Structural Integrity Assessments of 2-Methylpentane-Based Materials

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane Background

2-Methylpentane, also known as isohexane, is a branched alkane with the molecular formula C6H14. This colorless liquid hydrocarbon belongs to the family of isomers of hexane and plays a significant role in various industrial applications. Its unique structural properties make it an interesting subject for materials science research, particularly in the context of structural integrity assessments.

The chemical structure of 2-methylpentane consists of a five-carbon chain with a methyl group attached to the second carbon atom. This branching configuration imparts distinct physical and chemical properties to the compound, setting it apart from its linear counterpart, n-hexane. The presence of the methyl branch affects the molecule's overall shape, influencing its behavior in different environments and its potential as a base material for various applications.

2-Methylpentane is primarily derived from petroleum through fractional distillation and subsequent isomerization processes. Its production is closely tied to the refining industry, where it is often obtained as a byproduct or intentionally synthesized for specific uses. The availability and cost-effectiveness of 2-methylpentane have contributed to its widespread adoption in industrial settings.

In the realm of materials science, 2-methylpentane-based materials have garnered attention due to their unique combination of properties. These materials often exhibit low viscosity, high volatility, and good solvency characteristics. Such attributes make them suitable for use in a variety of applications, including solvents, fuel components, and as precursors in the synthesis of more complex chemical compounds.

The structural integrity of materials based on 2-methylpentane is a critical area of study, as it directly impacts their performance and safety in various applications. Factors such as temperature fluctuations, pressure changes, and chemical interactions can significantly affect the structural stability of these materials. Understanding these dynamics is crucial for developing robust and reliable products that can withstand the demands of their intended use.

Research into 2-methylpentane-based materials has led to advancements in several fields. In the automotive industry, for instance, these materials have been explored for their potential in improving fuel efficiency and reducing emissions. In the pharmaceutical sector, they have found applications in drug delivery systems and as extraction solvents. The electronics industry has also benefited from the unique properties of 2-methylpentane-based materials, particularly in the development of cleaning agents for sensitive components.

As environmental concerns continue to shape industrial practices, the study of 2-methylpentane and its derivatives has expanded to include assessments of their ecological impact and potential for sustainable use. This has led to investigations into biodegradable alternatives and more environmentally friendly production methods, aligning with global efforts towards greener technologies.

The chemical structure of 2-methylpentane consists of a five-carbon chain with a methyl group attached to the second carbon atom. This branching configuration imparts distinct physical and chemical properties to the compound, setting it apart from its linear counterpart, n-hexane. The presence of the methyl branch affects the molecule's overall shape, influencing its behavior in different environments and its potential as a base material for various applications.

2-Methylpentane is primarily derived from petroleum through fractional distillation and subsequent isomerization processes. Its production is closely tied to the refining industry, where it is often obtained as a byproduct or intentionally synthesized for specific uses. The availability and cost-effectiveness of 2-methylpentane have contributed to its widespread adoption in industrial settings.

In the realm of materials science, 2-methylpentane-based materials have garnered attention due to their unique combination of properties. These materials often exhibit low viscosity, high volatility, and good solvency characteristics. Such attributes make them suitable for use in a variety of applications, including solvents, fuel components, and as precursors in the synthesis of more complex chemical compounds.

The structural integrity of materials based on 2-methylpentane is a critical area of study, as it directly impacts their performance and safety in various applications. Factors such as temperature fluctuations, pressure changes, and chemical interactions can significantly affect the structural stability of these materials. Understanding these dynamics is crucial for developing robust and reliable products that can withstand the demands of their intended use.

Research into 2-methylpentane-based materials has led to advancements in several fields. In the automotive industry, for instance, these materials have been explored for their potential in improving fuel efficiency and reducing emissions. In the pharmaceutical sector, they have found applications in drug delivery systems and as extraction solvents. The electronics industry has also benefited from the unique properties of 2-methylpentane-based materials, particularly in the development of cleaning agents for sensitive components.

As environmental concerns continue to shape industrial practices, the study of 2-methylpentane and its derivatives has expanded to include assessments of their ecological impact and potential for sustainable use. This has led to investigations into biodegradable alternatives and more environmentally friendly production methods, aligning with global efforts towards greener technologies.

Market Analysis

The market for 2-methylpentane-based materials has shown significant growth potential in recent years, driven by increasing demand in various industrial sectors. These materials, known for their unique structural properties, have found applications in aerospace, automotive, and construction industries, among others.

