Comparative Study Of Liquid Crystal Vs Phase-Change Metasurfaces

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Technology Evolution and Objectives

Metasurfaces represent a revolutionary class of engineered surfaces composed of subwavelength structures that can manipulate electromagnetic waves in unprecedented ways. The evolution of metasurface technology has progressed significantly over the past two decades, transitioning from static designs with fixed functionalities to dynamic systems capable of real-time reconfiguration.

The initial development of metasurfaces emerged from metamaterial research in the early 2000s, when researchers discovered that two-dimensional arrays of resonant structures could achieve extraordinary optical properties. These first-generation metasurfaces featured fixed geometries that could control phase, amplitude, and polarization of incident light, enabling applications such as flat lenses, holograms, and wavefront shaping.

By the 2010s, the field witnessed a paradigm shift toward active metasurfaces, driven by the fundamental limitation of static designs. This transition was motivated by the growing demand for adaptive optical systems in telecommunications, sensing, and imaging. The incorporation of tunable materials became the cornerstone of this evolution, with liquid crystals and phase-change materials emerging as two particularly promising candidates.

Liquid crystal-based metasurfaces leverage the anisotropic optical properties of liquid crystal molecules, which can be reoriented under applied electric fields. This technology built upon decades of established liquid crystal display technology, offering relatively fast switching speeds (milliseconds), continuous tuning capabilities, and low power consumption for maintaining states. Early demonstrations appeared around 2015, with significant improvements in response time and tuning range following thereafter.

Phase-change material metasurfaces, conversely, exploit the dramatic contrast in optical properties between amorphous and crystalline states of materials like germanium-antimony-tellurium (GST) compounds. This approach gained momentum around 2016, offering advantages in non-volatile switching, higher modulation depth, and broader operating bandwidth compared to liquid crystal alternatives.

The current technological objective centers on developing metasurfaces that combine optimal performance metrics: wide tuning range, fast response time, low power consumption, and long-term reliability. Specifically for liquid crystal versus phase-change metasurfaces, researchers aim to overcome the inherent trade-offs between these platforms – liquid crystals offering continuous but volatile tuning, and phase-change materials providing non-volatile but discrete state changes.

Looking forward, the field is moving toward hybrid metasurface architectures that integrate multiple tuning mechanisms to achieve unprecedented functionalities. The ultimate goal is to create programmable metasurfaces that can dynamically reconfigure their electromagnetic response with high spatial resolution, enabling applications from adaptive optics to 6G communications and quantum information processing.

The initial development of metasurfaces emerged from metamaterial research in the early 2000s, when researchers discovered that two-dimensional arrays of resonant structures could achieve extraordinary optical properties. These first-generation metasurfaces featured fixed geometries that could control phase, amplitude, and polarization of incident light, enabling applications such as flat lenses, holograms, and wavefront shaping.

By the 2010s, the field witnessed a paradigm shift toward active metasurfaces, driven by the fundamental limitation of static designs. This transition was motivated by the growing demand for adaptive optical systems in telecommunications, sensing, and imaging. The incorporation of tunable materials became the cornerstone of this evolution, with liquid crystals and phase-change materials emerging as two particularly promising candidates.

Liquid crystal-based metasurfaces leverage the anisotropic optical properties of liquid crystal molecules, which can be reoriented under applied electric fields. This technology built upon decades of established liquid crystal display technology, offering relatively fast switching speeds (milliseconds), continuous tuning capabilities, and low power consumption for maintaining states. Early demonstrations appeared around 2015, with significant improvements in response time and tuning range following thereafter.

Phase-change material metasurfaces, conversely, exploit the dramatic contrast in optical properties between amorphous and crystalline states of materials like germanium-antimony-tellurium (GST) compounds. This approach gained momentum around 2016, offering advantages in non-volatile switching, higher modulation depth, and broader operating bandwidth compared to liquid crystal alternatives.

