Scaling Aperture Size While Preserving Beam Quality In Metasurface LiDAR

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface LiDAR Aperture Scaling Background and Objectives

LiDAR (Light Detection and Ranging) technology has evolved significantly over the past decades, transitioning from bulky mechanical systems to more compact and efficient solid-state solutions. Within this evolution, metasurface-based LiDAR represents one of the most promising frontiers in optical sensing technology. Metasurfaces—artificially engineered surfaces with subwavelength structures—have emerged as revolutionary optical components capable of manipulating light in ways conventional optics cannot achieve.

The historical trajectory of LiDAR development has been driven by demands for higher resolution, longer range, and more compact form factors across various applications including autonomous vehicles, robotics, and environmental monitoring. Traditional LiDAR systems faced fundamental limitations in size reduction while maintaining performance, creating a technological bottleneck that metasurface technology aims to address.

Metasurface LiDAR technology leverages nanophotonic principles to control light wavefronts with unprecedented precision. The critical challenge in this domain involves scaling the aperture size of metasurface-based beam steering devices while preserving beam quality—a fundamental trade-off that has limited practical implementation. Larger apertures theoretically enable longer detection ranges and higher resolution, but traditionally result in degraded beam quality due to fabrication constraints and physical limitations.

Current research objectives in metasurface LiDAR aperture scaling focus on several key areas: developing novel nanofabrication techniques to maintain phase uniformity across larger areas; implementing innovative metasurface architectures that can compensate for scaling-induced aberrations; and creating hierarchical designs that effectively combine multiple smaller, high-quality metasurfaces into larger functional arrays.

The technological trajectory indicates a convergence toward hybrid solutions that integrate conventional optics with metasurface elements to overcome scaling limitations. Recent breakthroughs in phase-gradient metasurfaces and reconfigurable designs have demonstrated promising results in maintaining beam quality while increasing aperture dimensions.

The ultimate objective of current research efforts is to achieve centimeter-scale metasurface apertures that maintain diffraction-limited beam quality while enabling wide-angle beam steering—a combination that would revolutionize LiDAR performance metrics including range, resolution, and form factor. This advancement would potentially enable the next generation of compact, high-performance sensing systems for autonomous navigation and environmental perception.

Industry projections suggest that successful scaling of metasurface apertures could reduce LiDAR system volumes by an order of magnitude while simultaneously improving detection range by 30-50%, representing a step-change in sensing capability for autonomous systems.

The historical trajectory of LiDAR development has been driven by demands for higher resolution, longer range, and more compact form factors across various applications including autonomous vehicles, robotics, and environmental monitoring. Traditional LiDAR systems faced fundamental limitations in size reduction while maintaining performance, creating a technological bottleneck that metasurface technology aims to address.

Metasurface LiDAR technology leverages nanophotonic principles to control light wavefronts with unprecedented precision. The critical challenge in this domain involves scaling the aperture size of metasurface-based beam steering devices while preserving beam quality—a fundamental trade-off that has limited practical implementation. Larger apertures theoretically enable longer detection ranges and higher resolution, but traditionally result in degraded beam quality due to fabrication constraints and physical limitations.

Current research objectives in metasurface LiDAR aperture scaling focus on several key areas: developing novel nanofabrication techniques to maintain phase uniformity across larger areas; implementing innovative metasurface architectures that can compensate for scaling-induced aberrations; and creating hierarchical designs that effectively combine multiple smaller, high-quality metasurfaces into larger functional arrays.

The technological trajectory indicates a convergence toward hybrid solutions that integrate conventional optics with metasurface elements to overcome scaling limitations. Recent breakthroughs in phase-gradient metasurfaces and reconfigurable designs have demonstrated promising results in maintaining beam quality while increasing aperture dimensions.

The ultimate objective of current research efforts is to achieve centimeter-scale metasurface apertures that maintain diffraction-limited beam quality while enabling wide-angle beam steering—a combination that would revolutionize LiDAR performance metrics including range, resolution, and form factor. This advancement would potentially enable the next generation of compact, high-performance sensing systems for autonomous navigation and environmental perception.

