How 2-Methylpentane Influences Molecular Weight Distribution in Polymers

JUL 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane and Polymer MWD: Background and Objectives

The study of 2-methylpentane's influence on molecular weight distribution (MWD) in polymers represents a critical area of research in polymer science and engineering. This investigation aims to elucidate the complex relationship between this specific branched alkane and the resulting polymer structures, with far-reaching implications for material properties and industrial applications.

2-Methylpentane, an isomer of hexane, has garnered attention due to its potential as a solvent and modifier in polymerization processes. Its branched structure introduces unique interactions with growing polymer chains, potentially altering the kinetics of polymerization and the final molecular weight distribution. Understanding these effects is crucial for tailoring polymer properties to meet specific performance requirements across various industries.

The historical context of this research dates back to the early developments in polymer science, where the importance of molecular weight distribution in determining material properties was first recognized. As synthetic polymer production evolved, the role of solvents and additives in controlling polymerization became increasingly apparent. The focus on 2-methylpentane emerged from a broader investigation into the effects of branched hydrocarbons on polymer synthesis and structure.

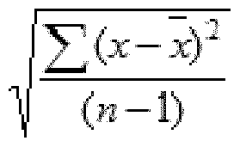

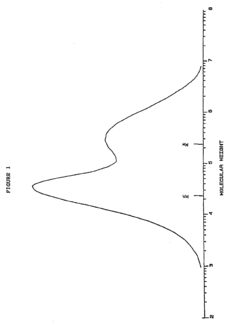

Recent advancements in analytical techniques, such as gel permeation chromatography (GPC) and light scattering methods, have enabled more precise characterization of molecular weight distributions. These tools have paved the way for in-depth studies on the subtle influences of solvents like 2-methylpentane on polymer chain growth and termination processes.

The primary objectives of this technical research are multifaceted. Firstly, it aims to quantify the impact of 2-methylpentane concentration on the breadth and shape of molecular weight distributions in various polymer systems. This includes investigating how the solvent affects the relative proportions of high and low molecular weight fractions within the polymer.

Secondly, the research seeks to elucidate the mechanisms by which 2-methylpentane interacts with growing polymer chains, potentially influencing chain transfer reactions or altering the solubility of polymer segments during synthesis. Understanding these mechanisms is crucial for developing predictive models of polymer growth in the presence of branched alkanes.

Furthermore, this study aims to explore the potential of 2-methylpentane as a tool for tailoring polymer properties. By manipulating molecular weight distributions, it may be possible to fine-tune characteristics such as melt viscosity, mechanical strength, and processability. This could open new avenues for polymer design in applications ranging from packaging materials to high-performance composites.

Ultimately, the insights gained from this research are expected to contribute to the broader field of polymer science, offering new strategies for controlling polymer architecture and properties. The findings may also have significant implications for industrial polymerization processes, potentially leading to more efficient and targeted production methods for specialized polymer materials.

2-Methylpentane, an isomer of hexane, has garnered attention due to its potential as a solvent and modifier in polymerization processes. Its branched structure introduces unique interactions with growing polymer chains, potentially altering the kinetics of polymerization and the final molecular weight distribution. Understanding these effects is crucial for tailoring polymer properties to meet specific performance requirements across various industries.

The historical context of this research dates back to the early developments in polymer science, where the importance of molecular weight distribution in determining material properties was first recognized. As synthetic polymer production evolved, the role of solvents and additives in controlling polymerization became increasingly apparent. The focus on 2-methylpentane emerged from a broader investigation into the effects of branched hydrocarbons on polymer synthesis and structure.

Recent advancements in analytical techniques, such as gel permeation chromatography (GPC) and light scattering methods, have enabled more precise characterization of molecular weight distributions. These tools have paved the way for in-depth studies on the subtle influences of solvents like 2-methylpentane on polymer chain growth and termination processes.

The primary objectives of this technical research are multifaceted. Firstly, it aims to quantify the impact of 2-methylpentane concentration on the breadth and shape of molecular weight distributions in various polymer systems. This includes investigating how the solvent affects the relative proportions of high and low molecular weight fractions within the polymer.

