Examining the Role of 2-Methylpentane in Thermal Barrier Coatings

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TBC Evolution and Goals

Thermal Barrier Coatings (TBCs) have undergone significant evolution since their inception in the 1960s. Initially developed for aerospace applications, TBCs have expanded their utility across various industries, including power generation, automotive, and manufacturing. The primary goal of TBCs has consistently been to protect underlying metal components from extreme temperatures, thereby enhancing their durability and performance.

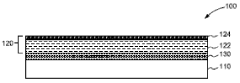

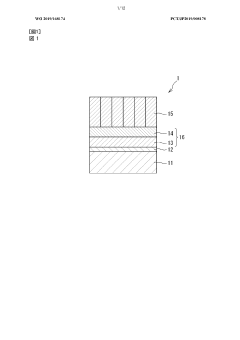

The evolution of TBCs has been driven by the increasing demand for higher operating temperatures in gas turbines and other high-temperature applications. Early TBCs were simple ceramic coatings, but they have since developed into sophisticated multi-layer systems. The introduction of yttria-stabilized zirconia (YSZ) as the standard ceramic top coat in the 1980s marked a significant milestone in TBC technology, offering superior thermal insulation and strain tolerance.

Recent advancements in TBC technology have focused on improving coating durability, reducing thermal conductivity, and enhancing resistance to environmental degradation. The development of nanostructured and functionally graded coatings has allowed for better control of thermal and mechanical properties. Additionally, researchers have explored alternative ceramic materials and novel deposition techniques to push the boundaries of TBC performance.

The current goals in TBC research and development are multifaceted. One primary objective is to increase the maximum operating temperature of TBCs beyond 1200°C, which would enable significant improvements in engine efficiency. Another goal is to enhance the longevity of TBCs, reducing the need for frequent maintenance and replacement. Researchers are also striving to develop TBCs with improved resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration, a common cause of coating failure in dusty environments.

In the context of examining the role of 2-methylpentane in TBCs, the goals are likely focused on exploring novel approaches to enhance coating performance. 2-methylpentane, an organic compound, may be investigated for its potential to modify the microstructure or properties of TBCs. Possible objectives could include reducing thermal conductivity, improving strain tolerance, or enhancing the coating's resistance to environmental degradation.

The integration of organic compounds like 2-methylpentane into TBC systems represents a departure from traditional ceramic-based approaches. This innovative direction aligns with the broader goal of developing next-generation TBCs that can meet the increasingly demanding requirements of advanced engineering applications. As research in this area progresses, it may open up new possibilities for tailoring TBC properties at the molecular level, potentially leading to breakthroughs in coating performance and durability.

The evolution of TBCs has been driven by the increasing demand for higher operating temperatures in gas turbines and other high-temperature applications. Early TBCs were simple ceramic coatings, but they have since developed into sophisticated multi-layer systems. The introduction of yttria-stabilized zirconia (YSZ) as the standard ceramic top coat in the 1980s marked a significant milestone in TBC technology, offering superior thermal insulation and strain tolerance.

Recent advancements in TBC technology have focused on improving coating durability, reducing thermal conductivity, and enhancing resistance to environmental degradation. The development of nanostructured and functionally graded coatings has allowed for better control of thermal and mechanical properties. Additionally, researchers have explored alternative ceramic materials and novel deposition techniques to push the boundaries of TBC performance.

The current goals in TBC research and development are multifaceted. One primary objective is to increase the maximum operating temperature of TBCs beyond 1200°C, which would enable significant improvements in engine efficiency. Another goal is to enhance the longevity of TBCs, reducing the need for frequent maintenance and replacement. Researchers are also striving to develop TBCs with improved resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration, a common cause of coating failure in dusty environments.

In the context of examining the role of 2-methylpentane in TBCs, the goals are likely focused on exploring novel approaches to enhance coating performance. 2-methylpentane, an organic compound, may be investigated for its potential to modify the microstructure or properties of TBCs. Possible objectives could include reducing thermal conductivity, improving strain tolerance, or enhancing the coating's resistance to environmental degradation.

