Tuning Mechanisms: MEMS, Liquid Crystal, And Phase-Change Materials

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MEMS Tuning Evolution and Objectives

Microelectromechanical Systems (MEMS) tuning technology has evolved significantly over the past three decades, transforming from rudimentary mechanical structures to sophisticated integrated systems capable of precise manipulation at the microscale. The journey began in the early 1990s with simple cantilever-based tuning mechanisms primarily used in optical applications. These early implementations suffered from limited tuning ranges and reliability issues, but established the foundation for future advancements.

By the early 2000s, MEMS tuning technology experienced its first major breakthrough with the development of comb-drive actuators and electrostatic tuning mechanisms. These innovations enabled more precise control and expanded the potential application domains beyond optics into RF communications and sensing technologies. The integration of MEMS with CMOS fabrication processes during this period marked a critical milestone, allowing for cost-effective mass production and wider industry adoption.

The 2010s witnessed the refinement of MEMS tuning mechanisms with the introduction of piezoelectric and thermal actuation methods, significantly improving response times and power efficiency. These advancements enabled MEMS tuners to achieve sub-microsecond switching speeds and higher reliability, making them viable for demanding applications in telecommunications and aerospace industries.

Current state-of-the-art MEMS tuning technology incorporates multi-physics approaches, combining electrostatic, piezoelectric, and thermal actuation methods to overcome the limitations of single-mechanism designs. This hybrid approach has expanded tuning ranges while maintaining precision control, addressing previous technical constraints that limited commercial applications.

The primary objective of MEMS tuning technology development is to achieve seamless integration with other tuning mechanisms such as liquid crystal and phase-change materials to create versatile, multi-functional tuning systems. This integration aims to leverage the complementary strengths of each technology: MEMS offers fast response times and high precision, liquid crystals provide continuous tuning capabilities, and phase-change materials deliver non-volatile switching with low power consumption.

Another critical objective is miniaturization while maintaining or improving performance metrics. As devices continue to shrink, MEMS tuning mechanisms must adapt to increasingly constrained spatial requirements without sacrificing functionality or reliability. This challenge drives research toward novel materials and fabrication techniques that can deliver higher performance in smaller form factors.

Looking forward, MEMS tuning technology aims to achieve greater autonomy through the incorporation of closed-loop control systems and self-calibration capabilities. These advancements will enable MEMS tuners to adapt to changing environmental conditions and maintain optimal performance over extended operational lifetimes, a crucial requirement for deployment in remote or inaccessible locations.

By the early 2000s, MEMS tuning technology experienced its first major breakthrough with the development of comb-drive actuators and electrostatic tuning mechanisms. These innovations enabled more precise control and expanded the potential application domains beyond optics into RF communications and sensing technologies. The integration of MEMS with CMOS fabrication processes during this period marked a critical milestone, allowing for cost-effective mass production and wider industry adoption.

The 2010s witnessed the refinement of MEMS tuning mechanisms with the introduction of piezoelectric and thermal actuation methods, significantly improving response times and power efficiency. These advancements enabled MEMS tuners to achieve sub-microsecond switching speeds and higher reliability, making them viable for demanding applications in telecommunications and aerospace industries.

Current state-of-the-art MEMS tuning technology incorporates multi-physics approaches, combining electrostatic, piezoelectric, and thermal actuation methods to overcome the limitations of single-mechanism designs. This hybrid approach has expanded tuning ranges while maintaining precision control, addressing previous technical constraints that limited commercial applications.

The primary objective of MEMS tuning technology development is to achieve seamless integration with other tuning mechanisms such as liquid crystal and phase-change materials to create versatile, multi-functional tuning systems. This integration aims to leverage the complementary strengths of each technology: MEMS offers fast response times and high precision, liquid crystals provide continuous tuning capabilities, and phase-change materials deliver non-volatile switching with low power consumption.

Another critical objective is miniaturization while maintaining or improving performance metrics. As devices continue to shrink, MEMS tuning mechanisms must adapt to increasingly constrained spatial requirements without sacrificing functionality or reliability. This challenge drives research toward novel materials and fabrication techniques that can deliver higher performance in smaller form factors.

Looking forward, MEMS tuning technology aims to achieve greater autonomy through the incorporation of closed-loop control systems and self-calibration capabilities. These advancements will enable MEMS tuners to adapt to changing environmental conditions and maintain optimal performance over extended operational lifetimes, a crucial requirement for deployment in remote or inaccessible locations.

Market Analysis for Tuning Mechanism Applications

The global market for tuning mechanisms is experiencing robust growth, driven by increasing demand across multiple industries including telecommunications, automotive, aerospace, and consumer electronics. The combined market value for MEMS, liquid crystal, and phase-change material tuning technologies reached approximately $12.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 14.3% through 2028.

MEMS-based tuning mechanisms currently dominate the market share at 47%, valued at $5.9 billion. This segment is primarily fueled by applications in RF filters, oscillators, and sensors for 5G infrastructure and smartphones. The automotive sector represents the fastest-growing application area for MEMS tuning, with demand increasing for advanced driver assistance systems (ADAS) and autonomous vehicle technologies.

