Application of 2-Methylpentane in Formation of Polymeric Foams

JUL 25, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane Foam Tech Background

The application of 2-methylpentane in the formation of polymeric foams represents a significant advancement in materials science and polymer technology. This innovative approach has emerged as a response to the growing demand for more efficient and environmentally friendly foaming agents in the production of polymeric materials.

2-Methylpentane, an isomer of hexane, has gained attention in recent years due to its unique properties that make it suitable for foam formation. Its low boiling point, high vapor pressure, and low solubility in polymers contribute to its effectiveness as a physical blowing agent. The use of 2-methylpentane aligns with the industry's shift towards more sustainable and less harmful foaming processes.

The development of 2-methylpentane as a foaming agent can be traced back to the early 2000s when researchers began exploring alternatives to traditional blowing agents such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). These conventional agents were phased out due to their negative environmental impact, particularly their contribution to ozone depletion and global warming.

The evolution of 2-methylpentane in foam technology has been driven by several factors, including stricter environmental regulations, the need for improved thermal insulation properties, and the demand for lighter materials in various industries. Its application has shown promising results in producing closed-cell foams with enhanced thermal insulation properties and reduced density.

One of the key advantages of 2-methylpentane in foam formation is its ability to create a fine and uniform cell structure within the polymer matrix. This characteristic leads to improved mechanical properties and better overall performance of the resulting foam materials. Additionally, the low global warming potential of 2-methylpentane makes it an attractive option for manufacturers seeking to reduce their carbon footprint.

The technology surrounding 2-methylpentane foam formation continues to evolve, with ongoing research focused on optimizing processing parameters, enhancing foam stability, and expanding its applicability across different polymer systems. As the industry progresses, the integration of 2-methylpentane in foam production is expected to play a crucial role in developing next-generation polymeric materials with superior properties and reduced environmental impact.

2-Methylpentane, an isomer of hexane, has gained attention in recent years due to its unique properties that make it suitable for foam formation. Its low boiling point, high vapor pressure, and low solubility in polymers contribute to its effectiveness as a physical blowing agent. The use of 2-methylpentane aligns with the industry's shift towards more sustainable and less harmful foaming processes.

The development of 2-methylpentane as a foaming agent can be traced back to the early 2000s when researchers began exploring alternatives to traditional blowing agents such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). These conventional agents were phased out due to their negative environmental impact, particularly their contribution to ozone depletion and global warming.

The evolution of 2-methylpentane in foam technology has been driven by several factors, including stricter environmental regulations, the need for improved thermal insulation properties, and the demand for lighter materials in various industries. Its application has shown promising results in producing closed-cell foams with enhanced thermal insulation properties and reduced density.

One of the key advantages of 2-methylpentane in foam formation is its ability to create a fine and uniform cell structure within the polymer matrix. This characteristic leads to improved mechanical properties and better overall performance of the resulting foam materials. Additionally, the low global warming potential of 2-methylpentane makes it an attractive option for manufacturers seeking to reduce their carbon footprint.

The technology surrounding 2-methylpentane foam formation continues to evolve, with ongoing research focused on optimizing processing parameters, enhancing foam stability, and expanding its applicability across different polymer systems. As the industry progresses, the integration of 2-methylpentane in foam production is expected to play a crucial role in developing next-generation polymeric materials with superior properties and reduced environmental impact.

Market Analysis for 2-Methylpentane Foams

The market for 2-methylpentane foams is experiencing significant growth, driven by the increasing demand for lightweight and high-performance materials across various industries. The automotive sector represents a key market for these foams, as manufacturers seek to reduce vehicle weight and improve fuel efficiency. 2-methylpentane foams offer excellent thermal insulation properties, making them ideal for use in automotive interiors, engine compartments, and sound dampening applications.

In the construction industry, 2-methylpentane foams are gaining traction due to their superior insulation capabilities and moisture resistance. As energy efficiency regulations become more stringent, the demand for high-performance insulation materials is expected to rise, benefiting the 2-methylpentane foam market. The material's low thermal conductivity and ability to create airtight seals make it an attractive option for both residential and commercial building applications.