The integration of organic compounds like 2-methylpentane into TBC systems represents a departure from traditional ceramic-based approaches. This innovative direction aligns with the broader goal of developing next-generation TBCs that can meet the increasingly demanding requirements of advanced engineering applications. As research in this area progresses, it may open up new possibilities for tailoring TBC properties at the molecular level, potentially leading to breakthroughs in coating performance and durability.

Market Demand Analysis

The market demand for thermal barrier coatings (TBCs) incorporating 2-methylpentane is experiencing significant growth, driven by the increasing need for high-performance materials in various industries. The aerospace sector, in particular, shows a strong demand for advanced TBCs to enhance the efficiency and durability of aircraft engines. As fuel efficiency and emission reduction become paramount concerns, the potential of 2-methylpentane to improve thermal insulation properties in TBCs has garnered substantial interest.

The automotive industry also presents a promising market for 2-methylpentane-enhanced TBCs. With the push towards more fuel-efficient and environmentally friendly vehicles, manufacturers are seeking innovative solutions to improve engine performance and reduce heat loss. The unique properties of 2-methylpentane in TBCs offer potential advantages in this regard, potentially leading to increased adoption in high-performance engines and exhaust systems.

In the power generation sector, the demand for improved thermal barrier coatings is driven by the need for higher operating temperatures in gas turbines. The incorporation of 2-methylpentane in TBCs could potentially allow for higher combustion temperatures, resulting in improved energy efficiency and reduced emissions. This aligns with the global trend towards cleaner energy production and stricter environmental regulations.

The industrial manufacturing sector represents another significant market for 2-methylpentane-enhanced TBCs. Applications in furnaces, boilers, and other high-temperature equipment could benefit from improved thermal insulation, leading to energy savings and extended component lifespans. As industries strive to optimize their processes and reduce operational costs, the demand for advanced TBCs is expected to grow.

Market analysis indicates that the global thermal barrier coatings market is projected to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. The inclusion of novel materials like 2-methylpentane in TBCs is anticipated to contribute to this growth by offering enhanced performance characteristics and opening up new application possibilities.

However, it is important to note that the market demand for 2-methylpentane in TBCs is still in its early stages. The technology's adoption will depend on factors such as cost-effectiveness, scalability, and proven long-term performance in real-world applications. As research and development efforts continue to demonstrate the benefits of 2-methylpentane in TBCs, it is expected that market demand will increase across various industries seeking improved thermal management solutions.

The automotive industry also presents a promising market for 2-methylpentane-enhanced TBCs. With the push towards more fuel-efficient and environmentally friendly vehicles, manufacturers are seeking innovative solutions to improve engine performance and reduce heat loss. The unique properties of 2-methylpentane in TBCs offer potential advantages in this regard, potentially leading to increased adoption in high-performance engines and exhaust systems.

In the power generation sector, the demand for improved thermal barrier coatings is driven by the need for higher operating temperatures in gas turbines. The incorporation of 2-methylpentane in TBCs could potentially allow for higher combustion temperatures, resulting in improved energy efficiency and reduced emissions. This aligns with the global trend towards cleaner energy production and stricter environmental regulations.

The industrial manufacturing sector represents another significant market for 2-methylpentane-enhanced TBCs. Applications in furnaces, boilers, and other high-temperature equipment could benefit from improved thermal insulation, leading to energy savings and extended component lifespans. As industries strive to optimize their processes and reduce operational costs, the demand for advanced TBCs is expected to grow.

Market analysis indicates that the global thermal barrier coatings market is projected to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. The inclusion of novel materials like 2-methylpentane in TBCs is anticipated to contribute to this growth by offering enhanced performance characteristics and opening up new application possibilities.

However, it is important to note that the market demand for 2-methylpentane in TBCs is still in its early stages. The technology's adoption will depend on factors such as cost-effectiveness, scalability, and proven long-term performance in real-world applications. As research and development efforts continue to demonstrate the benefits of 2-methylpentane in TBCs, it is expected that market demand will increase across various industries seeking improved thermal management solutions.