Liquid crystal tuning mechanisms hold approximately 32% of the market, valued at $4 billion. This technology finds extensive applications in optical communications, beam steering devices, and adaptive optics. The telecommunications industry remains the largest consumer of liquid crystal tuning solutions, particularly for wavelength selective switches and reconfigurable optical add-drop multiplexers (ROADMs).

Phase-change material (PCM) tuning mechanisms, though currently the smallest segment at 21% market share ($2.6 billion), are demonstrating the highest growth potential with a projected CAGR of 18.7%. This acceleration is driven by emerging applications in neuromorphic computing, non-volatile memory, and programmable photonics.

Regionally, North America leads the market with 38% share, followed by Asia-Pacific at 35%, Europe at 22%, and rest of the world at 5%. However, the Asia-Pacific region is expected to overtake North America by 2026, primarily due to rapid expansion of 5G infrastructure in China, South Korea, and Japan, coupled with increasing manufacturing capabilities for advanced electronics.

Key market drivers include the proliferation of IoT devices requiring compact tunable components, growing demand for reconfigurable communication systems, and increasing adoption of LiDAR technologies in autonomous vehicles. Additionally, the push toward higher frequency bands in wireless communications (mmWave and sub-THz) is creating substantial demand for precisely tunable RF components.

Market challenges include cost pressures, particularly for high-volume consumer applications, reliability concerns in harsh environments, and integration complexities when incorporating these tuning mechanisms into existing systems. The competitive landscape remains fragmented, with specialized players dominating specific technology niches rather than end-to-end solutions.

MEMS-based tuning mechanisms currently dominate the market share at 47%, valued at $5.9 billion. This segment is primarily fueled by applications in RF filters, oscillators, and sensors for 5G infrastructure and smartphones. The automotive sector represents the fastest-growing application area for MEMS tuning, with demand increasing for advanced driver assistance systems (ADAS) and autonomous vehicle technologies.

Liquid crystal tuning mechanisms hold approximately 32% of the market, valued at $4 billion. This technology finds extensive applications in optical communications, beam steering devices, and adaptive optics. The telecommunications industry remains the largest consumer of liquid crystal tuning solutions, particularly for wavelength selective switches and reconfigurable optical add-drop multiplexers (ROADMs).

Phase-change material (PCM) tuning mechanisms, though currently the smallest segment at 21% market share ($2.6 billion), are demonstrating the highest growth potential with a projected CAGR of 18.7%. This acceleration is driven by emerging applications in neuromorphic computing, non-volatile memory, and programmable photonics.

Regionally, North America leads the market with 38% share, followed by Asia-Pacific at 35%, Europe at 22%, and rest of the world at 5%. However, the Asia-Pacific region is expected to overtake North America by 2026, primarily due to rapid expansion of 5G infrastructure in China, South Korea, and Japan, coupled with increasing manufacturing capabilities for advanced electronics.

Key market drivers include the proliferation of IoT devices requiring compact tunable components, growing demand for reconfigurable communication systems, and increasing adoption of LiDAR technologies in autonomous vehicles. Additionally, the push toward higher frequency bands in wireless communications (mmWave and sub-THz) is creating substantial demand for precisely tunable RF components.

Market challenges include cost pressures, particularly for high-volume consumer applications, reliability concerns in harsh environments, and integration complexities when incorporating these tuning mechanisms into existing systems. The competitive landscape remains fragmented, with specialized players dominating specific technology niches rather than end-to-end solutions.

Current Challenges in MEMS, LC, and PCM Technologies

Despite significant advancements in tuning mechanisms across MEMS, Liquid Crystal, and Phase-Change Materials technologies, several critical challenges persist that impede their broader adoption and performance optimization. These challenges vary across the three technologies but share common themes related to reliability, scalability, and integration.

MEMS-based tuning mechanisms face substantial challenges in achieving consistent performance across varying environmental conditions. Temperature fluctuations significantly affect the mechanical properties of MEMS structures, causing drift in resonant frequencies and actuation characteristics. Additionally, long-term reliability issues arise from mechanical fatigue, stiction, and wear in moving components, particularly in high-frequency applications where components undergo millions of cycles. Miniaturization efforts are further constrained by fabrication limitations, with current lithographic techniques struggling to maintain precision at sub-micron scales while keeping manufacturing costs economically viable.

For Liquid Crystal (LC) technologies, response time remains a fundamental limitation, particularly at lower temperatures where viscosity increases substantially. This temperature dependence creates performance inconsistencies across operating environments. Another significant challenge is the limited tuning range achievable with conventional LC materials, restricting their application in systems requiring broad frequency or phase adjustments. The alignment stability of LC molecules under repeated electrical cycling also presents reliability concerns, with performance degradation observed over extended operational periods.

Phase-Change Materials (PCMs) face distinct challenges centered around power consumption and thermal management. The high energy requirements for phase transitions between amorphous and crystalline states limit their efficiency in portable or energy-constrained applications. Thermal crosstalk between adjacent PCM elements in densely packed arrays creates interference issues that compromise precision in multi-element tuning systems. Furthermore, the finite number of reliable switching cycles before material degradation occurs presents serious concerns for applications requiring frequent reconfiguration.

Cross-cutting challenges across all three technologies include integration complexities with conventional semiconductor manufacturing processes, packaging challenges that must simultaneously address mechanical, optical, and electrical requirements, and control system sophistication needed to achieve precise, repeatable tuning performance. The development of standardized characterization methodologies also lags behind technological advancement, making performance comparisons and reliability assessments difficult across different implementation approaches.

