How 2-Methylpentane Affects Polymeric Blending Characteristics

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane and Polymer Blending: Background and Objectives

The field of polymer blending has seen significant advancements in recent years, with researchers and industry professionals constantly seeking ways to enhance the properties and performance of polymeric materials. One area of particular interest is the use of additives and solvents to modify the blending characteristics of polymers. In this context, 2-methylpentane has emerged as a compound of interest due to its potential impact on polymer blending processes.

2-Methylpentane, an isomer of hexane, is a branched alkane with the molecular formula C6H14. Its unique structure and properties make it a promising candidate for influencing the behavior of polymer blends. The primary objective of this technical research is to explore and elucidate the effects of 2-methylpentane on the blending characteristics of various polymeric systems.

Understanding the role of 2-methylpentane in polymer blending is crucial for several reasons. Firstly, it can potentially lead to the development of new polymer blends with enhanced properties, such as improved miscibility, altered phase behavior, or modified rheological characteristics. These improvements could have far-reaching implications for industries ranging from packaging to automotive manufacturing.

Secondly, the study of 2-methylpentane's effects on polymer blending can provide valuable insights into the fundamental mechanisms governing polymer-solvent interactions. This knowledge can contribute to the broader understanding of polymer physics and chemistry, potentially leading to new theoretical models and predictive tools for polymer blend design.

The evolution of polymer blending technology has been driven by the need for materials with tailored properties that cannot be achieved through the use of single polymers alone. As the demand for advanced materials continues to grow across various sectors, the importance of understanding and controlling the blending process becomes increasingly critical.

In this context, the investigation of 2-methylpentane's role in polymer blending aligns with the ongoing trend towards more sophisticated and targeted approaches to material design. By focusing on the specific effects of this compound, we aim to contribute to the development of more efficient and effective blending strategies, ultimately leading to the creation of polymeric materials with superior performance characteristics.

This technical research report will delve into the current state of knowledge regarding 2-methylpentane and its interactions with polymeric systems. We will examine the existing literature, experimental data, and theoretical models to provide a comprehensive overview of the subject. Additionally, we will explore the potential applications and implications of using 2-methylpentane in polymer blending processes across various industries.

2-Methylpentane, an isomer of hexane, is a branched alkane with the molecular formula C6H14. Its unique structure and properties make it a promising candidate for influencing the behavior of polymer blends. The primary objective of this technical research is to explore and elucidate the effects of 2-methylpentane on the blending characteristics of various polymeric systems.

Understanding the role of 2-methylpentane in polymer blending is crucial for several reasons. Firstly, it can potentially lead to the development of new polymer blends with enhanced properties, such as improved miscibility, altered phase behavior, or modified rheological characteristics. These improvements could have far-reaching implications for industries ranging from packaging to automotive manufacturing.

Secondly, the study of 2-methylpentane's effects on polymer blending can provide valuable insights into the fundamental mechanisms governing polymer-solvent interactions. This knowledge can contribute to the broader understanding of polymer physics and chemistry, potentially leading to new theoretical models and predictive tools for polymer blend design.

The evolution of polymer blending technology has been driven by the need for materials with tailored properties that cannot be achieved through the use of single polymers alone. As the demand for advanced materials continues to grow across various sectors, the importance of understanding and controlling the blending process becomes increasingly critical.

In this context, the investigation of 2-methylpentane's role in polymer blending aligns with the ongoing trend towards more sophisticated and targeted approaches to material design. By focusing on the specific effects of this compound, we aim to contribute to the development of more efficient and effective blending strategies, ultimately leading to the creation of polymeric materials with superior performance characteristics.

This technical research report will delve into the current state of knowledge regarding 2-methylpentane and its interactions with polymeric systems. We will examine the existing literature, experimental data, and theoretical models to provide a comprehensive overview of the subject. Additionally, we will explore the potential applications and implications of using 2-methylpentane in polymer blending processes across various industries.

Market Analysis for 2-Methylpentane in Polymer Industry

The market for 2-methylpentane in the polymer industry has been experiencing steady growth due to its unique properties and versatile applications. This branched alkane, also known as isohexane, plays a crucial role in enhancing the performance of various polymeric blends. The global demand for 2-methylpentane in polymer applications is primarily driven by the increasing need for high-performance plastics in automotive, packaging, and consumer goods sectors.

In recent years, the automotive industry has emerged as a significant consumer of 2-methylpentane-enhanced polymers. These materials offer improved fuel efficiency through weight reduction while maintaining structural integrity. The packaging industry also shows a growing interest in 2-methylpentane-modified polymers due to their enhanced barrier properties and chemical resistance, which are essential for food and beverage packaging.