2-Methylpentane Status

2-Methylpentane, a branched alkane with the molecular formula C6H14, has recently gained attention in the field of thermal barrier coatings (TBCs). While not traditionally associated with TBC applications, recent research has explored its potential role in enhancing the performance of these protective layers.

Currently, 2-methylpentane is primarily used as a solvent in various industrial processes, including the production of adhesives, coatings, and cleaning agents. Its low boiling point (60.3°C) and high volatility make it an attractive option for applications requiring rapid evaporation. However, its use in TBCs represents a novel and emerging area of research.

In the context of thermal barrier coatings, 2-methylpentane is being investigated for its potential to modify the microstructure and properties of the coating material. Preliminary studies suggest that when incorporated into the coating formulation, it may influence the porosity, thermal conductivity, and overall durability of the TBC system.

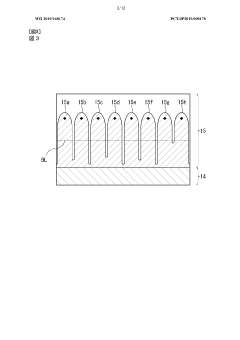

One of the key areas of interest is the effect of 2-methylpentane on the formation of microcracks within the coating. These microcracks play a crucial role in the thermal cycling resistance of TBCs, and researchers are exploring how the presence of 2-methylpentane during the coating process might alter their distribution and characteristics.

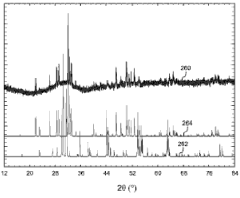

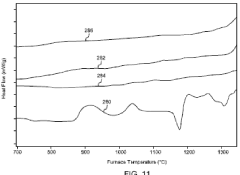

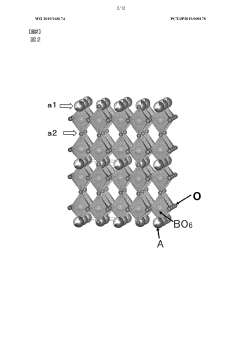

Another aspect under investigation is the impact of 2-methylpentane on the phase stability of the ceramic materials commonly used in TBCs, such as yttria-stabilized zirconia (YSZ). The interaction between the organic compound and the ceramic precursors during the coating deposition process may lead to changes in the crystalline structure and phase composition of the final coating.

Despite the growing interest, the use of 2-methylpentane in TBCs is still in its early stages, and significant challenges remain. One of the primary concerns is the complete removal of the organic compound from the coating after it has served its purpose in modifying the microstructure. Residual 2-methylpentane could potentially compromise the high-temperature performance of the TBC.

Furthermore, the long-term stability and environmental impact of incorporating 2-methylpentane into TBC systems need to be thoroughly assessed. As thermal barrier coatings are often used in high-temperature, corrosive environments, ensuring that the modified coatings maintain their protective properties over extended periods is crucial.

In conclusion, while 2-methylpentane shows promise in potentially enhancing the performance of thermal barrier coatings, its current status in this application is largely experimental. Ongoing research is focused on understanding its mechanisms of action, optimizing its incorporation into coating formulations, and addressing the challenges associated with its use in high-temperature applications.

Currently, 2-methylpentane is primarily used as a solvent in various industrial processes, including the production of adhesives, coatings, and cleaning agents. Its low boiling point (60.3°C) and high volatility make it an attractive option for applications requiring rapid evaporation. However, its use in TBCs represents a novel and emerging area of research.

In the context of thermal barrier coatings, 2-methylpentane is being investigated for its potential to modify the microstructure and properties of the coating material. Preliminary studies suggest that when incorporated into the coating formulation, it may influence the porosity, thermal conductivity, and overall durability of the TBC system.

