Polarization Management In Metasurface-Based Beam Steering

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Polarization Control Background and Objectives

Metasurfaces represent a revolutionary class of engineered surfaces composed of subwavelength optical antennas that enable unprecedented control over electromagnetic waves. Since their emergence in the early 2010s, metasurfaces have evolved from simple phase manipulation devices to sophisticated platforms capable of controlling multiple properties of light simultaneously, including polarization, phase, and amplitude. The ability to manipulate polarization states is particularly crucial for advanced beam steering applications across telecommunications, sensing, and imaging systems.

The historical development of polarization management in metasurfaces can be traced through several key phases. Initially, researchers focused on static polarization conversion using plasmonic structures. This evolved toward active polarization control through the integration of tunable materials such as liquid crystals and phase-change materials. The most recent advancements involve dynamic, real-time polarization manipulation using electrically or optically addressable metasurfaces.

Current technological trends indicate a convergence of polarization management with beam steering capabilities, enabling systems that can simultaneously control the direction and polarization state of electromagnetic waves. This convergence addresses critical needs in satellite communications, LiDAR systems, and next-generation wireless networks where polarization diversity enhances channel capacity and signal robustness.

The primary objective of research in metasurface-based polarization management for beam steering is to develop compact, efficient, and dynamically reconfigurable systems that overcome the limitations of conventional optical components. Specific goals include achieving wide-angle beam steering while maintaining polarization purity, developing broadband polarization control mechanisms, and reducing power consumption for active devices.

Another crucial objective is to bridge the gap between laboratory demonstrations and practical applications by addressing fabrication challenges, enhancing durability, and developing standardized characterization methods. The field aims to establish design principles that enable predictable performance across different operating conditions and integration with existing optical and electronic systems.

Looking forward, the evolution of this technology is expected to enable novel applications in quantum communications, holographic displays, and adaptive optics. The ultimate goal is to create metasurface platforms that can respond intelligently to changing environmental conditions or user requirements, autonomously optimizing polarization states for maximum system performance.

The historical development of polarization management in metasurfaces can be traced through several key phases. Initially, researchers focused on static polarization conversion using plasmonic structures. This evolved toward active polarization control through the integration of tunable materials such as liquid crystals and phase-change materials. The most recent advancements involve dynamic, real-time polarization manipulation using electrically or optically addressable metasurfaces.

Current technological trends indicate a convergence of polarization management with beam steering capabilities, enabling systems that can simultaneously control the direction and polarization state of electromagnetic waves. This convergence addresses critical needs in satellite communications, LiDAR systems, and next-generation wireless networks where polarization diversity enhances channel capacity and signal robustness.

The primary objective of research in metasurface-based polarization management for beam steering is to develop compact, efficient, and dynamically reconfigurable systems that overcome the limitations of conventional optical components. Specific goals include achieving wide-angle beam steering while maintaining polarization purity, developing broadband polarization control mechanisms, and reducing power consumption for active devices.

Another crucial objective is to bridge the gap between laboratory demonstrations and practical applications by addressing fabrication challenges, enhancing durability, and developing standardized characterization methods. The field aims to establish design principles that enable predictable performance across different operating conditions and integration with existing optical and electronic systems.

Looking forward, the evolution of this technology is expected to enable novel applications in quantum communications, holographic displays, and adaptive optics. The ultimate goal is to create metasurface platforms that can respond intelligently to changing environmental conditions or user requirements, autonomously optimizing polarization states for maximum system performance.

Market Applications for Metasurface Beam Steering Technology

Metasurface-based beam steering technology with advanced polarization management capabilities is poised to revolutionize multiple market sectors. The telecommunications industry stands as a primary beneficiary, particularly in the realm of 5G and upcoming 6G networks. These technologies demand precise beam steering for efficient signal transmission and reception, with polarization control enabling higher data throughput and improved signal quality. Market projections indicate substantial growth in this sector, driven by the increasing demand for high-speed, reliable wireless communications.

Automotive applications represent another significant market opportunity. LiDAR systems enhanced with metasurface-based beam steering technology can achieve superior range, resolution, and reliability compared to conventional mechanical systems. The ability to manipulate polarization states allows for better performance in adverse weather conditions, addressing a critical limitation in current autonomous driving systems. This technology could accelerate the adoption of higher levels of vehicle autonomy across consumer and commercial transportation sectors.