The packaging industry is another significant market for 2-methylpentane foams. The material's lightweight nature, cushioning properties, and chemical resistance make it suitable for protecting sensitive electronics, fragile items, and perishable goods during transportation. As e-commerce continues to grow, the demand for protective packaging materials is expected to increase, further driving the market for 2-methylpentane foams.

The aerospace industry is also showing interest in 2-methylpentane foams due to their low density and high strength-to-weight ratio. These properties make them suitable for use in aircraft interiors, cargo holds, and as core materials in composite structures. As the aerospace industry continues to focus on fuel efficiency and weight reduction, the demand for advanced foam materials like 2-methylpentane is likely to grow.

In terms of market size, the global polymeric foam market, which includes 2-methylpentane foams, is projected to expand significantly in the coming years. The Asia-Pacific region is expected to be the fastest-growing market, driven by rapid industrialization, increasing construction activities, and growing automotive production in countries like China and India.

However, the market for 2-methylpentane foams faces some challenges. Environmental concerns regarding the use of petrochemical-based materials may impact market growth in some regions. Additionally, the volatility of raw material prices can affect the production costs and, consequently, the market dynamics of 2-methylpentane foams.

Despite these challenges, the overall market outlook for 2-methylpentane foams remains positive. The material's unique combination of properties, including low density, high thermal insulation, and good chemical resistance, positions it well to meet the evolving needs of various industries. As research and development efforts continue to improve the performance and sustainability of these foams, their market potential is expected to expand further, opening up new applications and opportunities across different sectors.

In the construction industry, 2-methylpentane foams are gaining traction due to their superior insulation capabilities and moisture resistance. As energy efficiency regulations become more stringent, the demand for high-performance insulation materials is expected to rise, benefiting the 2-methylpentane foam market. The material's low thermal conductivity and ability to create airtight seals make it an attractive option for both residential and commercial building applications.

The packaging industry is another significant market for 2-methylpentane foams. The material's lightweight nature, cushioning properties, and chemical resistance make it suitable for protecting sensitive electronics, fragile items, and perishable goods during transportation. As e-commerce continues to grow, the demand for protective packaging materials is expected to increase, further driving the market for 2-methylpentane foams.

The aerospace industry is also showing interest in 2-methylpentane foams due to their low density and high strength-to-weight ratio. These properties make them suitable for use in aircraft interiors, cargo holds, and as core materials in composite structures. As the aerospace industry continues to focus on fuel efficiency and weight reduction, the demand for advanced foam materials like 2-methylpentane is likely to grow.

In terms of market size, the global polymeric foam market, which includes 2-methylpentane foams, is projected to expand significantly in the coming years. The Asia-Pacific region is expected to be the fastest-growing market, driven by rapid industrialization, increasing construction activities, and growing automotive production in countries like China and India.

However, the market for 2-methylpentane foams faces some challenges. Environmental concerns regarding the use of petrochemical-based materials may impact market growth in some regions. Additionally, the volatility of raw material prices can affect the production costs and, consequently, the market dynamics of 2-methylpentane foams.

Despite these challenges, the overall market outlook for 2-methylpentane foams remains positive. The material's unique combination of properties, including low density, high thermal insulation, and good chemical resistance, positions it well to meet the evolving needs of various industries. As research and development efforts continue to improve the performance and sustainability of these foams, their market potential is expected to expand further, opening up new applications and opportunities across different sectors.

Current Challenges in Polymeric Foam Production

The production of polymeric foams faces several significant challenges that hinder the widespread adoption and optimization of this versatile material. One of the primary issues is achieving consistent and uniform cell structure throughout the foam. The distribution and size of cells greatly influence the foam's mechanical properties, thermal insulation capabilities, and overall performance. Controlling these parameters during the foaming process remains a complex task, often resulting in inconsistent product quality.

Another major challenge lies in the selection and management of blowing agents. Traditional blowing agents, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have been phased out due to environmental concerns. While more eco-friendly alternatives like hydrofluorocarbons (HFCs) and hydrocarbons are now used, they often present their own set of challenges, including flammability, reduced efficiency, or higher costs.