In the aerospace sector, 2-methylpentane-based materials are gaining traction due to their lightweight nature and high strength-to-weight ratio. This makes them ideal for use in aircraft components, where weight reduction is crucial for fuel efficiency. The global aerospace composites market, which includes these materials, is expected to grow steadily over the next decade.

The automotive industry is another key market for 2-methylpentane-based materials. As automakers strive to meet stringent fuel efficiency standards and reduce vehicle weight, these materials are increasingly being used in body panels, interior components, and structural elements. The automotive lightweight materials market is projected to expand significantly, with 2-methylpentane-based materials playing a vital role.

In the construction sector, these materials are valued for their durability and resistance to environmental factors. They are being incorporated into building materials, insulation products, and structural components. The growing trend towards sustainable and energy-efficient construction is likely to drive further demand for 2-methylpentane-based materials in this sector.

The electronics industry is also emerging as a promising market for these materials. Their thermal stability and electrical insulation properties make them suitable for use in electronic components and packaging. As the demand for smaller, more efficient electronic devices continues to rise, the market for 2-methylpentane-based materials in this sector is expected to grow.

Geographically, North America and Europe currently lead the market for 2-methylpentane-based materials, owing to their advanced manufacturing capabilities and strong presence of key industries. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing aerospace sectors in countries like China and India.

Despite the positive outlook, the market faces challenges such as high production costs and competition from alternative materials. Manufacturers are investing in research and development to improve production efficiency and reduce costs, which is expected to drive market growth in the coming years.

Overall, the market for 2-methylpentane-based materials shows promising growth prospects across multiple industries. The increasing focus on lightweight, durable, and high-performance materials in various sectors is likely to sustain the demand for these materials in the foreseeable future.

In the aerospace sector, 2-methylpentane-based materials are gaining traction due to their lightweight nature and high strength-to-weight ratio. This makes them ideal for use in aircraft components, where weight reduction is crucial for fuel efficiency. The global aerospace composites market, which includes these materials, is expected to grow steadily over the next decade.

The automotive industry is another key market for 2-methylpentane-based materials. As automakers strive to meet stringent fuel efficiency standards and reduce vehicle weight, these materials are increasingly being used in body panels, interior components, and structural elements. The automotive lightweight materials market is projected to expand significantly, with 2-methylpentane-based materials playing a vital role.

In the construction sector, these materials are valued for their durability and resistance to environmental factors. They are being incorporated into building materials, insulation products, and structural components. The growing trend towards sustainable and energy-efficient construction is likely to drive further demand for 2-methylpentane-based materials in this sector.

The electronics industry is also emerging as a promising market for these materials. Their thermal stability and electrical insulation properties make them suitable for use in electronic components and packaging. As the demand for smaller, more efficient electronic devices continues to rise, the market for 2-methylpentane-based materials in this sector is expected to grow.

Geographically, North America and Europe currently lead the market for 2-methylpentane-based materials, owing to their advanced manufacturing capabilities and strong presence of key industries. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing aerospace sectors in countries like China and India.

Despite the positive outlook, the market faces challenges such as high production costs and competition from alternative materials. Manufacturers are investing in research and development to improve production efficiency and reduce costs, which is expected to drive market growth in the coming years.

Overall, the market for 2-methylpentane-based materials shows promising growth prospects across multiple industries. The increasing focus on lightweight, durable, and high-performance materials in various sectors is likely to sustain the demand for these materials in the foreseeable future.

Technical Challenges

The structural integrity assessment of 2-methylpentane-based materials presents several significant technical challenges. One of the primary difficulties lies in the complex molecular structure of 2-methylpentane, which can lead to unpredictable behavior under various stress conditions. This branched alkane's unique properties require specialized testing methodologies and advanced analytical techniques to accurately evaluate its structural performance.

A major challenge in assessing these materials is the lack of comprehensive historical data and established industry standards. Unlike more commonly used hydrocarbons, 2-methylpentane-based materials have limited precedent in structural applications, making it difficult to benchmark their performance against known parameters. This gap in knowledge necessitates extensive research and testing to develop reliable assessment protocols.

The temperature sensitivity of 2-methylpentane compounds poses another significant hurdle. These materials can exhibit substantial changes in their mechanical properties across different temperature ranges, complicating the assessment of their long-term structural integrity. Engineers must account for these variations when designing tests and interpreting results, requiring sophisticated thermal analysis techniques and environmental simulation capabilities.

