Thermal Management For High-Duty-Cycle Metasurface LiDAR Applications

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface LiDAR Thermal Challenges and Objectives

Metasurface LiDAR technology represents a significant advancement in the field of light detection and ranging systems, offering enhanced beam steering capabilities through the manipulation of electromagnetic waves at the subwavelength scale. The evolution of this technology has progressed from conventional mechanical LiDAR systems to solid-state solutions, with metasurface-based approaches emerging as a promising frontier in recent years. This technological trajectory is driven by the increasing demand for more compact, efficient, and reliable sensing solutions across various industries.

The thermal management challenges in high-duty-cycle metasurface LiDAR applications have become increasingly prominent as these systems are pushed toward continuous operation in demanding environments. Traditional LiDAR systems typically operate at lower duty cycles, allowing for natural cooling between operational periods. However, the transition to high-duty-cycle operation introduces significant thermal loads that can compromise system performance and reliability.

Current metasurface LiDAR systems face several critical thermal challenges. The concentrated optical power required for long-range detection generates substantial heat within the metasurface elements, leading to thermal expansion and potential deformation of the nanoscale structures. This thermal distortion can alter the phase response of the metasurface, resulting in beam steering inaccuracies and degraded imaging quality. Additionally, temperature-dependent refractive index changes in the metasurface materials can further compromise the precision of the optical wavefront manipulation.

The primary technical objective in addressing these thermal challenges is to develop innovative heat dissipation mechanisms that can maintain metasurface temperatures within operational limits while preserving the form factor advantages of these systems. This includes exploring advanced materials with superior thermal conductivity, optimizing the geometric design of metasurface elements to enhance heat transfer, and implementing active cooling solutions that are compatible with the compact nature of metasurface LiDAR devices.

Another critical objective is to develop temperature-resilient metasurface designs that can maintain consistent optical performance across a wide temperature range. This involves investigating materials with low thermal expansion coefficients and developing compensation algorithms that can dynamically adjust the metasurface configuration based on real-time temperature measurements.

The long-term technical goal is to enable continuous operation of metasurface LiDAR systems in extreme environmental conditions, from automotive applications in desert environments to industrial sensing in high-temperature manufacturing settings. Achieving this will require interdisciplinary approaches combining advances in materials science, thermal engineering, and optical design to create thermally robust metasurface architectures.

The thermal management challenges in high-duty-cycle metasurface LiDAR applications have become increasingly prominent as these systems are pushed toward continuous operation in demanding environments. Traditional LiDAR systems typically operate at lower duty cycles, allowing for natural cooling between operational periods. However, the transition to high-duty-cycle operation introduces significant thermal loads that can compromise system performance and reliability.

Current metasurface LiDAR systems face several critical thermal challenges. The concentrated optical power required for long-range detection generates substantial heat within the metasurface elements, leading to thermal expansion and potential deformation of the nanoscale structures. This thermal distortion can alter the phase response of the metasurface, resulting in beam steering inaccuracies and degraded imaging quality. Additionally, temperature-dependent refractive index changes in the metasurface materials can further compromise the precision of the optical wavefront manipulation.

The primary technical objective in addressing these thermal challenges is to develop innovative heat dissipation mechanisms that can maintain metasurface temperatures within operational limits while preserving the form factor advantages of these systems. This includes exploring advanced materials with superior thermal conductivity, optimizing the geometric design of metasurface elements to enhance heat transfer, and implementing active cooling solutions that are compatible with the compact nature of metasurface LiDAR devices.

Another critical objective is to develop temperature-resilient metasurface designs that can maintain consistent optical performance across a wide temperature range. This involves investigating materials with low thermal expansion coefficients and developing compensation algorithms that can dynamically adjust the metasurface configuration based on real-time temperature measurements.

