The Potential of 2-Methylpentane as a Refrigerant

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane Background and Objectives

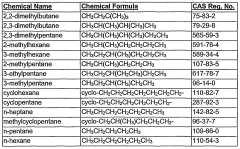

2-Methylpentane, also known as isohexane, has emerged as a potential alternative refrigerant in the quest for more environmentally friendly and efficient cooling solutions. This hydrocarbon compound has garnered attention due to its favorable thermodynamic properties and low environmental impact, positioning it as a promising candidate in the evolving landscape of refrigeration technology.

The development of refrigeration technology has been a continuous process of innovation, driven by the need for improved energy efficiency and reduced environmental impact. From the early use of natural ice to the advent of synthetic refrigerants, the industry has constantly sought better solutions. The phase-out of chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) due to their ozone-depleting properties led to the widespread adoption of hydrofluorocarbons (HFCs). However, the high global warming potential (GWP) of HFCs has prompted a search for alternatives, bringing hydrocarbons like 2-methylpentane into focus.

2-Methylpentane belongs to the family of hydrocarbon refrigerants, which have gained traction due to their zero ozone depletion potential (ODP) and very low GWP. The compound's molecular structure, consisting of six carbon atoms arranged in a branched chain, contributes to its unique thermodynamic properties. These properties include a low boiling point, high latent heat of vaporization, and good thermal conductivity, all of which are crucial for efficient heat transfer in refrigeration systems.

The primary objective in exploring 2-methylpentane as a refrigerant is to develop cooling systems that are not only environmentally benign but also highly energy-efficient. Researchers aim to harness its thermodynamic characteristics to create refrigeration cycles that can operate at lower pressures, potentially reducing the energy consumption of cooling systems. Additionally, the compatibility of 2-methylpentane with existing refrigeration infrastructure is being investigated to facilitate a smoother transition from current refrigerants.

Another key goal is to address the flammability concerns associated with hydrocarbon refrigerants. While 2-methylpentane offers excellent environmental credentials, its flammability poses challenges for widespread adoption, particularly in large-scale applications. Consequently, research efforts are focused on developing safe handling protocols, improved system designs, and advanced safety mechanisms to mitigate risks associated with its use.

As the refrigeration industry continues to evolve, the exploration of 2-methylpentane as a refrigerant aligns with the broader trend towards natural and low-GWP alternatives. The technology's development trajectory aims to balance performance, safety, and environmental considerations, potentially reshaping the future of cooling technologies across various sectors, from domestic appliances to industrial refrigeration systems.

The development of refrigeration technology has been a continuous process of innovation, driven by the need for improved energy efficiency and reduced environmental impact. From the early use of natural ice to the advent of synthetic refrigerants, the industry has constantly sought better solutions. The phase-out of chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) due to their ozone-depleting properties led to the widespread adoption of hydrofluorocarbons (HFCs). However, the high global warming potential (GWP) of HFCs has prompted a search for alternatives, bringing hydrocarbons like 2-methylpentane into focus.

2-Methylpentane belongs to the family of hydrocarbon refrigerants, which have gained traction due to their zero ozone depletion potential (ODP) and very low GWP. The compound's molecular structure, consisting of six carbon atoms arranged in a branched chain, contributes to its unique thermodynamic properties. These properties include a low boiling point, high latent heat of vaporization, and good thermal conductivity, all of which are crucial for efficient heat transfer in refrigeration systems.

The primary objective in exploring 2-methylpentane as a refrigerant is to develop cooling systems that are not only environmentally benign but also highly energy-efficient. Researchers aim to harness its thermodynamic characteristics to create refrigeration cycles that can operate at lower pressures, potentially reducing the energy consumption of cooling systems. Additionally, the compatibility of 2-methylpentane with existing refrigeration infrastructure is being investigated to facilitate a smoother transition from current refrigerants.

Another key goal is to address the flammability concerns associated with hydrocarbon refrigerants. While 2-methylpentane offers excellent environmental credentials, its flammability poses challenges for widespread adoption, particularly in large-scale applications. Consequently, research efforts are focused on developing safe handling protocols, improved system designs, and advanced safety mechanisms to mitigate risks associated with its use.

