Achieving Eye-Safety Compliance In High-Power Metasurface LiDARs

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface LiDAR Eye-Safety Background and Objectives

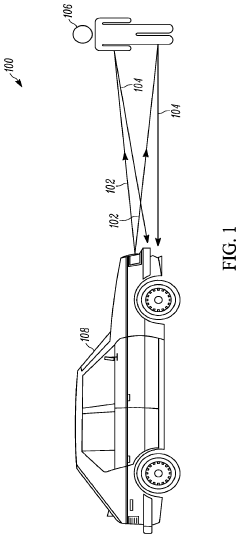

LiDAR (Light Detection and Ranging) technology has evolved significantly since its inception in the 1960s, with recent advancements focusing on miniaturization, cost reduction, and performance enhancement. The emergence of metasurface-based LiDAR represents a revolutionary step in this evolution, offering unprecedented capabilities in beam steering, focusing, and manipulation through engineered nanostructures that interact with light at subwavelength scales.

The development trajectory of LiDAR technology has progressed from bulky mechanical systems to solid-state solutions, with metasurface LiDARs emerging as a promising next-generation technology. These systems leverage artificially engineered surfaces with nanoscale features to control electromagnetic waves with exceptional precision, enabling more efficient and compact LiDAR systems suitable for autonomous vehicles, robotics, and advanced sensing applications.

However, as LiDAR systems advance toward higher power outputs to achieve greater range and resolution, eye safety has become a critical concern. High-power laser emissions can pose significant risks to human vision, particularly when operating in wavelengths that can penetrate and damage the retina. The challenge lies in balancing performance requirements with stringent safety standards established by regulatory bodies worldwide.

International safety standards such as IEC 60825 and ANSI Z136.1 classify lasers based on their potential hazards, with specific limits on permissible exposure. Class 1 lasers, considered safe under all normal use conditions, represent the ideal target for consumer and commercial LiDAR applications. The technical objective is to develop metasurface LiDAR systems that maintain Class 1 eye-safety compliance while delivering the high-power performance necessary for demanding applications.

Current research trends indicate growing interest in innovative approaches to achieve this balance, including wavelength optimization (shifting to eye-safer spectral regions), beam shaping techniques (distributing energy more safely), and dynamic power management systems. The integration of metasurfaces offers unique opportunities to address these challenges through precise control of beam characteristics.

The primary technical goals for eye-safe high-power metasurface LiDARs include: developing novel metasurface designs that enable efficient beam manipulation while maintaining safe power densities; creating intelligent power management systems that dynamically adjust laser output based on environmental conditions and proximity to potential observers; and establishing comprehensive testing methodologies to validate eye-safety compliance across various operational scenarios.

Additionally, there is a growing emphasis on developing metasurface LiDAR systems that operate in wavelength bands with inherently better eye-safety profiles, such as the 1400-2100nm range, where light is more readily absorbed by the eye's outer tissues before reaching the sensitive retina, thus allowing for higher power operation while maintaining safety margins.

The development trajectory of LiDAR technology has progressed from bulky mechanical systems to solid-state solutions, with metasurface LiDARs emerging as a promising next-generation technology. These systems leverage artificially engineered surfaces with nanoscale features to control electromagnetic waves with exceptional precision, enabling more efficient and compact LiDAR systems suitable for autonomous vehicles, robotics, and advanced sensing applications.

However, as LiDAR systems advance toward higher power outputs to achieve greater range and resolution, eye safety has become a critical concern. High-power laser emissions can pose significant risks to human vision, particularly when operating in wavelengths that can penetrate and damage the retina. The challenge lies in balancing performance requirements with stringent safety standards established by regulatory bodies worldwide.

International safety standards such as IEC 60825 and ANSI Z136.1 classify lasers based on their potential hazards, with specific limits on permissible exposure. Class 1 lasers, considered safe under all normal use conditions, represent the ideal target for consumer and commercial LiDAR applications. The technical objective is to develop metasurface LiDAR systems that maintain Class 1 eye-safety compliance while delivering the high-power performance necessary for demanding applications.