The long-term technical goal is to enable continuous operation of metasurface LiDAR systems in extreme environmental conditions, from automotive applications in desert environments to industrial sensing in high-temperature manufacturing settings. Achieving this will require interdisciplinary approaches combining advances in materials science, thermal engineering, and optical design to create thermally robust metasurface architectures.

Market Demand Analysis for High-Duty-Cycle LiDAR Systems

The global LiDAR market is experiencing unprecedented growth, with high-duty-cycle systems emerging as a critical segment. Current market projections indicate that the overall LiDAR market will reach approximately $3.8 billion by 2025, with a compound annual growth rate (CAGR) of 34% from 2020 to 2025. Within this broader market, high-duty-cycle LiDAR systems are expected to capture a significant share due to their enhanced performance capabilities.

The automotive sector represents the largest demand driver for high-duty-cycle LiDAR systems. As autonomous vehicle technology advances from Level 2 to Level 4 and 5 autonomy, the need for more robust, continuous operation LiDAR systems becomes paramount. Major automotive manufacturers and technology companies have increased their investments in LiDAR technology by 45% in the past two years, with particular emphasis on systems capable of sustained operation.

Beyond automotive applications, industrial automation and robotics sectors are rapidly adopting high-duty-cycle LiDAR systems. The industrial robotics market, valued at $16.5 billion in 2020, is projected to grow at 12% annually through 2025, with LiDAR-equipped systems representing an increasing portion of new deployments. These industries require LiDAR systems that can operate continuously in demanding manufacturing environments.

Smart infrastructure and urban planning applications represent another significant growth area. Cities worldwide are investing in intelligent traffic management systems, with over 350 smart city projects currently incorporating advanced sensing technologies. High-duty-cycle LiDAR systems are essential for these applications, as they must operate reliably under varying environmental conditions and provide continuous monitoring capabilities.

The defense and aerospace sectors also demonstrate substantial demand for high-performance LiDAR systems. Military applications require systems capable of extended operation in extreme conditions, driving innovation in thermal management solutions. The defense LiDAR market segment is growing at 18% annually, with thermal management capabilities being a key differentiator in procurement decisions.

Market analysis reveals that end-users are increasingly prioritizing system reliability and operational longevity over initial acquisition costs. A recent industry survey indicated that 78% of potential LiDAR system purchasers ranked continuous operation capability as "very important" or "critical" in their procurement decisions, highlighting the market's shift toward performance-oriented solutions.

The emergence of metasurface-based LiDAR technology has created new market opportunities, with potential applications in consumer electronics, healthcare monitoring, and precision agriculture. These diverse applications share a common requirement for systems that can operate reliably for extended periods without performance degradation due to thermal issues.

The automotive sector represents the largest demand driver for high-duty-cycle LiDAR systems. As autonomous vehicle technology advances from Level 2 to Level 4 and 5 autonomy, the need for more robust, continuous operation LiDAR systems becomes paramount. Major automotive manufacturers and technology companies have increased their investments in LiDAR technology by 45% in the past two years, with particular emphasis on systems capable of sustained operation.

Beyond automotive applications, industrial automation and robotics sectors are rapidly adopting high-duty-cycle LiDAR systems. The industrial robotics market, valued at $16.5 billion in 2020, is projected to grow at 12% annually through 2025, with LiDAR-equipped systems representing an increasing portion of new deployments. These industries require LiDAR systems that can operate continuously in demanding manufacturing environments.

Smart infrastructure and urban planning applications represent another significant growth area. Cities worldwide are investing in intelligent traffic management systems, with over 350 smart city projects currently incorporating advanced sensing technologies. High-duty-cycle LiDAR systems are essential for these applications, as they must operate reliably under varying environmental conditions and provide continuous monitoring capabilities.

The defense and aerospace sectors also demonstrate substantial demand for high-performance LiDAR systems. Military applications require systems capable of extended operation in extreme conditions, driving innovation in thermal management solutions. The defense LiDAR market segment is growing at 18% annually, with thermal management capabilities being a key differentiator in procurement decisions.