The current technological objective centers on developing metasurfaces that combine optimal performance metrics: wide tuning range, fast response time, low power consumption, and long-term reliability. Specifically for liquid crystal versus phase-change metasurfaces, researchers aim to overcome the inherent trade-offs between these platforms – liquid crystals offering continuous but volatile tuning, and phase-change materials providing non-volatile but discrete state changes.

Looking forward, the field is moving toward hybrid metasurface architectures that integrate multiple tuning mechanisms to achieve unprecedented functionalities. The ultimate goal is to create programmable metasurfaces that can dynamically reconfigure their electromagnetic response with high spatial resolution, enabling applications from adaptive optics to 6G communications and quantum information processing.

Market Applications and Demand Analysis for Advanced Metasurfaces

The metasurface technology market is experiencing significant growth, driven by increasing demand for miniaturized optical components and advanced wavefront manipulation capabilities. Current market projections indicate that the global metasurface market is expected to reach several billion dollars by 2030, with a compound annual growth rate exceeding 35% between 2023 and 2030. This remarkable growth trajectory is fueled by diverse applications across multiple industries seeking more compact, efficient, and versatile optical solutions.

In telecommunications, both liquid crystal and phase-change metasurfaces are gaining traction for beam steering applications in 5G and upcoming 6G networks. The telecommunications sector represents one of the largest potential markets, particularly as these technologies enable dynamic beam forming and reconfigurable intelligent surfaces that can optimize signal propagation in complex environments. Network infrastructure providers are actively exploring these technologies to enhance coverage and reduce power consumption.

The consumer electronics industry presents another substantial market opportunity, particularly for display technologies and augmented reality (AR) applications. Liquid crystal metasurfaces, leveraging established manufacturing infrastructure from the LCD industry, have a competitive advantage in near-term adoption for consumer products. Market research indicates that AR headset shipments are projected to grow significantly, creating demand for compact optical components that can deliver high-quality visual experiences while minimizing device form factors.

Defense and aerospace sectors demonstrate strong interest in both technologies for applications including adaptive optics, stealth technology, and advanced sensing systems. Phase-change metasurfaces, with their non-volatile switching capabilities and broader operational wavelength range, are particularly valued in this sector despite higher manufacturing complexity. Military and aerospace applications typically command premium pricing, making them attractive early markets despite lower volume requirements.

Medical imaging and biosensing represent emerging application areas with substantial growth potential. The ability of metasurfaces to manipulate light at the nanoscale enables novel diagnostic tools and imaging modalities. Market adoption in healthcare is typically slower due to regulatory requirements but offers significant long-term potential as these technologies mature.

Automotive applications, particularly for LiDAR systems and heads-up displays in autonomous vehicles, represent another growing market segment. The automotive industry's increasing focus on sensor integration and driver assistance systems creates demand for compact, reliable optical components that can withstand harsh environmental conditions.

The competitive landscape reveals different market entry strategies between established optics manufacturers expanding into metasurface technologies and startups focused exclusively on novel metasurface applications. Regional analysis shows North America leading in research and development investment, while Asia-Pacific demonstrates the fastest growth in manufacturing capacity and commercial deployment.

In telecommunications, both liquid crystal and phase-change metasurfaces are gaining traction for beam steering applications in 5G and upcoming 6G networks. The telecommunications sector represents one of the largest potential markets, particularly as these technologies enable dynamic beam forming and reconfigurable intelligent surfaces that can optimize signal propagation in complex environments. Network infrastructure providers are actively exploring these technologies to enhance coverage and reduce power consumption.

The consumer electronics industry presents another substantial market opportunity, particularly for display technologies and augmented reality (AR) applications. Liquid crystal metasurfaces, leveraging established manufacturing infrastructure from the LCD industry, have a competitive advantage in near-term adoption for consumer products. Market research indicates that AR headset shipments are projected to grow significantly, creating demand for compact optical components that can deliver high-quality visual experiences while minimizing device form factors.

