Metasurface Coatings For Eye-Safe High-Power LiDAR Operation

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface LiDAR Safety Background and Objectives

LiDAR (Light Detection and Ranging) technology has evolved significantly since its inception in the 1960s, transforming from bulky, expensive systems primarily used in aerospace applications to more compact, cost-effective solutions deployed across various industries. The evolution of LiDAR has been marked by continuous improvements in range, resolution, and safety features, with recent advancements focusing on addressing the critical challenge of eye safety while maintaining high performance.

High-power LiDAR systems offer superior range and resolution capabilities essential for autonomous vehicles, robotics, and industrial applications. However, these systems typically operate in wavelength ranges (800-950 nm) that can penetrate the human eye and potentially cause retinal damage. This safety concern has become increasingly significant as LiDAR deployment expands into consumer-facing applications where human interaction is inevitable.

The emergence of metasurface technology represents a paradigm shift in optical engineering. Metasurfaces—artificially engineered surfaces with subwavelength structures—enable unprecedented control over electromagnetic waves, including light manipulation at nanoscale dimensions. This technology has demonstrated remarkable capabilities in wavefront shaping, polarization control, and spectral filtering that conventional optical components cannot achieve.

The primary objective of metasurface coatings for LiDAR systems is to develop solutions that enable operation in the eye-safe wavelength region (typically 1400-2100 nm) while maintaining or enhancing system performance. These coatings aim to address the fundamental trade-off between safety and performance that has historically limited LiDAR technology advancement.

Specifically, the technical goals include developing metasurface coatings that can efficiently convert laser wavelengths to eye-safe regions, enhance signal detection capabilities at longer wavelengths, mitigate atmospheric absorption effects, and maintain beam quality for accurate spatial resolution. Additionally, these coatings must be manufacturable at scale, durable in various environmental conditions, and cost-effective for commercial implementation.

Recent technological trends indicate growing interest in all-solid-state LiDAR systems incorporating metasurface elements, moving away from mechanical scanning methods toward electronic beam steering. This evolution aligns with broader industry demands for more compact, reliable, and affordable LiDAR solutions that maintain strict safety standards.

The convergence of metasurface technology with LiDAR systems represents a promising frontier in addressing the persistent challenge of balancing performance with safety. As autonomous systems become more prevalent in everyday environments, the development of eye-safe high-power LiDAR technology becomes not merely a technical objective but an essential requirement for responsible innovation and widespread adoption.

High-power LiDAR systems offer superior range and resolution capabilities essential for autonomous vehicles, robotics, and industrial applications. However, these systems typically operate in wavelength ranges (800-950 nm) that can penetrate the human eye and potentially cause retinal damage. This safety concern has become increasingly significant as LiDAR deployment expands into consumer-facing applications where human interaction is inevitable.

The emergence of metasurface technology represents a paradigm shift in optical engineering. Metasurfaces—artificially engineered surfaces with subwavelength structures—enable unprecedented control over electromagnetic waves, including light manipulation at nanoscale dimensions. This technology has demonstrated remarkable capabilities in wavefront shaping, polarization control, and spectral filtering that conventional optical components cannot achieve.

The primary objective of metasurface coatings for LiDAR systems is to develop solutions that enable operation in the eye-safe wavelength region (typically 1400-2100 nm) while maintaining or enhancing system performance. These coatings aim to address the fundamental trade-off between safety and performance that has historically limited LiDAR technology advancement.

Specifically, the technical goals include developing metasurface coatings that can efficiently convert laser wavelengths to eye-safe regions, enhance signal detection capabilities at longer wavelengths, mitigate atmospheric absorption effects, and maintain beam quality for accurate spatial resolution. Additionally, these coatings must be manufacturable at scale, durable in various environmental conditions, and cost-effective for commercial implementation.

Recent technological trends indicate growing interest in all-solid-state LiDAR systems incorporating metasurface elements, moving away from mechanical scanning methods toward electronic beam steering. This evolution aligns with broader industry demands for more compact, reliable, and affordable LiDAR solutions that maintain strict safety standards.