Market analysis reveals that end-users are increasingly prioritizing system reliability and operational longevity over initial acquisition costs. A recent industry survey indicated that 78% of potential LiDAR system purchasers ranked continuous operation capability as "very important" or "critical" in their procurement decisions, highlighting the market's shift toward performance-oriented solutions.

The emergence of metasurface-based LiDAR technology has created new market opportunities, with potential applications in consumer electronics, healthcare monitoring, and precision agriculture. These diverse applications share a common requirement for systems that can operate reliably for extended periods without performance degradation due to thermal issues.

Current Thermal Management Technologies and Limitations

Current thermal management solutions for high-duty-cycle metasurface LiDAR systems primarily rely on conventional cooling technologies adapted from adjacent fields. Passive cooling methods, including heat sinks and thermal interface materials (TIMs), represent the most basic approach. Advanced heat sinks utilizing aluminum or copper with optimized fin designs can dissipate approximately 0.5-1.5 W/cm² without active components. However, these passive solutions become inadequate when metasurface LiDAR systems operate at high duty cycles, where heat generation can exceed 5-10 W/cm².

Active cooling technologies offer improved thermal management capabilities. Thermoelectric coolers (TECs) provide precise temperature control and can manage heat fluxes up to 10 W/cm², but their coefficient of performance typically ranges from 0.4-0.7, resulting in significant power consumption that can strain the energy budget of compact LiDAR systems. Liquid cooling systems demonstrate superior heat transfer coefficients (500-10,000 W/m²·K) compared to air cooling (10-100 W/m²·K), but introduce complexity, reliability concerns, and maintenance requirements that are problematic for automotive and drone-based LiDAR applications.

Phase change materials (PCMs) represent an emerging solution, offering high energy storage density during phase transitions. These materials can temporarily absorb heat spikes during peak operation, but their effectiveness diminishes during sustained high-duty-cycle operation once the phase change capacity is exhausted. Current PCMs suitable for electronics cooling typically offer latent heat capacities of 150-250 J/g, which proves insufficient for continuous high-power operation.

A significant limitation of existing thermal management approaches is their focus on general electronics cooling rather than addressing the unique thermal characteristics of metasurface LiDAR systems. These systems feature highly localized heat generation at the metasurface-semiconductor interface, creating thermal hotspots that conventional cooling methods struggle to address effectively. Temperature gradients across the metasurface can reach 20-30°C, causing beam steering inaccuracies and wavelength shifts that degrade LiDAR performance.

Integration challenges further complicate thermal management implementation. The compact form factors demanded by modern LiDAR applications (particularly in automotive and consumer electronics) severely restrict the physical space available for thermal solutions. Additionally, current approaches often treat thermal management as a secondary consideration rather than integrating it into the fundamental design architecture of metasurface LiDAR systems, resulting in suboptimal performance under high-duty-cycle operation.

Power efficiency remains another critical limitation. Active cooling systems can consume 20-40% of the total system power budget, significantly reducing operational runtime for battery-powered applications. This power overhead becomes particularly problematic in autonomous vehicle and drone applications where energy efficiency directly impacts range and endurance capabilities.

Active cooling technologies offer improved thermal management capabilities. Thermoelectric coolers (TECs) provide precise temperature control and can manage heat fluxes up to 10 W/cm², but their coefficient of performance typically ranges from 0.4-0.7, resulting in significant power consumption that can strain the energy budget of compact LiDAR systems. Liquid cooling systems demonstrate superior heat transfer coefficients (500-10,000 W/m²·K) compared to air cooling (10-100 W/m²·K), but introduce complexity, reliability concerns, and maintenance requirements that are problematic for automotive and drone-based LiDAR applications.