Defense and aerospace sectors demonstrate strong interest in both technologies for applications including adaptive optics, stealth technology, and advanced sensing systems. Phase-change metasurfaces, with their non-volatile switching capabilities and broader operational wavelength range, are particularly valued in this sector despite higher manufacturing complexity. Military and aerospace applications typically command premium pricing, making them attractive early markets despite lower volume requirements.

Medical imaging and biosensing represent emerging application areas with substantial growth potential. The ability of metasurfaces to manipulate light at the nanoscale enables novel diagnostic tools and imaging modalities. Market adoption in healthcare is typically slower due to regulatory requirements but offers significant long-term potential as these technologies mature.

Automotive applications, particularly for LiDAR systems and heads-up displays in autonomous vehicles, represent another growing market segment. The automotive industry's increasing focus on sensor integration and driver assistance systems creates demand for compact, reliable optical components that can withstand harsh environmental conditions.

The competitive landscape reveals different market entry strategies between established optics manufacturers expanding into metasurface technologies and startups focused exclusively on novel metasurface applications. Regional analysis shows North America leading in research and development investment, while Asia-Pacific demonstrates the fastest growth in manufacturing capacity and commercial deployment.

Current Challenges in Liquid Crystal and Phase-Change Metasurfaces

Despite significant advancements in metasurface technology, both liquid crystal (LC) and phase-change material (PCM) metasurfaces face substantial technical challenges that limit their widespread commercial adoption. These challenges span material properties, fabrication processes, performance metrics, and system integration aspects.

Liquid crystal metasurfaces encounter significant response time limitations, typically operating in the millisecond range, which restricts their application in high-speed optical systems. The temperature sensitivity of LCs presents another major hurdle, as their optical properties can fluctuate considerably with environmental temperature variations, necessitating precise thermal management systems that add complexity and cost.

The alignment stability of liquid crystals remains problematic, particularly in dynamic operating conditions where mechanical vibrations or long-term usage can disrupt molecular orientation. This instability directly impacts device reliability and performance consistency. Additionally, LC metasurfaces often require continuous power to maintain specific states, resulting in higher energy consumption compared to bistable alternatives.

For phase-change material metasurfaces, the primary challenge lies in their high switching energy requirements. The phase transition process demands substantial energy input, leading to power efficiency concerns in portable or energy-constrained applications. Closely related is the thermal management challenge, as the repeated heating-cooling cycles necessary for switching can create thermal stress and potential material degradation over time.

Endurance limitations plague PCM metasurfaces, with current materials typically supporting 10^5-10^6 switching cycles before performance degradation becomes significant. This falls short of the requirements for many commercial applications that demand millions of reliable operation cycles. The switching speed, while faster than LCs, still presents limitations for ultrafast applications, with typical transition times in the nanosecond to microsecond range.

Fabrication challenges exist for both technologies. LC metasurfaces require precise alignment layers and complex cell structures, while PCM integration demands careful thermal isolation and precise deposition techniques. These manufacturing complexities increase production costs and limit scalability. Furthermore, both technologies face integration challenges with existing photonic and electronic systems, requiring specialized interfaces and control circuitry.

The spectral operating range represents another limitation, as most current implementations work effectively only within narrow wavelength bands. Broadband operation remains elusive, particularly for applications requiring consistent performance across the visible and near-infrared spectrum. Resolution constraints also exist, with minimum feature sizes typically limited by fabrication capabilities rather than theoretical limits.

Liquid crystal metasurfaces encounter significant response time limitations, typically operating in the millisecond range, which restricts their application in high-speed optical systems. The temperature sensitivity of LCs presents another major hurdle, as their optical properties can fluctuate considerably with environmental temperature variations, necessitating precise thermal management systems that add complexity and cost.

The alignment stability of liquid crystals remains problematic, particularly in dynamic operating conditions where mechanical vibrations or long-term usage can disrupt molecular orientation. This instability directly impacts device reliability and performance consistency. Additionally, LC metasurfaces often require continuous power to maintain specific states, resulting in higher energy consumption compared to bistable alternatives.