Secondly, the research seeks to elucidate the mechanisms by which 2-methylpentane interacts with growing polymer chains, potentially influencing chain transfer reactions or altering the solubility of polymer segments during synthesis. Understanding these mechanisms is crucial for developing predictive models of polymer growth in the presence of branched alkanes.

Furthermore, this study aims to explore the potential of 2-methylpentane as a tool for tailoring polymer properties. By manipulating molecular weight distributions, it may be possible to fine-tune characteristics such as melt viscosity, mechanical strength, and processability. This could open new avenues for polymer design in applications ranging from packaging materials to high-performance composites.

Ultimately, the insights gained from this research are expected to contribute to the broader field of polymer science, offering new strategies for controlling polymer architecture and properties. The findings may also have significant implications for industrial polymerization processes, potentially leading to more efficient and targeted production methods for specialized polymer materials.

Market Analysis for 2-Methylpentane in Polymer Industry

The market for 2-methylpentane in the polymer industry has been experiencing steady growth due to its unique properties and versatile applications. This branched alkane serves as a valuable solvent and raw material in various polymer manufacturing processes, particularly in the production of polyolefins and specialty polymers. The global demand for 2-methylpentane in polymer applications is primarily driven by the expanding automotive, packaging, and construction industries.

In recent years, the polymer industry has shown an increased focus on tailoring molecular weight distributions to enhance specific material properties. This trend has led to a growing interest in the use of 2-methylpentane as a chain transfer agent and solvent in polymerization processes. Its ability to influence molecular weight distribution offers polymer manufacturers greater control over the final product characteristics, such as mechanical strength, processability, and thermal stability.

The Asia-Pacific region, particularly China and India, represents the largest and fastest-growing market for 2-methylpentane in polymer applications. This growth is attributed to the rapid industrialization, increasing disposable income, and rising demand for high-performance polymers in these countries. North America and Europe follow as significant markets, with a strong emphasis on research and development activities aimed at optimizing polymer properties through molecular weight control.

The automotive sector stands out as a key end-user industry for 2-methylpentane-influenced polymers. The demand for lightweight, durable materials in vehicle manufacturing has led to increased adoption of tailored polymers with specific molecular weight distributions. This trend is expected to continue as automakers strive to meet stringent fuel efficiency and emission standards.

Environmental regulations and sustainability concerns are shaping the market dynamics for 2-methylpentane in the polymer industry. Manufacturers are increasingly focusing on developing eco-friendly production processes and exploring bio-based alternatives. However, the unique properties of 2-methylpentane in molecular weight control continue to make it a preferred choice in many applications.

The market is characterized by a mix of large multinational chemical companies and specialized polymer manufacturers. Key players are investing in research and development to enhance the efficiency of 2-methylpentane in controlling molecular weight distribution and to explore novel applications. Collaborations between industry and academia are also on the rise, aiming to unlock new possibilities in polymer science through the strategic use of 2-methylpentane.

As the polymer industry continues to evolve, the demand for precise control over material properties is expected to drive further growth in the 2-methylpentane market. The compound's role in influencing molecular weight distribution positions it as a critical component in the development of next-generation polymers with enhanced performance characteristics.

In recent years, the polymer industry has shown an increased focus on tailoring molecular weight distributions to enhance specific material properties. This trend has led to a growing interest in the use of 2-methylpentane as a chain transfer agent and solvent in polymerization processes. Its ability to influence molecular weight distribution offers polymer manufacturers greater control over the final product characteristics, such as mechanical strength, processability, and thermal stability.

The Asia-Pacific region, particularly China and India, represents the largest and fastest-growing market for 2-methylpentane in polymer applications. This growth is attributed to the rapid industrialization, increasing disposable income, and rising demand for high-performance polymers in these countries. North America and Europe follow as significant markets, with a strong emphasis on research and development activities aimed at optimizing polymer properties through molecular weight control.