These technical hurdles collectively represent significant barriers to the widespread commercial deployment of advanced tuning mechanisms, particularly in demanding applications such as telecommunications, aerospace, and medical devices where reliability and performance consistency are paramount.

MEMS-based tuning mechanisms face substantial challenges in achieving consistent performance across varying environmental conditions. Temperature fluctuations significantly affect the mechanical properties of MEMS structures, causing drift in resonant frequencies and actuation characteristics. Additionally, long-term reliability issues arise from mechanical fatigue, stiction, and wear in moving components, particularly in high-frequency applications where components undergo millions of cycles. Miniaturization efforts are further constrained by fabrication limitations, with current lithographic techniques struggling to maintain precision at sub-micron scales while keeping manufacturing costs economically viable.

For Liquid Crystal (LC) technologies, response time remains a fundamental limitation, particularly at lower temperatures where viscosity increases substantially. This temperature dependence creates performance inconsistencies across operating environments. Another significant challenge is the limited tuning range achievable with conventional LC materials, restricting their application in systems requiring broad frequency or phase adjustments. The alignment stability of LC molecules under repeated electrical cycling also presents reliability concerns, with performance degradation observed over extended operational periods.

Phase-Change Materials (PCMs) face distinct challenges centered around power consumption and thermal management. The high energy requirements for phase transitions between amorphous and crystalline states limit their efficiency in portable or energy-constrained applications. Thermal crosstalk between adjacent PCM elements in densely packed arrays creates interference issues that compromise precision in multi-element tuning systems. Furthermore, the finite number of reliable switching cycles before material degradation occurs presents serious concerns for applications requiring frequent reconfiguration.

Cross-cutting challenges across all three technologies include integration complexities with conventional semiconductor manufacturing processes, packaging challenges that must simultaneously address mechanical, optical, and electrical requirements, and control system sophistication needed to achieve precise, repeatable tuning performance. The development of standardized characterization methodologies also lags behind technological advancement, making performance comparisons and reliability assessments difficult across different implementation approaches.

These technical hurdles collectively represent significant barriers to the widespread commercial deployment of advanced tuning mechanisms, particularly in demanding applications such as telecommunications, aerospace, and medical devices where reliability and performance consistency are paramount.

Comparative Analysis of Current Tuning Solutions

01 MEMS-based tuning mechanisms

Microelectromechanical systems (MEMS) provide precise tuning capabilities through mechanical movement at the microscale. These systems utilize electrostatic, piezoelectric, or thermal actuation to achieve variable capacitance, resonance frequency adjustment, or optical path modification. MEMS-based tuning mechanisms offer advantages including fast response times, high precision, and compatibility with integrated circuit manufacturing processes, making them suitable for applications in RF filters, oscillators, and optical systems.- MEMS-based tuning mechanisms: Microelectromechanical systems (MEMS) provide precise tuning capabilities through mechanical movement at the microscale. These systems utilize electrostatic, piezoelectric, or thermal actuation to achieve variable capacitance, resonance frequency adjustment, or optical path modulation. MEMS-based tuning mechanisms offer advantages including fast response times, high precision, and compatibility with semiconductor manufacturing processes, making them suitable for applications in RF filters, oscillators, and optical systems.

- Liquid crystal tuning technologies: Liquid crystal materials enable tunable optical and electronic properties through molecular reorientation in response to applied electric fields. These technologies allow for continuous adjustment of refractive index, polarization control, and phase modulation. Liquid crystal tuning mechanisms are employed in display technologies, optical filters, beam steering devices, and telecommunications equipment, offering advantages such as low power consumption, no moving parts, and voltage-controlled operation.

- Phase-change material tuning systems: Phase-change materials (PCMs) provide tuning capabilities through reversible transitions between amorphous and crystalline states, resulting in significant changes to optical and electrical properties. These materials can be switched rapidly using thermal, electrical, or optical stimuli, enabling binary or gradual tuning of reflectivity, transmissivity, or resistance. PCM-based tuning mechanisms are utilized in non-volatile memory, reconfigurable photonics, and programmable RF components.

- Hybrid and multi-material tuning approaches: Hybrid tuning mechanisms combine multiple technologies such as MEMS with liquid crystals or phase-change materials with MEMS to achieve enhanced performance characteristics. These integrated approaches leverage the complementary advantages of different tuning mechanisms, enabling wider tuning ranges, improved linearity, or multi-parameter adjustment. Hybrid systems can overcome limitations of individual technologies while enabling novel functionalities for advanced applications in communications, sensing, and imaging.

- Display-oriented tuning mechanisms: Specialized tuning mechanisms designed specifically for display applications incorporate technologies for pixel addressing, color modulation, and refresh rate control. These systems may utilize active matrix driving schemes, thin-film transistor arrays, or specialized electrode configurations to achieve precise control over display elements. Display-oriented tuning mechanisms focus on parameters such as response time, contrast ratio, viewing angle, and color gamut to optimize visual performance.