The market size for 2-methylpentane in polymer applications is closely tied to the overall growth of the specialty chemicals and advanced materials sectors. Regions with robust manufacturing bases, such as Asia-Pacific and North America, are the primary markets for 2-methylpentane in polymer blending. China, in particular, has seen a surge in demand, driven by its expanding automotive and electronics industries.

Environmental regulations and sustainability concerns are shaping market trends. There is an increasing focus on developing bio-based alternatives to petroleum-derived 2-methylpentane, which could impact market dynamics in the long term. However, the superior performance characteristics of 2-methylpentane in polymer blending continue to sustain its market demand.

The competitive landscape is characterized by a mix of large multinational chemical companies and specialized manufacturers. Key players are investing in research and development to enhance the efficiency of 2-methylpentane in polymer blending and to explore new applications. Collaborations between chemical suppliers and polymer manufacturers are becoming more common, aiming to develop tailored solutions for specific industry needs.

Price volatility of raw materials, particularly crude oil, remains a significant factor influencing the market for 2-methylpentane. Fluctuations in oil prices can impact production costs and, consequently, market growth. However, the value-added nature of 2-methylpentane in polymer applications often justifies its use despite price variations.

Looking ahead, the market for 2-methylpentane in the polymer industry is expected to continue its growth trajectory. Emerging applications in 3D printing materials and advanced composites are likely to open new avenues for market expansion. Additionally, the ongoing trend towards lightweight and high-performance materials in various industries is expected to sustain the demand for 2-methylpentane-enhanced polymers in the foreseeable future.

In recent years, the automotive industry has emerged as a significant consumer of 2-methylpentane-enhanced polymers. These materials offer improved fuel efficiency through weight reduction while maintaining structural integrity. The packaging industry also shows a growing interest in 2-methylpentane-modified polymers due to their enhanced barrier properties and chemical resistance, which are essential for food and beverage packaging.

The market size for 2-methylpentane in polymer applications is closely tied to the overall growth of the specialty chemicals and advanced materials sectors. Regions with robust manufacturing bases, such as Asia-Pacific and North America, are the primary markets for 2-methylpentane in polymer blending. China, in particular, has seen a surge in demand, driven by its expanding automotive and electronics industries.

Environmental regulations and sustainability concerns are shaping market trends. There is an increasing focus on developing bio-based alternatives to petroleum-derived 2-methylpentane, which could impact market dynamics in the long term. However, the superior performance characteristics of 2-methylpentane in polymer blending continue to sustain its market demand.

The competitive landscape is characterized by a mix of large multinational chemical companies and specialized manufacturers. Key players are investing in research and development to enhance the efficiency of 2-methylpentane in polymer blending and to explore new applications. Collaborations between chemical suppliers and polymer manufacturers are becoming more common, aiming to develop tailored solutions for specific industry needs.

Price volatility of raw materials, particularly crude oil, remains a significant factor influencing the market for 2-methylpentane. Fluctuations in oil prices can impact production costs and, consequently, market growth. However, the value-added nature of 2-methylpentane in polymer applications often justifies its use despite price variations.

Looking ahead, the market for 2-methylpentane in the polymer industry is expected to continue its growth trajectory. Emerging applications in 3D printing materials and advanced composites are likely to open new avenues for market expansion. Additionally, the ongoing trend towards lightweight and high-performance materials in various industries is expected to sustain the demand for 2-methylpentane-enhanced polymers in the foreseeable future.

Current Challenges in Polymeric Blending with 2-Methylpentane

The integration of 2-methylpentane into polymeric blending processes presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is the compatibility between 2-methylpentane and various polymer matrices. Due to its non-polar nature, 2-methylpentane often exhibits poor miscibility with polar polymers, leading to phase separation and inconsistent blend properties.

Another major challenge lies in controlling the volatility of 2-methylpentane during the blending process. Its low boiling point (60.3°C) makes it prone to evaporation at typical processing temperatures, potentially altering the intended composition of the polymer blend. This volatility not only affects the final product quality but also raises safety concerns in manufacturing environments.

The impact of 2-methylpentane on the rheological properties of polymer blends is a complex issue that requires careful consideration. Its presence can significantly alter the melt flow behavior of the blend, affecting processability and the ability to achieve desired product characteristics. Researchers are working to develop predictive models that can accurately account for these rheological changes.