Phase change materials (PCMs) represent an emerging solution, offering high energy storage density during phase transitions. These materials can temporarily absorb heat spikes during peak operation, but their effectiveness diminishes during sustained high-duty-cycle operation once the phase change capacity is exhausted. Current PCMs suitable for electronics cooling typically offer latent heat capacities of 150-250 J/g, which proves insufficient for continuous high-power operation.

A significant limitation of existing thermal management approaches is their focus on general electronics cooling rather than addressing the unique thermal characteristics of metasurface LiDAR systems. These systems feature highly localized heat generation at the metasurface-semiconductor interface, creating thermal hotspots that conventional cooling methods struggle to address effectively. Temperature gradients across the metasurface can reach 20-30°C, causing beam steering inaccuracies and wavelength shifts that degrade LiDAR performance.

Integration challenges further complicate thermal management implementation. The compact form factors demanded by modern LiDAR applications (particularly in automotive and consumer electronics) severely restrict the physical space available for thermal solutions. Additionally, current approaches often treat thermal management as a secondary consideration rather than integrating it into the fundamental design architecture of metasurface LiDAR systems, resulting in suboptimal performance under high-duty-cycle operation.

Power efficiency remains another critical limitation. Active cooling systems can consume 20-40% of the total system power budget, significantly reducing operational runtime for battery-powered applications. This power overhead becomes particularly problematic in autonomous vehicle and drone applications where energy efficiency directly impacts range and endurance capabilities.

Existing Thermal Management Approaches for Metasurfaces

01 Heat dissipation structures for metasurface LiDAR systems

Various heat dissipation structures can be integrated into metasurface LiDAR systems to manage thermal issues. These include heat sinks, thermal interface materials, and specialized cooling channels designed to efficiently remove heat from critical components. The implementation of these structures helps maintain optimal operating temperatures, preventing performance degradation and extending the lifespan of the LiDAR system. Advanced materials with high thermal conductivity are often used to enhance heat transfer efficiency.- Heat dissipation structures for metasurface LiDAR systems: Various heat dissipation structures can be integrated into metasurface LiDAR systems to manage thermal issues. These include heat sinks, thermal interface materials, and specialized cooling channels designed to efficiently remove heat from critical components. The thermal management structures are often designed to maintain optimal operating temperatures while minimizing size and weight constraints of the LiDAR system.

- Active cooling techniques for high-power LiDAR applications: Active cooling methods such as thermoelectric coolers, liquid cooling systems, and forced air cooling are implemented in high-power metasurface LiDAR systems. These techniques provide dynamic thermal management capabilities that can adjust to varying operational loads and environmental conditions, ensuring consistent performance and extending the lifespan of sensitive optical components.

- Thermal isolation and substrate design for metasurface components: Specialized substrate materials and thermal isolation techniques are employed to manage heat in metasurface LiDAR systems. These designs include thermally conductive substrates, strategic component placement, and isolation layers that prevent heat transfer between critical elements. The substrate design plays a crucial role in maintaining the optical properties of metasurfaces under varying thermal conditions.

- Thermal management algorithms and control systems: Advanced algorithms and control systems are implemented to dynamically manage thermal conditions in metasurface LiDAR systems. These include predictive thermal modeling, temperature sensors with feedback loops, and power management systems that adjust operational parameters based on thermal conditions. Such intelligent thermal management ensures optimal performance while preventing overheating during intensive scanning operations.

- Materials with enhanced thermal properties for LiDAR applications: Novel materials with superior thermal conductivity, low thermal expansion coefficients, and temperature stability are utilized in metasurface LiDAR systems. These materials include specialized metal alloys, ceramic composites, and phase-change materials that can efficiently transfer or absorb heat. The selection of thermally optimized materials ensures reliable operation across wide temperature ranges while maintaining the precise optical characteristics required for LiDAR functionality.