In aerospace and defense, metasurface-based beam steering with polarization management offers transformative capabilities for radar systems, satellite communications, and electronic warfare applications. The technology enables more agile, compact, and energy-efficient systems that can operate across multiple frequency bands while maintaining signal integrity through polarization diversity. Defense contractors are particularly interested in the technology's potential to enhance situational awareness while reducing the size, weight, and power requirements of deployed systems.

The consumer electronics market presents diverse applications, from augmented reality displays to wireless charging systems. In AR/VR devices, metasurface-based beam steering can create more immersive visual experiences through precise light manipulation, while polarization management reduces unwanted reflections and improves contrast. For wireless power transfer, the technology enables focused energy beams that increase efficiency and operational range.

Medical imaging and diagnostics represent a high-value niche market where metasurface beam steering technology could enable next-generation devices with enhanced resolution and depth penetration. Polarization-sensitive imaging techniques could provide additional diagnostic information not available with conventional methods, potentially improving early detection of various conditions.

Industrial sensing and manufacturing applications benefit from the technology's ability to enable precise, non-contact measurements and quality control processes. The manufacturing sector itself represents a market for metasurface production equipment and processes, as mass production techniques evolve to meet growing demand across these diverse application areas.

Automotive applications represent another significant market opportunity. LiDAR systems enhanced with metasurface-based beam steering technology can achieve superior range, resolution, and reliability compared to conventional mechanical systems. The ability to manipulate polarization states allows for better performance in adverse weather conditions, addressing a critical limitation in current autonomous driving systems. This technology could accelerate the adoption of higher levels of vehicle autonomy across consumer and commercial transportation sectors.

In aerospace and defense, metasurface-based beam steering with polarization management offers transformative capabilities for radar systems, satellite communications, and electronic warfare applications. The technology enables more agile, compact, and energy-efficient systems that can operate across multiple frequency bands while maintaining signal integrity through polarization diversity. Defense contractors are particularly interested in the technology's potential to enhance situational awareness while reducing the size, weight, and power requirements of deployed systems.

The consumer electronics market presents diverse applications, from augmented reality displays to wireless charging systems. In AR/VR devices, metasurface-based beam steering can create more immersive visual experiences through precise light manipulation, while polarization management reduces unwanted reflections and improves contrast. For wireless power transfer, the technology enables focused energy beams that increase efficiency and operational range.

Medical imaging and diagnostics represent a high-value niche market where metasurface beam steering technology could enable next-generation devices with enhanced resolution and depth penetration. Polarization-sensitive imaging techniques could provide additional diagnostic information not available with conventional methods, potentially improving early detection of various conditions.

Industrial sensing and manufacturing applications benefit from the technology's ability to enable precise, non-contact measurements and quality control processes. The manufacturing sector itself represents a market for metasurface production equipment and processes, as mass production techniques evolve to meet growing demand across these diverse application areas.

Current Challenges in Polarization-Dependent Metasurfaces

Despite significant advancements in metasurface-based beam steering technologies, polarization dependency remains one of the most critical challenges limiting their widespread application. Conventional metasurfaces typically exhibit strong polarization sensitivity, where the beam steering performance varies dramatically depending on the polarization state of the incident light. This fundamental limitation stems from the inherent anisotropic nature of many meta-atoms that constitute these surfaces.

The polarization dependency issue manifests in several problematic ways. First, most metasurfaces demonstrate optimal performance for only a specific polarization state (typically linear polarization along a particular axis), while showing significantly degraded efficiency for orthogonal polarizations. This creates a fundamental trade-off between steering efficiency and polarization insensitivity that designers must constantly navigate.

Another significant challenge is the polarization-dependent phase response of meta-atoms. The phase accumulation experienced by incident light often varies with polarization state, resulting in different deflection angles for different polarizations. This phenomenon severely limits the application of metasurfaces in scenarios requiring polarization-agnostic operation, such as in optical communications where signal polarization may be unknown or variable.

Cross-polarization effects present additional complications. Many metasurfaces inadvertently convert some portion of the incident light into orthogonal polarization states during the steering process. This not only reduces overall efficiency but also introduces unwanted beam splitting that compromises system performance in practical applications.

Temperature sensitivity further exacerbates polarization management challenges. The optical properties of materials used in metasurfaces often exhibit temperature-dependent behavior, causing the polarization response to drift with environmental conditions. This thermal instability creates reliability issues in real-world deployment scenarios.