02 Liquid crystal tuning technologies

Liquid crystal materials enable tunable optical and electrical properties through molecular reorientation in response to applied electric fields. These technologies allow for continuous adjustment of refractive index, polarization control, and phase modulation. Liquid crystal tuning mechanisms are employed in display technologies, optical filters, beam steering devices, and telecommunications equipment, offering advantages such as low power consumption, no moving parts, and voltage-controlled operation.Expand Specific Solutions03 Phase-change material tuning systems

Phase-change materials exhibit significant changes in optical and electrical properties when transitioning between amorphous and crystalline states. These materials can be rapidly and reversibly switched using thermal, electrical, or optical stimuli, enabling tunable resistance, reflectivity, or transmissivity. Applications include non-volatile memory, reconfigurable photonics, and programmable RF components, with benefits including non-volatility, high contrast ratios, and multi-level tuning capabilities.Expand Specific Solutions04 Hybrid and multi-mechanism tuning approaches

Combining multiple tuning mechanisms creates hybrid systems that leverage the advantages of different technologies. These approaches may integrate MEMS with liquid crystals, phase-change materials with MEMS, or other combinations to achieve enhanced performance characteristics. Hybrid tuning mechanisms offer expanded tuning ranges, improved response times, or multi-parameter adjustment capabilities that cannot be achieved with single-mechanism approaches, enabling more versatile and robust tunable devices.Expand Specific Solutions05 Display-specific tuning technologies

Specialized tuning mechanisms designed specifically for display applications incorporate techniques for pixel addressing, color management, and refresh rate optimization. These technologies may utilize active matrix driving schemes, color filter tuning, or backlight modulation to achieve desired visual characteristics. Display-specific tuning mechanisms focus on enhancing image quality, reducing power consumption, and enabling features such as high dynamic range or wide color gamut in various display technologies.Expand Specific Solutions

Industry Leaders in Tuning Technology Development

The tuning mechanisms market, encompassing MEMS, liquid crystal, and phase-change materials technologies, is currently in a growth phase characterized by increasing applications across telecommunications, electronics, and sensing industries. The global market size is expanding rapidly, driven by demand for miniaturized, energy-efficient components in consumer electronics and automotive sectors. Regarding technological maturity, MEMS technology leads with established players like Murata Manufacturing and NXP Semiconductors offering commercialized solutions, while liquid crystal tuning sees significant advancement from companies like JNC Corp. and Sony Group. Phase-change materials represent the emerging frontier, with research institutions (Agency for Science, Technology & Research, Technical University of Denmark) collaborating with semiconductor manufacturers (TSMC, GlobalFoundries) to develop next-generation applications, indicating a technology ecosystem spanning from mature commercial products to cutting-edge research.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has pioneered advanced phase-change material (PCM) tuning mechanisms for RF and optical applications. Their technology leverages the dramatic resistivity and optical property changes that occur when PCMs transition between amorphous and crystalline states. HRL's proprietary chalcogenide-based PCM compositions (typically Ge-Sb-Te alloys) are engineered for specific transition temperatures and electrical characteristics. For RF applications, HRL has developed PCM-based switches and tunable capacitors that achieve switching ratios exceeding 10^3 between states, with transition times under 100ns when activated by localized Joule heating. Their optical PCM devices utilize the significant refractive index contrast (Δn>1) between material states to create tunable photonic structures. HRL has also addressed reliability challenges through interface engineering techniques that minimize atomic migration and prevent delamination during repeated thermal cycling, achieving demonstrated lifetimes of over 10^6 switching cycles in controlled environments.

Strengths: Exceptional contrast between states enables high-performance switching, non-volatile operation eliminates static power consumption, and compatibility with standard semiconductor processes. Weaknesses: Relatively high switching energy requirements and potential for material degradation after extensive cycling (>10^6 cycles).

Sony Group Corp.

Technical Solution: Sony has developed advanced liquid crystal tuning mechanisms primarily for optical applications, including camera lenses and display technologies. Their approach utilizes electrically controlled birefringence (ECB) in specialized liquid crystal formulations to achieve variable optical properties. Sony's proprietary liquid crystal cells feature nano-structured alignment layers that enable fast switching speeds (under 5ms) and precise control of refractive indices. For imaging applications, Sony has created variable focus lenses using liquid crystal elements that can rapidly adjust focal length without mechanical movement, achieving a tuning range of approximately 0-3 diopters. The technology incorporates multi-layer electrode designs that create complex electric field distributions, allowing for sophisticated optical wavefront control. Sony has also developed temperature-stabilized formulations that maintain consistent performance across -20°C to 60°C, addressing a key limitation of traditional liquid crystal systems.

Strengths: No moving parts leads to high reliability, precise electronic control enables rapid tuning response, and low power consumption (typically <5mW). Weaknesses: Limited operating temperature range compared to MEMS solutions, and potential for optical aberrations at extreme tuning positions.