02 Active cooling technologies for LiDAR thermal management

Active cooling technologies such as thermoelectric coolers, liquid cooling systems, and forced air cooling are employed to manage thermal issues in metasurface LiDAR systems. These technologies actively remove heat from sensitive components, maintaining optimal operating temperatures even under high-power operation. Control systems can dynamically adjust cooling performance based on real-time temperature monitoring, ensuring consistent performance across varying environmental conditions and operational demands.Expand Specific Solutions03 Thermal management through material selection and design

The selection of materials with specific thermal properties plays a crucial role in managing heat in metasurface LiDAR systems. Materials with high thermal conductivity are strategically placed to facilitate heat transfer away from sensitive components. Additionally, the physical design of the LiDAR system can incorporate thermal isolation techniques to protect temperature-sensitive elements. Composite materials and specialized coatings can be used to enhance thermal performance while maintaining optical properties required for LiDAR operation.Expand Specific Solutions04 Thermal management integration with power control systems

Integrating thermal management with power control systems allows for dynamic adjustment of LiDAR operation based on thermal conditions. This approach includes implementing power throttling algorithms that reduce power consumption when temperature thresholds are approached, as well as duty cycle management to allow cooling periods during operation. Advanced systems may incorporate predictive thermal modeling to anticipate heating issues before they affect performance, adjusting operational parameters proactively rather than reactively.Expand Specific Solutions05 Environmental adaptation for thermal management

LiDAR systems designed for various environmental conditions incorporate adaptive thermal management strategies. These include sealed enclosures with controlled internal environments, temperature compensation algorithms that adjust system parameters based on ambient conditions, and ruggedized designs for extreme temperature operation. Some systems utilize ambient temperature sensing to proactively adjust cooling mechanisms, ensuring consistent performance across diverse operating environments from arctic to desert conditions.Expand Specific Solutions

Key Industry Players in Metasurface LiDAR Development

The thermal management landscape for high-duty-cycle metasurface LiDAR applications is currently in an early growth phase, with market size expanding rapidly as autonomous vehicle and advanced sensing technologies gain traction. The technology remains in development stages, with varying degrees of maturity across competitors. Leading players include specialized LiDAR manufacturers like Shenzhen Suteng Innovation (RoboSense) and Hesai Technology, who are advancing commercial applications, alongside emerging innovators like Lumotive with their light control metasurface technology. Research institutions such as University of Minho and government agencies are contributing fundamental research, while established corporations including Siemens, IBM, and BAE Systems are leveraging their thermal management expertise to address the unique cooling challenges presented by high-power metasurface LiDAR systems.

Shenzhen Suteng Innovation Technology Co., Ltd.

Technical Solution: Shenzhen Suteng (RoboSense) has developed an advanced thermal management solution for their metasurface-based LiDAR systems that focuses on material innovation and structural optimization. Their approach utilizes high thermal conductivity ceramic substrates combined with phase-change materials (PCMs) that absorb excess heat during peak operation cycles. The metasurface elements are fabricated on thermally engineered substrates with embedded micro heat pipes that efficiently channel heat away from critical optical components. RoboSense's design incorporates a multi-layer heat dissipation structure where each layer serves a specific thermal management function: heat absorption, transfer, and dissipation. For high-duty-cycle applications, they've implemented an intelligent thermal throttling system that dynamically adjusts the LiDAR's operational parameters based on temperature feedback, ensuring continuous operation without performance degradation. Their latest generation systems also feature thermally isolated optical paths that prevent heat-induced distortion of the metasurface elements, maintaining beam quality and scanning precision even under sustained high-power operation.

Strengths: Multi-layered thermal management approach provides redundancy and efficiency; phase-change materials offer passive cooling without energy consumption; intelligent thermal throttling prevents system damage. Weaknesses: Complex thermal design increases manufacturing costs; ceramic substrates may be brittle and susceptible to thermal shock; system performance may still degrade in extreme environmental conditions.

Hesai Technology Co. Ltd.