Industry projections suggest that successful scaling of metasurface apertures could reduce LiDAR system volumes by an order of magnitude while simultaneously improving detection range by 30-50%, representing a step-change in sensing capability for autonomous systems.

Market Analysis for High-Resolution LiDAR Systems

The global LiDAR market is experiencing robust growth, projected to reach $3.8 billion by 2025 with a CAGR of 34.0% from 2020. High-resolution LiDAR systems represent a premium segment within this market, driven primarily by autonomous vehicles, advanced driver-assistance systems (ADAS), and industrial automation applications. The demand for metasurface-based LiDAR solutions with larger aperture sizes is particularly strong in these sectors due to their potential to deliver superior range and resolution while maintaining compact form factors.

Autonomous vehicle manufacturers constitute the largest market segment, with companies like Waymo, Tesla, and traditional automakers investing heavily in LiDAR technology. This segment values the extended range and improved object detection capabilities that larger aperture metasurface LiDAR can provide, especially for highway driving scenarios where early obstacle detection is critical. Market research indicates that automotive LiDAR alone could reach $1.8 billion by 2025.

The industrial automation sector presents another significant market opportunity, particularly in warehouse robotics and manufacturing environments. These applications require high-precision sensing capabilities for object recognition and manipulation tasks. The market for industrial LiDAR systems is growing at approximately 28% annually, with particular demand for solutions that can maintain beam quality while offering wider field-of-view capabilities.

Smart infrastructure and urban planning applications represent an emerging market segment with substantial growth potential. Cities worldwide are investing in intelligent traffic management systems, pedestrian monitoring, and security applications that benefit from high-resolution LiDAR. This market segment is expected to grow at 40% annually over the next five years, albeit from a smaller base.

Consumer electronics represents a potentially transformative market for metasurface LiDAR technology. As smartphone manufacturers and AR/VR device makers seek to incorporate advanced 3D sensing capabilities, the demand for miniaturized yet high-performance LiDAR solutions is increasing. Apple's integration of LiDAR in premium devices has established a precedent that competitors are likely to follow, creating a mass-market opportunity for scaled-aperture metasurface technology.

Regional analysis shows North America leading LiDAR adoption with 42% market share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 38% annually, driven by rapid industrialization and smart city initiatives in China, Japan, and South Korea.

Customer requirements across these markets consistently emphasize the need for improved resolution without compromising on size, weight, power consumption, or cost. This directly aligns with the technical challenge of scaling aperture size while preserving beam quality in metasurface LiDAR systems, indicating strong market pull for innovations in this specific area.

Autonomous vehicle manufacturers constitute the largest market segment, with companies like Waymo, Tesla, and traditional automakers investing heavily in LiDAR technology. This segment values the extended range and improved object detection capabilities that larger aperture metasurface LiDAR can provide, especially for highway driving scenarios where early obstacle detection is critical. Market research indicates that automotive LiDAR alone could reach $1.8 billion by 2025.

The industrial automation sector presents another significant market opportunity, particularly in warehouse robotics and manufacturing environments. These applications require high-precision sensing capabilities for object recognition and manipulation tasks. The market for industrial LiDAR systems is growing at approximately 28% annually, with particular demand for solutions that can maintain beam quality while offering wider field-of-view capabilities.

Smart infrastructure and urban planning applications represent an emerging market segment with substantial growth potential. Cities worldwide are investing in intelligent traffic management systems, pedestrian monitoring, and security applications that benefit from high-resolution LiDAR. This market segment is expected to grow at 40% annually over the next five years, albeit from a smaller base.

Consumer electronics represents a potentially transformative market for metasurface LiDAR technology. As smartphone manufacturers and AR/VR device makers seek to incorporate advanced 3D sensing capabilities, the demand for miniaturized yet high-performance LiDAR solutions is increasing. Apple's integration of LiDAR in premium devices has established a precedent that competitors are likely to follow, creating a mass-market opportunity for scaled-aperture metasurface technology.