As the refrigeration industry continues to evolve, the exploration of 2-methylpentane as a refrigerant aligns with the broader trend towards natural and low-GWP alternatives. The technology's development trajectory aims to balance performance, safety, and environmental considerations, potentially reshaping the future of cooling technologies across various sectors, from domestic appliances to industrial refrigeration systems.

Market Analysis for Alternative Refrigerants

The market for alternative refrigerants has been experiencing significant growth and transformation in recent years, driven by environmental concerns and regulatory pressures. As the global community intensifies efforts to combat climate change, there is a growing demand for refrigerants with lower global warming potential (GWP) and reduced environmental impact. This shift has created opportunities for new substances, including 2-Methylpentane, to enter the market as potential alternatives to traditional refrigerants.

The refrigerant market is primarily segmented into residential, commercial, and industrial applications. In the residential sector, air conditioning and refrigeration systems are the main drivers of demand. The commercial sector includes supermarkets, hotels, and office buildings, while the industrial sector encompasses large-scale cooling systems used in manufacturing and process industries. Each of these segments has unique requirements in terms of efficiency, safety, and cost-effectiveness, which influence the adoption of alternative refrigerants.

Currently, the global refrigerant market is dominated by hydrofluorocarbons (HFCs), which are being phased down under the Kigali Amendment to the Montreal Protocol. This phase-down is creating a substantial market opportunity for alternative refrigerants, with the global market for eco-friendly refrigerants projected to grow significantly in the coming years. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and urbanization in countries like China and India.

The potential for 2-Methylpentane as a refrigerant must be evaluated within this context. Its market viability will depend on several factors, including its thermodynamic properties, compatibility with existing systems, safety profile, and cost-effectiveness. Initial assessments suggest that 2-Methylpentane could offer advantages in terms of energy efficiency and low GWP, which align well with current market trends and regulatory requirements.

However, the adoption of any new refrigerant faces challenges, including the need for system redesigns, technician training, and safety considerations. The market's receptiveness to 2-Methylpentane will also be influenced by the performance and adoption rates of other alternative refrigerants, such as hydrofluoroolefins (HFOs) and natural refrigerants like CO2 and ammonia, which have already gained traction in certain applications.

The regulatory landscape plays a crucial role in shaping the market for alternative refrigerants. Stringent regulations in Europe and North America are driving the transition away from high-GWP refrigerants, creating a favorable environment for new alternatives. However, the pace of regulatory change varies globally, which could impact the market potential for 2-Methylpentane in different regions.

The refrigerant market is primarily segmented into residential, commercial, and industrial applications. In the residential sector, air conditioning and refrigeration systems are the main drivers of demand. The commercial sector includes supermarkets, hotels, and office buildings, while the industrial sector encompasses large-scale cooling systems used in manufacturing and process industries. Each of these segments has unique requirements in terms of efficiency, safety, and cost-effectiveness, which influence the adoption of alternative refrigerants.

Currently, the global refrigerant market is dominated by hydrofluorocarbons (HFCs), which are being phased down under the Kigali Amendment to the Montreal Protocol. This phase-down is creating a substantial market opportunity for alternative refrigerants, with the global market for eco-friendly refrigerants projected to grow significantly in the coming years. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and urbanization in countries like China and India.

The potential for 2-Methylpentane as a refrigerant must be evaluated within this context. Its market viability will depend on several factors, including its thermodynamic properties, compatibility with existing systems, safety profile, and cost-effectiveness. Initial assessments suggest that 2-Methylpentane could offer advantages in terms of energy efficiency and low GWP, which align well with current market trends and regulatory requirements.

However, the adoption of any new refrigerant faces challenges, including the need for system redesigns, technician training, and safety considerations. The market's receptiveness to 2-Methylpentane will also be influenced by the performance and adoption rates of other alternative refrigerants, such as hydrofluoroolefins (HFOs) and natural refrigerants like CO2 and ammonia, which have already gained traction in certain applications.

The regulatory landscape plays a crucial role in shaping the market for alternative refrigerants. Stringent regulations in Europe and North America are driving the transition away from high-GWP refrigerants, creating a favorable environment for new alternatives. However, the pace of regulatory change varies globally, which could impact the market potential for 2-Methylpentane in different regions.