The automotive sector stands out as a key end-user industry for 2-methylpentane-influenced polymers. The demand for lightweight, durable materials in vehicle manufacturing has led to increased adoption of tailored polymers with specific molecular weight distributions. This trend is expected to continue as automakers strive to meet stringent fuel efficiency and emission standards.

Environmental regulations and sustainability concerns are shaping the market dynamics for 2-methylpentane in the polymer industry. Manufacturers are increasingly focusing on developing eco-friendly production processes and exploring bio-based alternatives. However, the unique properties of 2-methylpentane in molecular weight control continue to make it a preferred choice in many applications.

The market is characterized by a mix of large multinational chemical companies and specialized polymer manufacturers. Key players are investing in research and development to enhance the efficiency of 2-methylpentane in controlling molecular weight distribution and to explore novel applications. Collaborations between industry and academia are also on the rise, aiming to unlock new possibilities in polymer science through the strategic use of 2-methylpentane.

As the polymer industry continues to evolve, the demand for precise control over material properties is expected to drive further growth in the 2-methylpentane market. The compound's role in influencing molecular weight distribution positions it as a critical component in the development of next-generation polymers with enhanced performance characteristics.

Current Challenges in Polymer MWD Control

Controlling the molecular weight distribution (MWD) in polymer synthesis remains a significant challenge in the field of polymer science. The introduction of 2-methylpentane as a potential influencing factor adds another layer of complexity to this already intricate process. Current challenges in polymer MWD control stem from various factors, including the inherent nature of polymerization reactions, limitations in existing control mechanisms, and the unpredictable effects of additives like 2-methylpentane.

One of the primary challenges is the difficulty in achieving precise control over the initiation and termination rates of polymerization reactions. These rates directly impact the MWD, and even small fluctuations can lead to significant variations in the final polymer properties. The presence of 2-methylpentane may further complicate this by potentially altering reaction kinetics or serving as a chain transfer agent, thus affecting the growth and termination of polymer chains.

Another critical challenge lies in the limitations of current catalyst systems. While advanced catalysts have improved control over MWD, they often struggle to maintain consistency across different batches or when scaling up production. The interaction between 2-methylpentane and these catalyst systems is not yet fully understood, potentially leading to unpredictable effects on catalyst efficiency and selectivity.

The heterogeneity of polymerization reactions poses another significant hurdle. Local variations in temperature, concentration, and mixing efficiency within the reaction vessel can result in non-uniform growth of polymer chains, leading to broadened MWDs. The addition of 2-methylpentane may exacerbate these issues by introducing additional variables that affect local reaction conditions.

Furthermore, the characterization and real-time monitoring of MWD during polymerization remain challenging. Current analytical techniques often provide only post-reaction data, making it difficult to implement dynamic control strategies. The influence of 2-methylpentane on these analytical methods and the interpretation of results adds another layer of complexity to accurate MWD assessment.

The industry also faces challenges in developing robust mathematical models that can accurately predict and control MWD in the presence of additives like 2-methylpentane. Existing models often struggle to account for the complex interplay of various factors affecting polymer growth and termination, particularly when new variables are introduced.

Lastly, the environmental and safety considerations associated with using additives like 2-methylpentane in polymer production present additional challenges. Ensuring compliance with regulations while maintaining desired MWD control requires careful balancing of process parameters and additive concentrations.

Addressing these challenges requires a multidisciplinary approach, combining advances in catalyst design, reaction engineering, analytical techniques, and computational modeling. Understanding the specific role of 2-methylpentane in influencing MWD will be crucial in developing more precise and reliable control strategies for polymer synthesis.

One of the primary challenges is the difficulty in achieving precise control over the initiation and termination rates of polymerization reactions. These rates directly impact the MWD, and even small fluctuations can lead to significant variations in the final polymer properties. The presence of 2-methylpentane may further complicate this by potentially altering reaction kinetics or serving as a chain transfer agent, thus affecting the growth and termination of polymer chains.

