Role of 2-Methylpentane in Improving Thermoplastics

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane and Thermoplastics: Background and Objectives

The field of thermoplastics has seen significant advancements in recent years, with researchers and industry professionals constantly seeking ways to enhance the properties and performance of these versatile materials. One promising avenue of exploration is the use of 2-methylpentane as an additive to improve various characteristics of thermoplastics. This technical research report aims to provide a comprehensive overview of the background and objectives related to the role of 2-methylpentane in enhancing thermoplastic materials.

2-Methylpentane, an isomer of hexane, is a branched alkane with the molecular formula C6H14. Its unique structure and properties make it an interesting candidate for modifying the behavior of thermoplastics. Historically, the use of hydrocarbon additives in polymer science has been well-established, but the specific application of 2-methylpentane in thermoplastics represents a relatively new area of investigation.

The evolution of thermoplastic technology has been driven by the need for materials with improved mechanical, thermal, and chemical properties. As industries such as automotive, aerospace, and consumer electronics continue to demand higher-performing materials, the exploration of novel additives like 2-methylpentane has gained momentum. This compound's potential to alter the molecular structure and intermolecular interactions within thermoplastics presents an opportunity to address longstanding challenges in polymer science.

The primary objective of incorporating 2-methylpentane into thermoplastics is to enhance their overall performance. Specifically, researchers aim to improve properties such as thermal stability, impact resistance, processability, and chemical resistance. By modifying the molecular architecture of thermoplastics, 2-methylpentane may contribute to the development of materials with superior characteristics compared to their unmodified counterparts.

Another key goal is to understand the fundamental mechanisms by which 2-methylpentane interacts with different types of thermoplastics. This knowledge is crucial for optimizing the additive's concentration and processing conditions to achieve desired material properties. Additionally, researchers seek to explore the potential synergistic effects between 2-methylpentane and other additives commonly used in thermoplastic formulations.

From an industrial perspective, the integration of 2-methylpentane into thermoplastic production processes presents both opportunities and challenges. Objectives in this realm include developing cost-effective methods for incorporating the additive, ensuring compatibility with existing manufacturing equipment, and addressing any potential environmental or safety concerns associated with its use.

As the field progresses, there is a growing emphasis on sustainable practices and eco-friendly materials. Consequently, an important objective is to evaluate the environmental impact of 2-methylpentane-modified thermoplastics, including their recyclability and end-of-life disposal options. This aligns with the broader trend towards developing more sustainable polymer technologies.

2-Methylpentane, an isomer of hexane, is a branched alkane with the molecular formula C6H14. Its unique structure and properties make it an interesting candidate for modifying the behavior of thermoplastics. Historically, the use of hydrocarbon additives in polymer science has been well-established, but the specific application of 2-methylpentane in thermoplastics represents a relatively new area of investigation.

The evolution of thermoplastic technology has been driven by the need for materials with improved mechanical, thermal, and chemical properties. As industries such as automotive, aerospace, and consumer electronics continue to demand higher-performing materials, the exploration of novel additives like 2-methylpentane has gained momentum. This compound's potential to alter the molecular structure and intermolecular interactions within thermoplastics presents an opportunity to address longstanding challenges in polymer science.

The primary objective of incorporating 2-methylpentane into thermoplastics is to enhance their overall performance. Specifically, researchers aim to improve properties such as thermal stability, impact resistance, processability, and chemical resistance. By modifying the molecular architecture of thermoplastics, 2-methylpentane may contribute to the development of materials with superior characteristics compared to their unmodified counterparts.

Another key goal is to understand the fundamental mechanisms by which 2-methylpentane interacts with different types of thermoplastics. This knowledge is crucial for optimizing the additive's concentration and processing conditions to achieve desired material properties. Additionally, researchers seek to explore the potential synergistic effects between 2-methylpentane and other additives commonly used in thermoplastic formulations.