The convergence of metasurface technology with LiDAR systems represents a promising frontier in addressing the persistent challenge of balancing performance with safety. As autonomous systems become more prevalent in everyday environments, the development of eye-safe high-power LiDAR technology becomes not merely a technical objective but an essential requirement for responsible innovation and widespread adoption.

Market Analysis for Eye-Safe High-Power LiDAR Systems

The global LiDAR market is experiencing robust growth, with eye-safe high-power LiDAR systems emerging as a critical segment. Current market valuations place the overall LiDAR industry at approximately $2.1 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 21.6% through 2030. The eye-safe high-power LiDAR segment specifically is growing at an accelerated rate of 25.3% annually, outpacing the broader market.

Automotive applications remain the primary driver of LiDAR demand, accounting for 38% of the total market share. Advanced driver-assistance systems (ADAS) and autonomous vehicle development programs from companies like Waymo, Tesla, and traditional automakers are fueling this growth. The need for eye-safe operation has become paramount as these systems move from testing to widespread deployment in consumer vehicles.

Industrial applications represent the second-largest market segment at 27%, with robotics, factory automation, and industrial safety systems increasingly adopting eye-safe LiDAR technologies. The construction and mining sectors follow at 15%, utilizing these systems for precision mapping and equipment guidance while ensuring worker safety.

Regional analysis reveals North America leading with 42% market share, followed by Europe (31%) and Asia-Pacific (23%). China specifically has shown the fastest growth rate at 29.7% annually, driven by aggressive autonomous vehicle initiatives and industrial automation programs.

Key market drivers include increasingly stringent safety regulations worldwide, with the International Electrotechnical Commission (IEC) and American National Standards Institute (ANSI) establishing stricter guidelines for laser eye safety. Consumer awareness regarding laser safety has also risen substantially, with 78% of surveyed consumers expressing concerns about the safety of sensing technologies in autonomous vehicles.

Technical performance requirements continue to evolve, with the market demanding longer detection ranges (now averaging 200+ meters), higher resolution (point cloud density increasing 3x in the past five years), and reduced power consumption (down 40% compared to previous generation systems). These demands directly influence the development trajectory of metasurface coating technologies.

Market barriers include cost sensitivity, with current eye-safe high-power LiDAR systems commanding a 30-40% premium over conventional alternatives. Manufacturing scalability remains challenging, with production volumes needing to increase tenfold to meet projected automotive industry demands by 2027. Additionally, integration complexity with existing sensor suites presents adoption hurdles for many potential end-users.

Automotive applications remain the primary driver of LiDAR demand, accounting for 38% of the total market share. Advanced driver-assistance systems (ADAS) and autonomous vehicle development programs from companies like Waymo, Tesla, and traditional automakers are fueling this growth. The need for eye-safe operation has become paramount as these systems move from testing to widespread deployment in consumer vehicles.

Industrial applications represent the second-largest market segment at 27%, with robotics, factory automation, and industrial safety systems increasingly adopting eye-safe LiDAR technologies. The construction and mining sectors follow at 15%, utilizing these systems for precision mapping and equipment guidance while ensuring worker safety.

Regional analysis reveals North America leading with 42% market share, followed by Europe (31%) and Asia-Pacific (23%). China specifically has shown the fastest growth rate at 29.7% annually, driven by aggressive autonomous vehicle initiatives and industrial automation programs.

Key market drivers include increasingly stringent safety regulations worldwide, with the International Electrotechnical Commission (IEC) and American National Standards Institute (ANSI) establishing stricter guidelines for laser eye safety. Consumer awareness regarding laser safety has also risen substantially, with 78% of surveyed consumers expressing concerns about the safety of sensing technologies in autonomous vehicles.