Environmental and regulatory challenges also play a crucial role in the use of 2-methylpentane in polymeric blending. As a volatile organic compound (VOC), its emissions are subject to strict regulations in many jurisdictions. This necessitates the development of containment and recovery systems, adding complexity and cost to the manufacturing process.

The long-term stability of polymer blends containing 2-methylpentane is another area of concern. There are questions about how the presence of this compound affects the aging characteristics of the final product, including potential issues with leaching or gradual evaporation over time. This has implications for product durability and performance in various applications.

Achieving uniform dispersion of 2-methylpentane within the polymer matrix remains a technical hurdle. Conventional mixing techniques may not be sufficient to ensure homogeneous distribution, leading to localized variations in properties throughout the blended material. Advanced mixing technologies and compatibilizers are being explored to address this challenge.

Lastly, the scalability of laboratory findings to industrial production presents its own set of challenges. What works well in small-scale experiments may encounter unforeseen difficulties when scaled up to commercial production volumes. This includes issues related to heat management, mixing efficiency, and maintaining consistent quality across large batches.

Another major challenge lies in controlling the volatility of 2-methylpentane during the blending process. Its low boiling point (60.3°C) makes it prone to evaporation at typical processing temperatures, potentially altering the intended composition of the polymer blend. This volatility not only affects the final product quality but also raises safety concerns in manufacturing environments.

The impact of 2-methylpentane on the rheological properties of polymer blends is a complex issue that requires careful consideration. Its presence can significantly alter the melt flow behavior of the blend, affecting processability and the ability to achieve desired product characteristics. Researchers are working to develop predictive models that can accurately account for these rheological changes.

Environmental and regulatory challenges also play a crucial role in the use of 2-methylpentane in polymeric blending. As a volatile organic compound (VOC), its emissions are subject to strict regulations in many jurisdictions. This necessitates the development of containment and recovery systems, adding complexity and cost to the manufacturing process.

The long-term stability of polymer blends containing 2-methylpentane is another area of concern. There are questions about how the presence of this compound affects the aging characteristics of the final product, including potential issues with leaching or gradual evaporation over time. This has implications for product durability and performance in various applications.

Achieving uniform dispersion of 2-methylpentane within the polymer matrix remains a technical hurdle. Conventional mixing techniques may not be sufficient to ensure homogeneous distribution, leading to localized variations in properties throughout the blended material. Advanced mixing technologies and compatibilizers are being explored to address this challenge.

Lastly, the scalability of laboratory findings to industrial production presents its own set of challenges. What works well in small-scale experiments may encounter unforeseen difficulties when scaled up to commercial production volumes. This includes issues related to heat management, mixing efficiency, and maintaining consistent quality across large batches.

Existing Methodologies for 2-Methylpentane Incorporation

01 Polymer blending with 2-methylpentane

2-Methylpentane is used as a blending component in polymer formulations to modify the characteristics of the resulting material. This branched alkane can affect properties such as viscosity, solubility, and thermal behavior of the polymer blend. The incorporation of 2-methylpentane can lead to improved processing and performance characteristics in various polymer applications.- Polymer blending with 2-methylpentane: 2-Methylpentane is used as a blending component in polymer formulations to modify the characteristics of the resulting material. This branched alkane can affect properties such as viscosity, solubility, and thermal behavior of the polymer blend. The incorporation of 2-methylpentane can lead to improved processing and performance characteristics in various polymer applications.

- Impact on mechanical properties: The addition of 2-methylpentane to polymer blends can significantly influence the mechanical properties of the resulting material. It may affect tensile strength, elongation at break, and impact resistance. The concentration and distribution of 2-methylpentane within the polymer matrix play crucial roles in determining these mechanical characteristics, allowing for tailored material properties for specific applications.

- Thermal behavior and stability: 2-Methylpentane's presence in polymer blends can alter the thermal behavior and stability of the material. It may affect the glass transition temperature, melting point, and crystallization behavior of the polymer. The volatility of 2-methylpentane and its interaction with polymer chains can influence the overall thermal properties, potentially leading to changes in processing conditions and end-use performance.

- Compatibility and phase behavior: The compatibility of 2-methylpentane with various polymers and its effect on phase behavior are important considerations in blending. The miscibility of 2-methylpentane with different polymer types can lead to homogeneous or heterogeneous blends, affecting the overall properties and performance of the material. Understanding these interactions is crucial for optimizing blend compositions and achieving desired material characteristics.