For phase-change material metasurfaces, the primary challenge lies in their high switching energy requirements. The phase transition process demands substantial energy input, leading to power efficiency concerns in portable or energy-constrained applications. Closely related is the thermal management challenge, as the repeated heating-cooling cycles necessary for switching can create thermal stress and potential material degradation over time.

Endurance limitations plague PCM metasurfaces, with current materials typically supporting 10^5-10^6 switching cycles before performance degradation becomes significant. This falls short of the requirements for many commercial applications that demand millions of reliable operation cycles. The switching speed, while faster than LCs, still presents limitations for ultrafast applications, with typical transition times in the nanosecond to microsecond range.

Fabrication challenges exist for both technologies. LC metasurfaces require precise alignment layers and complex cell structures, while PCM integration demands careful thermal isolation and precise deposition techniques. These manufacturing complexities increase production costs and limit scalability. Furthermore, both technologies face integration challenges with existing photonic and electronic systems, requiring specialized interfaces and control circuitry.

The spectral operating range represents another limitation, as most current implementations work effectively only within narrow wavelength bands. Broadband operation remains elusive, particularly for applications requiring consistent performance across the visible and near-infrared spectrum. Resolution constraints also exist, with minimum feature sizes typically limited by fabrication capabilities rather than theoretical limits.

Comparative Analysis of LC and PCM Implementation Approaches

01 Liquid crystal metasurfaces for dynamic optical control

Liquid crystal metasurfaces enable dynamic control of optical properties through the application of external stimuli such as electric fields or temperature changes. These metasurfaces combine the tunable properties of liquid crystals with the engineered electromagnetic response of metasurfaces to create reconfigurable optical devices. The integration allows for real-time manipulation of light properties including phase, amplitude, and polarization, making them suitable for applications in beam steering, wavefront shaping, and adaptive optics.- Liquid crystal metasurfaces for tunable optical devices: Liquid crystal metasurfaces enable dynamic control of optical properties through the application of external stimuli such as electric fields or temperature changes. These metasurfaces combine the reconfigurability of liquid crystals with the unique optical properties of metasurfaces to create tunable devices for beam steering, wavefront shaping, and spectral filtering. The anisotropic nature of liquid crystals allows for continuous modulation of the refractive index, enabling precise control over phase, amplitude, and polarization of light.

- Phase-change materials for reconfigurable metasurfaces: Phase-change materials enable the creation of reconfigurable metasurfaces through reversible transitions between amorphous and crystalline states. These transitions, triggered by thermal, electrical, or optical stimuli, result in significant changes in optical properties. Phase-change metasurfaces offer non-volatile switching capabilities, maintaining their state without continuous power input, making them suitable for memory devices and programmable photonics. Common phase-change materials include chalcogenide compounds that exhibit large refractive index contrasts between their different phases.

- Hybrid metasurfaces combining liquid crystals and phase-change materials: Hybrid metasurfaces integrate both liquid crystal and phase-change material technologies to achieve enhanced functionality and performance. These composite structures leverage the continuous tunability of liquid crystals with the non-volatile switching of phase-change materials, enabling multi-state operation with reduced power consumption. The synergistic combination allows for hierarchical control of optical properties across different timescales and with varying degrees of persistence, opening new possibilities for adaptive optics and reconfigurable photonic systems.

- Applications in beam steering and wavefront manipulation: Liquid crystal and phase-change metasurfaces enable advanced beam steering and wavefront manipulation capabilities for applications in LiDAR, augmented reality, and optical communications. These metasurfaces can dynamically control the direction, shape, and focus of light beams without mechanical components, reducing system size and increasing reliability. The ability to rapidly reconfigure optical properties allows for adaptive optics that can compensate for environmental disturbances or switch between multiple operational modes on demand.

- Fabrication techniques and integration challenges: Advanced fabrication techniques are essential for creating high-performance liquid crystal and phase-change metasurfaces. These include nanolithography, self-assembly methods, and multi-layer deposition processes that enable precise control over nano-scale features. Integration challenges involve addressing thermal management issues, ensuring uniform switching behavior across large areas, and developing compatible electrode structures for electrical control. Recent innovations focus on scalable manufacturing approaches and integration with existing semiconductor technologies to enable commercial applications.