Regional analysis shows North America leading LiDAR adoption with 42% market share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 38% annually, driven by rapid industrialization and smart city initiatives in China, Japan, and South Korea.

Customer requirements across these markets consistently emphasize the need for improved resolution without compromising on size, weight, power consumption, or cost. This directly aligns with the technical challenge of scaling aperture size while preserving beam quality in metasurface LiDAR systems, indicating strong market pull for innovations in this specific area.

Technical Challenges in Large-Aperture Metasurface Development

The development of large-aperture metasurfaces for LiDAR applications faces several significant technical challenges that currently limit their widespread implementation. One of the primary obstacles is maintaining phase uniformity across expanded aperture sizes. As the metasurface area increases, ensuring consistent phase control becomes exponentially more difficult due to fabrication variations and material inconsistencies. These variations, often at the nanometer scale, can cause destructive interference patterns that severely degrade beam quality and coherence.

Manufacturing precision presents another substantial hurdle. Current nanofabrication techniques like electron beam lithography offer excellent resolution but become prohibitively expensive and time-consuming when scaled to larger areas. Alternative methods such as nanoimprint lithography show promise for larger-scale production but struggle to maintain the sub-wavelength precision required for optimal metasurface performance across expanded apertures.

Thermal management emerges as a critical challenge when scaling aperture size. Larger metasurfaces experience greater thermal gradients when subjected to high-power laser sources, leading to thermal expansion and refractive index changes that distort the wavefront. These thermal effects can dynamically alter the metasurface's optical properties during operation, resulting in beam steering errors and reduced resolution in LiDAR systems.

Material limitations further constrain large-aperture development. Current metasurface designs rely heavily on plasmonic materials like gold and silver or dielectric materials such as silicon and titanium dioxide. While these materials perform well in small-scale applications, they exhibit increased absorption losses and structural instability when implemented across larger areas, directly impacting beam quality and operational efficiency.

Computational complexity represents another significant barrier. Designing large-aperture metasurfaces requires massive computational resources to simulate electromagnetic interactions across millions of nanostructures. Traditional simulation approaches become computationally intractable as aperture size increases, necessitating new algorithmic approaches and approximation methods that may sacrifice accuracy for feasibility.

Integration challenges with existing optical systems also impede progress. Large-aperture metasurfaces must interface seamlessly with conventional optical components while maintaining their beam-forming advantages. Current packaging and integration methods often introduce additional aberrations at the boundaries between metasurfaces and traditional optics, degrading overall system performance.

Finally, polarization management becomes increasingly complex with larger apertures. Maintaining polarization purity across expanded metasurfaces is difficult due to fabrication non-uniformities and edge effects. Since many metasurface designs are inherently polarization-sensitive, these issues can significantly impact beam quality and limit the effectiveness of large-aperture implementations in practical LiDAR systems.

Manufacturing precision presents another substantial hurdle. Current nanofabrication techniques like electron beam lithography offer excellent resolution but become prohibitively expensive and time-consuming when scaled to larger areas. Alternative methods such as nanoimprint lithography show promise for larger-scale production but struggle to maintain the sub-wavelength precision required for optimal metasurface performance across expanded apertures.

Thermal management emerges as a critical challenge when scaling aperture size. Larger metasurfaces experience greater thermal gradients when subjected to high-power laser sources, leading to thermal expansion and refractive index changes that distort the wavefront. These thermal effects can dynamically alter the metasurface's optical properties during operation, resulting in beam steering errors and reduced resolution in LiDAR systems.

Material limitations further constrain large-aperture development. Current metasurface designs rely heavily on plasmonic materials like gold and silver or dielectric materials such as silicon and titanium dioxide. While these materials perform well in small-scale applications, they exhibit increased absorption losses and structural instability when implemented across larger areas, directly impacting beam quality and operational efficiency.