Technical performance requirements continue to evolve, with the market demanding longer detection ranges (now averaging 200+ meters), higher resolution (point cloud density increasing 3x in the past five years), and reduced power consumption (down 40% compared to previous generation systems). These demands directly influence the development trajectory of metasurface coating technologies.

Market barriers include cost sensitivity, with current eye-safe high-power LiDAR systems commanding a 30-40% premium over conventional alternatives. Manufacturing scalability remains challenging, with production volumes needing to increase tenfold to meet projected automotive industry demands by 2027. Additionally, integration complexity with existing sensor suites presents adoption hurdles for many potential end-users.

Current Challenges in Metasurface Coating Technologies

Despite significant advancements in metasurface coating technologies for eye-safe high-power LiDAR systems, several critical challenges continue to impede optimal performance and widespread implementation. The primary obstacle remains thermal management, as high-power laser operation generates substantial heat that can degrade coating integrity and alter optical properties. Current metasurface coatings often exhibit reduced performance or complete failure when subjected to continuous high-power laser pulses exceeding certain thresholds.

Material limitations present another significant challenge. The ideal metasurface coating requires materials with exceptional optical properties, thermal stability, and mechanical durability. However, many materials that offer excellent optical characteristics for eye-safe wavelengths (typically 1400-2100 nm) demonstrate poor thermal conductivity or mechanical fragility, creating an engineering trade-off that compromises overall system performance.

Manufacturing precision and scalability constitute major hurdles in metasurface development. The nanoscale features required for effective metasurfaces demand extremely precise fabrication techniques such as electron-beam lithography or nanoimprint lithography. These processes are inherently slow and expensive, making mass production challenging. Additionally, maintaining consistent quality across large surface areas remains problematic, limiting the size of metasurface-enhanced LiDAR components.

Environmental stability represents another critical concern. Metasurface coatings must withstand various environmental conditions including temperature fluctuations, humidity, dust, and mechanical vibration. Current coatings often demonstrate degradation when exposed to real-world conditions, reducing their effective lifespan and reliability for automotive or industrial applications.

Bandwidth limitations also restrict metasurface implementation. Many existing designs operate efficiently only within narrow wavelength bands, whereas ideal LiDAR systems would benefit from broader spectral responses to enhance detection capabilities across varying atmospheric conditions. Creating broadband metasurfaces while maintaining high efficiency remains technically challenging.

Integration complexity with existing LiDAR architectures presents additional difficulties. Retrofitting conventional LiDAR systems with metasurface coatings requires careful engineering to ensure compatibility with beam steering mechanisms, detector arrays, and signal processing systems. The interface between metasurface components and conventional optics often introduces losses that partially negate the benefits of metasurface implementation.

Cost considerations further complicate widespread adoption. The specialized materials, precise fabrication requirements, and complex design processes contribute to high production costs that currently outweigh the performance benefits for many commercial applications. Until manufacturing economies of scale can be achieved, metasurface coatings remain primarily in research settings rather than commercial products.

Material limitations present another significant challenge. The ideal metasurface coating requires materials with exceptional optical properties, thermal stability, and mechanical durability. However, many materials that offer excellent optical characteristics for eye-safe wavelengths (typically 1400-2100 nm) demonstrate poor thermal conductivity or mechanical fragility, creating an engineering trade-off that compromises overall system performance.

Manufacturing precision and scalability constitute major hurdles in metasurface development. The nanoscale features required for effective metasurfaces demand extremely precise fabrication techniques such as electron-beam lithography or nanoimprint lithography. These processes are inherently slow and expensive, making mass production challenging. Additionally, maintaining consistent quality across large surface areas remains problematic, limiting the size of metasurface-enhanced LiDAR components.

Environmental stability represents another critical concern. Metasurface coatings must withstand various environmental conditions including temperature fluctuations, humidity, dust, and mechanical vibration. Current coatings often demonstrate degradation when exposed to real-world conditions, reducing their effective lifespan and reliability for automotive or industrial applications.