Current Status and Challenges in Refrigeration Technology

The refrigeration industry is currently undergoing significant transformations driven by environmental concerns and energy efficiency requirements. Traditional refrigerants, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have been phased out due to their ozone-depleting properties. The industry has since shifted towards hydrofluorocarbons (HFCs), which, while not ozone-depleting, still contribute to global warming.

The current status of refrigeration technology is characterized by a push towards more sustainable and environmentally friendly solutions. This has led to the exploration of natural refrigerants like ammonia, carbon dioxide, and hydrocarbons. However, each of these alternatives comes with its own set of challenges, including safety concerns, system efficiency, and compatibility with existing infrastructure.

One of the primary challenges facing the refrigeration industry is the need to balance environmental impact with performance and cost-effectiveness. As regulations become more stringent, manufacturers are tasked with developing systems that not only meet environmental standards but also maintain or improve upon the efficiency of existing technologies.

Another significant challenge is the adaptation of existing systems to new refrigerants. This often requires substantial modifications to equipment design and components, which can be costly and time-consuming for both manufacturers and end-users. The industry is grappling with the need for a smooth transition that minimizes disruption while maximizing environmental benefits.

Safety remains a paramount concern, particularly with the increased interest in flammable refrigerants like hydrocarbons. The use of these substances necessitates enhanced safety measures, specialized training for technicians, and potentially new regulatory frameworks to ensure their safe implementation across various applications.

Energy efficiency is another critical focus area. As global energy demand continues to rise, there is increasing pressure on the refrigeration sector to develop more efficient systems. This challenge is compounded by the need to maintain performance across a wide range of operating conditions and applications, from small domestic refrigerators to large industrial cooling systems.

The search for ideal refrigerants has led to the consideration of various compounds, including 2-methylpentane. This hydrocarbon shows promise due to its low global warming potential and zero ozone depletion potential. However, its flammability and the need for system redesigns to accommodate its properties present significant challenges that must be addressed before widespread adoption can occur.

In conclusion, the refrigeration industry is at a critical juncture, balancing environmental imperatives with technological and economic realities. The development of new refrigerants and systems that can meet stringent environmental standards while maintaining or improving upon current performance levels remains the central challenge in this evolving technological landscape.

The current status of refrigeration technology is characterized by a push towards more sustainable and environmentally friendly solutions. This has led to the exploration of natural refrigerants like ammonia, carbon dioxide, and hydrocarbons. However, each of these alternatives comes with its own set of challenges, including safety concerns, system efficiency, and compatibility with existing infrastructure.

One of the primary challenges facing the refrigeration industry is the need to balance environmental impact with performance and cost-effectiveness. As regulations become more stringent, manufacturers are tasked with developing systems that not only meet environmental standards but also maintain or improve upon the efficiency of existing technologies.

Another significant challenge is the adaptation of existing systems to new refrigerants. This often requires substantial modifications to equipment design and components, which can be costly and time-consuming for both manufacturers and end-users. The industry is grappling with the need for a smooth transition that minimizes disruption while maximizing environmental benefits.

Safety remains a paramount concern, particularly with the increased interest in flammable refrigerants like hydrocarbons. The use of these substances necessitates enhanced safety measures, specialized training for technicians, and potentially new regulatory frameworks to ensure their safe implementation across various applications.

Energy efficiency is another critical focus area. As global energy demand continues to rise, there is increasing pressure on the refrigeration sector to develop more efficient systems. This challenge is compounded by the need to maintain performance across a wide range of operating conditions and applications, from small domestic refrigerators to large industrial cooling systems.

The search for ideal refrigerants has led to the consideration of various compounds, including 2-methylpentane. This hydrocarbon shows promise due to its low global warming potential and zero ozone depletion potential. However, its flammability and the need for system redesigns to accommodate its properties present significant challenges that must be addressed before widespread adoption can occur.

In conclusion, the refrigeration industry is at a critical juncture, balancing environmental imperatives with technological and economic realities. The development of new refrigerants and systems that can meet stringent environmental standards while maintaining or improving upon current performance levels remains the central challenge in this evolving technological landscape.