Computational complexity represents another significant barrier. Designing large-aperture metasurfaces requires massive computational resources to simulate electromagnetic interactions across millions of nanostructures. Traditional simulation approaches become computationally intractable as aperture size increases, necessitating new algorithmic approaches and approximation methods that may sacrifice accuracy for feasibility.

Integration challenges with existing optical systems also impede progress. Large-aperture metasurfaces must interface seamlessly with conventional optical components while maintaining their beam-forming advantages. Current packaging and integration methods often introduce additional aberrations at the boundaries between metasurfaces and traditional optics, degrading overall system performance.

Finally, polarization management becomes increasingly complex with larger apertures. Maintaining polarization purity across expanded metasurfaces is difficult due to fabrication non-uniformities and edge effects. Since many metasurface designs are inherently polarization-sensitive, these issues can significantly impact beam quality and limit the effectiveness of large-aperture implementations in practical LiDAR systems.

Current Approaches to Beam Quality Preservation in Large Apertures

01 Metasurface design for LiDAR aperture optimization

Metasurfaces can be designed with specific patterns and structures to optimize the aperture size of LiDAR systems. These engineered surfaces manipulate electromagnetic waves at the subwavelength scale, allowing for reduced aperture sizes while maintaining or improving beam quality. The metasurface elements can be arranged to control the phase, amplitude, and polarization of light, enabling more compact and efficient LiDAR systems with enhanced performance characteristics.- Metasurface design for LiDAR aperture optimization: Metasurfaces can be designed with specific patterns and structures to optimize the aperture size of LiDAR systems. These designs allow for more compact LiDAR systems without compromising performance. By manipulating the phase and amplitude of light at the subwavelength scale, metasurfaces enable control over the aperture characteristics, resulting in improved beam quality and detection range while maintaining a smaller form factor.

- Beam quality enhancement through metasurface technology: Metasurfaces can significantly enhance beam quality in LiDAR systems by controlling wavefront shaping and reducing aberrations. These engineered surfaces enable precise manipulation of light propagation, resulting in more focused and coherent beams. Advanced metasurface designs incorporate nanostructures that can correct phase distortions, minimize beam divergence, and improve overall beam quality, leading to more accurate and longer-range LiDAR performance.

- Aperture size optimization for LiDAR performance: The aperture size of LiDAR systems directly impacts their performance characteristics, including range, resolution, and field of view. Optimizing aperture dimensions involves balancing competing factors such as system compactness, power requirements, and detection capabilities. Advanced designs incorporate variable aperture sizes that can be dynamically adjusted based on environmental conditions and detection requirements, enhancing the versatility and effectiveness of LiDAR systems in various applications.

- Integration of metasurfaces with conventional LiDAR components: Integrating metasurfaces with conventional LiDAR components creates hybrid systems that leverage the advantages of both technologies. These integrated designs can incorporate metasurfaces into existing optical paths to enhance beam steering, focusing, and collimation without requiring complete system redesigns. The integration enables improved performance in terms of beam quality and aperture efficiency while maintaining compatibility with established LiDAR architectures and manufacturing processes.

- Novel materials for metasurface-based LiDAR systems: Advanced materials play a crucial role in developing high-performance metasurfaces for LiDAR applications. Materials with specific optical properties, such as high refractive index contrast and low absorption losses, enable more efficient light manipulation at the nanoscale. Recent developments include phase-change materials, plasmonic structures, and dielectric resonators that can be precisely engineered to achieve desired beam characteristics. These novel materials contribute to improved beam quality, reduced aperture size requirements, and enhanced overall system performance.