Key Patents and Breakthroughs in Tuning Mechanisms

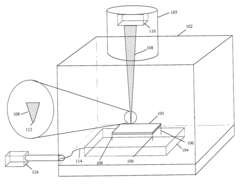

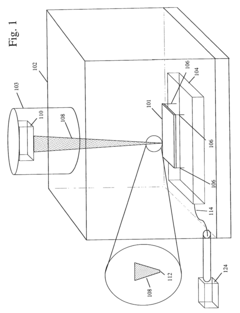

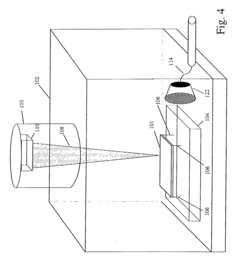

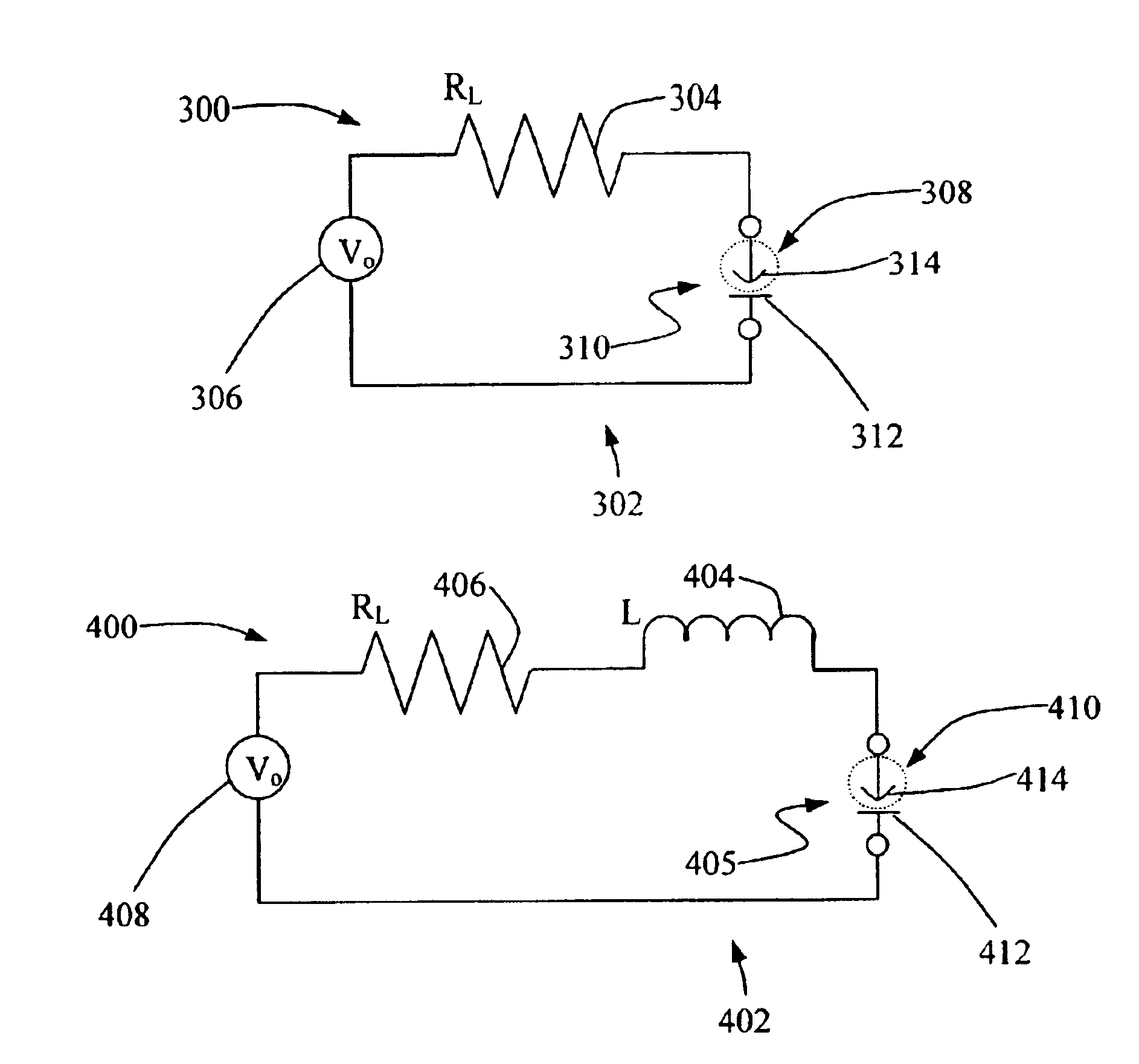

Micro electrical mechanical system (MEMS) tuning using focused ion beams

PatentInactiveUS20040085159A1

Innovation

- The use of focused-ion-beam (FIB) micromachining for real-time tuning of MEMS devices, allowing precise material removal with submicron accuracy and minimal debris, enabling quick and clean adjustment of resonant frequencies and Q factors without substantial heating, using a vacuum system and buffer electronics for in-situ operation.