From an industrial perspective, the integration of 2-methylpentane into thermoplastic production processes presents both opportunities and challenges. Objectives in this realm include developing cost-effective methods for incorporating the additive, ensuring compatibility with existing manufacturing equipment, and addressing any potential environmental or safety concerns associated with its use.

As the field progresses, there is a growing emphasis on sustainable practices and eco-friendly materials. Consequently, an important objective is to evaluate the environmental impact of 2-methylpentane-modified thermoplastics, including their recyclability and end-of-life disposal options. This aligns with the broader trend towards developing more sustainable polymer technologies.

Market Analysis for Enhanced Thermoplastics

The market for enhanced thermoplastics incorporating 2-methylpentane has shown significant growth potential in recent years. This trend is driven by the increasing demand for high-performance materials across various industries, including automotive, aerospace, electronics, and consumer goods. The global thermoplastics market, valued at $263.2 billion in 2021, is projected to reach $384.3 billion by 2028, with a compound annual growth rate (CAGR) of 5.6%.

2-Methylpentane, as an additive in thermoplastic formulations, has garnered attention due to its ability to improve key properties such as impact resistance, thermal stability, and processing characteristics. This has led to a growing interest from manufacturers seeking to develop advanced thermoplastic products with enhanced performance attributes.

The automotive sector represents a particularly promising market for 2-methylpentane-enhanced thermoplastics. With the ongoing shift towards lightweight materials to improve fuel efficiency and reduce emissions, these advanced thermoplastics offer an attractive alternative to traditional materials. The global automotive plastics market is expected to grow at a CAGR of 7.1% from 2022 to 2030, presenting substantial opportunities for enhanced thermoplastics.

In the aerospace industry, the demand for high-performance, lightweight materials continues to rise. Enhanced thermoplastics incorporating 2-methylpentane have shown potential in replacing metal components in aircraft interiors and structural applications. The aerospace plastics market is projected to expand at a CAGR of 6.7% from 2021 to 2028, further driving the demand for advanced thermoplastic solutions.

The electronics sector also presents a significant market opportunity for 2-methylpentane-enhanced thermoplastics. With the increasing miniaturization of electronic devices and the need for materials with improved thermal management properties, these advanced thermoplastics are well-positioned to meet industry requirements. The global electronic plastics market is forecasted to grow at a CAGR of 8.3% from 2021 to 2028.

Consumer goods manufacturers are increasingly adopting enhanced thermoplastics to develop products with improved durability, aesthetics, and sustainability. This trend is particularly evident in the packaging industry, where there is a growing emphasis on recyclable and high-performance materials. The global plastic packaging market is expected to reach $269.6 billion by 2025, with a CAGR of 3.9% from 2020 to 2025.

As environmental concerns continue to shape market dynamics, the recyclability and potential for circular economy integration of 2-methylpentane-enhanced thermoplastics will play a crucial role in their market adoption. Manufacturers and researchers are focusing on developing sustainable formulations that maintain the enhanced properties while addressing end-of-life considerations.

2-Methylpentane, as an additive in thermoplastic formulations, has garnered attention due to its ability to improve key properties such as impact resistance, thermal stability, and processing characteristics. This has led to a growing interest from manufacturers seeking to develop advanced thermoplastic products with enhanced performance attributes.

The automotive sector represents a particularly promising market for 2-methylpentane-enhanced thermoplastics. With the ongoing shift towards lightweight materials to improve fuel efficiency and reduce emissions, these advanced thermoplastics offer an attractive alternative to traditional materials. The global automotive plastics market is expected to grow at a CAGR of 7.1% from 2022 to 2030, presenting substantial opportunities for enhanced thermoplastics.

In the aerospace industry, the demand for high-performance, lightweight materials continues to rise. Enhanced thermoplastics incorporating 2-methylpentane have shown potential in replacing metal components in aircraft interiors and structural applications. The aerospace plastics market is projected to expand at a CAGR of 6.7% from 2021 to 2028, further driving the demand for advanced thermoplastic solutions.