02 Beam quality enhancement through metasurface technology

Metasurfaces can significantly improve LiDAR beam quality by controlling wavefront shaping and reducing aberrations. By incorporating subwavelength structures that precisely manipulate light propagation, these advanced optical components can generate highly directional beams with reduced side lobes and improved spatial coherence. This enhancement in beam quality leads to better resolution, increased detection range, and improved signal-to-noise ratio in LiDAR systems, particularly important for applications requiring high precision measurements.Expand Specific Solutions03 Aperture size reduction while maintaining performance

Innovative metasurface designs enable significant reduction in LiDAR aperture size without compromising performance metrics. By leveraging the unique properties of metasurfaces to manipulate light at the subwavelength scale, engineers can create more compact LiDAR systems that maintain beam quality, range, and resolution. This miniaturization is achieved through carefully designed nanostructures that efficiently control light propagation, enabling the development of smaller, lighter LiDAR systems suitable for integration into space-constrained applications like autonomous vehicles and drones.Expand Specific Solutions04 Dynamic beam steering and focusing capabilities

Metasurface-based LiDAR systems can incorporate dynamic beam steering and focusing capabilities, allowing for adaptive control of the aperture and beam characteristics. These systems can electronically or mechanically reconfigure the metasurface elements to adjust the beam direction, focus, and shape in real-time. This adaptability enables LiDAR systems to optimize their performance based on changing environmental conditions or specific detection requirements, enhancing overall system versatility and effectiveness.Expand Specific Solutions05 Integration of metasurfaces with conventional LiDAR components

Metasurfaces can be effectively integrated with conventional LiDAR components to create hybrid systems that leverage the advantages of both technologies. By combining metasurfaces with traditional optical elements such as lenses, mirrors, and detectors, engineers can develop LiDAR systems with optimized aperture size and superior beam quality. These hybrid approaches often result in systems that overcome the limitations of conventional designs while maintaining compatibility with existing manufacturing processes and integration standards.Expand Specific Solutions

Leading Companies and Research Institutions in Metasurface LiDAR

The metasurface LiDAR market is currently in an early growth phase, characterized by rapid technological innovation and increasing commercial applications. The global market size for advanced LiDAR systems is projected to reach $3.8 billion by 2025, with metasurface technology representing a disruptive segment. From a technical maturity perspective, companies are at varying development stages. Lumotive and Metalenz lead with commercialized metasurface beam steering solutions, while established LiDAR manufacturers like RoboSense, Hesai, and Bosch are integrating this technology into their product roadmaps. Research institutions including Caltech and Zhejiang University contribute fundamental breakthroughs, while technology conglomerates such as Huawei, Sony, and Philips leverage their manufacturing expertise to scale production. The competitive landscape reveals a blend of specialized startups, established LiDAR providers, and diversified technology corporations racing to overcome aperture scaling challenges while maintaining beam quality.

Hesai Technology Co. Ltd.

Technical Solution: Hesai has developed a hybrid metasurface-enhanced LiDAR architecture that addresses aperture scaling challenges through their proprietary "AT128" technology platform. Their solution integrates metasurface optical elements with conventional optics to achieve larger effective aperture sizes while maintaining exceptional beam quality. Hesai's approach utilizes a segmented metasurface design where each segment is optimized for a specific field angle, enabling consistent performance across the entire scanning range. This segmentation strategy allows for effective scaling of the aperture size by maintaining local phase coherence within each segment while ensuring global coordination across the entire aperture. Their technology incorporates proprietary manufacturing processes that enable production of large-area metasurfaces with nanoscale precision at automotive-grade volumes. Hesai has demonstrated this technology in commercial products achieving detection ranges exceeding 200 meters with centimeter-level precision, while maintaining a compact form factor suitable for vehicle integration. Their metasurface design also incorporates features that mitigate environmental effects such as temperature variations and vibration, ensuring consistent beam quality under real-world operating conditions.

Strengths: Established production capabilities for automotive-grade LiDAR systems; practical hybrid approach balancing performance with manufacturability; extensive field validation data from deployed systems. Weaknesses: Hybrid approach may not achieve the same size reduction as pure metasurface solutions; established product lines may slow transition to new technologies; competitive market position may limit information sharing about technical details.