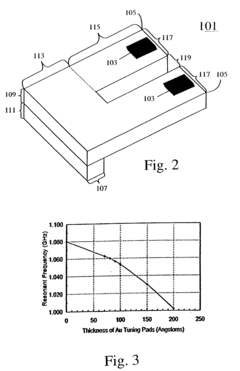

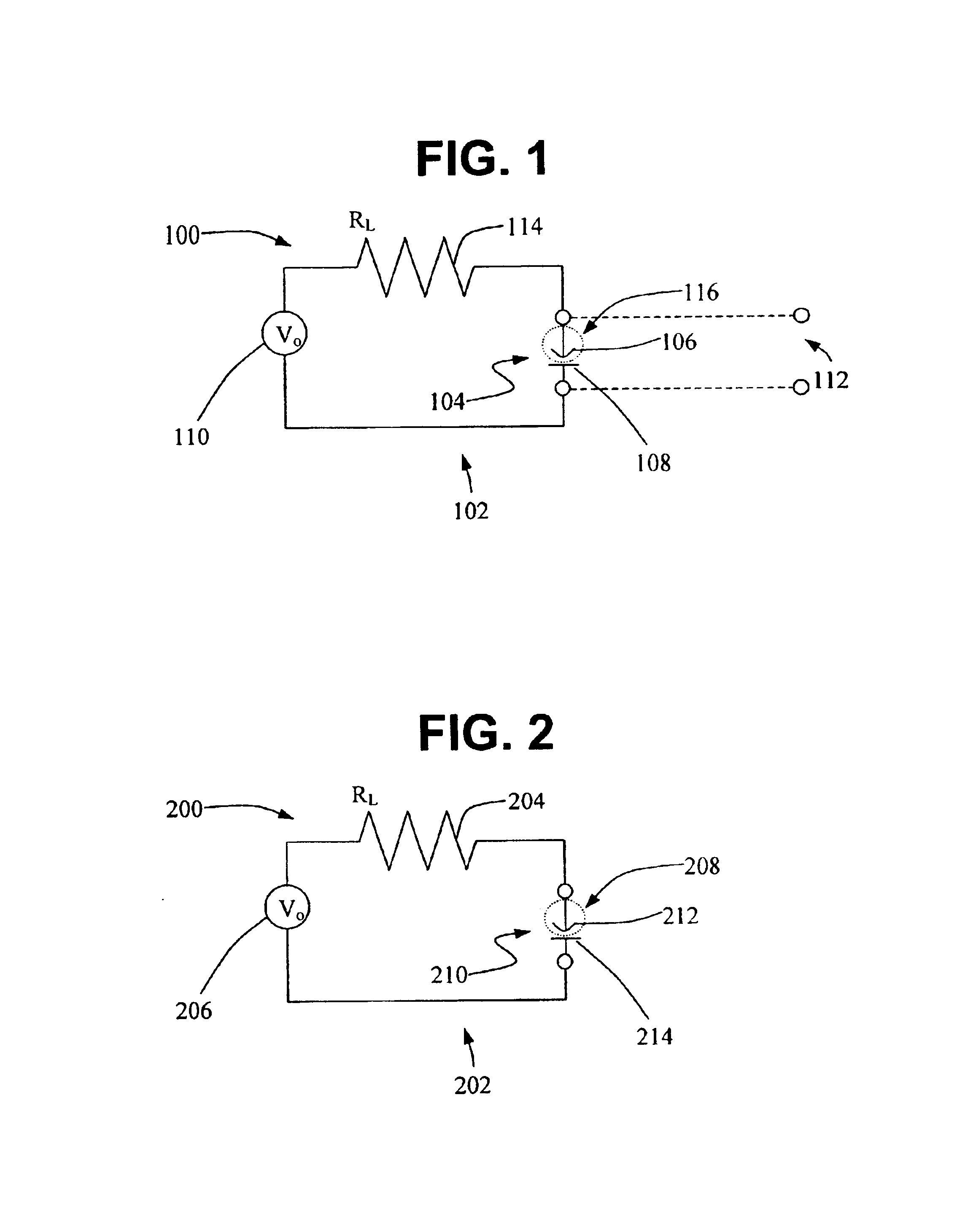

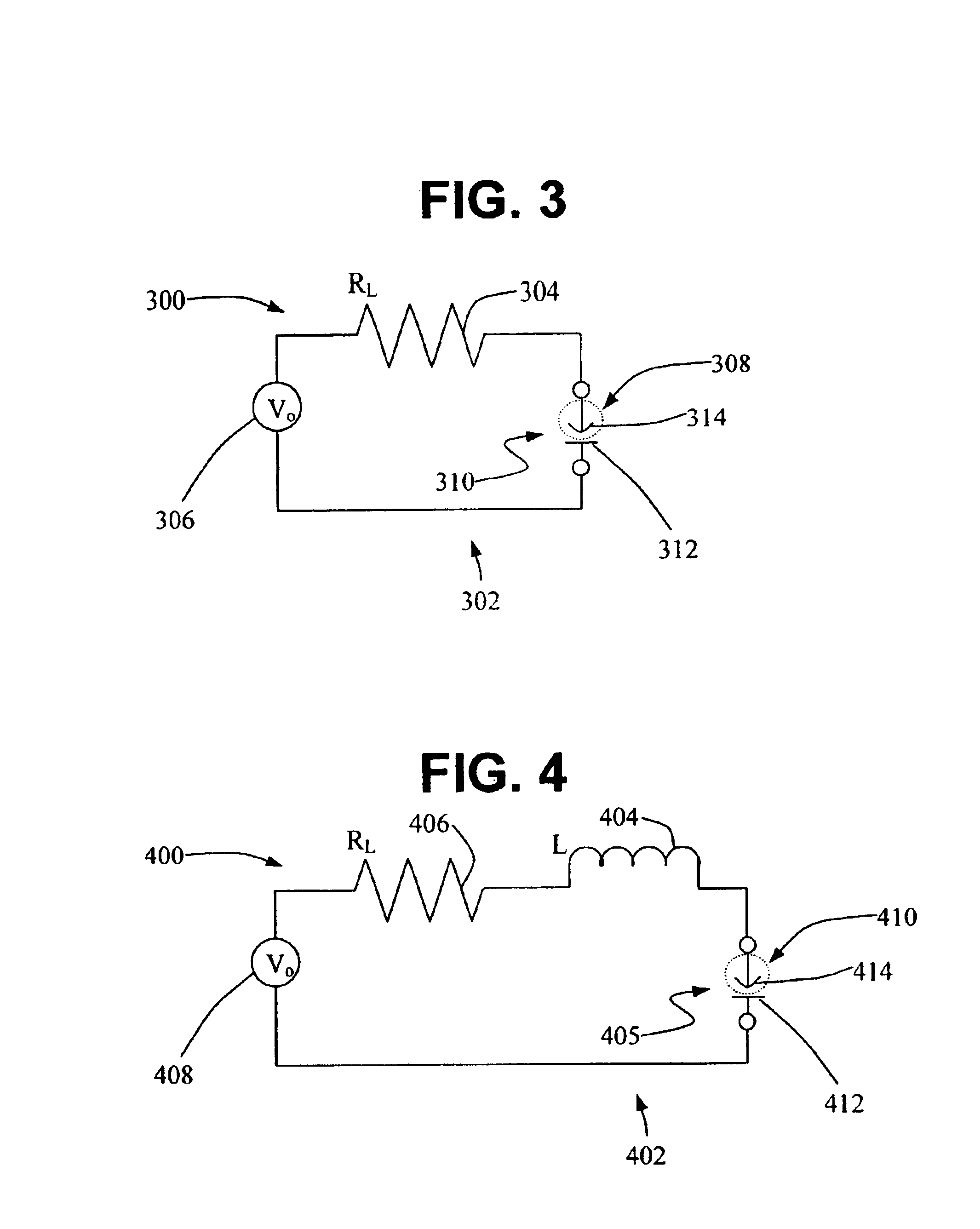

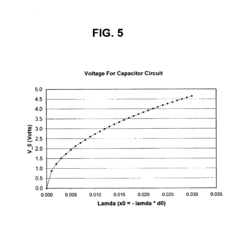

Multi-tunable microelectromechanical system (MEMS) resonators

PatentInactiveUS7095295B1

Innovation

- A method for tuning MEMS resonators by adjusting the voltage supplied to a cantilevered resonator, using a capacitor-based circuit with a load resistor, allowing for both increases and decreases in resonant frequency while controlling bandwidth, through the use of non-dimensional parameters λ and μ.

Manufacturing Processes and Scalability Considerations

The manufacturing processes for tuning mechanisms based on MEMS, liquid crystal, and phase-change materials present distinct challenges and opportunities for scalable production. MEMS-based tuning devices typically require specialized fabrication facilities with cleanroom environments, utilizing processes similar to semiconductor manufacturing. These include photolithography, etching, and deposition techniques that enable precise creation of microscale mechanical structures. While MEMS manufacturing has matured significantly over the past decades, the complexity of moving parts and the need for hermetic packaging continue to impact production yields and costs.

Liquid crystal tuning mechanisms benefit from established manufacturing infrastructure developed for the display industry. The production process involves precise deposition of alignment layers, liquid crystal filling, and electrode patterning. This manufacturing maturity offers advantages in terms of cost efficiency and scalability. However, challenges remain in achieving consistent molecular alignment and maintaining performance stability across varying environmental conditions, particularly for non-display applications requiring precise optical control.

Phase-change material (PCM) based tuning mechanisms represent a newer manufacturing frontier with promising scalability characteristics. These systems typically employ chalcogenide materials that undergo reversible transitions between amorphous and crystalline states. The manufacturing process involves thin-film deposition techniques such as sputtering or chemical vapor deposition, followed by precise thermal management systems for controlled phase transitions. While PCM technology benefits from compatibility with standard semiconductor processes, the precise control of material composition and phase transition characteristics presents ongoing manufacturing challenges.