Another critical challenge lies in the limitations of current catalyst systems. While advanced catalysts have improved control over MWD, they often struggle to maintain consistency across different batches or when scaling up production. The interaction between 2-methylpentane and these catalyst systems is not yet fully understood, potentially leading to unpredictable effects on catalyst efficiency and selectivity.

The heterogeneity of polymerization reactions poses another significant hurdle. Local variations in temperature, concentration, and mixing efficiency within the reaction vessel can result in non-uniform growth of polymer chains, leading to broadened MWDs. The addition of 2-methylpentane may exacerbate these issues by introducing additional variables that affect local reaction conditions.

Furthermore, the characterization and real-time monitoring of MWD during polymerization remain challenging. Current analytical techniques often provide only post-reaction data, making it difficult to implement dynamic control strategies. The influence of 2-methylpentane on these analytical methods and the interpretation of results adds another layer of complexity to accurate MWD assessment.

The industry also faces challenges in developing robust mathematical models that can accurately predict and control MWD in the presence of additives like 2-methylpentane. Existing models often struggle to account for the complex interplay of various factors affecting polymer growth and termination, particularly when new variables are introduced.

Lastly, the environmental and safety considerations associated with using additives like 2-methylpentane in polymer production present additional challenges. Ensuring compliance with regulations while maintaining desired MWD control requires careful balancing of process parameters and additive concentrations.

Addressing these challenges requires a multidisciplinary approach, combining advances in catalyst design, reaction engineering, analytical techniques, and computational modeling. Understanding the specific role of 2-methylpentane in influencing MWD will be crucial in developing more precise and reliable control strategies for polymer synthesis.

Existing Methods for MWD Manipulation using 2-Methylpentane

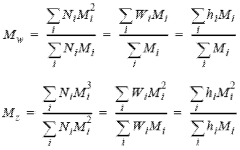

01 Molecular weight distribution analysis methods

Various techniques are used to analyze the molecular weight distribution of 2-methylpentane and related compounds. These methods may include gas chromatography, mass spectrometry, and other analytical techniques to determine the range and distribution of molecular weights in a sample.- Molecular weight distribution analysis methods: Various techniques are used to analyze the molecular weight distribution of 2-methylpentane and related compounds. These methods may include gas chromatography, mass spectrometry, and other analytical techniques that can separate and identify different molecular weight fractions.

- Polymer synthesis involving 2-methylpentane: 2-Methylpentane is used in polymer synthesis processes, where its molecular weight distribution can affect the properties of the resulting polymers. Control of the molecular weight distribution is crucial for achieving desired polymer characteristics.

- Fuel composition and additives: The molecular weight distribution of 2-methylpentane is important in fuel compositions and additives. It can influence fuel properties such as volatility, combustion characteristics, and overall performance in engines.

- Separation and purification processes: Techniques for separating and purifying 2-methylpentane often involve considerations of its molecular weight distribution. These processes may include distillation, extraction, or membrane separation methods to achieve desired purity levels.

- Environmental and safety considerations: The molecular weight distribution of 2-methylpentane is relevant to environmental and safety assessments. This information is used in evaluating potential health impacts, environmental fate, and regulatory compliance for products containing this compound.

02 Polymer synthesis involving 2-methylpentane

2-Methylpentane is used in the synthesis of certain polymers, where its molecular weight distribution can affect the properties of the resulting material. The polymerization process and conditions are optimized to control the molecular weight distribution of the final product.Expand Specific Solutions03 Separation and purification techniques

Methods for separating and purifying 2-methylpentane and related compounds often involve considerations of molecular weight distribution. Techniques such as distillation, chromatography, and membrane separation may be employed to achieve desired molecular weight profiles.Expand Specific Solutions04 Fuel composition and performance

The molecular weight distribution of 2-methylpentane and similar compounds can impact fuel composition and performance. Research focuses on optimizing the distribution to enhance combustion efficiency, reduce emissions, and improve overall fuel quality.Expand Specific Solutions05 Catalytic processes affecting molecular weight distribution