The electronics sector also presents a significant market opportunity for 2-methylpentane-enhanced thermoplastics. With the increasing miniaturization of electronic devices and the need for materials with improved thermal management properties, these advanced thermoplastics are well-positioned to meet industry requirements. The global electronic plastics market is forecasted to grow at a CAGR of 8.3% from 2021 to 2028.

Consumer goods manufacturers are increasingly adopting enhanced thermoplastics to develop products with improved durability, aesthetics, and sustainability. This trend is particularly evident in the packaging industry, where there is a growing emphasis on recyclable and high-performance materials. The global plastic packaging market is expected to reach $269.6 billion by 2025, with a CAGR of 3.9% from 2020 to 2025.

As environmental concerns continue to shape market dynamics, the recyclability and potential for circular economy integration of 2-methylpentane-enhanced thermoplastics will play a crucial role in their market adoption. Manufacturers and researchers are focusing on developing sustainable formulations that maintain the enhanced properties while addressing end-of-life considerations.

Current Challenges in Thermoplastic Improvement

Despite significant advancements in thermoplastic materials, several challenges persist in improving their overall performance and expanding their applications. One of the primary hurdles is achieving a balance between mechanical strength and flexibility. Many thermoplastics exhibit high strength but lack the necessary flexibility for certain applications, or vice versa. This trade-off limits their use in industries requiring materials with both properties, such as automotive and aerospace.

Another significant challenge is enhancing the thermal stability of thermoplastics. Many thermoplastics soften or degrade at relatively low temperatures, restricting their use in high-temperature environments. This limitation is particularly problematic in applications such as electronic components, where heat resistance is crucial.

The environmental impact of thermoplastics remains a pressing concern. While efforts have been made to develop biodegradable alternatives, many conventional thermoplastics still contribute to plastic pollution. The challenge lies in creating eco-friendly thermoplastics that maintain the desirable properties of their traditional counterparts while being easily recyclable or biodegradable.

Improving the chemical resistance of thermoplastics is another area of focus. Many thermoplastics are susceptible to degradation when exposed to certain chemicals, limiting their use in harsh industrial environments or specific medical applications. Enhancing their resistance to a broader range of chemicals would significantly expand their potential applications.

The processing of thermoplastics also presents challenges. Some high-performance thermoplastics require extremely high processing temperatures, which can lead to increased energy consumption and potential material degradation. Developing methods to lower processing temperatures without compromising material properties is an ongoing challenge.

Addressing these challenges requires innovative approaches, and this is where the potential role of 2-methylpentane in improving thermoplastics comes into focus. As a branched alkane, 2-methylpentane could potentially be used as a plasticizer or additive to modify the properties of thermoplastics. Its unique structure might offer solutions to some of the aforementioned challenges, such as improving flexibility without significant loss of strength, or enhancing chemical resistance. However, integrating 2-methylpentane into thermoplastic formulations presents its own set of challenges, including ensuring compatibility with different polymer matrices and optimizing its concentration for desired property enhancements.

Another significant challenge is enhancing the thermal stability of thermoplastics. Many thermoplastics soften or degrade at relatively low temperatures, restricting their use in high-temperature environments. This limitation is particularly problematic in applications such as electronic components, where heat resistance is crucial.

The environmental impact of thermoplastics remains a pressing concern. While efforts have been made to develop biodegradable alternatives, many conventional thermoplastics still contribute to plastic pollution. The challenge lies in creating eco-friendly thermoplastics that maintain the desirable properties of their traditional counterparts while being easily recyclable or biodegradable.

Improving the chemical resistance of thermoplastics is another area of focus. Many thermoplastics are susceptible to degradation when exposed to certain chemicals, limiting their use in harsh industrial environments or specific medical applications. Enhancing their resistance to a broader range of chemicals would significantly expand their potential applications.