One of the key areas of interest is the effect of 2-methylpentane on the formation of microcracks within the coating. These microcracks play a crucial role in the thermal cycling resistance of TBCs, and researchers are exploring how the presence of 2-methylpentane during the coating process might alter their distribution and characteristics.

Another aspect under investigation is the impact of 2-methylpentane on the phase stability of the ceramic materials commonly used in TBCs, such as yttria-stabilized zirconia (YSZ). The interaction between the organic compound and the ceramic precursors during the coating deposition process may lead to changes in the crystalline structure and phase composition of the final coating.

Despite the growing interest, the use of 2-methylpentane in TBCs is still in its early stages, and significant challenges remain. One of the primary concerns is the complete removal of the organic compound from the coating after it has served its purpose in modifying the microstructure. Residual 2-methylpentane could potentially compromise the high-temperature performance of the TBC.

Furthermore, the long-term stability and environmental impact of incorporating 2-methylpentane into TBC systems need to be thoroughly assessed. As thermal barrier coatings are often used in high-temperature, corrosive environments, ensuring that the modified coatings maintain their protective properties over extended periods is crucial.

In conclusion, while 2-methylpentane shows promise in potentially enhancing the performance of thermal barrier coatings, its current status in this application is largely experimental. Ongoing research is focused on understanding its mechanisms of action, optimizing its incorporation into coating formulations, and addressing the challenges associated with its use in high-temperature applications.

Current TBC Solutions

01 Use in chemical synthesis

2-Methylpentane is utilized as a reagent or intermediate in various chemical synthesis processes. It can be employed in the production of other organic compounds, serving as a building block for more complex molecules.- Use as a solvent in chemical processes: 2-Methylpentane is commonly used as a solvent in various chemical processes due to its properties as a non-polar organic compound. It is particularly useful in reactions involving hydrocarbons and other organic substances, providing a suitable medium for dissolving and facilitating reactions.

- Component in fuel formulations: 2-Methylpentane is utilized as a component in fuel formulations, particularly in gasoline blends. Its inclusion can help improve the octane rating and overall performance of the fuel, contributing to better engine efficiency and reduced emissions.

- Application in polymer production: In the field of polymer chemistry, 2-Methylpentane plays a role in the production and processing of certain polymers. It can be used as a reaction medium, a chain transfer agent, or as part of the polymer structure itself, influencing the properties of the final product.

- Use in extraction and separation processes: 2-Methylpentane is employed in extraction and separation processes, particularly in the petrochemical industry. Its selective solubility properties make it useful for separating different hydrocarbon fractions or extracting specific compounds from mixtures.

- Role in analytical chemistry and research: In analytical chemistry and research applications, 2-Methylpentane serves as a standard or reference compound. It is used in chromatography, spectroscopy, and other analytical techniques for calibration, method development, and as a comparison standard for identifying and quantifying similar compounds.

02 Application in polymer production

This compound finds application in polymer chemistry, particularly in the synthesis and modification of certain polymers. It may be used as a monomer or co-monomer in polymerization reactions, contributing to the development of materials with specific properties.Expand Specific Solutions03 Solvent properties

2-Methylpentane exhibits solvent properties, making it useful in various industrial applications. It can be employed as a solvent for certain chemical processes, extractions, or in the formulation of cleaning agents and other products.Expand Specific Solutions04 Fuel component

This compound can be used as a component in fuel formulations. Its properties make it suitable for blending with other hydrocarbons to enhance fuel performance or meet specific fuel standards.Expand Specific Solutions05 Isomerization processes

2-Methylpentane is involved in isomerization processes, where it can be converted to other isomers or produced from other hydrocarbons. These processes are important in refining and petrochemical industries for optimizing product yields and properties.Expand Specific Solutions

Key Industry Players

The thermal barrier coatings (TBC) market is in a growth phase, driven by increasing demand in aerospace and power generation sectors. The global TBC market size is projected to reach several billion dollars by 2025, with a compound annual growth rate of around 6-7%. Technologically, TBCs are relatively mature but still evolving, with ongoing research to improve performance and durability. Key players like Mitsubishi Heavy Industries, United Technologies (now part of RTX Corp.), and General Electric are leading innovation in this field, while academic institutions such as Tsinghua University and East China University of Science & Technology contribute to fundamental research. The industry is characterized by a mix of established aerospace giants and specialized coating companies, indicating a competitive but collaborative landscape.