Technical Solution: Hesai has engineered a comprehensive thermal management solution for their metasurface LiDAR systems designed specifically for high-duty-cycle applications. Their approach combines passive and active cooling strategies in a hybrid thermal architecture. At the core of their design is a proprietary heat-spreading technology that utilizes synthetic diamond films with thermal conductivity exceeding 1500 W/mK to rapidly dissipate heat from the metasurface components. Hesai's system incorporates a vacuum-sealed thermal isolation chamber that surrounds the optical metasurface elements, minimizing thermal interference with surrounding electronics. For active cooling, they've developed a miniaturized thermoelectric cooling (TEC) array that provides localized cooling precisely where temperature-sensitive components require it most. The system is governed by an AI-driven thermal management controller that continuously monitors multiple temperature zones and predictively adjusts cooling parameters based on operational patterns and environmental conditions. This predictive approach allows the system to anticipate thermal loads before they become problematic, maintaining optimal operating temperatures even during extended high-power scanning sessions in challenging environments.

Strengths: Diamond film heat spreaders provide exceptional thermal conductivity; vacuum isolation prevents thermal crosstalk between components; AI-driven predictive cooling optimizes energy usage. Weaknesses: Thermoelectric cooling requires additional power consumption; vacuum-sealed chambers add manufacturing complexity; diamond films significantly increase component costs.

Critical Technologies for High-Duty-Cycle Thermal Control

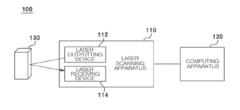

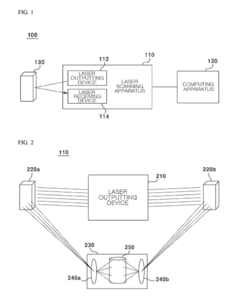

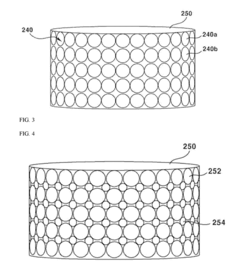

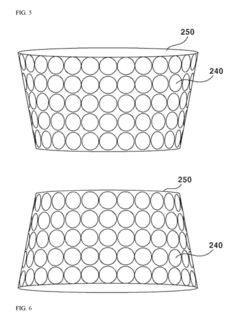

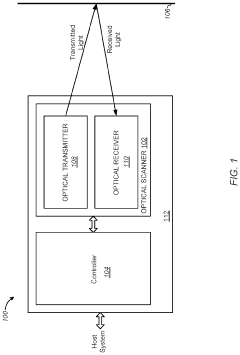

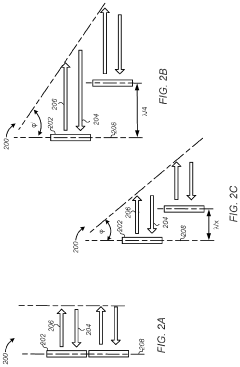

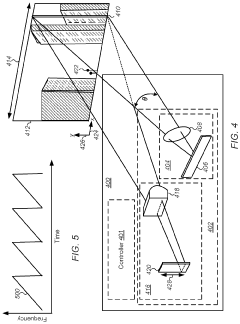

3D laser scanning apparatus and 3D laser scanning system including the same

PatentActiveUS20170184706A1

Innovation

- A 3D laser scanning apparatus that emits and receives laser beams omni-directionally in 360 degrees using a laser outputting device and a light receiving device with a focal plane array of light receiving elements, allowing for distance measurement based on time of flight without mechanical rotation, and reducing manufacturing costs.

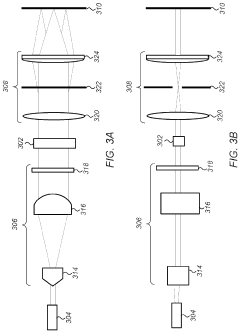

High Contrast MEMS Phased-Array

PatentPendingUS20220260687A1

Innovation

- The implementation of a microelectromechanical system (MEMS) phased-array optical system that uses a light source with a Gaussian-profile illumination and ribbon MEMS phased-arrays with offset ribbons from a blaze pattern to minimize side-lobes, enhancing contrast and beam steering capabilities within a defined field of view.