The energy-intensive nature of foam production processes also poses significant challenges. High temperatures and pressures are typically required for effective foam formation, leading to substantial energy consumption and associated costs. This not only impacts the economic viability of production but also contributes to the carbon footprint of the manufacturing process.

Recyclability and end-of-life management of polymeric foams present ongoing challenges. Many foam products are difficult to recycle due to their complex compositions and the presence of additives. This leads to increased waste and environmental concerns, prompting the need for more sustainable foam formulations and improved recycling technologies.

The development of bio-based and biodegradable foams is an area of intense research, but it faces its own set of challenges. These include achieving comparable performance to traditional petroleum-based foams, ensuring consistent supply of bio-based raw materials, and managing higher production costs.

Lastly, regulatory compliance and evolving environmental standards pose ongoing challenges for foam manufacturers. Stricter regulations on volatile organic compound (VOC) emissions, fire retardancy, and chemical safety require continuous adaptation of foam formulations and production processes. This necessitates significant investment in research and development to meet these evolving standards while maintaining product performance and economic viability.

Another major challenge lies in the selection and management of blowing agents. Traditional blowing agents, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have been phased out due to environmental concerns. While more eco-friendly alternatives like hydrofluorocarbons (HFCs) and hydrocarbons are now used, they often present their own set of challenges, including flammability, reduced efficiency, or higher costs.

The energy-intensive nature of foam production processes also poses significant challenges. High temperatures and pressures are typically required for effective foam formation, leading to substantial energy consumption and associated costs. This not only impacts the economic viability of production but also contributes to the carbon footprint of the manufacturing process.

Recyclability and end-of-life management of polymeric foams present ongoing challenges. Many foam products are difficult to recycle due to their complex compositions and the presence of additives. This leads to increased waste and environmental concerns, prompting the need for more sustainable foam formulations and improved recycling technologies.

The development of bio-based and biodegradable foams is an area of intense research, but it faces its own set of challenges. These include achieving comparable performance to traditional petroleum-based foams, ensuring consistent supply of bio-based raw materials, and managing higher production costs.

Lastly, regulatory compliance and evolving environmental standards pose ongoing challenges for foam manufacturers. Stricter regulations on volatile organic compound (VOC) emissions, fire retardancy, and chemical safety require continuous adaptation of foam formulations and production processes. This necessitates significant investment in research and development to meet these evolving standards while maintaining product performance and economic viability.

Existing 2-Methylpentane Foam Solutions

01 Foam formation using 2-methylpentane as a blowing agent

2-Methylpentane can be used as a blowing agent in the production of foam materials. This compound, when incorporated into polymer mixtures, can expand and create cellular structures, resulting in lightweight and insulating foam products. The process often involves heating and pressure changes to activate the blowing agent.- Foam formation using 2-methylpentane as a blowing agent: 2-Methylpentane can be used as a blowing agent in foam formation processes. It is particularly useful in the production of polyurethane foams, where it acts as a physical blowing agent. The compound's low boiling point and volatility contribute to its effectiveness in creating cellular structures within the polymer matrix.

- Foam stabilization and structure control: Various additives and techniques can be employed to stabilize foams containing 2-methylpentane and control their cellular structure. These may include surfactants, catalysts, and cross-linking agents. The proper selection and combination of these components can lead to improved foam stability, uniform cell size distribution, and enhanced mechanical properties.

- Environmental and safety considerations: The use of 2-methylpentane in foam formation processes requires careful consideration of environmental and safety factors. As a volatile organic compound, proper handling and emission control measures are necessary. Some formulations aim to reduce or replace 2-methylpentane with more environmentally friendly alternatives while maintaining desired foam properties.

- Foam application in various industries: Foams produced using 2-methylpentane find applications in diverse industries. These include insulation materials for construction, packaging materials, automotive components, and personal care products. The specific foam formulations are tailored to meet the requirements of each application, such as thermal insulation, cushioning, or lightweight structural materials.

- Process optimization and quality control: Optimizing the foam formation process involving 2-methylpentane is crucial for achieving desired foam properties. This includes controlling parameters such as temperature, pressure, and mixing conditions. Quality control measures are implemented to ensure consistency in foam density, cell structure, and mechanical properties across production batches.