Current research trends indicate growing interest in innovative approaches to achieve this balance, including wavelength optimization (shifting to eye-safer spectral regions), beam shaping techniques (distributing energy more safely), and dynamic power management systems. The integration of metasurfaces offers unique opportunities to address these challenges through precise control of beam characteristics.

The primary technical goals for eye-safe high-power metasurface LiDARs include: developing novel metasurface designs that enable efficient beam manipulation while maintaining safe power densities; creating intelligent power management systems that dynamically adjust laser output based on environmental conditions and proximity to potential observers; and establishing comprehensive testing methodologies to validate eye-safety compliance across various operational scenarios.

Additionally, there is a growing emphasis on developing metasurface LiDAR systems that operate in wavelength bands with inherently better eye-safety profiles, such as the 1400-2100nm range, where light is more readily absorbed by the eye's outer tissues before reaching the sensitive retina, thus allowing for higher power operation while maintaining safety margins.

Market Analysis for Eye-Safe High-Power LiDAR Systems

The global market for eye-safe high-power LiDAR systems is experiencing robust growth, driven by increasing applications in autonomous vehicles, industrial automation, and advanced sensing technologies. Current market valuations indicate that the LiDAR market reached approximately 2.1 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 21.6% through 2030.

The automotive sector represents the largest market segment, accounting for over 40% of total LiDAR demand. This is primarily fueled by the rapid development of advanced driver-assistance systems (ADAS) and autonomous driving technologies. Within this segment, eye-safety compliance has emerged as a critical factor influencing purchasing decisions, with over 85% of automotive manufacturers citing safety standards as a primary consideration.

Industrial applications constitute the second-largest market segment at 25%, where high-power LiDAR systems are increasingly deployed in manufacturing, warehousing, and logistics operations. The demand for eye-safe systems in these environments is particularly acute due to human-machine collaboration scenarios.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization and automotive sector expansion in China, Japan, and South Korea.

Consumer sensitivity to eye-safety has become a significant market differentiator. Recent surveys indicate that 73% of end-users express concerns about potential eye hazards from LiDAR systems, particularly in consumer-facing applications. This has created a premium market segment for demonstrably eye-safe technologies, with price premiums of 15-20% for systems with enhanced safety features.

Regulatory frameworks are increasingly stringent, with the International Electrotechnical Commission (IEC) standards for laser safety becoming more widely adopted globally. The market is witnessing a shift toward Class 1 laser systems that are inherently safe under all conditions of normal use, creating both challenges and opportunities for manufacturers.

The metasurface LiDAR subsegment is projected to grow at 32% annually, outpacing the broader LiDAR market. This accelerated growth is attributed to the technology's potential to deliver higher performance while maintaining eye-safety compliance through innovative beam steering and power management capabilities.

Market consolidation is evident, with several major acquisitions occurring in the past 24 months as established automotive and technology companies seek to secure advanced LiDAR capabilities. Venture capital investment in eye-safe LiDAR startups has reached 1.8 billion USD since 2020, indicating strong confidence in the technology's commercial potential and market demand.

The automotive sector represents the largest market segment, accounting for over 40% of total LiDAR demand. This is primarily fueled by the rapid development of advanced driver-assistance systems (ADAS) and autonomous driving technologies. Within this segment, eye-safety compliance has emerged as a critical factor influencing purchasing decisions, with over 85% of automotive manufacturers citing safety standards as a primary consideration.

Industrial applications constitute the second-largest market segment at 25%, where high-power LiDAR systems are increasingly deployed in manufacturing, warehousing, and logistics operations. The demand for eye-safe systems in these environments is particularly acute due to human-machine collaboration scenarios.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization and automotive sector expansion in China, Japan, and South Korea.

Consumer sensitivity to eye-safety has become a significant market differentiator. Recent surveys indicate that 73% of end-users express concerns about potential eye hazards from LiDAR systems, particularly in consumer-facing applications. This has created a premium market segment for demonstrably eye-safe technologies, with price premiums of 15-20% for systems with enhanced safety features.