02 Phase-change materials in metasurface design

Phase-change materials incorporated into metasurfaces provide non-volatile switching capabilities between different optical states. These materials undergo significant changes in their optical properties when transitioning between amorphous and crystalline phases, which can be triggered by thermal, electrical, or optical stimuli. This characteristic enables the development of reconfigurable metasurfaces with memory effects, allowing them to maintain their optical state without continuous power input, which is advantageous for energy-efficient optical devices and information storage applications.Expand Specific Solutions03 Advanced fabrication techniques for metasurfaces

Novel fabrication methods are essential for creating high-performance liquid crystal and phase-change metasurfaces. These techniques include nanoimprint lithography, electron beam lithography, and self-assembly processes that enable precise control over the nanoscale structures required for effective light manipulation. Advanced deposition methods for phase-change materials and liquid crystal alignment techniques ensure optimal integration of active materials with metasurface structures, resulting in improved optical performance and device reliability.Expand Specific Solutions04 Applications in telecommunications and display technologies

Liquid crystal and phase-change metasurfaces offer significant advantages for telecommunications and display technologies. In telecommunications, these metasurfaces enable beam steering for satellite communications, reconfigurable antennas, and optical switching for high-speed data transmission. For display applications, they provide enhanced color reproduction, wider viewing angles, and reduced power consumption compared to conventional technologies. The ability to dynamically control light at the subwavelength scale opens possibilities for holographic displays and augmented reality devices.Expand Specific Solutions05 Integration of artificial intelligence with metasurface technology

The combination of artificial intelligence with liquid crystal and phase-change metasurfaces represents an emerging frontier in optical technology. Machine learning algorithms are being employed to optimize metasurface designs for specific applications, predict optical responses, and enable adaptive control systems. This integration allows for intelligent optical systems that can automatically adjust their properties based on environmental conditions or user requirements, leading to self-optimizing optical components for communications, sensing, and imaging applications.Expand Specific Solutions

Leading Research Groups and Companies in Metasurface Technology

The liquid crystal vs phase-change metasurfaces market is in an early growth stage, characterized by increasing research activity and emerging commercial applications. The global market for these advanced optical technologies is projected to expand significantly, driven by applications in display technologies, telecommunications, and sensing. Technologically, liquid crystal metasurfaces are more mature, with companies like BOE Technology, Samsung Display, and Merck leading development with established manufacturing capabilities. Phase-change metasurfaces represent a newer frontier, with research institutions like Northwestern University and Tsinghua University making significant advances alongside industrial players such as FUJIFILM and Sharp. Japanese corporations (Sony, Dai Nippon Printing) and Chinese enterprises (BOE) are particularly competitive in this space, leveraging their expertise in display technologies to accelerate commercialization.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed advanced liquid crystal metasurfaces that utilize their expertise in display technology. Their approach incorporates nanopatterned liquid crystal cells with precisely controlled molecular orientation to achieve dynamic tuning of electromagnetic wave properties. Samsung's technology enables active control of phase, amplitude, and polarization states across visible and infrared wavelengths. Their metasurfaces feature sub-wavelength pixel architectures that can be electrically addressed individually, allowing for programmable wavefront shaping with response times in milliseconds. Samsung has integrated these liquid crystal metasurfaces with their existing thin-film transistor backplane technology to create large-area, high-resolution reconfigurable optical elements for applications in beam steering, holographic displays, and adaptive optics.

Strengths: Leverages existing LCD manufacturing infrastructure; offers fast switching speeds (milliseconds); provides continuous tuning of optical properties; enables large-area fabrication. Weaknesses: Temperature sensitivity affects performance stability; limited operating wavelength range compared to phase-change materials; requires constant power to maintain states.