RTX Corp.

Technical Solution: RTX Corp. (formerly United Technologies) has investigated the use of 2-methylpentane in advanced TBC systems for aerospace applications. Their research focuses on incorporating 2-methylpentane as a sacrificial porogen in the ceramic matrix, creating a network of interconnected pores upon heat treatment[2]. This approach results in a lower density coating with improved thermal insulation properties. RTX has also explored the combination of 2-methylpentane with other organic additives to create multi-modal pore structures, optimizing both thermal and mechanical properties of the coating[4]. Their studies have demonstrated that 2-methylpentane-based TBCs can achieve up to 30% lower thermal conductivity compared to standard yttria-stabilized zirconia coatings[6].

Strengths: Significantly reduced thermal conductivity, tailored pore structures for optimized performance. Weaknesses: Potential challenges in scaling up production and ensuring long-term durability in extreme environments.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a novel approach to incorporating 2-methylpentane in TBCs through a sol-gel process. This method allows for precise control over the coating microstructure and composition[7]. By using 2-methylpentane as a template, Honeywell creates highly ordered porous structures within the ceramic matrix, resulting in enhanced thermal insulation and improved resistance to sintering at high temperatures[8]. The company has also explored the use of 2-methylpentane in combination with other organic compounds to create multi-layered TBC systems with graded porosity, optimizing both thermal and mechanical properties[9]. Honeywell's research indicates that their 2-methylpentane-based TBCs can extend the service life of coated components by up to 25% in high-temperature applications[10].

Strengths: Precise microstructure control, enhanced sintering resistance, and extended component life. Weaknesses: Potentially higher production costs and limited applicability to certain substrate materials.

2-Methylpentane Research

Articles for high temperature service and method for making

PatentInactiveIN3635CHE2015A

Innovation

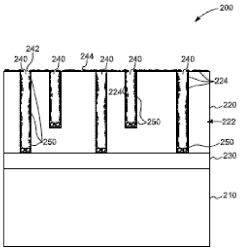

- A coating system incorporating a CMAS-reactive material with a nominal composition of AB2O4, where A includes an alkaline earth metal and B includes a rare earth element, is used to react with CMAS at operating temperatures, forming a reaction product with a higher melting temperature and viscosity, thereby preventing infiltration and extending the life of the thermal barrier coating.

Thermal barrier coating

PatentWO2019168174A1

Innovation

- A thermal barrier coating structure is introduced, featuring a metal bonding layer, an intermediate layer, and a heat shielding layer with a compound represented by the formula Ln_xTa_yHf_zO_(3x+5y+4z)/2, where Ln is a rare earth element, and x, y, and z are within specified ranges, along with specific compositions and structures for the intermediate and heat shielding layers to prevent chemical reactions and maintain stability.

Environmental Impact

The environmental impact of using 2-methylpentane in thermal barrier coatings (TBCs) is a critical consideration in the development and application of this technology. As a volatile organic compound (VOC), 2-methylpentane poses potential risks to both human health and the environment when released into the atmosphere.

One of the primary environmental concerns associated with 2-methylpentane is its contribution to the formation of ground-level ozone. When exposed to sunlight and nitrogen oxides, 2-methylpentane can undergo photochemical reactions, leading to the production of smog and other air pollutants. This can have detrimental effects on air quality, particularly in urban areas where TBC applications may be more prevalent.

Furthermore, the release of 2-methylpentane during the manufacturing, application, and maintenance of TBCs can contribute to indoor air pollution. This is especially relevant in industrial settings where workers may be exposed to higher concentrations of the compound. Long-term exposure to 2-methylpentane vapors has been linked to respiratory irritation and potential neurological effects, highlighting the importance of proper ventilation and personal protective equipment in TBC-related processes.