Existing 2-Methylpentane Refrigeration Solutions

01 Use in chemical synthesis

2-Methylpentane is utilized as a reagent or intermediate in various chemical synthesis processes. It can be employed in the production of other organic compounds, serving as a building block for more complex molecules.- Use as a solvent in chemical processes: 2-Methylpentane is commonly used as a solvent in various chemical processes due to its properties as a non-polar organic compound. It is particularly useful in reactions involving hydrocarbons and other organic substances, providing a suitable medium for dissolving and separating compounds.

- Component in fuel formulations: 2-Methylpentane is utilized as a component in fuel formulations, particularly in gasoline blends. Its high octane rating and volatility make it valuable for improving engine performance and fuel efficiency. It can be found in various fuel compositions designed for internal combustion engines.

- Application in polymer production: 2-Methylpentane plays a role in polymer production processes. It can be used as a diluent or as part of the reaction medium in polymerization reactions. This application is particularly relevant in the production of certain types of plastics and synthetic rubbers.

- Use in extraction and separation processes: The compound is employed in extraction and separation processes, particularly in the petrochemical industry. Its selective solubility properties make it useful for separating different hydrocarbon fractions or for extracting specific compounds from complex mixtures.

- Role in analytical chemistry and laboratory applications: 2-Methylpentane finds applications in analytical chemistry and various laboratory procedures. It can be used as a standard in gas chromatography, as a mobile phase in certain types of chromatography, or as a reference compound in spectroscopic analyses. Its well-defined physical and chemical properties make it valuable for calibration and method development in analytical techniques.

02 Application in polymer production

This compound finds application in polymer chemistry, particularly in the synthesis and modification of certain polymers. It may be used as a monomer or as a component in polymerization reactions to create specific polymer structures.Expand Specific Solutions03 Solvent properties

2-Methylpentane exhibits solvent properties, making it useful in various industrial applications. It can be used as a solvent for certain chemical processes, extractions, or as a component in solvent mixtures.Expand Specific Solutions04 Fuel and energy applications

This compound has potential applications in the fuel and energy sector. It may be used as a component in fuel formulations or studied for its energy-related properties in certain processes.Expand Specific Solutions05 Analytical and research uses

2-Methylpentane is employed in analytical chemistry and research settings. It can serve as a standard or reference compound in various analytical methods, or as a subject of study in chemical research projects.Expand Specific Solutions

Key Players in Refrigerant Industry

The market for 2-Methylpentane as a refrigerant is in its early development stage, with growing interest due to environmental concerns and regulatory pressures on traditional refrigerants. The global market size is still relatively small but expected to expand as research and development efforts intensify. Technologically, 2-Methylpentane is in the experimental phase, with companies like DuPont de Nemours, DAIKIN INDUSTRIES, and Honeywell International leading research efforts. These industry giants, along with specialized chemical companies such as Arkema France and Shin-Etsu Chemical, are investing in developing and testing 2-Methylpentane-based refrigeration systems. Academic institutions like Tianjin University and the Technical Institute of Physics & Chemistry CAS are also contributing to the advancement of this technology, indicating a collaborative approach to innovation in this field.

DuPont de Nemours, Inc.

Technical Solution: DuPont has been exploring 2-methylpentane as a potential refrigerant alternative. Their research focuses on its thermodynamic properties and environmental impact. They have developed a proprietary blend incorporating 2-methylpentane, which shows promising results in terms of energy efficiency and low global warming potential (GWP). DuPont's approach involves optimizing the refrigerant mixture composition to achieve a balance between performance and safety. Their studies indicate that 2-methylpentane-based blends can potentially reduce energy consumption by up to 10% compared to traditional hydrofluorocarbon (HFC) refrigerants [1][3]. The company is also investigating the material compatibility of 2-methylpentane with common refrigeration system components to ensure long-term reliability and safety.