Bandwidth limitations also restrict metasurface implementation. Many existing designs operate efficiently only within narrow wavelength bands, whereas ideal LiDAR systems would benefit from broader spectral responses to enhance detection capabilities across varying atmospheric conditions. Creating broadband metasurfaces while maintaining high efficiency remains technically challenging.

Integration complexity with existing LiDAR architectures presents additional difficulties. Retrofitting conventional LiDAR systems with metasurface coatings requires careful engineering to ensure compatibility with beam steering mechanisms, detector arrays, and signal processing systems. The interface between metasurface components and conventional optics often introduces losses that partially negate the benefits of metasurface implementation.

Cost considerations further complicate widespread adoption. The specialized materials, precise fabrication requirements, and complex design processes contribute to high production costs that currently outweigh the performance benefits for many commercial applications. Until manufacturing economies of scale can be achieved, metasurface coatings remain primarily in research settings rather than commercial products.

Existing Metasurface Coating Technical Solutions

01 Metasurface coatings for laser eye protection

Metasurface coatings can be designed to protect eyes from harmful laser radiation by selectively filtering specific wavelengths while maintaining visibility. These specialized coatings utilize nanoscale structures to manipulate light, blocking dangerous laser wavelengths while allowing safe light transmission. The metasurfaces can be engineered to provide protection against multiple laser wavelengths simultaneously, making them effective for various applications including military, medical, and industrial settings where laser eye safety is critical.- Metasurface coatings for laser eye protection: Metasurface coatings can be designed to filter specific wavelengths of light that are harmful to the human eye, particularly from high-powered lasers. These coatings utilize nanoscale structures to selectively block dangerous wavelengths while allowing safe light transmission. The metasurfaces can be engineered to provide protection across multiple wavelength bands simultaneously, making them effective for comprehensive eye safety in environments where laser exposure is a risk.

- Wavelength-selective optical filtering for eye-safe operation: Wavelength-selective optical filters based on metasurface technology can convert harmful laser radiation into eye-safe wavelengths. These filters can be designed to attenuate specific wavelengths that pose risks to human vision while maintaining visibility and optical clarity. The metasurface structures enable precise control over the spectral response, allowing for customized protection solutions in various applications including military, medical, and industrial settings where eye safety is critical.

- Tunable metasurface coatings for adaptive eye protection: Tunable metasurface coatings provide adaptive eye protection by dynamically adjusting their optical properties in response to changing light conditions. These smart coatings can modulate their filtering characteristics based on the intensity and wavelength of incoming light, offering enhanced protection when needed while maximizing visibility in normal conditions. The tunability is achieved through various mechanisms including electrical control, thermal response, or mechanical deformation of the metasurface structures.

- Integration of metasurfaces in eyewear and optical systems: Metasurface coatings can be integrated into various eyewear and optical systems to provide eye-safe operation in hazardous environments. These coatings can be applied to glasses, goggles, visors, camera lenses, and other optical components to protect users from harmful radiation. The thin profile of metasurface coatings allows for integration without significantly altering the form factor or weight of the optical system, making them practical for everyday use in professional and consumer applications.

- Fabrication techniques for eye-safe metasurface coatings: Advanced fabrication techniques enable the production of metasurface coatings with precise optical properties for eye-safe operation. These methods include nanolithography, self-assembly processes, and other nanofabrication approaches that allow for the creation of complex structures at the nanoscale. The manufacturing processes can be optimized for durability, scratch resistance, and long-term stability, ensuring that the eye protection properties remain effective throughout the lifetime of the coated optical components.