Merck Patent GmbH

Technical Solution: Merck has pioneered specialized liquid crystal materials specifically engineered for metasurface applications. Their proprietary liquid crystal formulations feature enhanced birefringence properties and tailored molecular structures that respond to external stimuli with precise optical modulation capabilities. Merck's technology focuses on creating liquid crystal compounds with optimized electro-optical coefficients that enable efficient phase modulation with reduced driving voltages. Their materials incorporate stabilizing additives that extend operational temperature ranges and improve long-term reliability. Merck has developed both nematic and smectic liquid crystal variants optimized for different metasurface architectures, with their latest generation materials achieving switching speeds approaching 1 millisecond while maintaining high optical transparency and low absorption losses across targeted wavelength bands.

Strengths: Industry-leading expertise in liquid crystal material science; offers customized formulations for specific applications; provides materials with exceptional optical quality and uniformity. Weaknesses: Requires integration with complex electrode structures; performance degrades at temperature extremes; higher cost compared to conventional liquid crystal materials.

Key Patents and Scientific Breakthroughs in Metasurface Design

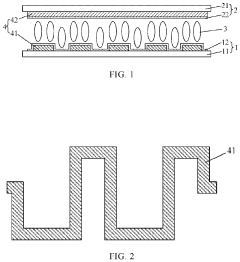

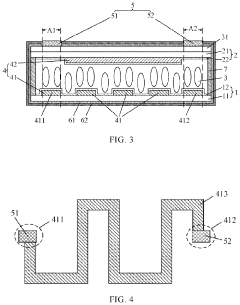

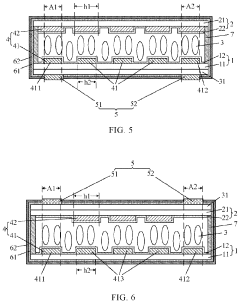

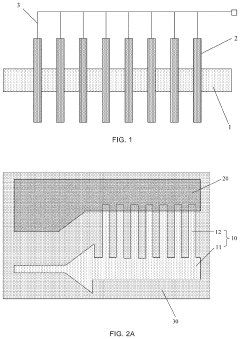

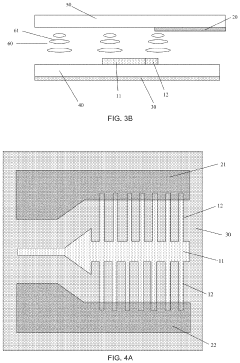

Liquid crystal phase shifter including a liquid crystal layer located between first and second flexible substrates, where a third flexible substrate provides a feed portion

PatentActiveUS11424520B2

Innovation

- A liquid crystal phase shifter design incorporating flexible substrates and alignment layers, with a microstrip line and phased electrode configuration, allowing for phase shifting of electromagnetic waves while enabling deformability and reduced thickness and weight.

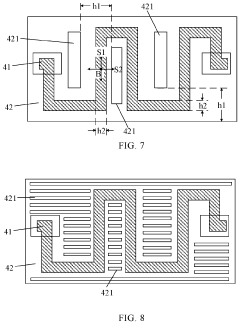

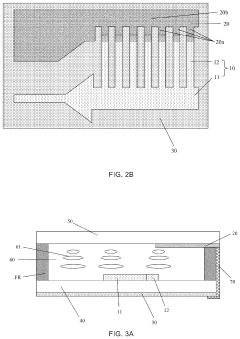

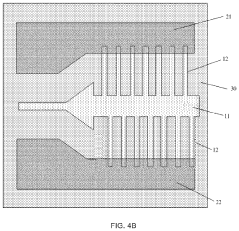

Liquid crystal phase shifter, method for operating the same, liquid crystal antenna, and communication apparatus

PatentActiveUS11799179B2

Innovation

- The design includes a liquid crystal phase shifter with a second electrode layer positioned in a peripheral region of the substrate, reducing the length of conductive wires and their inductance and resistance, and featuring a microstrip electrode layer with branch structures that receive different voltages to create an electric field and rotate liquid crystal molecules, thereby changing the dielectric constant and achieving a larger phase shift.