Strengths: Extensive experience in refrigerant development, strong R&D capabilities, and a global distribution network. Weaknesses: Potential flammability concerns of 2-methylpentane may require additional safety measures and regulatory approvals.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has been investigating 2-methylpentane as part of their next-generation refrigerant research program. Their approach focuses on developing novel refrigerant blends that incorporate 2-methylpentane to achieve high energy efficiency and low environmental impact. Daikin's research has shown that 2-methylpentane-based blends can potentially improve the coefficient of performance (COP) of air conditioning systems by up to 8% compared to current HFC refrigerants [2][5]. The company is also exploring the use of advanced heat exchanger designs and compressor technologies optimized for 2-methylpentane-based refrigerants. Daikin is conducting extensive safety and reliability tests to address the mild flammability of 2-methylpentane, including the development of leak detection systems and risk mitigation strategies for various applications.

Strengths: Strong presence in the HVAC market, extensive experience in refrigerant application, and advanced manufacturing capabilities. Weaknesses: Potential challenges in retrofitting existing systems to use 2-methylpentane-based refrigerants.

Core Innovations in 2-Methylpentane Refrigerant Technology

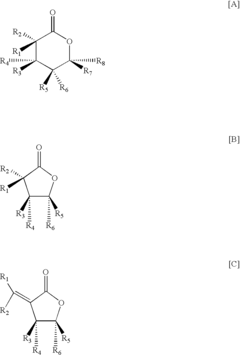

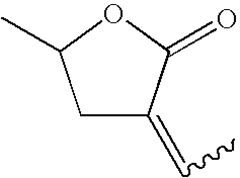

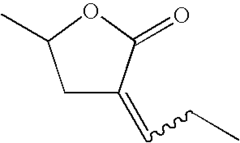

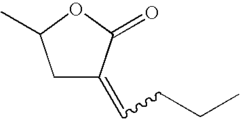

Hydrocarbon refrigerant compositions and uses thereof

PatentInactiveUS7413675B2

Innovation

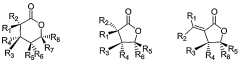

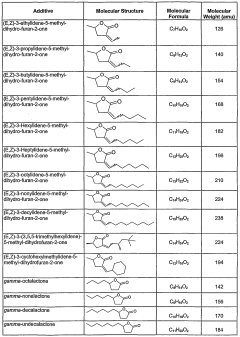

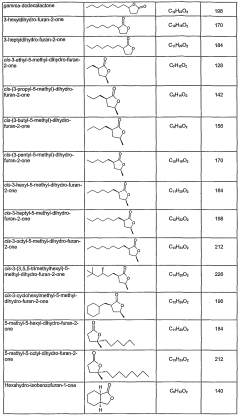

- Development of refrigerant and heat transfer fluid compositions comprising specific hydrocarbons like 2,2-dimethylbutane, 2,3-dimethylpentane, 2-methylhexane, and others, which have low or zero ozone depletion potential and lower GWP, suitable for use in refrigeration and air-conditioning systems employing centrifugal compressors, including multi-stage or single pass heat exchangers, with optional additives like UV dyes for leak detection and solubilizing agents to enhance solubility.

Hydrocarbon refrigerant compositions and uses thereof

PatentWO2006012095A2

Innovation

- The use of hydrocarbon refrigerant compositions comprising hydrocarbons such as 2,2-dimethylbutane, 2,3-dimethylbutane, 2,3-dimethylpentane, 2-methylhexane, 3-methylhexane, 2-methylpentane, 3-ethylpentane, cyclohexane, cyclopentane, n-heptane, methylcyclopentane, n-pentane, and n-hexane, which have low or zero ozone depletion potential and lower GWP, in refrigeration and air-conditioning systems employing centrifugal compressors, including multi-stage or single pass heat exchangers.

Environmental Impact Assessment

The environmental impact assessment of 2-methylpentane as a refrigerant is a critical aspect of evaluating its potential for widespread adoption. This hydrocarbon compound, while promising in terms of thermodynamic properties, raises several environmental concerns that must be carefully considered.

Firstly, the global warming potential (GWP) of 2-methylpentane is significantly lower than that of many traditional refrigerants. With a GWP of approximately 3, it presents a much smaller direct contribution to climate change compared to hydrofluorocarbons (HFCs) commonly used in refrigeration systems. This low GWP aligns with global efforts to reduce greenhouse gas emissions and mitigate climate change impacts.