Lumotive, Inc.

Technical Solution: Lumotive has pioneered Liquid Crystal Metasurface (LCM) technology specifically for LiDAR applications, addressing the aperture scaling challenge through their proprietary beam-steering technology. Their solution utilizes tunable liquid crystal cells integrated with metasurface structures to create a programmable, semiconductor-based beam steering system. This approach enables larger aperture sizes without compromising beam quality by employing a phase-modulation technique that maintains coherence across the expanded aperture. Lumotive's technology implements a digital control layer that precisely manages the phase profile across the metasurface, allowing for dynamic compensation of wavefront distortions that typically occur with larger apertures. Their system achieves this while maintaining a compact form factor suitable for automotive and industrial applications, with reported angular resolution improvements of up to 10x compared to conventional mechanical LiDAR systems.

Strengths: Programmable beam steering without moving parts reduces mechanical failure points; scalable semiconductor manufacturing process allows for cost-effective production; dynamic phase control enables real-time beam quality optimization. Weaknesses: Liquid crystal response times may limit scanning speeds in extreme temperature conditions; power consumption can be higher than passive metasurface solutions; complex control electronics add to system complexity.

Key Patents and Research on Metasurface Beam Quality Control

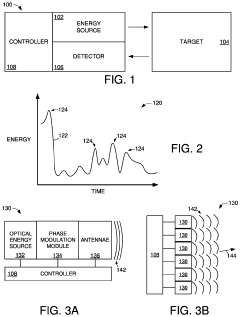

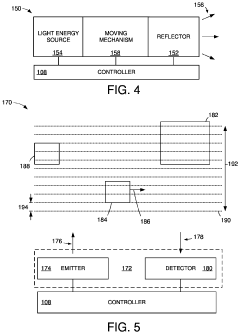

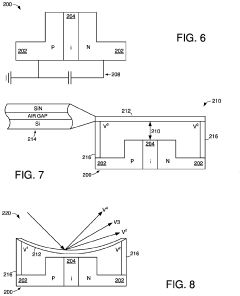

Lidar with metasurface beam steering

PatentPendingUS20220413103A1

Innovation

- A metasurface that continuously extends between electrical contacts, separated from a silicon substrate by an air gap, is used to create an electrostatic force that alters the air gap size in response to voltage bias, enabling efficient and accurate beam steering and optimization of light detection and ranging systems.

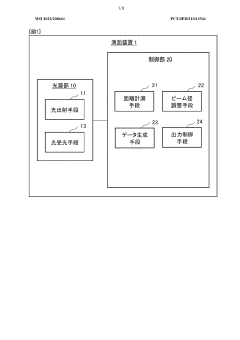

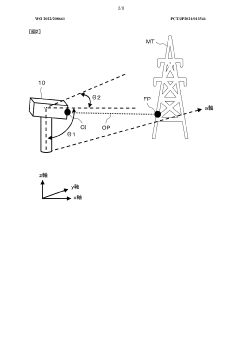

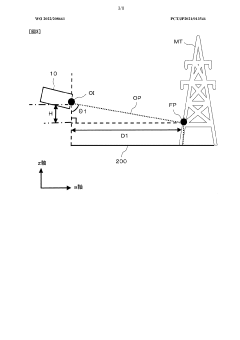

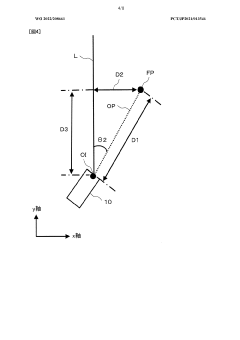

Ranging device, ranging device control method, and ranging system

PatentWO2022208661A1

Innovation

- A ranging device and system that adjusts the beam diameter of the laser beam based on distance, using a beam expander to change the beam diameter from a first diameter to a second, smaller diameter at the incident position, enhancing spatial resolution by maintaining accurate measurements even at farther distances.