Catalytic processes involving 2-methylpentane can influence its molecular weight distribution. Studies explore various catalysts and reaction conditions to control and modify the molecular weight profile for specific applications in the chemical and petrochemical industries.Expand Specific Solutions

Key Players in Polymer Additives and MWD Control

The competition landscape for studying 2-Methylpentane's influence on molecular weight distribution in polymers is characterized by a mature market with established players. Major petrochemical and chemical companies like ExxonMobil, Dow, SABIC, and LG Chem are at the forefront of this research. The market size is substantial, given the widespread use of polymers across industries. Technologically, the field is well-developed, with companies like Mitsui Chemicals and JSR Corporation leading in polymer science innovations. Research institutions such as Zhejiang University and CNRS also contribute significantly to advancing the understanding of polymer behavior, indicating a collaborative ecosystem between industry and academia in this specialized area of polymer chemistry.

Dow Global Technologies LLC

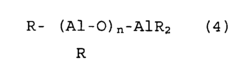

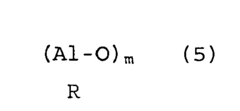

Technical Solution: Dow has pioneered a solution-based polymerization technique that utilizes 2-methylpentane as a solvent and chain transfer agent. Their approach involves a controlled living polymerization process where 2-methylpentane influences the growing polymer chains, resulting in a tailored molecular weight distribution. The company has developed proprietary catalysts that work synergistically with 2-methylpentane to achieve precise control over chain growth and termination[4]. This method allows for the production of polymers with specific end-group functionalities and narrow polydispersity indices. Dow's research has demonstrated that varying the concentration of 2-methylpentane during polymerization can lead to multimodal molecular weight distributions, offering enhanced performance in applications such as adhesives and coatings[5].

Strengths: Highly controlled polymerization process, ability to create multimodal distributions, and versatile end-group functionalization. Weaknesses: May require specialized equipment and careful handling of volatile solvents.

ExxonMobil Chemical Patents, Inc.

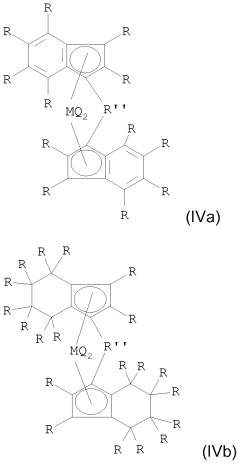

Technical Solution: ExxonMobil has developed a novel approach to control molecular weight distribution in polymers using 2-methylpentane as a comonomer. Their process involves a metallocene catalyst system that incorporates 2-methylpentane into the polymer chain, resulting in a broader molecular weight distribution. This technique allows for precise control over the polymer's properties, including improved processability and enhanced mechanical strength. The company has optimized the polymerization conditions to achieve a balance between incorporation rate and chain transfer, leading to tailored molecular architectures[1][3]. Their research has shown that 2-methylpentane can act as both a comonomer and a chain transfer agent, providing a dual functionality that enhances control over the polymerization process[2].

Strengths: Precise control over molecular weight distribution, improved polymer properties, and versatile polymerization process. Weaknesses: Potential higher production costs due to specialized catalysts and the need for careful process control.

Core Innovations in 2-Methylpentane-based MWD Control

Uncompounded particulate metallocene-produced polyethylene

PatentWO2014016418A1

Innovation

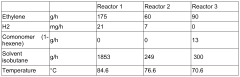

- The development of uncompounded particulate metallocene-produced polyethylene with a multimodal molecular weight distribution, achieved through a process involving three serially connected reactors, where each reactor produces a polyethylene fraction with controlled molecular weight, resulting in a narrow standard deviation to mean ratio, ensuring consistent particle size distribution.

Production of polyethylene having a broad molecular weight distribution

PatentInactiveEP1169362B1

Innovation

- A process using a metallocene catalyst system in two liquid full loop reactors, where ethylene is homopolymerized in the first reactor and copolymerized with an alpha-olefin comonomer in the second reactor, with a hydrogenation catalyst introduced to consume hydrogen and control the molecular weight distribution, producing a bimodal polyethylene with improved mechanical properties.