- Processing and rheological effects: 2-Methylpentane can significantly impact the processing behavior and rheological properties of polymer blends. It may alter the melt flow characteristics, viscosity, and shear behavior of the material during processing. These effects can influence the ease of processing, molding behavior, and final product quality. Optimizing the concentration and distribution of 2-methylpentane in the blend can lead to improved processability and enhanced product performance.

02 Impact on thermal and mechanical properties

The addition of 2-methylpentane to polymer blends can significantly influence their thermal and mechanical properties. It may affect the glass transition temperature, melting point, and crystallization behavior of the polymers. The presence of 2-methylpentane can also modify the tensile strength, elongation at break, and impact resistance of the resulting material, allowing for tailored performance in specific applications.Expand Specific Solutions03 Solubility and compatibility in polymer systems

2-Methylpentane's solubility and compatibility characteristics play a crucial role in polymer blending. Its branched structure can affect its interaction with different polymer chains, influencing the miscibility and phase behavior of the blend. Understanding these interactions is essential for achieving desired blend properties and preventing phase separation or other undesirable effects in the final product.Expand Specific Solutions04 Processing and rheological effects

The incorporation of 2-methylpentane into polymer blends can have significant effects on processing characteristics and rheological behavior. It may alter the melt flow index, viscosity, and shear thinning behavior of the polymer melt. These changes can impact extrusion, injection molding, and other polymer processing techniques, potentially leading to improved processability or the need for adjusted processing parameters.Expand Specific Solutions05 Applications and performance enhancements

The use of 2-methylpentane in polymer blending can lead to performance enhancements in various applications. It may improve the flexibility, chemical resistance, or weatherability of the final product. These characteristics make 2-methylpentane-containing polymer blends suitable for use in automotive parts, packaging materials, coatings, and other specialized applications where specific property profiles are required.Expand Specific Solutions

Key Players in 2-Methylpentane and Polymer Blend Manufacturing

The competitive landscape for "How 2-Methylpentane Affects Polymeric Blending Characteristics" is in a developing stage, with growing market potential as industries seek improved polymer blending solutions. The market size is expanding due to increased demand for advanced materials in various sectors. Technologically, the field is progressing, with companies like Mitsui Chemicals, BASF, and SABIC leading research efforts. These firms, along with others such as Evonik and Sinopec, are investing in R&D to enhance understanding of 2-methylpentane's effects on polymer blending. The involvement of academic institutions like Université Claude Bernard Lyon 1 and research organizations like CNRS indicates ongoing scientific exploration, suggesting that while advancements are being made, there is still room for innovation and technological maturation in this specific area of polymer science.

BASF Corp.

Technical Solution: BASF has developed a novel approach to enhance polymeric blending characteristics using 2-methylpentane as a key component. Their method involves incorporating 2-methylpentane into polymer blends to act as a compatibilizer, improving the miscibility of otherwise immiscible polymers[1]. This technique allows for the creation of polymer blends with enhanced mechanical properties and improved phase morphology. BASF's research has shown that the addition of 2-methylpentane in small quantities (typically 1-5% by weight) can significantly reduce interfacial tension between polymer phases, resulting in finer dispersion and better overall blend performance[3]. The company has also explored the use of 2-methylpentane as a processing aid, facilitating easier extrusion and molding of complex polymer blends[5].

Strengths: Improved miscibility of polymer blends, enhanced mechanical properties, and better processing characteristics. Weaknesses: Potential volatility of 2-methylpentane during processing, which may require specialized equipment or handling procedures.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a proprietary technology that utilizes 2-methylpentane as a blending agent in their high-performance polymer formulations. Their approach focuses on using 2-methylpentane to modify the interfacial properties of polymer blends, particularly in polyolefin-based systems[2]. SABIC's research has demonstrated that the incorporation of 2-methylpentane can lead to improved dispersion of minor components in polymer blends, resulting in enhanced mechanical properties and better overall performance[4]. The company has also explored the use of 2-methylpentane in conjunction with other additives to create synergistic effects, further optimizing blend characteristics. SABIC's technology has been successfully applied in the development of advanced packaging materials and automotive components, where precise control of blend morphology is crucial[6].

Strengths: Enhanced dispersion of blend components, improved mechanical properties, and versatility in various applications. Weaknesses: Potential cost increase due to the addition of 2-methylpentane, and possible regulatory considerations for certain end-use products.

