability and performance of the resulting dispersions.Expand Specific Solutions03 2-Methylpentane in polymer processing

Applications of 2-methylpentane in polymer processing, including its use as a dispersing agent or solvent in polymer formulations. It can improve the dispersion of additives, enhance polymer properties, and facilitate processing techniques.Expand Specific Solutions04 2-Methylpentane in chemical reactions and catalysis

Use of 2-methylpentane as a reactant or solvent in various chemical reactions and catalytic processes. Its involvement in these processes can lead to the formation of new compounds or improve reaction efficiencies.Expand Specific Solutions05 Environmental and safety considerations for 2-methylpentane dispersions

Addressing environmental and safety aspects related to the use of 2-methylpentane in dispersions. This includes developing eco-friendly formulations, handling procedures, and disposal methods to minimize environmental impact and ensure safe usage.Expand Specific Solutions

Key Players in Nanomaterial Dispersion Industry

The role of 2-Methylpentane in nanomaterial dispersion technologies is an emerging field with growing interest. The market is in its early development stage, with potential for significant expansion as nanomaterials gain wider industrial applications. While exact market size is unclear, increasing research activities suggest promising growth. Technologically, it's still evolving, with academic institutions like Northwestern University, Fudan University, and University of Leeds leading research efforts. Companies such as Wanhua Chemical Group and LG Chem are also exploring commercial applications, indicating a gradual shift towards industrial maturity. However, further development is needed to fully realize the potential of 2-Methylpentane in nanomaterial dispersion.

Applied Graphene Materials UK Ltd.

Technical Solution: Applied Graphene Materials UK Ltd. has developed a proprietary dispersion technology that utilizes 2-methylpentane as a key component in their graphene production process. Their method involves a liquid-phase exfoliation technique where graphite is dispersed in a mixture of 2-methylpentane and other carefully selected solvents. This combination allows for efficient exfoliation of graphene layers while maintaining the structural integrity of the nanomaterial. The company has optimized the process to produce high-quality, few-layer graphene with lateral dimensions ranging from 0.5 to 5 micrometers [4]. The resulting graphene dispersions have shown excellent stability and compatibility with various polymer matrices, making them suitable for applications in composites, coatings, and lubricants. Applied Graphene Materials has also developed a range of graphene dispersions specifically tailored for different end-use applications, leveraging the unique properties of 2-methylpentane in their formulations [5].

Strengths: Production of stable graphene dispersions, compatibility with various polymer matrices, tailored formulations for specific applications. Weaknesses: Limited scalability compared to larger chemical companies, potential cost concerns for high-volume production.

Air Products & Chemicals, Inc.

Technical Solution: Air Products & Chemicals, Inc. has developed an innovative approach to utilizing 2-methylpentane in nanomaterial dispersion technologies, particularly focusing on carbon nanotubes (CNTs) and graphene. Their method involves using 2-methylpentane as a co-solvent in a supercritical fluid exfoliation process. By combining 2-methylpentane with supercritical carbon dioxide, they have created a hybrid solvent system that effectively disperses and exfoliates nanomaterials while minimizing damage to their structure. This technique has shown to produce high-quality CNTs and graphene with improved yield and purity compared to conventional liquid-phase exfoliation methods [6]. The company has also developed specialized equipment for this process, allowing for continuous production of nanomaterial dispersions. Additionally, Air Products has explored the use of 2-methylpentane-based dispersions in the development of advanced gas separation membranes and electrodes for fuel cells [7].

Strengths: Efficient exfoliation process, high-quality nanomaterial production, potential for continuous manufacturing. Weaknesses: High initial equipment costs, complexity of supercritical fluid processes, potential safety concerns with pressurized systems.

Core Innovations in 2-Methylpentane Dispersion Technology

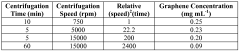

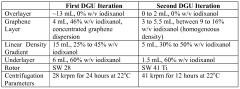

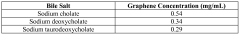

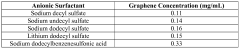

Sorting two-dimensional nanomaterials by thickness

PatentWO2011020035A2

Innovation

- The use of surface active components to create stable dispersions of two-dimensional nanomaterials in water, allowing for differential buoyant densities through density gradient ultracentrifugation, enabling effective separation and recovery of nanomaterials by thickness, without chemical modification or oxidation.

dispersions

PatentWO2021005368A1

Innovation

- A method involving the creation of a dispersing medium with a non-aqueous solvent and grinding media, applying shear forces to break down agglomerates into smaller particles, and using non-covalent modifications to enhance dispersion stability, such as surfactants and specific solvents like butyl acetate or xylene, to prevent re-agglomeration.