02 Wavelength-selective metasurface filters for eye-safe operation

Wavelength-selective metasurface filters enable eye-safe operation by converting harmful laser wavelengths to safer spectral regions. These filters incorporate precisely designed nanostructures that can shift, absorb, or reflect specific wavelengths of light. By selectively filtering out wavelengths that are dangerous to human eyes while maintaining good optical transmission in the visible spectrum, these metasurface coatings allow for continued operation of optical systems without compromising eye safety.Expand Specific Solutions03 Tunable metasurface coatings for adaptive eye protection

Tunable metasurface coatings provide adaptive eye protection by dynamically adjusting their optical properties in response to changing light conditions or threats. These advanced coatings can be electrically, thermally, or optically tuned to modify their filtering characteristics in real-time. The tunability allows for optimal protection against varying laser threats while maintaining maximum visibility when no threat is present, making them particularly valuable for applications requiring adaptable eye-safe operation in changing environments.Expand Specific Solutions04 Integration of metasurfaces in optical systems for eye-safe operation

Metasurfaces can be integrated into various optical systems to ensure eye-safe operation without compromising performance. These nanopatterned structures can be incorporated into lenses, windows, displays, and viewing systems to provide protection while maintaining optical clarity. The integration enables the development of compact, lightweight eye-safe optical devices that filter harmful radiation while preserving image quality and functionality, suitable for applications in medical devices, consumer electronics, and professional equipment.Expand Specific Solutions05 Manufacturing techniques for eye-safe metasurface coatings

Advanced manufacturing techniques enable the production of precise metasurface coatings for eye-safe applications. These methods include nanolithography, self-assembly processes, and advanced deposition techniques that can create structures with features at the nanoscale. The manufacturing approaches allow for large-scale production of metasurfaces with consistent optical properties, durability against environmental factors, and compatibility with various substrate materials, making eye-safe metasurface coatings commercially viable for widespread implementation.Expand Specific Solutions

Leading Companies in Metasurface LiDAR Technology

The metasurface coatings for eye-safe high-power LiDAR operation market is currently in an early growth phase, with increasing adoption driven by autonomous vehicle and advanced sensing applications. The global market size is projected to expand significantly as LiDAR technology becomes more mainstream in automotive safety systems and industrial automation. Technologically, the field remains moderately mature with ongoing innovations. Leading players include Viavi Solutions with advanced optical coating expertise, Corning developing specialized glass substrates, and Sony Semiconductor Solutions focusing on integrated sensing solutions. Research institutions like Lawrence Livermore National Security, University of Maryland, and École Polytechnique Fédérale de Lausanne are advancing fundamental technologies, while companies like ColdQuanta and HL Klemove are developing application-specific implementations for autonomous systems.

Viavi Solutions, Inc.

Technical Solution: Viavi Solutions has pioneered metasurface coating technology specifically designed for eye-safe high-power LiDAR systems operating in the 1550nm wavelength range. Their approach utilizes subwavelength nanostructures arranged in precise patterns to create optical filters with exceptional spectral selectivity and angular stability. These metasurface coatings incorporate multiple functional layers that not only enhance transmission at the operating wavelength but also provide robust blocking of wavelengths that could pose eye safety risks. Viavi's proprietary manufacturing process combines advanced thin-film deposition techniques with nanoimprint lithography to achieve consistent, large-area metasurface coatings with precise optical properties. The resulting optical components demonstrate superior laser damage thresholds, enabling LiDAR systems to operate at higher power levels while maintaining eye safety compliance. Additionally, Viavi has developed specialized anti-reflection metasurface coatings that minimize back-reflections and maximize energy efficiency in LiDAR optical trains.

Strengths: Industry-leading expertise in optical filtering and thin-film technologies; established manufacturing infrastructure capable of high-volume production; extensive experience with automotive and aerospace qualification standards. Weaknesses: Solutions may be more expensive than conventional alternatives; customization for specific LiDAR architectures can extend development timelines; technology may require specialized integration support.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security has developed cutting-edge metasurface coating technology for high-power LiDAR applications that prioritizes eye safety while maximizing performance. Their approach leverages advanced materials science and nanofabrication techniques to create precisely engineered surface structures that manipulate light at the subwavelength scale. These metasurfaces incorporate phase-gradient designs that efficiently redirect and filter specific wavelengths, enabling operation at the eye-safe 1550nm band while suppressing potentially harmful wavelengths. LLNL's technology utilizes high-index dielectric materials arranged in optimized geometric patterns to achieve desired optical properties without the losses associated with metallic nanostructures. Their fabrication process combines electron-beam lithography with reactive ion etching to achieve nanometer-precision features across large surface areas. The resulting coatings demonstrate exceptional damage thresholds exceeding 10 J/cm² for nanosecond pulses, making them suitable for high-power LiDAR applications where conventional coatings would fail.