However, the ozone depletion potential (ODP) of 2-methylpentane must also be taken into account. While it does not contain chlorine or bromine atoms that are typically associated with ozone depletion, its potential indirect effects on stratospheric ozone through atmospheric reactions should be thoroughly investigated to ensure long-term environmental safety.

The atmospheric lifetime of 2-methylpentane is relatively short, estimated to be a few days to weeks. This short lifetime means that any released refrigerant would break down quickly in the atmosphere, reducing its long-term environmental impact. However, the breakdown products and their potential environmental effects must be studied to fully understand the compound's lifecycle impact.

Another environmental consideration is the potential for ground-level ozone formation. As a volatile organic compound (VOC), 2-methylpentane can participate in photochemical reactions in the lower atmosphere, potentially contributing to smog formation in urban areas. The extent of this impact would depend on factors such as local atmospheric conditions and the scale of potential refrigerant leaks.

The flammability of 2-methylpentane presents both safety and environmental challenges. While not directly an environmental issue, the risk of fire or explosion could lead to secondary environmental impacts in the event of accidents or improper handling. This necessitates stringent safety measures and proper disposal protocols to minimize environmental risks.

From a lifecycle perspective, the production and disposal of 2-methylpentane must be evaluated. The energy intensity of its manufacturing process, potential for industrial emissions, and end-of-life management strategies all contribute to its overall environmental footprint. Developing sustainable production methods and establishing effective recycling programs would be crucial in minimizing these impacts.

In conclusion, while 2-methylpentane shows promise as a low-GWP refrigerant, a comprehensive environmental impact assessment must consider its full lifecycle, from production to disposal, including potential atmospheric reactions, safety considerations, and indirect environmental effects. Balancing its benefits against potential risks will be key in determining its viability as a sustainable refrigerant solution.

Firstly, the global warming potential (GWP) of 2-methylpentane is significantly lower than that of many traditional refrigerants. With a GWP of approximately 3, it presents a much smaller direct contribution to climate change compared to hydrofluorocarbons (HFCs) commonly used in refrigeration systems. This low GWP aligns with global efforts to reduce greenhouse gas emissions and mitigate climate change impacts.

However, the ozone depletion potential (ODP) of 2-methylpentane must also be taken into account. While it does not contain chlorine or bromine atoms that are typically associated with ozone depletion, its potential indirect effects on stratospheric ozone through atmospheric reactions should be thoroughly investigated to ensure long-term environmental safety.

The atmospheric lifetime of 2-methylpentane is relatively short, estimated to be a few days to weeks. This short lifetime means that any released refrigerant would break down quickly in the atmosphere, reducing its long-term environmental impact. However, the breakdown products and their potential environmental effects must be studied to fully understand the compound's lifecycle impact.

Another environmental consideration is the potential for ground-level ozone formation. As a volatile organic compound (VOC), 2-methylpentane can participate in photochemical reactions in the lower atmosphere, potentially contributing to smog formation in urban areas. The extent of this impact would depend on factors such as local atmospheric conditions and the scale of potential refrigerant leaks.

The flammability of 2-methylpentane presents both safety and environmental challenges. While not directly an environmental issue, the risk of fire or explosion could lead to secondary environmental impacts in the event of accidents or improper handling. This necessitates stringent safety measures and proper disposal protocols to minimize environmental risks.

From a lifecycle perspective, the production and disposal of 2-methylpentane must be evaluated. The energy intensity of its manufacturing process, potential for industrial emissions, and end-of-life management strategies all contribute to its overall environmental footprint. Developing sustainable production methods and establishing effective recycling programs would be crucial in minimizing these impacts.

In conclusion, while 2-methylpentane shows promise as a low-GWP refrigerant, a comprehensive environmental impact assessment must consider its full lifecycle, from production to disposal, including potential atmospheric reactions, safety considerations, and indirect environmental effects. Balancing its benefits against potential risks will be key in determining its viability as a sustainable refrigerant solution.