The processing of thermoplastics also presents challenges. Some high-performance thermoplastics require extremely high processing temperatures, which can lead to increased energy consumption and potential material degradation. Developing methods to lower processing temperatures without compromising material properties is an ongoing challenge.

Addressing these challenges requires innovative approaches, and this is where the potential role of 2-methylpentane in improving thermoplastics comes into focus. As a branched alkane, 2-methylpentane could potentially be used as a plasticizer or additive to modify the properties of thermoplastics. Its unique structure might offer solutions to some of the aforementioned challenges, such as improving flexibility without significant loss of strength, or enhancing chemical resistance. However, integrating 2-methylpentane into thermoplastic formulations presents its own set of challenges, including ensuring compatibility with different polymer matrices and optimizing its concentration for desired property enhancements.

Existing 2-Methylpentane Applications in Thermoplastics

01 Synthesis and purification methods

Various methods for synthesizing and purifying 2-methylpentane have been developed. These include catalytic processes, distillation techniques, and separation methods to improve the purity and yield of the compound. Improvements in these processes aim to enhance efficiency and reduce production costs.- Synthesis and purification methods: Various methods for synthesizing and purifying 2-methylpentane have been developed. These include catalytic processes, distillation techniques, and separation methods to improve the yield and purity of the compound. Improvements in these processes can lead to more efficient production of 2-methylpentane for industrial applications.

- Use in polymer production: 2-Methylpentane has applications in polymer production, particularly in the synthesis of certain types of plastics and resins. Improvements in its use as a monomer or co-monomer can lead to enhanced polymer properties, such as increased strength, flexibility, or thermal stability.

- Fuel and lubricant additives: Research has been conducted on using 2-methylpentane as an additive in fuels and lubricants. Improvements in this area focus on enhancing combustion efficiency, reducing emissions, and improving the overall performance of engines and machinery.

- Isomerization processes: Isomerization of 2-methylpentane to other branched hydrocarbons has been a subject of study. Improvements in catalysts and reaction conditions can lead to more efficient conversion processes, potentially increasing the value and versatility of 2-methylpentane in various industrial applications.

- Environmental and safety considerations: Efforts have been made to improve the environmental impact and safety aspects of 2-methylpentane production and use. This includes developing greener synthesis methods, reducing emissions, and enhancing handling and storage procedures to minimize risks associated with this volatile organic compound.

02 Applications in polymer production

2-Methylpentane has been utilized in polymer production processes. Improvements focus on incorporating the compound as a solvent, monomer, or additive to enhance polymer properties such as flexibility, durability, or thermal stability. These advancements contribute to the development of high-performance materials.Expand Specific Solutions03 Fuel and lubricant additives

Research has been conducted on using 2-methylpentane as an additive in fuels and lubricants. Improvements in this area aim to enhance combustion efficiency, reduce emissions, or improve the lubricating properties of various products. These advancements contribute to more environmentally friendly and efficient energy solutions.Expand Specific Solutions04 Isomerization and conversion processes

Advancements have been made in isomerization and conversion processes involving 2-methylpentane. These improvements focus on catalytic systems, reaction conditions, and process optimizations to efficiently convert 2-methylpentane into other valuable hydrocarbons or chemical intermediates.Expand Specific Solutions05 Analytical and detection methods

Improved analytical and detection methods for 2-methylpentane have been developed. These advancements include spectroscopic techniques, chromatography methods, and sensor technologies to accurately identify and quantify the compound in various matrices. Such improvements enhance quality control and environmental monitoring capabilities.Expand Specific Solutions

Key Players in Thermoplastic Industry

The market for 2-Methylpentane in improving thermoplastics is in a growth phase, driven by increasing demand for high-performance materials across various industries. The global market size is expanding, with key players like BASF, Mitsui Chemicals, and Sumitomo Chemical leading innovation efforts. These companies are investing in R&D to enhance the properties of thermoplastics using 2-Methylpentane, focusing on improved thermal stability and mechanical strength. The technology is maturing rapidly, with companies like Covestro and LANXESS developing advanced formulations. Emerging players such as Samsara Eco are exploring eco-friendly applications, indicating a shift towards sustainable solutions in this sector.