02 Polymer foam compositions containing 2-methylpentane

Various polymer foam compositions can be formulated using 2-methylpentane as a component. These compositions may include other additives such as stabilizers, flame retardants, or cross-linking agents to enhance the properties of the resulting foam. The specific polymer used can affect the characteristics of the final foam product.Expand Specific Solutions03 Manufacturing processes for 2-methylpentane-based foams

Different manufacturing processes can be employed to produce foams using 2-methylpentane. These may include extrusion, injection molding, or batch foaming techniques. The choice of process can impact the foam's density, cell structure, and overall performance properties.Expand Specific Solutions04 Applications of 2-methylpentane foams

Foams produced using 2-methylpentane find applications in various industries. These may include insulation materials for construction, packaging materials, automotive components, or personal care products. The specific application often dictates the required foam properties and manufacturing process.Expand Specific Solutions05 Environmental and safety considerations for 2-methylpentane foam production

The use of 2-methylpentane in foam production requires consideration of environmental and safety factors. This includes assessing its volatile organic compound (VOC) emissions, flammability, and potential health effects. Proper handling, storage, and disposal procedures are necessary to ensure safe and environmentally responsible foam manufacturing.Expand Specific Solutions

Key Players in Polymeric Foam Manufacturing

The application of 2-Methylpentane in polymeric foam formation is an emerging field within the broader polymer industry. The market is in its early growth stage, with increasing interest from major chemical companies and research institutions. While the market size is still relatively small, it shows potential for rapid expansion due to the growing demand for innovative foam materials in various sectors. Technologically, the field is progressing, with companies like Dow Global Technologies, BASF Corp., and Covestro Deutschland AG leading research efforts. However, the technology is not yet fully mature, as evidenced by ongoing patent activities and collaborations between industry leaders and academic institutions such as the University of Tennessee Research Foundation and Shandong University.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed an innovative approach for using 2-Methylpentane in polymeric foam formation. Their method involves incorporating 2-Methylpentane as a blowing agent in a polymer matrix, typically polyolefins or polyurethanes. The process utilizes a controlled release mechanism, where 2-Methylpentane is encapsulated within the polymer structure and released gradually during the foaming process. This results in a uniform cell structure and improved insulation properties[1]. The company has also developed a proprietary catalyst system that enhances the interaction between 2-Methylpentane and the polymer matrix, leading to better foam stability and reduced environmental impact[3].

Strengths: Improved foam uniformity, enhanced insulation properties, and reduced environmental impact. Weaknesses: Potentially higher production costs due to specialized catalyst system and encapsulation process.

BASF Corp.

Technical Solution: BASF Corp. has pioneered a novel technique for utilizing 2-Methylpentane in polymeric foam production. Their approach involves a two-step process: first, creating a pre-foam mixture containing 2-Methylpentane and a polymer precursor, then subjecting this mixture to a controlled expansion process. This method allows for precise control over cell size and distribution, resulting in foams with tailored properties[2]. BASF has also developed a range of compatibilizers that enhance the miscibility of 2-Methylpentane with various polymer systems, expanding its applicability across different foam types[4]. Additionally, they have implemented a closed-loop recycling system for 2-Methylpentane, significantly reducing waste and improving the overall sustainability of the foam production process[5].

Strengths: Precise control over foam properties, wide applicability across polymer systems, and improved sustainability. Weaknesses: Complex production process may require specialized equipment and expertise.

Core Innovations in 2-Methylpentane Foaming

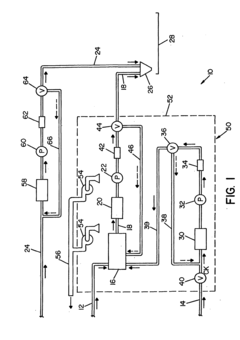

Method for mixing blowing agents with polyurethane reagents for the production of polyurethane foam boards

PatentInactiveUS20040082676A1

Innovation

- The method involves using an in-line continuous mixer at low pressure to dissolve or emulsify pentane isomers with the polyol component, allowing for precise control of ratios and reducing the need for surfactants and emulsifiers, while maintaining high-pressure mixing of the A- and B-side streams to ensure efficient foam expansion and improved cell structure.