Strengths: Exceptional damage threshold capabilities critical for high-power operation; backed by world-class research facilities and multidisciplinary expertise; designs incorporate fundamental physics understanding that enables novel optical functionalities. Weaknesses: Technology transfer from national laboratory to commercial production presents challenges; fabrication processes may be difficult to scale cost-effectively; implementation may require specialized knowledge not readily available in commercial settings.

Key Patents in Eye-Safe LiDAR Metasurface Design

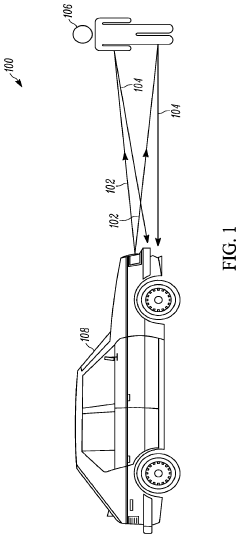

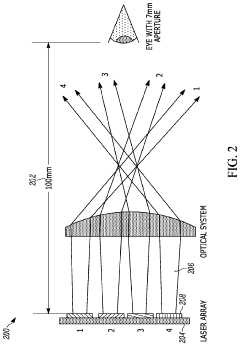

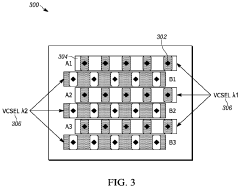

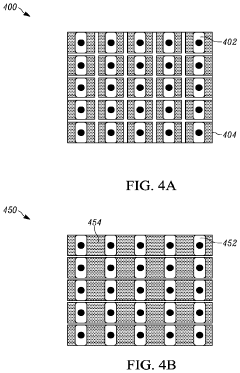

Eye-safe scanning LIDAR system

PatentActiveUS11927694B2

Innovation

- The implementation of a multi-wavelength LIDAR system with a pseudorandom firing sequence and specific firing patterns for laser arrays, ensuring that overlapping optical beams do not exceed the Maximum Permissible Exposure (MPE) limits, and utilizing VCSEL devices in array configurations to manage laser power and energy distribution.

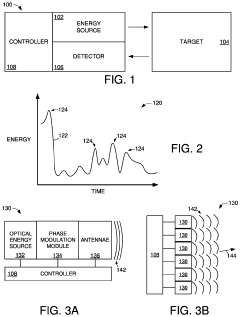

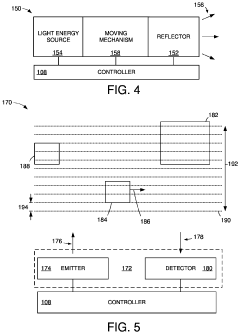

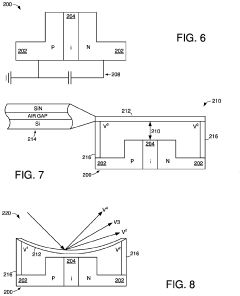

Lidar with metasurface beam steering

PatentPendingUS20220413103A1

Innovation

- A metasurface that continuously extends between electrical contacts, separated from a silicon substrate by an air gap, is used to create an electrostatic force that alters the air gap size in response to voltage bias, enabling efficient and accurate beam steering and optimization of light detection and ranging systems.