Critical Patents in 2-Methylpentane-Polymer Blend Technology

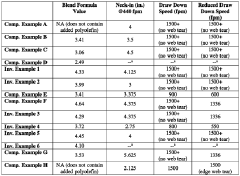

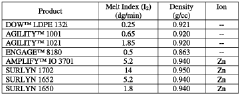

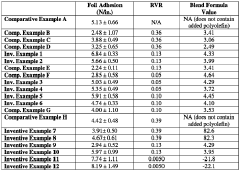

Polymer blends for use in multilayer structure and multilayer structures comprising the same

PatentWO2018094197A1

Innovation

- A polymer blend comprising an ionomer of a copolymer of ethylene and acrylic or methacrylic acid, combined with a polyolefin, specifically designed to meet certain melt index and density criteria, is used as a tie layer to enhance adhesion and facilitate extrusion coating while minimizing issues like draw down and neck-in.

Polyethylene blend compositions and film

PatentInactiveIN1980KOLNP2015A

Innovation

- A polymer blend comprising 5-95 wt% of a first polyethylene copolymer with specific density, melt index, and molecular weight distribution, combined with a second polyethylene copolymer, which together satisfy certain relationships to enhance melt strength, shear thinning behavior, and dart impact properties, resulting in films with improved stiffness-toughness balance and optical properties.

Environmental Impact of 2-Methylpentane in Polymer Processing

The environmental impact of 2-methylpentane in polymer processing is a critical consideration for sustainable manufacturing practices. This volatile organic compound (VOC) is commonly used as a solvent in various polymer blending processes, but its release into the environment can have significant consequences.

2-Methylpentane, when emitted during polymer processing, contributes to the formation of ground-level ozone and smog. These air pollutants can have detrimental effects on human health, particularly respiratory systems, and can damage vegetation. The compound's low boiling point and high vapor pressure increase its potential for atmospheric release, exacerbating its environmental footprint.

In aquatic ecosystems, 2-methylpentane can be toxic to marine life, disrupting the balance of aquatic habitats. Its low water solubility and tendency to float on water surfaces can create a barrier that interferes with oxygen transfer, potentially leading to hypoxic conditions in affected water bodies.

From a global perspective, 2-methylpentane contributes to greenhouse gas emissions, albeit indirectly. While not a direct greenhouse gas itself, its role in the formation of tropospheric ozone, a potent greenhouse gas, links it to climate change concerns.

The polymer industry has been implementing various strategies to mitigate the environmental impact of 2-methylpentane. Closed-loop systems and solvent recovery technologies have been developed to capture and recycle the compound, reducing emissions and waste. Additionally, some manufacturers are exploring alternative, more environmentally friendly solvents or solvent-free processes to eliminate the use of 2-methylpentane altogether.

Regulatory bodies worldwide have imposed strict limits on VOC emissions, including 2-methylpentane, from industrial processes. These regulations have driven innovation in pollution control technologies and process optimization. Many companies are now adopting best available techniques (BAT) to minimize environmental impact while maintaining product quality and production efficiency.

Life cycle assessments (LCAs) of polymer products are increasingly taking into account the environmental impact of solvents like 2-methylpentane. These assessments help manufacturers make informed decisions about material selection and process design, considering the entire life cycle of the product from raw material extraction to end-of-life disposal.

As the polymer industry continues to evolve, there is a growing emphasis on green chemistry principles. Research is ongoing to develop bio-based alternatives to petroleum-derived solvents like 2-methylpentane, which could potentially offer similar performance characteristics with a reduced environmental footprint.

2-Methylpentane, when emitted during polymer processing, contributes to the formation of ground-level ozone and smog. These air pollutants can have detrimental effects on human health, particularly respiratory systems, and can damage vegetation. The compound's low boiling point and high vapor pressure increase its potential for atmospheric release, exacerbating its environmental footprint.

In aquatic ecosystems, 2-methylpentane can be toxic to marine life, disrupting the balance of aquatic habitats. Its low water solubility and tendency to float on water surfaces can create a barrier that interferes with oxygen transfer, potentially leading to hypoxic conditions in affected water bodies.

From a global perspective, 2-methylpentane contributes to greenhouse gas emissions, albeit indirectly. While not a direct greenhouse gas itself, its role in the formation of tropospheric ozone, a potent greenhouse gas, links it to climate change concerns.

The polymer industry has been implementing various strategies to mitigate the environmental impact of 2-methylpentane. Closed-loop systems and solvent recovery technologies have been developed to capture and recycle the compound, reducing emissions and waste. Additionally, some manufacturers are exploring alternative, more environmentally friendly solvents or solvent-free processes to eliminate the use of 2-methylpentane altogether.