Manufacturing Scalability and Cost Considerations

Manufacturing scalability and cost considerations represent critical factors in determining the commercial viability of metasurface technologies. Liquid crystal (LC) metasurfaces benefit from established manufacturing infrastructure developed over decades for the display industry. The fabrication processes for LC-based devices utilize mature technologies including photolithography, thin-film deposition, and LCD assembly lines that operate at industrial scales. This manufacturing maturity translates to lower production costs, with estimates suggesting LC metasurface production can leverage approximately 70% of existing LCD manufacturing equipment.

In contrast, phase-change material (PCM) metasurfaces face more significant manufacturing challenges. The deposition of phase-change materials like germanium-antimony-tellurium (GST) compounds requires precise control of stoichiometry and crystallization conditions. Current fabrication methods primarily rely on specialized physical vapor deposition techniques such as sputtering or thermal evaporation, which have not yet been optimized for high-volume production. The temperature sensitivity during PCM deposition also necessitates careful thermal management throughout the manufacturing process.

Cost analysis reveals that LC metasurfaces currently maintain a substantial advantage, with production costs estimated at $15-25 per square inch for medium-volume manufacturing. PCM metasurfaces, however, command significantly higher costs ranging from $50-120 per square inch at comparable volumes, primarily due to material costs and more complex fabrication requirements. The specialized chalcogenide materials used in PCMs are more expensive than the organic compounds used in LC devices.

Scaling considerations further differentiate these technologies. LC metasurfaces can be manufactured in large panels exceeding 2 meters in diagonal dimension using existing infrastructure, while PCM fabrication currently faces size limitations of approximately 30cm diagonal due to uniformity challenges in phase-change material deposition across larger areas. This size limitation restricts potential applications and increases per-unit costs for PCM solutions.

Future manufacturing developments may narrow this gap. Research into solution-processed PCMs and roll-to-roll compatible deposition techniques shows promise for reducing PCM manufacturing costs by potentially 60-70% within the next five years. Similarly, advances in atomic layer deposition methods could improve the uniformity and quality of PCM layers while reducing material waste, further enhancing cost-effectiveness for high-volume production scenarios.

In contrast, phase-change material (PCM) metasurfaces face more significant manufacturing challenges. The deposition of phase-change materials like germanium-antimony-tellurium (GST) compounds requires precise control of stoichiometry and crystallization conditions. Current fabrication methods primarily rely on specialized physical vapor deposition techniques such as sputtering or thermal evaporation, which have not yet been optimized for high-volume production. The temperature sensitivity during PCM deposition also necessitates careful thermal management throughout the manufacturing process.

Cost analysis reveals that LC metasurfaces currently maintain a substantial advantage, with production costs estimated at $15-25 per square inch for medium-volume manufacturing. PCM metasurfaces, however, command significantly higher costs ranging from $50-120 per square inch at comparable volumes, primarily due to material costs and more complex fabrication requirements. The specialized chalcogenide materials used in PCMs are more expensive than the organic compounds used in LC devices.

Scaling considerations further differentiate these technologies. LC metasurfaces can be manufactured in large panels exceeding 2 meters in diagonal dimension using existing infrastructure, while PCM fabrication currently faces size limitations of approximately 30cm diagonal due to uniformity challenges in phase-change material deposition across larger areas. This size limitation restricts potential applications and increases per-unit costs for PCM solutions.

Future manufacturing developments may narrow this gap. Research into solution-processed PCMs and roll-to-roll compatible deposition techniques shows promise for reducing PCM manufacturing costs by potentially 60-70% within the next five years. Similarly, advances in atomic layer deposition methods could improve the uniformity and quality of PCM layers while reducing material waste, further enhancing cost-effectiveness for high-volume production scenarios.

Environmental Impact and Sustainability of Metasurface Materials

The environmental impact and sustainability considerations of metasurface materials represent critical factors in evaluating the long-term viability of both liquid crystal (LC) and phase-change material (PCM) metasurfaces. These advanced optical technologies must be assessed not only for their performance characteristics but also for their ecological footprint throughout their lifecycle.