Environmental Impact of 2-Methylpentane in Nanomaterial Processing

The environmental impact of 2-methylpentane in nanomaterial processing is a critical consideration for the sustainable development of nanotechnology. As a solvent widely used in nanomaterial dispersion technologies, 2-methylpentane plays a significant role in the production and application of various nanomaterials. However, its use also raises concerns about potential environmental consequences.

One of the primary environmental issues associated with 2-methylpentane is its volatility. As a highly volatile organic compound (VOC), it can easily evaporate into the atmosphere during nanomaterial processing. This contributes to the formation of ground-level ozone and smog, which can have detrimental effects on air quality and human health. Additionally, the release of VOCs like 2-methylpentane can lead to the depletion of the ozone layer, exacerbating global climate change.

Water pollution is another significant environmental concern related to the use of 2-methylpentane in nanomaterial processing. If not properly managed, this solvent can contaminate water sources through spills or improper disposal. Even small amounts of 2-methylpentane can have harmful effects on aquatic ecosystems, potentially disrupting the balance of marine and freshwater environments.

The persistence of 2-methylpentane in the environment is also a matter of concern. While it is not considered highly persistent, improper handling and disposal can lead to its accumulation in soil and sediments. This can result in long-term environmental impacts, affecting soil quality and potentially entering the food chain through bioaccumulation in plants and animals.

Furthermore, the production and use of 2-methylpentane contribute to the overall carbon footprint of nanomaterial processing. The energy-intensive manufacturing process of this solvent, coupled with its transportation and storage, adds to greenhouse gas emissions. This aspect must be considered when evaluating the life cycle environmental impact of nanomaterials produced using 2-methylpentane-based dispersion technologies.

To mitigate these environmental impacts, researchers and industry professionals are exploring alternative solvents and green chemistry approaches. These include the use of bio-based solvents, supercritical fluids, and water-based dispersion systems. Additionally, improved process engineering and closed-loop recycling systems are being developed to minimize the release of 2-methylpentane into the environment during nanomaterial processing.

Regulatory bodies worldwide are also taking steps to address the environmental concerns associated with 2-methylpentane and similar solvents. Stricter emission controls, waste management protocols, and occupational safety guidelines are being implemented to reduce the environmental footprint of nanomaterial production processes involving such chemicals.

One of the primary environmental issues associated with 2-methylpentane is its volatility. As a highly volatile organic compound (VOC), it can easily evaporate into the atmosphere during nanomaterial processing. This contributes to the formation of ground-level ozone and smog, which can have detrimental effects on air quality and human health. Additionally, the release of VOCs like 2-methylpentane can lead to the depletion of the ozone layer, exacerbating global climate change.

Water pollution is another significant environmental concern related to the use of 2-methylpentane in nanomaterial processing. If not properly managed, this solvent can contaminate water sources through spills or improper disposal. Even small amounts of 2-methylpentane can have harmful effects on aquatic ecosystems, potentially disrupting the balance of marine and freshwater environments.

The persistence of 2-methylpentane in the environment is also a matter of concern. While it is not considered highly persistent, improper handling and disposal can lead to its accumulation in soil and sediments. This can result in long-term environmental impacts, affecting soil quality and potentially entering the food chain through bioaccumulation in plants and animals.

Furthermore, the production and use of 2-methylpentane contribute to the overall carbon footprint of nanomaterial processing. The energy-intensive manufacturing process of this solvent, coupled with its transportation and storage, adds to greenhouse gas emissions. This aspect must be considered when evaluating the life cycle environmental impact of nanomaterials produced using 2-methylpentane-based dispersion technologies.

To mitigate these environmental impacts, researchers and industry professionals are exploring alternative solvents and green chemistry approaches. These include the use of bio-based solvents, supercritical fluids, and water-based dispersion systems. Additionally, improved process engineering and closed-loop recycling systems are being developed to minimize the release of 2-methylpentane into the environment during nanomaterial processing.

Regulatory bodies worldwide are also taking steps to address the environmental concerns associated with 2-methylpentane and similar solvents. Stricter emission controls, waste management protocols, and occupational safety guidelines are being implemented to reduce the environmental footprint of nanomaterial production processes involving such chemicals.