Regulatory frameworks are increasingly stringent, with the International Electrotechnical Commission (IEC) standards for laser safety becoming more widely adopted globally. The market is witnessing a shift toward Class 1 laser systems that are inherently safe under all conditions of normal use, creating both challenges and opportunities for manufacturers.

The metasurface LiDAR subsegment is projected to grow at 32% annually, outpacing the broader LiDAR market. This accelerated growth is attributed to the technology's potential to deliver higher performance while maintaining eye-safety compliance through innovative beam steering and power management capabilities.

Market consolidation is evident, with several major acquisitions occurring in the past 24 months as established automotive and technology companies seek to secure advanced LiDAR capabilities. Venture capital investment in eye-safe LiDAR startups has reached 1.8 billion USD since 2020, indicating strong confidence in the technology's commercial potential and market demand.

Current Challenges in Metasurface LiDAR Eye-Safety Compliance

Despite the promising advancements in metasurface LiDAR technology, ensuring eye safety compliance presents significant challenges that must be addressed before widespread commercial deployment. The primary concern stems from the fundamental conflict between the need for high optical power to achieve extended detection ranges and the regulatory limitations imposed to protect human vision. Current international standards, including IEC 60825 and ANSI Z136.1, establish strict maximum permissible exposure (MPE) limits that vary based on wavelength, pulse duration, and beam characteristics.

Metasurface LiDARs operating at 905nm and 1550nm wavelengths face different compliance hurdles. The 905nm systems encounter more stringent power restrictions as this wavelength can penetrate the eye's cornea and focus directly on the retina, potentially causing permanent damage. While 1550nm systems benefit from higher MPE thresholds due to corneal absorption, they still face challenges when implementing high-power configurations necessary for long-range detection.

The miniaturized nature of metasurface optical components creates unique thermal management issues that can affect beam stability and wavelength consistency. As power levels increase to extend detection range, thermal effects can cause wavelength drift, potentially shifting emissions into more hazardous spectral regions. This unpredictable behavior complicates compliance certification and requires sophisticated monitoring systems.

Beam steering mechanisms in metasurface LiDARs introduce additional complexity for eye safety compliance. Unlike conventional mechanical systems, metasurface-based beam steering can produce rapid changes in beam direction and focus characteristics. Current safety standards were primarily developed for more predictable beam patterns, creating regulatory gaps for these dynamic optical systems. The potential for unexpected beam convergence or hotspots during steering operations presents unaddressed safety concerns.

Manufacturing inconsistencies in metasurface fabrication further complicate compliance efforts. Nanoscale variations in metasurface structures can lead to unpredictable optical behavior, including scattered light, diffraction effects, and power distribution anomalies. These variations make it difficult to guarantee consistent safety performance across production units without implementing costly quality control measures.

The integration of multiple metasurface elements in advanced LiDAR systems creates complex beam interaction scenarios that are challenging to model for safety certification. When multiple beams interact or when beam characteristics change dynamically based on environmental conditions, traditional safety testing protocols may not adequately capture all potential hazard scenarios.

Current testing and certification methodologies lack standardized approaches specifically designed for metasurface optical systems. The unique beam characteristics, dynamic operation modes, and novel failure mechanisms of these systems require updated testing protocols that can accurately assess safety across all operational conditions and failure modes.

Metasurface LiDARs operating at 905nm and 1550nm wavelengths face different compliance hurdles. The 905nm systems encounter more stringent power restrictions as this wavelength can penetrate the eye's cornea and focus directly on the retina, potentially causing permanent damage. While 1550nm systems benefit from higher MPE thresholds due to corneal absorption, they still face challenges when implementing high-power configurations necessary for long-range detection.

The miniaturized nature of metasurface optical components creates unique thermal management issues that can affect beam stability and wavelength consistency. As power levels increase to extend detection range, thermal effects can cause wavelength drift, potentially shifting emissions into more hazardous spectral regions. This unpredictable behavior complicates compliance certification and requires sophisticated monitoring systems.