Compatibility issues with other materials used in conjunction with 2-methylpentane-based compounds present additional challenges. The potential for chemical interactions or degradation when in contact with metals, polymers, or other substances must be thoroughly investigated to ensure the overall structural integrity of composite systems. This demands extensive compatibility testing and the development of specialized interface analysis methods.

The dynamic behavior of 2-methylpentane materials under cyclic loading and fatigue conditions is another area of technical complexity. Understanding how these materials respond to repeated stress and strain over time is crucial for predicting their long-term performance in structural applications. However, developing accurate fatigue models for these relatively novel materials requires extensive experimental data and advanced computational techniques.

Environmental factors such as humidity, UV exposure, and chemical exposure can significantly impact the structural integrity of 2-methylpentane-based materials. Assessing the long-term effects of these environmental stressors demands accelerated aging tests and sophisticated degradation modeling. The development of reliable predictive models for environmental aging remains a significant technical challenge in this field.

Lastly, the scalability of laboratory test results to real-world applications presents a formidable challenge. Bridging the gap between small-scale material tests and the behavior of full-scale structures requires innovative approaches to data extrapolation and validation. This challenge is particularly acute for 2-methylpentane-based materials due to their limited history in structural applications, necessitating careful consideration of scale effects and potential unforeseen behaviors in larger structures.

A major challenge in assessing these materials is the lack of comprehensive historical data and established industry standards. Unlike more commonly used hydrocarbons, 2-methylpentane-based materials have limited precedent in structural applications, making it difficult to benchmark their performance against known parameters. This gap in knowledge necessitates extensive research and testing to develop reliable assessment protocols.

The temperature sensitivity of 2-methylpentane compounds poses another significant hurdle. These materials can exhibit substantial changes in their mechanical properties across different temperature ranges, complicating the assessment of their long-term structural integrity. Engineers must account for these variations when designing tests and interpreting results, requiring sophisticated thermal analysis techniques and environmental simulation capabilities.

Compatibility issues with other materials used in conjunction with 2-methylpentane-based compounds present additional challenges. The potential for chemical interactions or degradation when in contact with metals, polymers, or other substances must be thoroughly investigated to ensure the overall structural integrity of composite systems. This demands extensive compatibility testing and the development of specialized interface analysis methods.

The dynamic behavior of 2-methylpentane materials under cyclic loading and fatigue conditions is another area of technical complexity. Understanding how these materials respond to repeated stress and strain over time is crucial for predicting their long-term performance in structural applications. However, developing accurate fatigue models for these relatively novel materials requires extensive experimental data and advanced computational techniques.

Environmental factors such as humidity, UV exposure, and chemical exposure can significantly impact the structural integrity of 2-methylpentane-based materials. Assessing the long-term effects of these environmental stressors demands accelerated aging tests and sophisticated degradation modeling. The development of reliable predictive models for environmental aging remains a significant technical challenge in this field.

Lastly, the scalability of laboratory test results to real-world applications presents a formidable challenge. Bridging the gap between small-scale material tests and the behavior of full-scale structures requires innovative approaches to data extrapolation and validation. This challenge is particularly acute for 2-methylpentane-based materials due to their limited history in structural applications, necessitating careful consideration of scale effects and potential unforeseen behaviors in larger structures.

Current Solutions

01 Structural integrity testing methods for 2-methylpentane-based materials

Various testing methods are employed to assess the structural integrity of 2-methylpentane-based materials. These may include non-destructive testing techniques, stress analysis, and fatigue testing to evaluate material properties and performance under different conditions. Such methods help in understanding the material's behavior and ensuring its reliability in various applications.- Structural integrity testing methods for 2-methylpentane-based materials: Various testing methods are employed to assess the structural integrity of 2-methylpentane-based materials. These may include non-destructive testing techniques, stress analysis, and fatigue testing to evaluate material properties and performance under different conditions.

- Composition and manufacturing of 2-methylpentane-based materials: The composition and manufacturing processes of 2-methylpentane-based materials are crucial for ensuring structural integrity. This includes optimizing the chemical formulation, processing techniques, and quality control measures to produce materials with desired mechanical properties.

- Applications of 2-methylpentane-based materials in structural components: 2-Methylpentane-based materials find applications in various structural components due to their unique properties. These materials are used in industries such as automotive, aerospace, and construction, where structural integrity is paramount.