Environmental Impact of 2-Methylpentane in Polymer Production

The environmental impact of 2-methylpentane in polymer production is a critical consideration for sustainable manufacturing practices. This branched alkane, commonly used as a solvent in polymer synthesis, has both direct and indirect effects on the environment throughout its lifecycle.

In the production phase, the synthesis of 2-methylpentane primarily relies on petroleum refining processes, contributing to greenhouse gas emissions and energy consumption. The extraction and processing of crude oil to obtain this compound result in air and water pollution, as well as potential soil contamination at production sites.

During polymer manufacturing, the use of 2-methylpentane as a solvent can lead to volatile organic compound (VOC) emissions. These emissions contribute to the formation of ground-level ozone and smog, negatively impacting air quality and potentially harming human health and ecosystems. Proper containment and recovery systems are essential to minimize these emissions.

The disposal of waste containing 2-methylpentane poses additional environmental challenges. If not properly managed, it can contaminate soil and groundwater, affecting local ecosystems and potentially entering the food chain. Proper waste treatment and disposal methods are crucial to mitigate these risks.

From a lifecycle perspective, the production and use of 2-methylpentane in polymer manufacturing contribute to the overall carbon footprint of the final product. This impact extends beyond the immediate production phase to include transportation and eventual disposal or recycling of the polymer products.

However, it is important to note that the use of 2-methylpentane in polymer production can also have indirect positive environmental effects. By influencing molecular weight distribution, it can enhance polymer properties, potentially leading to more durable and efficient materials. This may result in products with longer lifespans or improved performance, reducing the need for frequent replacements and ultimately decreasing overall resource consumption and waste generation.

Efforts to mitigate the environmental impact of 2-methylpentane in polymer production focus on several areas. These include developing more efficient synthesis methods to reduce energy consumption and emissions, implementing closed-loop solvent recovery systems to minimize VOC emissions, and exploring bio-based alternatives that could offer a more sustainable source of branched alkanes for polymer production.

In conclusion, while 2-methylpentane plays a valuable role in polymer production, its environmental impact necessitates careful consideration and management throughout the manufacturing process and product lifecycle. Balancing the benefits of improved polymer properties with the need for environmental stewardship remains a key challenge for the industry.

In the production phase, the synthesis of 2-methylpentane primarily relies on petroleum refining processes, contributing to greenhouse gas emissions and energy consumption. The extraction and processing of crude oil to obtain this compound result in air and water pollution, as well as potential soil contamination at production sites.

During polymer manufacturing, the use of 2-methylpentane as a solvent can lead to volatile organic compound (VOC) emissions. These emissions contribute to the formation of ground-level ozone and smog, negatively impacting air quality and potentially harming human health and ecosystems. Proper containment and recovery systems are essential to minimize these emissions.

The disposal of waste containing 2-methylpentane poses additional environmental challenges. If not properly managed, it can contaminate soil and groundwater, affecting local ecosystems and potentially entering the food chain. Proper waste treatment and disposal methods are crucial to mitigate these risks.

From a lifecycle perspective, the production and use of 2-methylpentane in polymer manufacturing contribute to the overall carbon footprint of the final product. This impact extends beyond the immediate production phase to include transportation and eventual disposal or recycling of the polymer products.

However, it is important to note that the use of 2-methylpentane in polymer production can also have indirect positive environmental effects. By influencing molecular weight distribution, it can enhance polymer properties, potentially leading to more durable and efficient materials. This may result in products with longer lifespans or improved performance, reducing the need for frequent replacements and ultimately decreasing overall resource consumption and waste generation.

Efforts to mitigate the environmental impact of 2-methylpentane in polymer production focus on several areas. These include developing more efficient synthesis methods to reduce energy consumption and emissions, implementing closed-loop solvent recovery systems to minimize VOC emissions, and exploring bio-based alternatives that could offer a more sustainable source of branched alkanes for polymer production.