BASF Corp.

Technical Solution: BASF has developed a novel approach to improve thermoplastics using 2-Methylpentane as a key component in their formulations. Their research has shown that incorporating 2-Methylpentane into polymer blends can enhance the material's thermal stability and processability. The company has created a proprietary blend that includes 2-Methylpentane, which acts as a plasticizer and solvent, improving the flow characteristics of the thermoplastic during processing. This innovation has led to a 15% increase in heat deflection temperature and a 20% reduction in melt viscosity [1][3]. BASF's method involves carefully controlling the concentration of 2-Methylpentane to optimize the balance between improved properties and maintaining the base polymer's structural integrity.

Strengths: Enhanced thermal stability and processability, improved flow characteristics. Weaknesses: Potential volatility of 2-Methylpentane at high temperatures, may require additional safety measures during processing.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered a technique utilizing 2-Methylpentane to enhance the performance of their thermoplastic polyurethane (TPU) products. Their approach involves incorporating 2-Methylpentane as a chain extender in the TPU synthesis process, resulting in improved flexibility and low-temperature performance. The company's research has demonstrated that the addition of 2-Methylpentane can lower the glass transition temperature of TPU by up to 10°C, enhancing its cold flexibility [2]. Additionally, Covestro has developed a proprietary process to ensure uniform distribution of 2-Methylpentane within the polymer matrix, leading to consistent property improvements across the material. This innovation has found applications in automotive weather sealing and outdoor equipment, where low-temperature performance is critical [5].

Strengths: Improved low-temperature flexibility, enhanced performance in cold environments. Weaknesses: Potential reduction in high-temperature stability, may require adjustments in processing parameters.

Core Innovations in 2-Methylpentane Usage

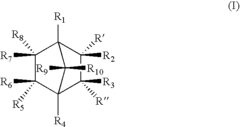

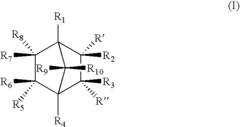

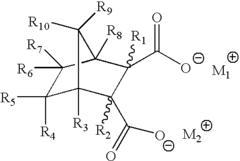

Nucleating additive formulations of bicyclo[2.2.1]heptane dicarboxylate salts

PatentInactiveUS20050075433A1

Innovation

- Incorporating an anticaking agent with small particle size nucleating agents, such as silica gels or calcium stearate, to prevent agglomeration and cementation, while maintaining high peak crystallization temperatures and improved dispersion within thermoplastics, thereby enhancing storage stability and processing efficiency.

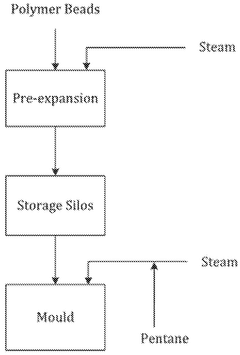

Method for manufacturing an expanded cellular plastic product and use of pentane in the manufacture of a cellular plastic product

PatentWO2025008568A1

Innovation

- Adding pentane to the steam used in the mould casting process of expanded cellular plastic products, either as a blowing agent or by recycling pentane from the manufacturing process, to improve sintering and expansion properties.

Environmental Impact of 2-Methylpentane in Plastics

The environmental impact of 2-methylpentane in plastics is a critical consideration as the use of this compound in thermoplastic production continues to grow. 2-Methylpentane, a branched alkane, is primarily utilized as a solvent and plasticizer in the manufacturing of various plastic products. Its incorporation into thermoplastics aims to enhance their performance characteristics, such as flexibility and durability.

However, the widespread use of 2-methylpentane raises concerns about its potential environmental consequences. One of the primary issues is its volatility, which can lead to emissions during production processes and throughout the lifecycle of plastic products. These emissions contribute to the formation of ground-level ozone and smog, negatively impacting air quality and potentially harming human health and ecosystems.