- Environmental factors affecting structural integrity of 2-methylpentane-based materials: Environmental factors such as temperature, humidity, and chemical exposure can impact the structural integrity of 2-methylpentane-based materials. Understanding these effects is crucial for designing and implementing appropriate protective measures and maintenance strategies.

- Modeling and simulation of 2-methylpentane-based materials for structural analysis: Advanced modeling and simulation techniques are employed to predict and analyze the structural behavior of 2-methylpentane-based materials. These computational methods help in optimizing material design, assessing performance, and identifying potential failure modes.

02 Composition and manufacturing of 2-methylpentane-based materials for improved structural integrity

The structural integrity of 2-methylpentane-based materials can be enhanced through careful composition design and manufacturing processes. This may involve the addition of reinforcing agents, optimizing molecular structure, or employing specific processing techniques to improve mechanical properties and durability of the resulting materials.Expand Specific Solutions03 Applications of 2-methylpentane-based materials in structural components

2-Methylpentane-based materials find applications in various structural components due to their unique properties. These materials may be used in automotive parts, aerospace components, or construction materials where specific structural integrity requirements need to be met. The selection of these materials is based on their performance characteristics and ability to withstand specific environmental conditions.Expand Specific Solutions04 Monitoring and analysis of 2-methylpentane-based materials' structural integrity

Advanced monitoring and analysis techniques are employed to assess the ongoing structural integrity of 2-methylpentane-based materials in various applications. This may include real-time monitoring systems, predictive modeling, and data analysis to detect potential issues and ensure the continued reliability and safety of structures incorporating these materials.Expand Specific Solutions05 Environmental factors affecting the structural integrity of 2-methylpentane-based materials

The structural integrity of 2-methylpentane-based materials can be influenced by various environmental factors. Research focuses on understanding and mitigating the effects of temperature fluctuations, chemical exposure, and mechanical stresses on these materials. This knowledge is crucial for designing and implementing appropriate protective measures to maintain long-term structural integrity in different operating conditions.Expand Specific Solutions

Industry Leaders

The structural integrity assessment of 2-methylpentane-based materials is an emerging field with growing market potential. The industry is in its early development stage, characterized by ongoing research and technological advancements. While the market size is currently modest, it is expected to expand as applications in various sectors become more prevalent. Companies like BASF Corp., Mitsui Chemicals, and Dow Global Technologies are at the forefront of this technology, leveraging their expertise in chemical engineering and materials science. The involvement of academic institutions such as Northwestern University and Rice University indicates a focus on fundamental research, suggesting that the technology is still maturing and has room for significant innovation and improvement in the coming years.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals, Inc. has developed an innovative approach to structural integrity assessments of 2-methylpentane-based materials, focusing on their application in specialty chemicals and plastics. Their methodology incorporates advanced molecular dynamics simulations to predict material behavior at the atomic level[13]. They have also implemented high-throughput screening techniques to rapidly evaluate the structural properties of various 2-methylpentane-based formulations[15]. Mitsui's research has led to the development of novel 2-methylpentane-based copolymers with improved impact resistance and chemical stability, targeting applications in the electronics and automotive industries[17].

Strengths: Advanced computational modeling, efficient material screening processes, and focus on high-value applications. Weaknesses: Potential challenges in scaling up from molecular simulations to bulk material production and possible high costs associated with specialty chemical development.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced techniques for structural integrity assessments of 2-methylpentane-based materials. Their approach involves using high-resolution microscopy and spectroscopy to analyze the molecular structure and bonding of these materials[1]. They have also implemented finite element analysis (FEA) simulations to predict the mechanical behavior under various stress conditions[3]. BASF's research has led to the development of novel 2-methylpentane-based composites with enhanced structural properties, suitable for applications in automotive and aerospace industries[5].

Strengths: Comprehensive analysis techniques, advanced simulation capabilities, and innovative material development. Weaknesses: High cost of specialized equipment and potential limitations in real-world application validation.