Liquid crystal metasurfaces generally demonstrate favorable environmental attributes compared to their phase-change counterparts. The primary materials used in LC metasurfaces—organic compounds and liquid crystal polymers—typically require lower processing temperatures during manufacturing, resulting in reduced energy consumption. Additionally, these materials often contain fewer toxic elements and can be synthesized from renewable resources in some cases, offering a pathway toward more sustainable production methods.

In contrast, phase-change metasurfaces frequently incorporate chalcogenide compounds such as germanium-antimony-tellurium (GST) or other materials containing rare or potentially toxic elements. The extraction and processing of these elements can lead to significant environmental degradation, including habitat destruction, water pollution, and high carbon emissions. Furthermore, the manufacturing of PCM metasurfaces typically demands higher temperature processes and more energy-intensive deposition techniques, contributing to a larger carbon footprint.

End-of-life considerations also favor liquid crystal technologies. LC materials generally present fewer challenges for recycling and disposal, with some components being biodegradable or recoverable through established recycling processes. Phase-change materials, however, may require specialized handling due to the presence of elements that could pose environmental hazards if improperly disposed of, potentially leading to soil or groundwater contamination.

The operational sustainability of these technologies must also be considered. LC metasurfaces typically consume less power during operation, as they require energy primarily during state transitions rather than for maintaining a particular state. This characteristic makes them particularly suitable for energy-efficient applications. PCM metasurfaces, while offering excellent stability, often demand more energy for switching between states, especially when thermal mechanisms are employed for phase transitions.

Recent research trends indicate growing interest in developing more environmentally friendly alternatives for both technologies. For LC metasurfaces, this includes exploration of bio-based liquid crystals and reduced reliance on petroleum-derived compounds. For PCM metasurfaces, efforts focus on finding less toxic phase-change materials and improving energy efficiency in the switching mechanisms, potentially through more targeted heating approaches or alternative stimulation methods.

Liquid crystal metasurfaces generally demonstrate favorable environmental attributes compared to their phase-change counterparts. The primary materials used in LC metasurfaces—organic compounds and liquid crystal polymers—typically require lower processing temperatures during manufacturing, resulting in reduced energy consumption. Additionally, these materials often contain fewer toxic elements and can be synthesized from renewable resources in some cases, offering a pathway toward more sustainable production methods.

In contrast, phase-change metasurfaces frequently incorporate chalcogenide compounds such as germanium-antimony-tellurium (GST) or other materials containing rare or potentially toxic elements. The extraction and processing of these elements can lead to significant environmental degradation, including habitat destruction, water pollution, and high carbon emissions. Furthermore, the manufacturing of PCM metasurfaces typically demands higher temperature processes and more energy-intensive deposition techniques, contributing to a larger carbon footprint.

End-of-life considerations also favor liquid crystal technologies. LC materials generally present fewer challenges for recycling and disposal, with some components being biodegradable or recoverable through established recycling processes. Phase-change materials, however, may require specialized handling due to the presence of elements that could pose environmental hazards if improperly disposed of, potentially leading to soil or groundwater contamination.

The operational sustainability of these technologies must also be considered. LC metasurfaces typically consume less power during operation, as they require energy primarily during state transitions rather than for maintaining a particular state. This characteristic makes them particularly suitable for energy-efficient applications. PCM metasurfaces, while offering excellent stability, often demand more energy for switching between states, especially when thermal mechanisms are employed for phase transitions.

Recent research trends indicate growing interest in developing more environmentally friendly alternatives for both technologies. For LC metasurfaces, this includes exploration of bio-based liquid crystals and reduced reliance on petroleum-derived compounds. For PCM metasurfaces, efforts focus on finding less toxic phase-change materials and improving energy efficiency in the switching mechanisms, potentially through more targeted heating approaches or alternative stimulation methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!