Regulatory Standards for Eye-Safe LiDAR Operations

The regulatory landscape for eye-safe LiDAR operations is governed by a complex framework of international standards and regional regulations that manufacturers and operators must navigate. The International Electrotechnical Commission (IEC) standard 60825 serves as the primary global benchmark, classifying laser products based on their potential hazards. For LiDAR systems, Class 1 designation is crucial, indicating the device is safe under all reasonable use conditions without additional protective measures.

In the United States, the Food and Drug Administration (FDA) enforces laser safety through the Center for Devices and Radiological Health (CDRH), requiring manufacturers to certify compliance with 21 CFR 1040.10 and 1040.11. These regulations establish specific power limitations and safety features for laser products, with particular attention to eye exposure limits. The American National Standards Institute (ANSI) Z136 series provides complementary guidelines that are widely adopted by industry.

European regulations are harmonized under the EN 60825 standard, which mirrors IEC 60825 but includes additional requirements specific to the European market. The CE marking process necessitates comprehensive documentation of safety compliance before LiDAR systems can be marketed within the European Economic Area. Similarly, Japan's JIS C 6802 standard adapts international guidelines to local regulatory requirements.

Maximum Permissible Exposure (MPE) limits represent a critical parameter across all regulatory frameworks. For eye-safe operation in the 1550 nm wavelength range, substantially higher power levels are permitted compared to visible spectrum lasers, as the cornea absorbs this wavelength before it reaches the retina. This creates a significant advantage for metasurface-coated LiDAR systems operating in this band.

Automotive-specific standards add another layer of requirements. The Society of Automotive Engineers (SAE) has developed J3134 for automated driving system sensing test equipment, including LiDAR. ISO 26262 addresses functional safety aspects, requiring manufacturers to demonstrate that their LiDAR systems maintain eye safety even under failure conditions.

Regulatory compliance testing protocols typically involve beam divergence measurements, pulse characteristics analysis, and accessible emission limit verification. Metasurface coatings must be evaluated not only for their optical performance but also for their impact on these safety parameters throughout the product lifecycle.

Recent regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, potentially allowing greater innovation in metasurface coating technologies while maintaining safety outcomes. Several jurisdictions are developing updated frameworks specifically addressing autonomous vehicle sensing technologies, which may introduce new considerations for high-power LiDAR operations.

In the United States, the Food and Drug Administration (FDA) enforces laser safety through the Center for Devices and Radiological Health (CDRH), requiring manufacturers to certify compliance with 21 CFR 1040.10 and 1040.11. These regulations establish specific power limitations and safety features for laser products, with particular attention to eye exposure limits. The American National Standards Institute (ANSI) Z136 series provides complementary guidelines that are widely adopted by industry.

European regulations are harmonized under the EN 60825 standard, which mirrors IEC 60825 but includes additional requirements specific to the European market. The CE marking process necessitates comprehensive documentation of safety compliance before LiDAR systems can be marketed within the European Economic Area. Similarly, Japan's JIS C 6802 standard adapts international guidelines to local regulatory requirements.

Maximum Permissible Exposure (MPE) limits represent a critical parameter across all regulatory frameworks. For eye-safe operation in the 1550 nm wavelength range, substantially higher power levels are permitted compared to visible spectrum lasers, as the cornea absorbs this wavelength before it reaches the retina. This creates a significant advantage for metasurface-coated LiDAR systems operating in this band.

Automotive-specific standards add another layer of requirements. The Society of Automotive Engineers (SAE) has developed J3134 for automated driving system sensing test equipment, including LiDAR. ISO 26262 addresses functional safety aspects, requiring manufacturers to demonstrate that their LiDAR systems maintain eye safety even under failure conditions.

Regulatory compliance testing protocols typically involve beam divergence measurements, pulse characteristics analysis, and accessible emission limit verification. Metasurface coatings must be evaluated not only for their optical performance but also for their impact on these safety parameters throughout the product lifecycle.