Beam steering mechanisms in metasurface LiDARs introduce additional complexity for eye safety compliance. Unlike conventional mechanical systems, metasurface-based beam steering can produce rapid changes in beam direction and focus characteristics. Current safety standards were primarily developed for more predictable beam patterns, creating regulatory gaps for these dynamic optical systems. The potential for unexpected beam convergence or hotspots during steering operations presents unaddressed safety concerns.

Manufacturing inconsistencies in metasurface fabrication further complicate compliance efforts. Nanoscale variations in metasurface structures can lead to unpredictable optical behavior, including scattered light, diffraction effects, and power distribution anomalies. These variations make it difficult to guarantee consistent safety performance across production units without implementing costly quality control measures.

The integration of multiple metasurface elements in advanced LiDAR systems creates complex beam interaction scenarios that are challenging to model for safety certification. When multiple beams interact or when beam characteristics change dynamically based on environmental conditions, traditional safety testing protocols may not adequately capture all potential hazard scenarios.

Current testing and certification methodologies lack standardized approaches specifically designed for metasurface optical systems. The unique beam characteristics, dynamic operation modes, and novel failure mechanisms of these systems require updated testing protocols that can accurately assess safety across all operational conditions and failure modes.

Current Eye-Safety Solutions for High-Power LiDAR Systems

01 Metasurface beam steering for eye-safe LiDAR

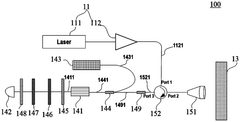

Metasurfaces can be used in LiDAR systems to control and steer laser beams in ways that enhance eye safety. These optical structures allow for precise manipulation of beam direction, intensity, and divergence, enabling the development of LiDAR systems that maintain effective detection capabilities while operating at eye-safe power levels. The metasurface elements can dynamically adjust the beam properties based on operational conditions to ensure compliance with safety standards.- Metasurface design for eye-safe LiDAR systems: Metasurfaces can be designed to manipulate light in ways that enhance eye safety in LiDAR systems. These nanostructured optical components can control beam divergence, intensity distribution, and wavelength characteristics to ensure that the emitted laser radiation remains within eye-safe limits. By engineering the metasurface pattern, manufacturers can create LiDAR systems that maintain performance while complying with international eye safety standards such as IEC 60825.

- Wavelength management for eye-safety compliance: Managing the wavelength of LiDAR systems is crucial for eye safety compliance. Metasurface-based LiDARs can be designed to operate at wavelengths that are inherently safer for human eyes, such as 1550 nm, which is absorbed by the cornea and lens rather than reaching the retina. These metasurfaces can also incorporate wavelength filtering and conversion mechanisms to ensure that any potentially harmful wavelengths are attenuated or eliminated from the output beam.

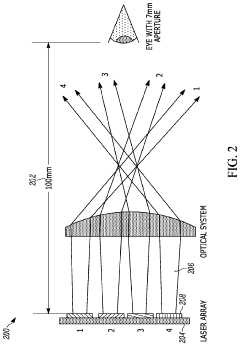

- Power control and beam shaping techniques: Metasurfaces enable sophisticated power control and beam shaping techniques that are essential for eye-safe LiDAR operation. These include dynamic power adjustment based on environmental conditions, beam diffusion to reduce power density, and spatial light modulation to create safer beam profiles. By distributing the laser energy across a wider area or implementing pulsed operation with controlled duty cycles, metasurface LiDARs can maintain detection capabilities while reducing potential eye hazards.

- Monitoring and safety feedback systems: Advanced metasurface LiDAR systems incorporate monitoring and safety feedback mechanisms to ensure continuous eye-safety compliance. These systems may include real-time power monitoring, automatic shutdown features if anomalies are detected, and adaptive control algorithms that adjust output parameters based on proximity to potential observers. Such safety systems are crucial for maintaining compliance with regulatory standards while optimizing LiDAR performance in dynamic environments.