Key Innovations

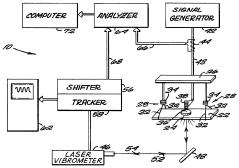

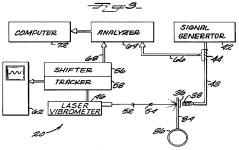

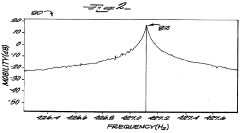

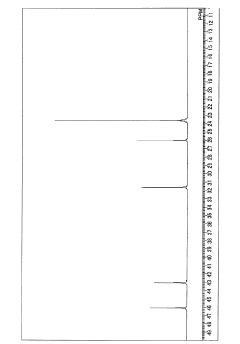

Method and apparatus for determining material structural integrity

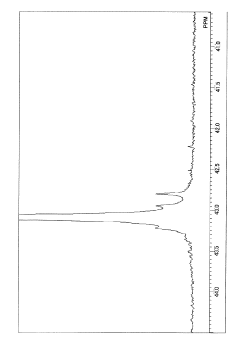

PatentInactiveUS5520052A

Innovation

- Combining laser vibrometry with damping analysis techniques to measure the damping loss factor of materials over a known frequency range, allowing for the determination of structural integrity through the use of vibrational force and velocity measurements, and plotting drive point mobility to derive the damping loss factor.

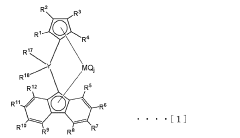

4-methylpentene-1 polymer with syndiotactic structure

PatentInactiveJPWO2010023906A1

Innovation

- A 4-methylpentene-1 polymer with a syndiotactic structure is developed, characterized by specific molecular weight, syndiotactic dyad fraction, and melting point, which can be produced using a catalyst system containing a bridged metallocene compound, allowing for high molecular weight and improved stretchability without breakage, and adjustable gas permeability through a laminate structure.

Safety Regulations

Safety regulations play a crucial role in the structural integrity assessments of 2-methylpentane-based materials. These regulations are designed to ensure the safe handling, storage, and use of such materials in various industrial applications. The primary focus of these safety regulations is to mitigate potential risks associated with the flammability, volatility, and chemical reactivity of 2-methylpentane and its derivatives.

One of the key aspects of safety regulations for 2-methylpentane-based materials is the establishment of proper storage and handling protocols. These protocols typically include requirements for specialized containment systems, ventilation measures, and fire suppression equipment. Additionally, regulations often mandate the use of appropriate personal protective equipment (PPE) for workers who come into contact with these materials.

The transportation of 2-methylpentane-based materials is subject to strict safety regulations due to their flammable nature. These regulations often include specific packaging requirements, labeling standards, and transportation route restrictions. Furthermore, emergency response procedures are typically outlined to address potential spills or accidents during transit.

In the context of structural integrity assessments, safety regulations often require regular inspections and testing of storage tanks, pipelines, and other containment systems used for 2-methylpentane-based materials. These assessments aim to identify potential weaknesses or degradation in the structural components that could lead to leaks or failures.

Environmental safety regulations also play a significant role in the management of 2-methylpentane-based materials. These regulations typically focus on preventing soil and water contamination, as well as minimizing air pollution from volatile organic compound (VOC) emissions. Compliance with these environmental regulations often requires the implementation of advanced monitoring systems and emission control technologies.

Workplace safety regulations for facilities handling 2-methylpentane-based materials often include requirements for employee training programs. These programs typically cover topics such as proper material handling techniques, emergency response procedures, and the use of safety equipment. Regular safety drills and simulations may also be mandated to ensure preparedness for potential incidents.

The development and enforcement of safety regulations for 2-methylpentane-based materials involve collaboration between various regulatory bodies, industry experts, and research institutions. These regulations are periodically reviewed and updated to incorporate new scientific findings, technological advancements, and lessons learned from incidents or near-misses in the industry.

One of the key aspects of safety regulations for 2-methylpentane-based materials is the establishment of proper storage and handling protocols. These protocols typically include requirements for specialized containment systems, ventilation measures, and fire suppression equipment. Additionally, regulations often mandate the use of appropriate personal protective equipment (PPE) for workers who come into contact with these materials.

The transportation of 2-methylpentane-based materials is subject to strict safety regulations due to their flammable nature. These regulations often include specific packaging requirements, labeling standards, and transportation route restrictions. Furthermore, emergency response procedures are typically outlined to address potential spills or accidents during transit.

In the context of structural integrity assessments, safety regulations often require regular inspections and testing of storage tanks, pipelines, and other containment systems used for 2-methylpentane-based materials. These assessments aim to identify potential weaknesses or degradation in the structural components that could lead to leaks or failures.

Environmental safety regulations also play a significant role in the management of 2-methylpentane-based materials. These regulations typically focus on preventing soil and water contamination, as well as minimizing air pollution from volatile organic compound (VOC) emissions. Compliance with these environmental regulations often requires the implementation of advanced monitoring systems and emission control technologies.