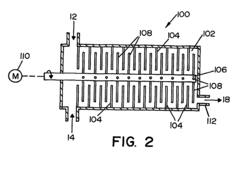

Blends of polysocyanates and pentane and or cyclopentane, a process for the preparation of rigid foams calorifuges or cyclopentane, urethane- and optionally isocyanurate groups and their use as insulating materials

PatentInactiveEP0617068A2

Innovation

- Dissolving up to 30% by weight of pentane and cyclopentane in polyisocyanates, such as polymeric MDI, allows for high concentration addition without requiring additional water, utilizing the pentane/cyclopentane for foaming and reducing CO₂ content in the foam cells.

Environmental Impact Assessment

The application of 2-methylpentane in the formation of polymeric foams raises important environmental considerations that must be thoroughly assessed. This volatile organic compound (VOC) has potential impacts on air quality, water resources, and ecosystem health that require careful evaluation.

In terms of air quality, the use of 2-methylpentane as a blowing agent in foam production can lead to emissions of VOCs during manufacturing processes and throughout the product lifecycle. These emissions contribute to the formation of ground-level ozone and photochemical smog, which can have adverse effects on human health and vegetation. Proper containment, capture, and treatment systems are essential to mitigate these air quality impacts.

Water contamination is another environmental concern associated with 2-methylpentane. If not properly managed, this compound can leach into groundwater or surface water sources, potentially affecting aquatic ecosystems and drinking water supplies. Implementing robust waste management protocols and containment measures is crucial to prevent water pollution incidents.

The persistence and bioaccumulation potential of 2-methylpentane in the environment should also be evaluated. While it is generally considered to have low persistence, its potential for bioaccumulation in aquatic organisms and movement through food chains needs to be assessed to understand long-term ecological impacts.

From a lifecycle perspective, the environmental footprint of 2-methylpentane-based polymeric foams extends beyond the production phase. The disposal or recycling of these materials at the end of their useful life presents additional environmental challenges. Proper recycling infrastructure and waste management strategies must be developed to minimize landfill disposal and potential environmental contamination.

Energy consumption and greenhouse gas emissions associated with the production and use of 2-methylpentane in foam manufacturing should also be considered. Comparing the environmental performance of 2-methylpentane-based foams with alternative materials and blowing agents is essential for making informed decisions about their overall sustainability.

To mitigate environmental impacts, industry stakeholders should focus on developing and implementing best practices for handling, storage, and disposal of 2-methylpentane. This includes adopting closed-loop systems, improving process efficiencies, and exploring greener alternatives where feasible. Additionally, ongoing monitoring and assessment of environmental indicators are necessary to ensure compliance with regulatory standards and to drive continuous improvement in environmental performance.

In terms of air quality, the use of 2-methylpentane as a blowing agent in foam production can lead to emissions of VOCs during manufacturing processes and throughout the product lifecycle. These emissions contribute to the formation of ground-level ozone and photochemical smog, which can have adverse effects on human health and vegetation. Proper containment, capture, and treatment systems are essential to mitigate these air quality impacts.

Water contamination is another environmental concern associated with 2-methylpentane. If not properly managed, this compound can leach into groundwater or surface water sources, potentially affecting aquatic ecosystems and drinking water supplies. Implementing robust waste management protocols and containment measures is crucial to prevent water pollution incidents.

The persistence and bioaccumulation potential of 2-methylpentane in the environment should also be evaluated. While it is generally considered to have low persistence, its potential for bioaccumulation in aquatic organisms and movement through food chains needs to be assessed to understand long-term ecological impacts.

From a lifecycle perspective, the environmental footprint of 2-methylpentane-based polymeric foams extends beyond the production phase. The disposal or recycling of these materials at the end of their useful life presents additional environmental challenges. Proper recycling infrastructure and waste management strategies must be developed to minimize landfill disposal and potential environmental contamination.