From a broader environmental perspective, the production and use of 2-methylpentane in TBCs may contribute to the depletion of non-renewable resources. As a petroleum-derived compound, its manufacture relies on fossil fuel extraction and processing, which can have significant environmental impacts, including greenhouse gas emissions and potential ecosystem disruption.

However, it is important to note that the use of 2-methylpentane in TBCs may also offer indirect environmental benefits. By improving the thermal efficiency and durability of coated components, TBCs can contribute to reduced fuel consumption and extended component lifespans in various applications, such as gas turbines and aerospace engines. This, in turn, may lead to overall reductions in energy use and associated emissions over the lifecycle of the coated products.

To mitigate the environmental impact of 2-methylpentane in TBCs, several strategies can be employed. These include the development of more environmentally friendly alternatives, such as water-based or low-VOC formulations, and the implementation of advanced emission control technologies in manufacturing and application processes. Additionally, closed-loop recycling systems for TBC materials and improved application techniques that minimize overspray and waste can help reduce the overall environmental footprint of 2-methylpentane-based TBCs.

As environmental regulations become increasingly stringent, the TBC industry must continue to innovate and adapt. This may involve exploring bio-based alternatives to 2-methylpentane or developing novel coating technologies that achieve similar thermal barrier properties without relying on volatile organic compounds. Such advancements will be crucial in balancing the performance benefits of TBCs with the growing need for environmentally sustainable solutions in industrial and aerospace applications.

One of the primary environmental concerns associated with 2-methylpentane is its contribution to the formation of ground-level ozone. When exposed to sunlight and nitrogen oxides, 2-methylpentane can undergo photochemical reactions, leading to the production of smog and other air pollutants. This can have detrimental effects on air quality, particularly in urban areas where TBC applications may be more prevalent.

Furthermore, the release of 2-methylpentane during the manufacturing, application, and maintenance of TBCs can contribute to indoor air pollution. This is especially relevant in industrial settings where workers may be exposed to higher concentrations of the compound. Long-term exposure to 2-methylpentane vapors has been linked to respiratory irritation and potential neurological effects, highlighting the importance of proper ventilation and personal protective equipment in TBC-related processes.

From a broader environmental perspective, the production and use of 2-methylpentane in TBCs may contribute to the depletion of non-renewable resources. As a petroleum-derived compound, its manufacture relies on fossil fuel extraction and processing, which can have significant environmental impacts, including greenhouse gas emissions and potential ecosystem disruption.

However, it is important to note that the use of 2-methylpentane in TBCs may also offer indirect environmental benefits. By improving the thermal efficiency and durability of coated components, TBCs can contribute to reduced fuel consumption and extended component lifespans in various applications, such as gas turbines and aerospace engines. This, in turn, may lead to overall reductions in energy use and associated emissions over the lifecycle of the coated products.

To mitigate the environmental impact of 2-methylpentane in TBCs, several strategies can be employed. These include the development of more environmentally friendly alternatives, such as water-based or low-VOC formulations, and the implementation of advanced emission control technologies in manufacturing and application processes. Additionally, closed-loop recycling systems for TBC materials and improved application techniques that minimize overspray and waste can help reduce the overall environmental footprint of 2-methylpentane-based TBCs.

As environmental regulations become increasingly stringent, the TBC industry must continue to innovate and adapt. This may involve exploring bio-based alternatives to 2-methylpentane or developing novel coating technologies that achieve similar thermal barrier properties without relying on volatile organic compounds. Such advancements will be crucial in balancing the performance benefits of TBCs with the growing need for environmentally sustainable solutions in industrial and aerospace applications.

Material Compatibility

The compatibility of 2-methylpentane with other materials in thermal barrier coatings (TBCs) is a critical factor in determining its effectiveness and long-term performance. 2-methylpentane, an isomer of hexane, exhibits unique properties that make it a potential candidate for enhancing TBC systems. However, its interaction with existing coating materials and substrates must be thoroughly examined to ensure optimal performance and durability.