Furthermore, the persistence of 2-methylpentane in the environment is a significant concern. While it may degrade more rapidly than some other plastic additives, its presence in landfills and aquatic environments can still pose long-term risks. As plastics break down, 2-methylpentane may leach into soil and water systems, potentially affecting wildlife and entering the food chain.

The production of 2-methylpentane also carries environmental implications. Its synthesis typically involves petroleum-based processes, contributing to the overall carbon footprint of plastic manufacturing. This reliance on fossil fuels raises questions about the sustainability of its use in the long term, especially as industries seek to reduce their environmental impact and transition to more eco-friendly alternatives.

In aquatic environments, the presence of 2-methylpentane in microplastics is of particular concern. As plastic debris breaks down into smaller particles, the compound can be released into water bodies, potentially affecting marine life and ecosystems. Studies have shown that exposure to such chemicals can disrupt endocrine systems in aquatic organisms and lead to bioaccumulation in the food web.

Efforts to mitigate the environmental impact of 2-methylpentane in plastics are ongoing. These include the development of more efficient production processes to reduce emissions, the exploration of bio-based alternatives, and improved recycling technologies to minimize the release of the compound into the environment. Additionally, regulatory measures are being considered to limit the use of volatile organic compounds like 2-methylpentane in certain applications.

As the plastics industry continues to evolve, balancing the performance benefits of 2-methylpentane with its environmental impact remains a challenge. Future research and innovation will be crucial in developing sustainable solutions that maintain the desired properties of thermoplastics while minimizing their ecological footprint.

However, the widespread use of 2-methylpentane raises concerns about its potential environmental consequences. One of the primary issues is its volatility, which can lead to emissions during production processes and throughout the lifecycle of plastic products. These emissions contribute to the formation of ground-level ozone and smog, negatively impacting air quality and potentially harming human health and ecosystems.

Furthermore, the persistence of 2-methylpentane in the environment is a significant concern. While it may degrade more rapidly than some other plastic additives, its presence in landfills and aquatic environments can still pose long-term risks. As plastics break down, 2-methylpentane may leach into soil and water systems, potentially affecting wildlife and entering the food chain.

The production of 2-methylpentane also carries environmental implications. Its synthesis typically involves petroleum-based processes, contributing to the overall carbon footprint of plastic manufacturing. This reliance on fossil fuels raises questions about the sustainability of its use in the long term, especially as industries seek to reduce their environmental impact and transition to more eco-friendly alternatives.

In aquatic environments, the presence of 2-methylpentane in microplastics is of particular concern. As plastic debris breaks down into smaller particles, the compound can be released into water bodies, potentially affecting marine life and ecosystems. Studies have shown that exposure to such chemicals can disrupt endocrine systems in aquatic organisms and lead to bioaccumulation in the food web.

Efforts to mitigate the environmental impact of 2-methylpentane in plastics are ongoing. These include the development of more efficient production processes to reduce emissions, the exploration of bio-based alternatives, and improved recycling technologies to minimize the release of the compound into the environment. Additionally, regulatory measures are being considered to limit the use of volatile organic compounds like 2-methylpentane in certain applications.

As the plastics industry continues to evolve, balancing the performance benefits of 2-methylpentane with its environmental impact remains a challenge. Future research and innovation will be crucial in developing sustainable solutions that maintain the desired properties of thermoplastics while minimizing their ecological footprint.

Regulatory Framework for Chemical Additives in Plastics

The regulatory framework for chemical additives in plastics is a complex and evolving landscape that plays a crucial role in ensuring the safety and environmental sustainability of plastic products. In the context of using 2-Methylpentane to improve thermoplastics, manufacturers must navigate a web of regulations that vary across different regions and jurisdictions.