Scalability considerations vary significantly across these technologies. MEMS devices face challenges in maintaining consistent mechanical properties and reliability at high volumes, though established foundry services have improved accessibility. Liquid crystal technologies offer excellent scalability for standard configurations but may require specialized equipment for novel architectures. PCM-based solutions show promising scalability potential due to their solid-state nature, though material optimization and long-term stability verification remain areas requiring further development.

Cost structures also differ markedly. MEMS typically involve higher initial tooling costs but can achieve competitive unit economics at volume. Liquid crystal solutions generally offer lower entry barriers but may incur higher integration costs for specialized applications. PCM manufacturing costs are currently higher due to material complexity and process control requirements, though economies of scale are expected as adoption increases.

Environmental considerations and sustainability metrics are increasingly important in manufacturing strategy. MEMS fabrication involves various chemicals requiring careful handling and disposal. Liquid crystal production has benefited from decades of environmental optimization in the display industry. PCM manufacturing processes are still evolving, with ongoing efforts to reduce rare element usage and improve recycling capabilities.

Liquid crystal tuning mechanisms benefit from established manufacturing infrastructure developed for the display industry. The production process involves precise deposition of alignment layers, liquid crystal filling, and electrode patterning. This manufacturing maturity offers advantages in terms of cost efficiency and scalability. However, challenges remain in achieving consistent molecular alignment and maintaining performance stability across varying environmental conditions, particularly for non-display applications requiring precise optical control.