- Certification and testing protocols: Specific certification and testing protocols have been developed for verifying the eye-safety compliance of metasurface LiDAR systems. These protocols include standardized measurement techniques for laser emission characteristics, exposure limit calculations based on international safety standards, and validation procedures for different operational modes. Manufacturers must demonstrate compliance through rigorous testing that accounts for both normal operation and potential failure modes to ensure that their metasurface LiDAR products meet or exceed safety requirements.

02 Power management techniques for eye-safe operation

Various power management techniques can be implemented in metasurface LiDAR systems to ensure eye safety compliance. These include adaptive power control algorithms that adjust laser output based on distance to objects, environmental conditions, and detection requirements. By dynamically managing power levels while maintaining detection performance, these systems can operate within eye-safe limits across various operational scenarios without compromising functionality.Expand Specific Solutions03 Wavelength selection for enhanced eye safety

Selection of specific wavelengths for LiDAR operation can significantly impact eye safety compliance. Metasurface LiDAR systems can be designed to operate at wavelengths that are inherently safer for human eyes, such as those in the 1400-1550 nm range, which are absorbed by the cornea and lens before reaching the retina. The metasurface elements can be optimized to efficiently work with these safer wavelengths while maintaining detection performance and range capabilities.Expand Specific Solutions04 Safety monitoring and compliance verification systems

Integrated safety monitoring systems can be incorporated into metasurface LiDAR designs to continuously verify eye-safety compliance during operation. These systems include real-time power monitoring, automatic shutdown mechanisms if safety thresholds are exceeded, and built-in testing capabilities. Some designs incorporate redundant safety features and self-diagnostic routines to ensure that the LiDAR system remains within regulatory safety limits under all operating conditions.Expand Specific Solutions05 Beam pattern optimization for safety and performance

Advanced beam pattern optimization techniques can be employed in metasurface LiDAR systems to enhance both safety and performance. By carefully designing the spatial and temporal characteristics of the emitted light patterns, these systems can distribute energy more effectively, reducing peak intensities while maintaining detection capabilities. Multiple beam configurations, pulse modulation strategies, and dynamic beam shaping can all contribute to achieving eye-safe operation without sacrificing the range or resolution of the LiDAR system.Expand Specific Solutions

Leading Companies in Metasurface LiDAR Development

The eye-safety compliance landscape in high-power metasurface LiDAR technology is currently in a transitional growth phase, with the market expected to reach significant expansion as autonomous vehicle adoption increases. Companies like Hesai Technology, RoboSense, and Innoviz Technologies are leading technological advancement with innovative approaches to balance power requirements with safety standards. Emerging players such as Lumotive are pioneering metasurface-based beam steering solutions that address eye-safety concerns while maintaining performance. Traditional automotive suppliers including Bosch and Koito Manufacturing are integrating these technologies into their product ecosystems. The technology is approaching maturity in controlled environments but still faces challenges in variable real-world conditions, with academic institutions like Caltech and Zhejiang University contributing fundamental research to overcome these limitations.

Opsys Tech Ltd.

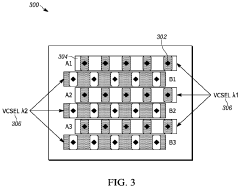

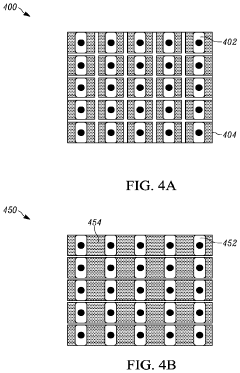

Technical Solution: Opsys Tech has developed an innovative approach to eye-safety compliance in high-power LiDAR systems through their Pure Solid-State Scanning (PSSS) technology enhanced with metasurface optics. Their solution integrates specially designed metasurface elements that enable precise control over laser beam characteristics without requiring mechanical components. The metasurfaces in Opsys' system consist of nanoscale structures that manipulate light at the sub-wavelength level, allowing for sophisticated beam shaping and energy distribution control. Their LiDAR architecture employs a unique combination of VCSEL (Vertical-Cavity Surface-Emitting Laser) arrays and metasurface optical elements to create a system that inherently distributes laser energy across multiple beams, reducing peak power density while maintaining effective detection range. This approach enables their LiDAR systems to achieve Class 1 eye-safety ratings under IEC 60825-1 standards while delivering detection ranges suitable for automotive and industrial applications. The metasurface components in their design enable dynamic adjustment of beam divergence based on detection requirements, automatically expanding beam width when operating at close ranges where eye-safety concerns are most critical.