In conclusion, while 2-methylpentane plays a valuable role in polymer production, its environmental impact necessitates careful consideration and management throughout the manufacturing process and product lifecycle. Balancing the benefits of improved polymer properties with the need for environmental stewardship remains a key challenge for the industry.

Regulatory Framework for Polymer Additives

The regulatory framework for polymer additives plays a crucial role in ensuring the safety and quality of polymeric materials, particularly when considering the influence of substances like 2-methylpentane on molecular weight distribution. Regulatory bodies worldwide have established guidelines and standards to govern the use of additives in polymer production, with a focus on protecting human health and the environment.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of polymer additives used in food contact materials. The FDA's Code of Federal Regulations (CFR) Title 21, Part 175-178, provides specific guidelines for additives in polymers intended for food packaging and other food-related applications. These regulations outline permissible substances, usage limits, and testing requirements to ensure the safety of polymer products.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to polymer additives. Under REACH, manufacturers and importers must register substances used in polymer production, including additives like 2-methylpentane, and provide safety data to the European Chemicals Agency (ECHA). This regulation aims to protect human health and the environment by assessing and managing the risks associated with chemical substances.

In addition to regional regulations, international standards such as those developed by the International Organization for Standardization (ISO) provide guidelines for polymer additives. ISO 10093:2020, for instance, specifies methods for the determination of low molecular mass components and polymer additives in plastics. These standards help ensure consistency in testing and evaluation across different jurisdictions.

Specific to molecular weight distribution, regulatory frameworks often require manufacturers to provide detailed information on the impact of additives on polymer properties. This includes data on changes in molecular weight distribution, which can affect the mechanical, thermal, and chemical properties of the final product. Regulatory bodies may require extensive testing and documentation to demonstrate that the use of additives like 2-methylpentane does not compromise the safety or performance of the polymer.

Environmental considerations are also a significant aspect of the regulatory framework for polymer additives. Many countries have implemented regulations to address the environmental impact of polymers and their additives throughout their lifecycle. These regulations may include requirements for biodegradability, recyclability, or restrictions on substances that may pose environmental risks.

As research continues to uncover the complex interactions between additives and polymer structures, regulatory frameworks are evolving to keep pace with new scientific findings. This dynamic regulatory landscape necessitates ongoing compliance efforts from polymer manufacturers and additive suppliers to ensure their products meet the latest safety and environmental standards.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of polymer additives used in food contact materials. The FDA's Code of Federal Regulations (CFR) Title 21, Part 175-178, provides specific guidelines for additives in polymers intended for food packaging and other food-related applications. These regulations outline permissible substances, usage limits, and testing requirements to ensure the safety of polymer products.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to polymer additives. Under REACH, manufacturers and importers must register substances used in polymer production, including additives like 2-methylpentane, and provide safety data to the European Chemicals Agency (ECHA). This regulation aims to protect human health and the environment by assessing and managing the risks associated with chemical substances.

In addition to regional regulations, international standards such as those developed by the International Organization for Standardization (ISO) provide guidelines for polymer additives. ISO 10093:2020, for instance, specifies methods for the determination of low molecular mass components and polymer additives in plastics. These standards help ensure consistency in testing and evaluation across different jurisdictions.

Specific to molecular weight distribution, regulatory frameworks often require manufacturers to provide detailed information on the impact of additives on polymer properties. This includes data on changes in molecular weight distribution, which can affect the mechanical, thermal, and chemical properties of the final product. Regulatory bodies may require extensive testing and documentation to demonstrate that the use of additives like 2-methylpentane does not compromise the safety or performance of the polymer.

Environmental considerations are also a significant aspect of the regulatory framework for polymer additives. Many countries have implemented regulations to address the environmental impact of polymers and their additives throughout their lifecycle. These regulations may include requirements for biodegradability, recyclability, or restrictions on substances that may pose environmental risks.

As research continues to uncover the complex interactions between additives and polymer structures, regulatory frameworks are evolving to keep pace with new scientific findings. This dynamic regulatory landscape necessitates ongoing compliance efforts from polymer manufacturers and additive suppliers to ensure their products meet the latest safety and environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!