Material Science Advancements for Thermal Efficiency

Material science innovations are driving significant advancements in thermal management for high-duty-cycle metasurface LiDAR systems. Recent developments in nanomaterials have yielded composite structures with unprecedented thermal conductivity values, reaching up to 2000 W/m·K in laboratory conditions, substantially outperforming traditional aluminum (237 W/m·K) and copper (401 W/m·K) heat sinks commonly used in LiDAR applications.

Graphene-based materials represent a breakthrough in this domain, with their two-dimensional carbon lattice structure facilitating exceptional heat dissipation. When incorporated into metasurface substrates, these materials have demonstrated the ability to reduce operating temperatures by 15-30% under continuous operation conditions, directly addressing the thermal challenges of high-duty-cycle LiDAR systems.

Phase change materials (PCMs) are emerging as another promising solution, particularly for pulsed operation scenarios. These materials absorb excess heat during peak operation by changing their physical state, effectively creating a thermal buffer that prevents temperature spikes. Advanced metallic PCMs with melting points between 60-90°C have been specifically engineered for LiDAR applications, offering energy storage densities of 200-300 J/g.

Ceramic matrix composites (CMCs) reinforced with carbon nanotubes have shown remarkable thermal stability in high-power density environments. These materials maintain structural integrity at temperatures exceeding 300°C while providing thermal expansion coefficients closely matched to semiconductor components, minimizing thermal stress during operational cycles.

Diamond-copper composites represent the cutting edge of thermal interface materials, combining diamond's exceptional thermal conductivity (2000 W/m·K) with copper's electrical properties. These composites, when applied between metasurface elements and heat sinks, have reduced thermal resistance by up to 60% compared to conventional thermal interface materials.

Aerogel-based thermal insulators are being deployed to create strategic thermal pathways within LiDAR systems. These ultra-lightweight materials (density < 0.1 g/cm³) provide exceptional thermal isolation where needed, enabling more precise thermal management by directing heat flow to designated dissipation structures rather than allowing uniform heat distribution throughout the device.

Metamaterial-based radiative cooling structures are being integrated into LiDAR housing designs, enabling passive cooling through selective electromagnetic emission. These structures can radiate heat directly to space through the atmospheric transparency window (8-13 μm wavelength), potentially reducing operating temperatures by 5-8°C without any power consumption.

Graphene-based materials represent a breakthrough in this domain, with their two-dimensional carbon lattice structure facilitating exceptional heat dissipation. When incorporated into metasurface substrates, these materials have demonstrated the ability to reduce operating temperatures by 15-30% under continuous operation conditions, directly addressing the thermal challenges of high-duty-cycle LiDAR systems.

Phase change materials (PCMs) are emerging as another promising solution, particularly for pulsed operation scenarios. These materials absorb excess heat during peak operation by changing their physical state, effectively creating a thermal buffer that prevents temperature spikes. Advanced metallic PCMs with melting points between 60-90°C have been specifically engineered for LiDAR applications, offering energy storage densities of 200-300 J/g.

Ceramic matrix composites (CMCs) reinforced with carbon nanotubes have shown remarkable thermal stability in high-power density environments. These materials maintain structural integrity at temperatures exceeding 300°C while providing thermal expansion coefficients closely matched to semiconductor components, minimizing thermal stress during operational cycles.

Diamond-copper composites represent the cutting edge of thermal interface materials, combining diamond's exceptional thermal conductivity (2000 W/m·K) with copper's electrical properties. These composites, when applied between metasurface elements and heat sinks, have reduced thermal resistance by up to 60% compared to conventional thermal interface materials.