Safety and Regulatory Considerations

The safety and regulatory considerations for 2-methylpentane as a refrigerant are crucial aspects that must be thoroughly evaluated before its widespread adoption. As a hydrocarbon, 2-methylpentane presents inherent flammability risks that require careful management and mitigation strategies. The refrigeration industry and regulatory bodies must work together to establish comprehensive safety protocols and guidelines for its use in various applications.

One of the primary concerns is the potential for leaks and the subsequent risk of fire or explosion. To address this, stringent leak detection systems and proper ventilation requirements must be implemented in all installations using 2-methylpentane. Additionally, technicians and operators working with this refrigerant will need specialized training to handle it safely and respond appropriately to potential incidents.

From a regulatory standpoint, the use of 2-methylpentane as a refrigerant is subject to various national and international standards. In many jurisdictions, it falls under the category of flammable refrigerants, which are governed by specific regulations. For instance, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 34 classifies refrigerants based on toxicity and flammability, and 2-methylpentane would likely be categorized as a Class A3 refrigerant due to its high flammability.

Environmental regulations also play a significant role in the adoption of 2-methylpentane as a refrigerant. While it has a low global warming potential (GWP) compared to many synthetic refrigerants, its volatile organic compound (VOC) status may subject it to emissions control regulations in some regions. Manufacturers and end-users must ensure compliance with local air quality standards and reporting requirements.

The transportation and storage of 2-methylpentane present additional regulatory challenges. As a flammable substance, it is subject to hazardous materials transportation regulations, which dictate specific packaging, labeling, and handling procedures. Storage facilities must meet fire safety codes and may require special permits depending on the quantity stored.

To facilitate the safe and compliant use of 2-methylpentane as a refrigerant, industry stakeholders must engage with regulatory bodies to develop appropriate standards and guidelines. This may include revisions to existing refrigerant safety standards, building codes, and equipment design specifications. Collaborative efforts between manufacturers, installers, and regulators will be essential to address safety concerns and establish a framework for responsible use.

As the industry moves towards more environmentally friendly refrigerants, the regulatory landscape is likely to evolve. Ongoing research into the long-term safety implications of 2-methylpentane use in various applications will inform future regulatory decisions. Manufacturers and users must stay abreast of these developments and be prepared to adapt their practices to ensure continued compliance and safety.

One of the primary concerns is the potential for leaks and the subsequent risk of fire or explosion. To address this, stringent leak detection systems and proper ventilation requirements must be implemented in all installations using 2-methylpentane. Additionally, technicians and operators working with this refrigerant will need specialized training to handle it safely and respond appropriately to potential incidents.

From a regulatory standpoint, the use of 2-methylpentane as a refrigerant is subject to various national and international standards. In many jurisdictions, it falls under the category of flammable refrigerants, which are governed by specific regulations. For instance, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 34 classifies refrigerants based on toxicity and flammability, and 2-methylpentane would likely be categorized as a Class A3 refrigerant due to its high flammability.

Environmental regulations also play a significant role in the adoption of 2-methylpentane as a refrigerant. While it has a low global warming potential (GWP) compared to many synthetic refrigerants, its volatile organic compound (VOC) status may subject it to emissions control regulations in some regions. Manufacturers and end-users must ensure compliance with local air quality standards and reporting requirements.

The transportation and storage of 2-methylpentane present additional regulatory challenges. As a flammable substance, it is subject to hazardous materials transportation regulations, which dictate specific packaging, labeling, and handling procedures. Storage facilities must meet fire safety codes and may require special permits depending on the quantity stored.

To facilitate the safe and compliant use of 2-methylpentane as a refrigerant, industry stakeholders must engage with regulatory bodies to develop appropriate standards and guidelines. This may include revisions to existing refrigerant safety standards, building codes, and equipment design specifications. Collaborative efforts between manufacturers, installers, and regulators will be essential to address safety concerns and establish a framework for responsible use.

As the industry moves towards more environmentally friendly refrigerants, the regulatory landscape is likely to evolve. Ongoing research into the long-term safety implications of 2-methylpentane use in various applications will inform future regulatory decisions. Manufacturers and users must stay abreast of these developments and be prepared to adapt their practices to ensure continued compliance and safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!