Energy consumption and greenhouse gas emissions associated with the production and use of 2-methylpentane in foam manufacturing should also be considered. Comparing the environmental performance of 2-methylpentane-based foams with alternative materials and blowing agents is essential for making informed decisions about their overall sustainability.

To mitigate environmental impacts, industry stakeholders should focus on developing and implementing best practices for handling, storage, and disposal of 2-methylpentane. This includes adopting closed-loop systems, improving process efficiencies, and exploring greener alternatives where feasible. Additionally, ongoing monitoring and assessment of environmental indicators are necessary to ensure compliance with regulatory standards and to drive continuous improvement in environmental performance.

Regulatory Compliance for Chemical Foaming Agents

The regulatory landscape for chemical foaming agents, including 2-Methylpentane, is complex and constantly evolving. Manufacturers and users of these substances must navigate a web of international, national, and regional regulations to ensure compliance and product safety.

At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized framework for communicating chemical hazards. Companies using 2-Methylpentane in polymeric foam production must adhere to GHS guidelines for labeling and safety data sheets.

In the United States, the Environmental Protection Agency (EPA) regulates chemical foaming agents under the Toxic Substances Control Act (TSCA). The EPA maintains an inventory of existing chemicals and requires manufacturers to submit premanufacture notices for new substances. 2-Methylpentane and similar compounds are subject to reporting requirements and potential restrictions based on their environmental and health impacts.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another crucial framework. Companies importing or manufacturing 2-Methylpentane in quantities over one tonne per year must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information.

Occupational safety regulations, such as those enforced by the U.S. Occupational Safety and Health Administration (OSHA), mandate specific workplace practices and exposure limits for chemical foaming agents. Employers must provide appropriate personal protective equipment and implement safety protocols to protect workers handling these substances.

Environmental regulations also play a significant role in compliance for chemical foaming agents. Many countries have implemented restrictions on volatile organic compounds (VOCs) and ozone-depleting substances, which may impact the use of certain foaming agents. While 2-Methylpentane is not an ozone-depleting substance, its VOC status may subject it to emission controls in some jurisdictions.

Industry-specific standards, such as those set by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO), provide guidelines for the quality and performance of polymeric foams. Compliance with these standards is often necessary for market acceptance and may be required by regulatory bodies.

As sustainability concerns grow, regulations are increasingly focusing on the entire lifecycle of chemical products. This includes considerations for recyclability, biodegradability, and overall environmental footprint. Manufacturers using 2-Methylpentane in foam production may need to address these aspects to meet emerging regulatory requirements and consumer expectations.

At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized framework for communicating chemical hazards. Companies using 2-Methylpentane in polymeric foam production must adhere to GHS guidelines for labeling and safety data sheets.

In the United States, the Environmental Protection Agency (EPA) regulates chemical foaming agents under the Toxic Substances Control Act (TSCA). The EPA maintains an inventory of existing chemicals and requires manufacturers to submit premanufacture notices for new substances. 2-Methylpentane and similar compounds are subject to reporting requirements and potential restrictions based on their environmental and health impacts.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another crucial framework. Companies importing or manufacturing 2-Methylpentane in quantities over one tonne per year must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information.

Occupational safety regulations, such as those enforced by the U.S. Occupational Safety and Health Administration (OSHA), mandate specific workplace practices and exposure limits for chemical foaming agents. Employers must provide appropriate personal protective equipment and implement safety protocols to protect workers handling these substances.

Environmental regulations also play a significant role in compliance for chemical foaming agents. Many countries have implemented restrictions on volatile organic compounds (VOCs) and ozone-depleting substances, which may impact the use of certain foaming agents. While 2-Methylpentane is not an ozone-depleting substance, its VOC status may subject it to emission controls in some jurisdictions.

Industry-specific standards, such as those set by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO), provide guidelines for the quality and performance of polymeric foams. Compliance with these standards is often necessary for market acceptance and may be required by regulatory bodies.

As sustainability concerns grow, regulations are increasingly focusing on the entire lifecycle of chemical products. This includes considerations for recyclability, biodegradability, and overall environmental footprint. Manufacturers using 2-Methylpentane in foam production may need to address these aspects to meet emerging regulatory requirements and consumer expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!