Manufacturing Processes for Large-Scale Metasurface Production

The manufacturing of large-scale metasurfaces for LiDAR applications presents significant challenges that must be addressed to enable commercial viability. Current fabrication methods such as electron-beam lithography offer high precision but suffer from low throughput and high costs, making them impractical for mass production of large-aperture metasurfaces.

Nanoimprint lithography (NIL) has emerged as a promising approach for scaling metasurface production. This technique allows for the replication of nanoscale features over large areas with high fidelity and throughput. Recent advancements in roll-to-roll NIL systems have demonstrated the ability to produce metasurfaces on flexible substrates at speeds exceeding 10 m²/min, representing a significant improvement over traditional methods.

Deep ultraviolet (DUV) lithography, borrowed from the semiconductor industry, offers another viable path for large-scale metasurface fabrication. Modern DUV steppers can achieve feature sizes down to 38nm with high throughput, making them suitable for metasurface elements requiring sub-wavelength features. The established infrastructure in semiconductor manufacturing facilities provides an advantage for scaling this approach.

Self-assembly techniques utilizing block copolymers have shown potential for creating highly uniform nanostructures over large areas. These bottom-up approaches can complement traditional top-down fabrication methods, particularly for creating periodic metasurface structures with consistent optical properties across large apertures.

Quality control remains a critical challenge in scaled production. Advanced metrology systems incorporating machine vision and AI-based defect detection are being developed to ensure beam quality consistency across large metasurfaces. These systems can identify phase discontinuities and structural defects that would compromise LiDAR performance.

Material selection plays a crucial role in manufacturing scalability. Silicon-based metasurfaces offer compatibility with established CMOS processes but face limitations in optical efficiency. Alternative materials such as titanium dioxide and gallium nitride provide superior optical properties but require development of specialized deposition and etching processes for large-area fabrication.

Cost modeling indicates that economies of scale can reduce production costs significantly. Analysis shows that transitioning from laboratory-scale to industrial production could potentially reduce the cost per unit area by a factor of 50-100, bringing large-aperture metasurface LiDAR systems within commercial viability thresholds for automotive and industrial applications.

Nanoimprint lithography (NIL) has emerged as a promising approach for scaling metasurface production. This technique allows for the replication of nanoscale features over large areas with high fidelity and throughput. Recent advancements in roll-to-roll NIL systems have demonstrated the ability to produce metasurfaces on flexible substrates at speeds exceeding 10 m²/min, representing a significant improvement over traditional methods.

Deep ultraviolet (DUV) lithography, borrowed from the semiconductor industry, offers another viable path for large-scale metasurface fabrication. Modern DUV steppers can achieve feature sizes down to 38nm with high throughput, making them suitable for metasurface elements requiring sub-wavelength features. The established infrastructure in semiconductor manufacturing facilities provides an advantage for scaling this approach.

Self-assembly techniques utilizing block copolymers have shown potential for creating highly uniform nanostructures over large areas. These bottom-up approaches can complement traditional top-down fabrication methods, particularly for creating periodic metasurface structures with consistent optical properties across large apertures.

Quality control remains a critical challenge in scaled production. Advanced metrology systems incorporating machine vision and AI-based defect detection are being developed to ensure beam quality consistency across large metasurfaces. These systems can identify phase discontinuities and structural defects that would compromise LiDAR performance.

Material selection plays a crucial role in manufacturing scalability. Silicon-based metasurfaces offer compatibility with established CMOS processes but face limitations in optical efficiency. Alternative materials such as titanium dioxide and gallium nitride provide superior optical properties but require development of specialized deposition and etching processes for large-area fabrication.

Cost modeling indicates that economies of scale can reduce production costs significantly. Analysis shows that transitioning from laboratory-scale to industrial production could potentially reduce the cost per unit area by a factor of 50-100, bringing large-aperture metasurface LiDAR systems within commercial viability thresholds for automotive and industrial applications.