Strengths: Truly solid-state design with no moving parts enhances reliability and durability; distributed laser architecture inherently improves eye-safety profile; compact form factor suitable for integration into various platforms. Weaknesses: Manufacturing complexity of metasurface components increases production costs; beam quality and uniformity can be challenging to maintain across wide temperature ranges; system requires sophisticated calibration procedures.

Hesai Technology Co. Ltd.

Technical Solution: Hesai has developed innovative metasurface-based LiDAR systems that address eye-safety compliance through their proprietary "Dynamic Power Adjustment" technology. This approach utilizes metasurface optical components to precisely control laser beam divergence and power distribution across the field of view. Their AT128 and FT120 models incorporate microelectromechanical systems (MEMS) with metasurface elements that dynamically adjust laser power based on detection range and environmental conditions. The metasurface structures enable beam shaping that maintains power density below the Maximum Permissible Exposure (MPE) limits defined by IEC 60825 standards while preserving detection range performance. Hesai's implementation includes real-time monitoring systems that adjust laser output power when objects or people are detected at close range, ensuring eye-safety compliance without compromising long-range detection capabilities. Their patented optical design distributes laser energy more uniformly across the beam profile, reducing peak intensity while maintaining sufficient return signal strength for accurate measurements.

Strengths: Advanced dynamic power adjustment capability allows for optimal performance at various ranges while maintaining eye safety; proprietary metasurface designs enable precise beam shaping for uniform power distribution. Weaknesses: System complexity increases manufacturing costs; power adjustment mechanisms may introduce latency in certain operational scenarios; requires sophisticated calibration to maintain performance across temperature variations.

Key Patents in Metasurface LiDAR Eye-Safety Technology

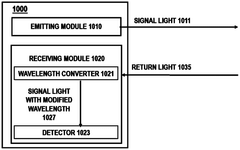

Eye-safe scanning LIDAR system

PatentActiveUS11927694B2

Innovation

- The implementation of a multi-wavelength LIDAR system with a pseudorandom firing sequence and specific firing patterns for laser arrays, ensuring that overlapping optical beams do not exceed the Maximum Permissible Exposure (MPE) limits, and utilizing VCSEL devices in array configurations to manage laser power and energy distribution.

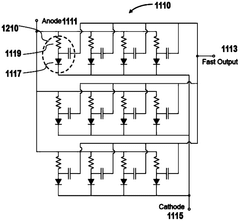

Systems and methods for improving lidar performance

PatentWO2021164067A1

Innovation

- Implementation of a wavelength converter that transforms longer wavelength echo signals to shorter wavelengths, enabling the use of eye-safe laser beams while overcoming detection challenges associated with longer wavelengths.

- Utilization of pulsed fiber lasers instead of pulsed diode lasers to provide more stable eye-safe light beams in the 1400-2050 nm wavelength range.

- Integration of single-photon level sensitivity detectors (such as analog silicon photomultipliers) in the receiving module to detect weak echo signals, improving detection range and signal-to-noise ratio.

Regulatory Framework for Laser Eye-Safety Certification

Laser eye-safety certification is governed by a complex framework of international and regional standards that manufacturers of high-power metasurface LiDAR systems must navigate. The International Electrotechnical Commission (IEC) standard 60825-1 serves as the primary global benchmark, classifying lasers into categories (1, 1M, 2, 2M, 3R, 3B, and 4) based on their potential hazard level. For automotive and consumer LiDAR applications, achieving Class 1 certification is typically mandatory, indicating the system is safe under all reasonably foreseeable use conditions.