Scalability and Industrial Application Prospects

The scalability and industrial application prospects of 2-methylpentane in nanomaterial dispersion technologies are promising, with significant potential for widespread adoption across various sectors. The unique properties of 2-methylpentane, including its low boiling point and excellent solvency, make it an attractive option for large-scale nanomaterial dispersion processes.

In terms of scalability, 2-methylpentane offers several advantages that facilitate its integration into industrial-scale operations. Its low viscosity and high volatility allow for efficient mixing and dispersion of nanomaterials, reducing processing times and energy requirements. This characteristic is particularly beneficial in continuous flow systems, where rapid and uniform dispersion is crucial for maintaining product quality and consistency.

The industrial applications of 2-methylpentane in nanomaterial dispersion span a wide range of sectors. In the electronics industry, it shows great promise for the production of conductive inks and coatings, enabling the manufacture of flexible and printed electronics at scale. The automotive sector can leverage this technology for the development of advanced composite materials, enhancing vehicle performance and fuel efficiency.

Furthermore, the use of 2-methylpentane in nanomaterial dispersion technologies presents opportunities in the field of energy storage. Its ability to create stable dispersions of nanomaterials can contribute to the development of high-performance battery electrodes and supercapacitors, potentially revolutionizing energy storage solutions for both portable electronics and grid-scale applications.

The construction industry stands to benefit from the scalability of 2-methylpentane-based nanomaterial dispersions in the production of advanced concrete formulations. These materials can exhibit enhanced strength, durability, and self-healing properties, leading to more resilient and sustainable infrastructure.

However, the widespread industrial adoption of this technology faces certain challenges. Environmental and safety considerations must be addressed, as 2-methylpentane is a volatile organic compound. Developing closed-loop systems and implementing effective solvent recovery processes will be crucial for minimizing environmental impact and ensuring regulatory compliance.

Economic factors also play a role in the scalability of this technology. While the initial investment in specialized equipment and processes may be substantial, the long-term benefits in terms of improved product performance and manufacturing efficiency could justify the costs for many industries.

In conclusion, the scalability and industrial application prospects of 2-methylpentane in nanomaterial dispersion technologies are significant. With continued research and development focused on optimizing processes and addressing environmental concerns, this technology has the potential to transform various industrial sectors, driving innovation and improving product performance across a wide range of applications.

In terms of scalability, 2-methylpentane offers several advantages that facilitate its integration into industrial-scale operations. Its low viscosity and high volatility allow for efficient mixing and dispersion of nanomaterials, reducing processing times and energy requirements. This characteristic is particularly beneficial in continuous flow systems, where rapid and uniform dispersion is crucial for maintaining product quality and consistency.

The industrial applications of 2-methylpentane in nanomaterial dispersion span a wide range of sectors. In the electronics industry, it shows great promise for the production of conductive inks and coatings, enabling the manufacture of flexible and printed electronics at scale. The automotive sector can leverage this technology for the development of advanced composite materials, enhancing vehicle performance and fuel efficiency.

Furthermore, the use of 2-methylpentane in nanomaterial dispersion technologies presents opportunities in the field of energy storage. Its ability to create stable dispersions of nanomaterials can contribute to the development of high-performance battery electrodes and supercapacitors, potentially revolutionizing energy storage solutions for both portable electronics and grid-scale applications.

The construction industry stands to benefit from the scalability of 2-methylpentane-based nanomaterial dispersions in the production of advanced concrete formulations. These materials can exhibit enhanced strength, durability, and self-healing properties, leading to more resilient and sustainable infrastructure.

However, the widespread industrial adoption of this technology faces certain challenges. Environmental and safety considerations must be addressed, as 2-methylpentane is a volatile organic compound. Developing closed-loop systems and implementing effective solvent recovery processes will be crucial for minimizing environmental impact and ensuring regulatory compliance.

Economic factors also play a role in the scalability of this technology. While the initial investment in specialized equipment and processes may be substantial, the long-term benefits in terms of improved product performance and manufacturing efficiency could justify the costs for many industries.

In conclusion, the scalability and industrial application prospects of 2-methylpentane in nanomaterial dispersion technologies are significant. With continued research and development focused on optimizing processes and addressing environmental concerns, this technology has the potential to transform various industrial sectors, driving innovation and improving product performance across a wide range of applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!