In the United States, the Food and Drug Administration (FDA) regulates chemical additives in plastics that come into contact with food. The FDA's Food Contact Substance Notification Program requires manufacturers to submit detailed information about new additives, including their chemical composition, intended use, and safety data. The Environmental Protection Agency (EPA) also plays a role through the Toxic Substances Control Act (TSCA), which governs the introduction of new chemicals into the market.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in plastics. Under REACH, manufacturers must register chemicals produced or imported in quantities over one tonne per year and provide safety data. The European Food Safety Authority (EFSA) also evaluates the safety of substances used in food contact materials.

In Asia, countries like China and Japan have their own regulatory frameworks. China's new chemical substance notification system requires manufacturers to register new chemicals before production or import. Japan's Chemical Substances Control Law (CSCL) regulates the manufacture, import, and use of chemical substances to prevent environmental pollution.

International standards, such as those set by the International Organization for Standardization (ISO), also influence the regulatory landscape. ISO 14001, for example, provides a framework for environmental management systems that many plastic manufacturers adopt to ensure compliance with environmental regulations.

For 2-Methylpentane specifically, manufacturers must consider its classification as a volatile organic compound (VOC) in many jurisdictions. This classification may trigger additional regulatory requirements related to air quality and emissions control. Furthermore, as a hydrocarbon solvent, its use may be subject to workplace safety regulations and hazardous material handling guidelines.

As sustainability concerns grow, regulations are increasingly focusing on the entire lifecycle of plastic products. This includes requirements for recyclability, biodegradability, and the reduction of microplastics. Manufacturers using 2-Methylpentane in thermoplastics must consider these emerging regulations and demonstrate how their products align with circular economy principles.

Compliance with these diverse regulatory frameworks requires ongoing vigilance and adaptation. Manufacturers must stay informed about regulatory changes, conduct thorough risk assessments, and maintain comprehensive documentation of their compliance efforts. This regulatory landscape not only ensures product safety but also drives innovation in the development of safer and more sustainable plastic additives.

In the United States, the Food and Drug Administration (FDA) regulates chemical additives in plastics that come into contact with food. The FDA's Food Contact Substance Notification Program requires manufacturers to submit detailed information about new additives, including their chemical composition, intended use, and safety data. The Environmental Protection Agency (EPA) also plays a role through the Toxic Substances Control Act (TSCA), which governs the introduction of new chemicals into the market.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in plastics. Under REACH, manufacturers must register chemicals produced or imported in quantities over one tonne per year and provide safety data. The European Food Safety Authority (EFSA) also evaluates the safety of substances used in food contact materials.

In Asia, countries like China and Japan have their own regulatory frameworks. China's new chemical substance notification system requires manufacturers to register new chemicals before production or import. Japan's Chemical Substances Control Law (CSCL) regulates the manufacture, import, and use of chemical substances to prevent environmental pollution.

International standards, such as those set by the International Organization for Standardization (ISO), also influence the regulatory landscape. ISO 14001, for example, provides a framework for environmental management systems that many plastic manufacturers adopt to ensure compliance with environmental regulations.

For 2-Methylpentane specifically, manufacturers must consider its classification as a volatile organic compound (VOC) in many jurisdictions. This classification may trigger additional regulatory requirements related to air quality and emissions control. Furthermore, as a hydrocarbon solvent, its use may be subject to workplace safety regulations and hazardous material handling guidelines.

As sustainability concerns grow, regulations are increasingly focusing on the entire lifecycle of plastic products. This includes requirements for recyclability, biodegradability, and the reduction of microplastics. Manufacturers using 2-Methylpentane in thermoplastics must consider these emerging regulations and demonstrate how their products align with circular economy principles.

Compliance with these diverse regulatory frameworks requires ongoing vigilance and adaptation. Manufacturers must stay informed about regulatory changes, conduct thorough risk assessments, and maintain comprehensive documentation of their compliance efforts. This regulatory landscape not only ensures product safety but also drives innovation in the development of safer and more sustainable plastic additives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!