Regulatory bodies worldwide have imposed strict limits on VOC emissions, including 2-methylpentane, from industrial processes. These regulations have driven innovation in pollution control technologies and process optimization. Many companies are now adopting best available techniques (BAT) to minimize environmental impact while maintaining product quality and production efficiency.

Life cycle assessments (LCAs) of polymer products are increasingly taking into account the environmental impact of solvents like 2-methylpentane. These assessments help manufacturers make informed decisions about material selection and process design, considering the entire life cycle of the product from raw material extraction to end-of-life disposal.

As the polymer industry continues to evolve, there is a growing emphasis on green chemistry principles. Research is ongoing to develop bio-based alternatives to petroleum-derived solvents like 2-methylpentane, which could potentially offer similar performance characteristics with a reduced environmental footprint.

Regulatory Framework for Solvent Use in Polymer Industry

The regulatory framework for solvent use in the polymer industry is a complex and evolving landscape that significantly impacts the application of 2-Methylpentane in polymeric blending processes. This framework is primarily driven by environmental, health, and safety concerns associated with volatile organic compounds (VOCs) and hazardous air pollutants (HAPs).

In the United States, the Environmental Protection Agency (EPA) regulates solvent use under the Clean Air Act, particularly through the National Emission Standards for Hazardous Air Pollutants (NESHAP) and the New Source Performance Standards (NSPS). These regulations set limits on emissions and require the implementation of Maximum Achievable Control Technology (MACT) for various industrial processes, including polymer manufacturing.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of solvents in polymer production. REACH requires manufacturers and importers to register chemicals and provide safety data, potentially limiting the use of certain solvents based on their environmental and health impacts.

Many countries have adopted similar regulatory frameworks, often modeled after the US or EU systems. For instance, China's Measures for Environmental Management of New Chemical Substances (MEP Order 7) requires registration and risk assessment of new chemicals, including solvents used in polymer blending.

Specific to 2-Methylpentane, its use in polymer blending is subject to regulations governing VOC emissions and workplace exposure limits. The Occupational Safety and Health Administration (OSHA) in the US sets permissible exposure limits (PELs) for workers handling such solvents, while the National Institute for Occupational Safety and Health (NIOSH) provides recommended exposure limits (RELs).

Industry-specific standards, such as those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO), also play a crucial role in defining best practices for solvent use in polymer processing. These standards often incorporate regulatory requirements and provide guidelines for safe and efficient use of solvents like 2-Methylpentane.

As environmental concerns grow, there is an increasing trend towards stricter regulations on solvent use. This has led to the development and adoption of alternative technologies, such as water-based systems, high-solid formulations, and solvent-free processes in polymer blending. Manufacturers using 2-Methylpentane must stay abreast of these regulatory changes and adapt their processes accordingly to ensure compliance and maintain market competitiveness.

In the United States, the Environmental Protection Agency (EPA) regulates solvent use under the Clean Air Act, particularly through the National Emission Standards for Hazardous Air Pollutants (NESHAP) and the New Source Performance Standards (NSPS). These regulations set limits on emissions and require the implementation of Maximum Achievable Control Technology (MACT) for various industrial processes, including polymer manufacturing.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of solvents in polymer production. REACH requires manufacturers and importers to register chemicals and provide safety data, potentially limiting the use of certain solvents based on their environmental and health impacts.

Many countries have adopted similar regulatory frameworks, often modeled after the US or EU systems. For instance, China's Measures for Environmental Management of New Chemical Substances (MEP Order 7) requires registration and risk assessment of new chemicals, including solvents used in polymer blending.

Specific to 2-Methylpentane, its use in polymer blending is subject to regulations governing VOC emissions and workplace exposure limits. The Occupational Safety and Health Administration (OSHA) in the US sets permissible exposure limits (PELs) for workers handling such solvents, while the National Institute for Occupational Safety and Health (NIOSH) provides recommended exposure limits (RELs).

Industry-specific standards, such as those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO), also play a crucial role in defining best practices for solvent use in polymer processing. These standards often incorporate regulatory requirements and provide guidelines for safe and efficient use of solvents like 2-Methylpentane.

As environmental concerns grow, there is an increasing trend towards stricter regulations on solvent use. This has led to the development and adoption of alternative technologies, such as water-based systems, high-solid formulations, and solvent-free processes in polymer blending. Manufacturers using 2-Methylpentane must stay abreast of these regulatory changes and adapt their processes accordingly to ensure compliance and maintain market competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!