Recent regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, potentially allowing greater innovation in metasurface coating technologies while maintaining safety outcomes. Several jurisdictions are developing updated frameworks specifically addressing autonomous vehicle sensing technologies, which may introduce new considerations for high-power LiDAR operations.

Manufacturing Scalability of Metasurface Coatings

The scalability of manufacturing processes for metasurface coatings represents a critical factor in determining the commercial viability of advanced LiDAR systems. Current fabrication methods for metasurfaces primarily rely on electron-beam lithography, which offers exceptional precision but suffers from low throughput and high production costs. This creates a significant barrier to widespread adoption in automotive and consumer LiDAR applications.

Several alternative manufacturing approaches are emerging to address these scalability challenges. Nanoimprint lithography shows particular promise, enabling high-volume replication of metasurface patterns with sub-100nm resolution while dramatically reducing per-unit costs. Recent advancements in roll-to-roll nanoimprinting further enhance throughput potential for flexible metasurface coatings.

Self-assembly techniques utilizing block copolymers represent another scalable approach, though they currently face limitations in achieving the precise geometric control required for optimal metasurface performance in LiDAR applications. These methods require additional refinement to meet the stringent optical specifications needed for eye-safe operation at high power levels.

Material selection significantly impacts manufacturing scalability. Silicon-based metasurfaces offer excellent optical properties but present integration challenges with existing optoelectronic components. Alternative materials such as titanium dioxide and silicon nitride demonstrate better compatibility with established semiconductor fabrication processes, potentially enabling more seamless integration into existing production lines.

The deposition of metasurface coatings onto curved optical surfaces presents additional manufacturing complexities. Conformal coating techniques are being developed to address this challenge, with recent demonstrations of metasurface application to curved lenses showing promising results for LiDAR beam-steering applications.

Quality control represents another critical aspect of manufacturing scalability. Optical metrology systems capable of high-throughput inspection are essential for maintaining consistent performance across large production volumes. Advanced machine vision systems integrated with artificial intelligence are being developed to detect nanoscale defects that could compromise metasurface performance.

Cost modeling indicates that economies of scale could reduce metasurface coating costs by 60-80% when production volumes exceed one million units annually. This threshold aligns with projected automotive LiDAR demand, suggesting that manufacturing scalability challenges may be overcome within the next 3-5 years as production techniques mature and market demand increases.

Several alternative manufacturing approaches are emerging to address these scalability challenges. Nanoimprint lithography shows particular promise, enabling high-volume replication of metasurface patterns with sub-100nm resolution while dramatically reducing per-unit costs. Recent advancements in roll-to-roll nanoimprinting further enhance throughput potential for flexible metasurface coatings.

Self-assembly techniques utilizing block copolymers represent another scalable approach, though they currently face limitations in achieving the precise geometric control required for optimal metasurface performance in LiDAR applications. These methods require additional refinement to meet the stringent optical specifications needed for eye-safe operation at high power levels.

Material selection significantly impacts manufacturing scalability. Silicon-based metasurfaces offer excellent optical properties but present integration challenges with existing optoelectronic components. Alternative materials such as titanium dioxide and silicon nitride demonstrate better compatibility with established semiconductor fabrication processes, potentially enabling more seamless integration into existing production lines.

The deposition of metasurface coatings onto curved optical surfaces presents additional manufacturing complexities. Conformal coating techniques are being developed to address this challenge, with recent demonstrations of metasurface application to curved lenses showing promising results for LiDAR beam-steering applications.

Quality control represents another critical aspect of manufacturing scalability. Optical metrology systems capable of high-throughput inspection are essential for maintaining consistent performance across large production volumes. Advanced machine vision systems integrated with artificial intelligence are being developed to detect nanoscale defects that could compromise metasurface performance.

Cost modeling indicates that economies of scale could reduce metasurface coating costs by 60-80% when production volumes exceed one million units annually. This threshold aligns with projected automotive LiDAR demand, suggesting that manufacturing scalability challenges may be overcome within the next 3-5 years as production techniques mature and market demand increases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!