Workplace safety regulations for facilities handling 2-methylpentane-based materials often include requirements for employee training programs. These programs typically cover topics such as proper material handling techniques, emergency response procedures, and the use of safety equipment. Regular safety drills and simulations may also be mandated to ensure preparedness for potential incidents.

The development and enforcement of safety regulations for 2-methylpentane-based materials involve collaboration between various regulatory bodies, industry experts, and research institutions. These regulations are periodically reviewed and updated to incorporate new scientific findings, technological advancements, and lessons learned from incidents or near-misses in the industry.

Environmental Impact

The environmental impact of 2-methylpentane-based materials is a critical consideration in their structural integrity assessments. These materials, commonly used in various industrial applications, have both direct and indirect effects on the environment throughout their lifecycle.

During the production phase, the synthesis of 2-methylpentane-based materials often involves energy-intensive processes and the use of potentially hazardous chemicals. This can lead to increased greenhouse gas emissions and the release of volatile organic compounds (VOCs) into the atmosphere. Additionally, the extraction and processing of raw materials required for production may contribute to habitat destruction and resource depletion.

In their use phase, 2-methylpentane-based materials can have varying environmental impacts depending on their specific applications. When used in structural components, these materials may offer advantages such as lightweight properties, potentially reducing fuel consumption in transportation applications. However, their durability and resistance to environmental factors can also result in prolonged persistence in the environment if not properly managed at the end of their lifecycle.

The disposal and end-of-life management of 2-methylpentane-based materials present significant environmental challenges. These materials are often not biodegradable and can persist in landfills for extended periods. Improper disposal may lead to soil and water contamination, affecting ecosystems and potentially entering the food chain. Recycling options for these materials are limited, further complicating their environmental footprint.

Leaching of chemical components from 2-methylpentane-based materials is another environmental concern. Under certain conditions, these materials may release harmful substances into the surrounding environment, potentially impacting soil and water quality. This is particularly relevant in applications where the materials are exposed to harsh environmental conditions or come into contact with water bodies.

The structural integrity of 2-methylpentane-based materials also has indirect environmental implications. Failure or degradation of these materials in critical applications can lead to accidents or the need for premature replacement, resulting in increased resource consumption and waste generation. Therefore, ensuring the long-term structural integrity of these materials is crucial not only for safety but also for minimizing their overall environmental impact.

Efforts to mitigate the environmental impact of 2-methylpentane-based materials include developing more sustainable production processes, improving recycling technologies, and exploring bio-based alternatives. Research into enhancing the durability and recyclability of these materials is ongoing, with the aim of creating more environmentally friendly lifecycle options.

During the production phase, the synthesis of 2-methylpentane-based materials often involves energy-intensive processes and the use of potentially hazardous chemicals. This can lead to increased greenhouse gas emissions and the release of volatile organic compounds (VOCs) into the atmosphere. Additionally, the extraction and processing of raw materials required for production may contribute to habitat destruction and resource depletion.

In their use phase, 2-methylpentane-based materials can have varying environmental impacts depending on their specific applications. When used in structural components, these materials may offer advantages such as lightweight properties, potentially reducing fuel consumption in transportation applications. However, their durability and resistance to environmental factors can also result in prolonged persistence in the environment if not properly managed at the end of their lifecycle.

The disposal and end-of-life management of 2-methylpentane-based materials present significant environmental challenges. These materials are often not biodegradable and can persist in landfills for extended periods. Improper disposal may lead to soil and water contamination, affecting ecosystems and potentially entering the food chain. Recycling options for these materials are limited, further complicating their environmental footprint.

Leaching of chemical components from 2-methylpentane-based materials is another environmental concern. Under certain conditions, these materials may release harmful substances into the surrounding environment, potentially impacting soil and water quality. This is particularly relevant in applications where the materials are exposed to harsh environmental conditions or come into contact with water bodies.

The structural integrity of 2-methylpentane-based materials also has indirect environmental implications. Failure or degradation of these materials in critical applications can lead to accidents or the need for premature replacement, resulting in increased resource consumption and waste generation. Therefore, ensuring the long-term structural integrity of these materials is crucial not only for safety but also for minimizing their overall environmental impact.

Efforts to mitigate the environmental impact of 2-methylpentane-based materials include developing more sustainable production processes, improving recycling technologies, and exploring bio-based alternatives. Research into enhancing the durability and recyclability of these materials is ongoing, with the aim of creating more environmentally friendly lifecycle options.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!