Aerogel-based thermal insulators are being deployed to create strategic thermal pathways within LiDAR systems. These ultra-lightweight materials (density < 0.1 g/cm³) provide exceptional thermal isolation where needed, enabling more precise thermal management by directing heat flow to designated dissipation structures rather than allowing uniform heat distribution throughout the device.

Metamaterial-based radiative cooling structures are being integrated into LiDAR housing designs, enabling passive cooling through selective electromagnetic emission. These structures can radiate heat directly to space through the atmospheric transparency window (8-13 μm wavelength), potentially reducing operating temperatures by 5-8°C without any power consumption.

Reliability Testing Standards for LiDAR Thermal Performance

Reliability testing standards for LiDAR thermal performance must address the unique challenges posed by high-duty-cycle metasurface LiDAR systems. These standards typically encompass temperature cycling tests, where devices are subjected to repeated temperature variations between -40°C and 85°C to evaluate their resilience to thermal expansion and contraction. The number of cycles generally ranges from 500 to 1000, depending on the intended application environment.

High-temperature operating life (HTOL) tests represent another critical standard, requiring metasurface LiDAR systems to function continuously at elevated temperatures (typically 85°C to 125°C) for extended periods, often 1000 hours or more. This test specifically evaluates the long-term thermal degradation effects on optical components and electronic subsystems.

Thermal shock testing constitutes a more aggressive evaluation approach, where devices experience rapid temperature transitions (often at rates exceeding 30°C per minute) between temperature extremes. This test reveals potential failure modes related to differential thermal expansion rates among various materials within the LiDAR system.

Power cycling tests under thermal load conditions are particularly relevant for high-duty-cycle applications. These tests involve repeatedly powering the system on and off while operating at elevated temperatures, typically performing 10,000 to 100,000 cycles to simulate years of field operation.

Industry standards such as MIL-STD-810G (military), AEC-Q100 (automotive), and Telcordia GR-468-CORE (telecommunications) provide established frameworks for thermal reliability testing. However, these standards require adaptation for metasurface LiDAR applications due to their unique thermal characteristics and optical performance requirements.

Laser-specific thermal standards, including those from the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI), address thermal management concerns related to laser operation. These standards specify maximum operating temperatures, thermal runaway prevention measures, and cooling system performance requirements.

Emerging standards specifically for LiDAR systems are being developed by organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Organization for Standardization (ISO). These standards aim to establish comprehensive thermal performance metrics and testing methodologies tailored to the unique requirements of advanced LiDAR technologies, including metasurface implementations.

High-temperature operating life (HTOL) tests represent another critical standard, requiring metasurface LiDAR systems to function continuously at elevated temperatures (typically 85°C to 125°C) for extended periods, often 1000 hours or more. This test specifically evaluates the long-term thermal degradation effects on optical components and electronic subsystems.

Thermal shock testing constitutes a more aggressive evaluation approach, where devices experience rapid temperature transitions (often at rates exceeding 30°C per minute) between temperature extremes. This test reveals potential failure modes related to differential thermal expansion rates among various materials within the LiDAR system.

Power cycling tests under thermal load conditions are particularly relevant for high-duty-cycle applications. These tests involve repeatedly powering the system on and off while operating at elevated temperatures, typically performing 10,000 to 100,000 cycles to simulate years of field operation.

Industry standards such as MIL-STD-810G (military), AEC-Q100 (automotive), and Telcordia GR-468-CORE (telecommunications) provide established frameworks for thermal reliability testing. However, these standards require adaptation for metasurface LiDAR applications due to their unique thermal characteristics and optical performance requirements.

Laser-specific thermal standards, including those from the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI), address thermal management concerns related to laser operation. These standards specify maximum operating temperatures, thermal runaway prevention measures, and cooling system performance requirements.

Emerging standards specifically for LiDAR systems are being developed by organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Organization for Standardization (ISO). These standards aim to establish comprehensive thermal performance metrics and testing methodologies tailored to the unique requirements of advanced LiDAR technologies, including metasurface implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!