In the United States, the Food and Drug Administration (FDA) enforces laser safety through the Center for Devices and Radiological Health (CDRH), which has adopted standards largely aligned with IEC guidelines but with some region-specific requirements. The FDA's 21 CFR 1040.10 and 1040.11 regulations provide the legal framework for laser product safety, including specific provisions for LiDAR systems used in various applications.

The European Union implements laser safety through the EN 60825-1 standard, which mirrors the IEC framework but includes additional requirements under broader directives such as the General Product Safety Directive (GPSD) and specific automotive regulations for vehicle-mounted LiDAR systems. Manufacturers seeking to deploy metasurface LiDAR technology in Europe must obtain CE marking, demonstrating compliance with all applicable directives.

Asian markets present varying regulatory landscapes. Japan follows the JIS C 6802 standard, closely aligned with IEC guidelines. China implements the GB 7247.1 standard with additional certification requirements through the China Compulsory Certification (CCC) system for certain applications. South Korea adheres to KS C IEC 60825-1, with oversight from the Korean Agency for Technology and Standards.

The certification process for high-power metasurface LiDARs typically involves several critical steps: comprehensive risk assessment, laboratory testing by accredited facilities, documentation of safety features, and submission of technical files to relevant regulatory bodies. Key parameters evaluated include Maximum Permissible Exposure (MPE), Accessible Emission Limit (AEL), Nominal Ocular Hazard Distance (NOHD), and beam divergence characteristics.

Recent regulatory trends indicate increasing scrutiny of pulsed laser systems, which are common in high-performance LiDAR applications. Regulatory bodies are developing more nuanced frameworks to address the unique characteristics of metasurface-based beam steering technologies, which can create complex emission patterns not fully addressed by traditional safety standards developed for conventional laser systems.

In the United States, the Food and Drug Administration (FDA) enforces laser safety through the Center for Devices and Radiological Health (CDRH), which has adopted standards largely aligned with IEC guidelines but with some region-specific requirements. The FDA's 21 CFR 1040.10 and 1040.11 regulations provide the legal framework for laser product safety, including specific provisions for LiDAR systems used in various applications.

The European Union implements laser safety through the EN 60825-1 standard, which mirrors the IEC framework but includes additional requirements under broader directives such as the General Product Safety Directive (GPSD) and specific automotive regulations for vehicle-mounted LiDAR systems. Manufacturers seeking to deploy metasurface LiDAR technology in Europe must obtain CE marking, demonstrating compliance with all applicable directives.

Asian markets present varying regulatory landscapes. Japan follows the JIS C 6802 standard, closely aligned with IEC guidelines. China implements the GB 7247.1 standard with additional certification requirements through the China Compulsory Certification (CCC) system for certain applications. South Korea adheres to KS C IEC 60825-1, with oversight from the Korean Agency for Technology and Standards.

The certification process for high-power metasurface LiDARs typically involves several critical steps: comprehensive risk assessment, laboratory testing by accredited facilities, documentation of safety features, and submission of technical files to relevant regulatory bodies. Key parameters evaluated include Maximum Permissible Exposure (MPE), Accessible Emission Limit (AEL), Nominal Ocular Hazard Distance (NOHD), and beam divergence characteristics.

Recent regulatory trends indicate increasing scrutiny of pulsed laser systems, which are common in high-performance LiDAR applications. Regulatory bodies are developing more nuanced frameworks to address the unique characteristics of metasurface-based beam steering technologies, which can create complex emission patterns not fully addressed by traditional safety standards developed for conventional laser systems.

Risk Assessment Methodologies for LiDAR Implementation

Risk assessment for high-power metasurface LiDAR systems requires comprehensive methodologies to ensure eye safety compliance while maintaining optimal performance. The primary assessment framework begins with laser classification according to IEC 60825-1 standards, which categorizes lasers based on their potential to cause harm. For metasurface LiDARs, which often operate at higher power levels to achieve extended range detection, this classification becomes particularly critical.