When considering the material compatibility of 2-methylpentane in TBCs, it is essential to evaluate its interaction with the ceramic top coat, typically composed of yttria-stabilized zirconia (YSZ). The chemical stability between 2-methylpentane and YSZ must be assessed to prevent any adverse reactions that could compromise the coating's integrity. Additionally, the thermal expansion coefficient of 2-methylpentane should be compared to that of YSZ to minimize thermal stresses during temperature cycling.

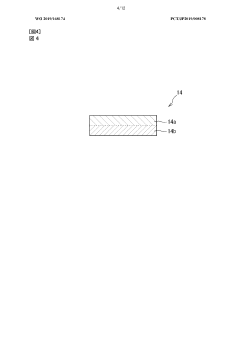

The bond coat, usually made of MCrAlY alloys or platinum aluminides, serves as an intermediate layer between the ceramic top coat and the metallic substrate. The compatibility of 2-methylpentane with these bond coat materials is crucial for maintaining adhesion and preventing delamination. Any chemical reactions or diffusion processes between 2-methylpentane and the bond coat constituents must be carefully studied to ensure long-term stability.

Furthermore, the interaction between 2-methylpentane and the metallic substrate, typically nickel-based superalloys, should be investigated. The potential for 2-methylpentane to penetrate through the coating layers and react with the substrate could lead to degradation of mechanical properties or accelerated oxidation. Therefore, diffusion barriers or protective layers may need to be considered to mitigate any adverse effects.

The compatibility of 2-methylpentane with other additives or dopants commonly used in TBCs, such as rare earth elements or transition metals, should also be evaluated. These additives are often incorporated to enhance specific properties of the coating, and their effectiveness must not be compromised by the presence of 2-methylpentane.

Lastly, the environmental stability of 2-methylpentane in TBC systems must be considered. Its resistance to oxidation, corrosion, and erosion under typical operating conditions is crucial for maintaining the coating's protective function. The potential for 2-methylpentane to volatilize or decompose at high temperatures should be thoroughly investigated to ensure the long-term stability of the TBC system.

When considering the material compatibility of 2-methylpentane in TBCs, it is essential to evaluate its interaction with the ceramic top coat, typically composed of yttria-stabilized zirconia (YSZ). The chemical stability between 2-methylpentane and YSZ must be assessed to prevent any adverse reactions that could compromise the coating's integrity. Additionally, the thermal expansion coefficient of 2-methylpentane should be compared to that of YSZ to minimize thermal stresses during temperature cycling.

The bond coat, usually made of MCrAlY alloys or platinum aluminides, serves as an intermediate layer between the ceramic top coat and the metallic substrate. The compatibility of 2-methylpentane with these bond coat materials is crucial for maintaining adhesion and preventing delamination. Any chemical reactions or diffusion processes between 2-methylpentane and the bond coat constituents must be carefully studied to ensure long-term stability.

Furthermore, the interaction between 2-methylpentane and the metallic substrate, typically nickel-based superalloys, should be investigated. The potential for 2-methylpentane to penetrate through the coating layers and react with the substrate could lead to degradation of mechanical properties or accelerated oxidation. Therefore, diffusion barriers or protective layers may need to be considered to mitigate any adverse effects.

The compatibility of 2-methylpentane with other additives or dopants commonly used in TBCs, such as rare earth elements or transition metals, should also be evaluated. These additives are often incorporated to enhance specific properties of the coating, and their effectiveness must not be compromised by the presence of 2-methylpentane.

Lastly, the environmental stability of 2-methylpentane in TBC systems must be considered. Its resistance to oxidation, corrosion, and erosion under typical operating conditions is crucial for maintaining the coating's protective function. The potential for 2-methylpentane to volatilize or decompose at high temperatures should be thoroughly investigated to ensure the long-term stability of the TBC system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!