Phase-change material (PCM) based tuning mechanisms represent a newer manufacturing frontier with promising scalability characteristics. These systems typically employ chalcogenide materials that undergo reversible transitions between amorphous and crystalline states. The manufacturing process involves thin-film deposition techniques such as sputtering or chemical vapor deposition, followed by precise thermal management systems for controlled phase transitions. While PCM technology benefits from compatibility with standard semiconductor processes, the precise control of material composition and phase transition characteristics presents ongoing manufacturing challenges.

Scalability considerations vary significantly across these technologies. MEMS devices face challenges in maintaining consistent mechanical properties and reliability at high volumes, though established foundry services have improved accessibility. Liquid crystal technologies offer excellent scalability for standard configurations but may require specialized equipment for novel architectures. PCM-based solutions show promising scalability potential due to their solid-state nature, though material optimization and long-term stability verification remain areas requiring further development.

Cost structures also differ markedly. MEMS typically involve higher initial tooling costs but can achieve competitive unit economics at volume. Liquid crystal solutions generally offer lower entry barriers but may incur higher integration costs for specialized applications. PCM manufacturing costs are currently higher due to material complexity and process control requirements, though economies of scale are expected as adoption increases.

Environmental considerations and sustainability metrics are increasingly important in manufacturing strategy. MEMS fabrication involves various chemicals requiring careful handling and disposal. Liquid crystal production has benefited from decades of environmental optimization in the display industry. PCM manufacturing processes are still evolving, with ongoing efforts to reduce rare element usage and improve recycling capabilities.

Energy Efficiency and Sustainability Aspects

The energy efficiency of tuning mechanisms represents a critical factor in their practical implementation and long-term sustainability. MEMS-based tuning systems demonstrate significant advantages in power consumption, typically requiring only minimal energy during state transitions and virtually zero power to maintain static states. This characteristic makes MEMS particularly valuable for battery-powered and energy-harvesting applications where power budgets are severely constrained.

Liquid crystal tuning mechanisms present a moderate energy profile, consuming power primarily during reconfiguration processes. However, their energy requirements have been progressively decreasing through technological advancements in low-power driving circuits and optimization of LC materials. Recent developments in bistable liquid crystal configurations have further enhanced energy efficiency by eliminating the need for continuous power to maintain states.

Phase-change materials (PCMs) currently exhibit the highest energy demands among these technologies, particularly during the phase transition process which requires precise thermal management. The heating and cooling cycles necessary for state changes can be energy-intensive, though significant improvements have emerged through localized heating techniques and thermal isolation strategies.

From a lifecycle perspective, MEMS devices generally demonstrate favorable sustainability metrics due to their silicon-based fabrication, which aligns with established semiconductor manufacturing processes. The primary environmental concerns relate to specialized etching chemicals and cleanroom energy consumption during production.

Liquid crystal technologies present moderate environmental impacts, with considerations regarding the synthesis of specialized organic compounds and disposal challenges. Recent industry initiatives have focused on developing bio-based liquid crystal materials to address these sustainability concerns.

PCM-based systems face more substantial sustainability challenges due to their reliance on rare earth elements and energy-intensive manufacturing processes. Research efforts are increasingly directed toward developing PCMs with reduced environmental footprints through alternative material compositions and more efficient fabrication techniques.

The energy return on investment (EROI) varies significantly across applications, with communications infrastructure demonstrating the most favorable metrics due to operational efficiency gains. Emerging energy harvesting integration with tuning mechanisms, particularly with MEMS and certain liquid crystal configurations, presents promising pathways toward self-powered systems that could dramatically improve overall sustainability profiles.

Liquid crystal tuning mechanisms present a moderate energy profile, consuming power primarily during reconfiguration processes. However, their energy requirements have been progressively decreasing through technological advancements in low-power driving circuits and optimization of LC materials. Recent developments in bistable liquid crystal configurations have further enhanced energy efficiency by eliminating the need for continuous power to maintain states.

Phase-change materials (PCMs) currently exhibit the highest energy demands among these technologies, particularly during the phase transition process which requires precise thermal management. The heating and cooling cycles necessary for state changes can be energy-intensive, though significant improvements have emerged through localized heating techniques and thermal isolation strategies.

From a lifecycle perspective, MEMS devices generally demonstrate favorable sustainability metrics due to their silicon-based fabrication, which aligns with established semiconductor manufacturing processes. The primary environmental concerns relate to specialized etching chemicals and cleanroom energy consumption during production.

Liquid crystal technologies present moderate environmental impacts, with considerations regarding the synthesis of specialized organic compounds and disposal challenges. Recent industry initiatives have focused on developing bio-based liquid crystal materials to address these sustainability concerns.

PCM-based systems face more substantial sustainability challenges due to their reliance on rare earth elements and energy-intensive manufacturing processes. Research efforts are increasingly directed toward developing PCMs with reduced environmental footprints through alternative material compositions and more efficient fabrication techniques.

The energy return on investment (EROI) varies significantly across applications, with communications infrastructure demonstrating the most favorable metrics due to operational efficiency gains. Emerging energy harvesting integration with tuning mechanisms, particularly with MEMS and certain liquid crystal configurations, presents promising pathways toward self-powered systems that could dramatically improve overall sustainability profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!