Quantitative risk assessment techniques must incorporate Maximum Permissible Exposure (MPE) calculations that account for the unique beam characteristics of metasurface-based systems. These calculations must consider not only peak power but also the spatial and temporal distribution of energy, as metasurfaces can significantly alter beam profiles compared to conventional LiDAR systems.

Failure Mode and Effects Analysis (FMEA) represents another essential methodology, specifically adapted for metasurface LiDAR implementations. This approach identifies potential failure points in the optical system that could lead to unsafe emission levels, including metasurface degradation, control system malfunctions, or beam steering errors that might concentrate energy beyond safe thresholds.

Monte Carlo simulations provide valuable insights by modeling various operational scenarios and environmental conditions. These simulations can predict the probability of eye safety violations under different use cases, accounting for variables such as atmospheric conditions, reflective surfaces, and dynamic beam steering patterns unique to metasurface technology.

Real-time monitoring methodologies constitute a critical component of risk management. These systems continuously evaluate beam characteristics, comparing them against predefined safety thresholds. For metasurface LiDARs, this monitoring must account for the dynamic nature of beam forming and steering, implementing immediate power reduction protocols when potential hazards are detected.

Regulatory compliance verification methodologies ensure adherence to international standards such as IEC 60825, ANSI Z136.1, and regional regulations. These methodologies include documentation procedures, testing protocols, and certification processes specifically tailored to the unique characteristics of metasurface-based systems.

Human factors analysis examines the interaction between users and LiDAR systems, identifying scenarios where inadvertent exposure might occur. This analysis is particularly important for automotive and consumer applications where untrained individuals may encounter these systems. The assessment must consider the unique beam patterns and operational modes of metasurface technology.

Finally, comprehensive risk assessment methodologies must include mitigation strategy evaluation, which assesses the effectiveness of implemented safety measures such as automatic power reduction, fail-safe mechanisms, and physical barriers. These evaluations must be periodically updated as metasurface technology evolves and new potential hazards are identified.

Quantitative risk assessment techniques must incorporate Maximum Permissible Exposure (MPE) calculations that account for the unique beam characteristics of metasurface-based systems. These calculations must consider not only peak power but also the spatial and temporal distribution of energy, as metasurfaces can significantly alter beam profiles compared to conventional LiDAR systems.

Failure Mode and Effects Analysis (FMEA) represents another essential methodology, specifically adapted for metasurface LiDAR implementations. This approach identifies potential failure points in the optical system that could lead to unsafe emission levels, including metasurface degradation, control system malfunctions, or beam steering errors that might concentrate energy beyond safe thresholds.

Monte Carlo simulations provide valuable insights by modeling various operational scenarios and environmental conditions. These simulations can predict the probability of eye safety violations under different use cases, accounting for variables such as atmospheric conditions, reflective surfaces, and dynamic beam steering patterns unique to metasurface technology.

Real-time monitoring methodologies constitute a critical component of risk management. These systems continuously evaluate beam characteristics, comparing them against predefined safety thresholds. For metasurface LiDARs, this monitoring must account for the dynamic nature of beam forming and steering, implementing immediate power reduction protocols when potential hazards are detected.

Regulatory compliance verification methodologies ensure adherence to international standards such as IEC 60825, ANSI Z136.1, and regional regulations. These methodologies include documentation procedures, testing protocols, and certification processes specifically tailored to the unique characteristics of metasurface-based systems.

Human factors analysis examines the interaction between users and LiDAR systems, identifying scenarios where inadvertent exposure might occur. This analysis is particularly important for automotive and consumer applications where untrained individuals may encounter these systems. The assessment must consider the unique beam patterns and operational modes of metasurface technology.

Finally, comprehensive risk assessment methodologies must include mitigation strategy evaluation, which assesses the effectiveness of implemented safety measures such as automatic power reduction, fail-safe mechanisms, and physical barriers. These evaluations must be periodically updated as metasurface technology evolves and new potential hazards are identified.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!