Integration Strategies with Existing LiDAR Ecosystems

The integration of metasurface LiDAR systems with scaled aperture sizes into existing LiDAR ecosystems presents both significant opportunities and challenges. Current LiDAR infrastructure has been optimized around conventional optical systems, making the transition to metasurface-based solutions a complex undertaking that requires careful strategic planning.

Compatibility with existing signal processing algorithms represents a primary integration concern. Most deployed LiDAR systems utilize processing pipelines optimized for specific beam characteristics and signal patterns. Metasurface LiDAR with scaled apertures produces different beam profiles and return signal characteristics, necessitating adaptation layers or middleware solutions to ensure seamless data interpretation.

Hardware integration pathways can follow several approaches. The modular replacement strategy allows for gradual adoption, where metasurface components replace conventional optics while maintaining electronic interfaces. Alternatively, hybrid systems can leverage both technologies simultaneously during transition periods, with metasurface elements handling specific scanning regions or resolution requirements.

Calibration and testing protocols require significant modification to accommodate the unique properties of metasurface LiDAR. New calibration methods must account for the complex phase manipulation characteristics of metasurfaces while ensuring beam quality metrics remain consistent across operating conditions. Industry standardization bodies are beginning to develop specific testing protocols for metasurface-based sensing systems.

Data fusion represents another critical integration challenge. Metasurface LiDAR data must be effectively combined with information from other sensors in multi-modal perception systems. The unique resolution and field-of-view characteristics of scaled-aperture metasurface systems require specialized fusion algorithms to maximize the complementary benefits of different sensing modalities.

Manufacturing and supply chain considerations also impact integration strategies. Current LiDAR production facilities are optimized for conventional optical components. Transitioning to metasurface fabrication requires new manufacturing processes, quality control measures, and supplier relationships. Several tier-one automotive suppliers have begun establishing dedicated metasurface production lines to address this challenge.

Regulatory compliance and certification pathways must be established for metasurface LiDAR integration. While fundamental safety standards remain applicable, the novel beam characteristics of metasurface systems may require additional validation to ensure compliance with eye safety regulations and electromagnetic compatibility standards across global markets.

Compatibility with existing signal processing algorithms represents a primary integration concern. Most deployed LiDAR systems utilize processing pipelines optimized for specific beam characteristics and signal patterns. Metasurface LiDAR with scaled apertures produces different beam profiles and return signal characteristics, necessitating adaptation layers or middleware solutions to ensure seamless data interpretation.

Hardware integration pathways can follow several approaches. The modular replacement strategy allows for gradual adoption, where metasurface components replace conventional optics while maintaining electronic interfaces. Alternatively, hybrid systems can leverage both technologies simultaneously during transition periods, with metasurface elements handling specific scanning regions or resolution requirements.

Calibration and testing protocols require significant modification to accommodate the unique properties of metasurface LiDAR. New calibration methods must account for the complex phase manipulation characteristics of metasurfaces while ensuring beam quality metrics remain consistent across operating conditions. Industry standardization bodies are beginning to develop specific testing protocols for metasurface-based sensing systems.

Data fusion represents another critical integration challenge. Metasurface LiDAR data must be effectively combined with information from other sensors in multi-modal perception systems. The unique resolution and field-of-view characteristics of scaled-aperture metasurface systems require specialized fusion algorithms to maximize the complementary benefits of different sensing modalities.

Manufacturing and supply chain considerations also impact integration strategies. Current LiDAR production facilities are optimized for conventional optical components. Transitioning to metasurface fabrication requires new manufacturing processes, quality control measures, and supplier relationships. Several tier-one automotive suppliers have begun establishing dedicated metasurface production lines to address this challenge.

Regulatory compliance and certification pathways must be established for metasurface LiDAR integration. While fundamental safety standards remain applicable, the novel beam characteristics of metasurface systems may require additional validation to ensure compliance with eye safety regulations and electromagnetic compatibility standards across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!