Fabrication constraints also significantly impact polarization management capabilities. Current nanofabrication techniques struggle to produce the complex three-dimensional structures that would be ideal for polarization-independent operation. The resulting geometric approximations and fabrication imperfections often lead to unintended polarization effects that are difficult to model or compensate for in the design phase.

Bandwidth limitations represent another critical challenge. Most polarization management solutions in metasurfaces work effectively only within narrow spectral ranges. Achieving broadband polarization control remains elusive, particularly for applications requiring operation across multiple wavelength bands or with ultrashort pulses that inherently contain broad spectral content.

The polarization dependency issue manifests in several problematic ways. First, most metasurfaces demonstrate optimal performance for only a specific polarization state (typically linear polarization along a particular axis), while showing significantly degraded efficiency for orthogonal polarizations. This creates a fundamental trade-off between steering efficiency and polarization insensitivity that designers must constantly navigate.

Another significant challenge is the polarization-dependent phase response of meta-atoms. The phase accumulation experienced by incident light often varies with polarization state, resulting in different deflection angles for different polarizations. This phenomenon severely limits the application of metasurfaces in scenarios requiring polarization-agnostic operation, such as in optical communications where signal polarization may be unknown or variable.

Cross-polarization effects present additional complications. Many metasurfaces inadvertently convert some portion of the incident light into orthogonal polarization states during the steering process. This not only reduces overall efficiency but also introduces unwanted beam splitting that compromises system performance in practical applications.

Temperature sensitivity further exacerbates polarization management challenges. The optical properties of materials used in metasurfaces often exhibit temperature-dependent behavior, causing the polarization response to drift with environmental conditions. This thermal instability creates reliability issues in real-world deployment scenarios.

Fabrication constraints also significantly impact polarization management capabilities. Current nanofabrication techniques struggle to produce the complex three-dimensional structures that would be ideal for polarization-independent operation. The resulting geometric approximations and fabrication imperfections often lead to unintended polarization effects that are difficult to model or compensate for in the design phase.

Bandwidth limitations represent another critical challenge. Most polarization management solutions in metasurfaces work effectively only within narrow spectral ranges. Achieving broadband polarization control remains elusive, particularly for applications requiring operation across multiple wavelength bands or with ultrashort pulses that inherently contain broad spectral content.

State-of-the-Art Polarization Management Solutions

01 Metasurface designs for polarization-dependent beam steering

Metasurfaces can be designed with specific nanostructures that enable polarization-dependent beam steering capabilities. These designs typically incorporate anisotropic elements that respond differently to various polarization states of incident light. By engineering the phase response of these elements, the metasurface can direct beams in different directions based on the polarization state of the incoming light, enabling advanced optical control for applications in communications and sensing.- Metasurface designs for polarization-dependent beam steering: Metasurfaces can be designed with specific nanostructures that respond differently to various polarization states of incident light, enabling polarization-dependent beam steering. These designs typically incorporate anisotropic elements or asymmetric unit cells that interact differently with different polarization components, allowing for selective directional control of electromagnetic waves based on their polarization state. This approach enables advanced functionalities in optical systems where beam direction needs to be controlled based on polarization.

- Reconfigurable metasurfaces for dynamic beam steering: Reconfigurable metasurfaces incorporate active elements that can dynamically alter their electromagnetic properties in response to external stimuli such as electrical signals, temperature changes, or mechanical deformation. These adaptive structures enable real-time control of beam steering and polarization manipulation without physical modification of the device. The reconfigurability allows for versatile applications in communications, sensing, and imaging systems where beam direction needs to be rapidly adjusted based on changing requirements.

- Integration of metasurfaces with optical systems for polarization control: Metasurfaces can be integrated with conventional optical components to create hybrid systems with enhanced polarization control and beam steering capabilities. These integrated designs combine the compact form factor of metasurfaces with established optical technologies to achieve superior performance in applications such as optical communications, LiDAR systems, and augmented reality displays. The integration enables more efficient manipulation of light while maintaining compatibility with existing optical infrastructures.

- Frequency-selective metasurfaces for polarization-controlled beam steering: Frequency-selective metasurfaces are designed to exhibit different beam steering behaviors depending on both the frequency of incident electromagnetic waves and their polarization state. These structures incorporate resonant elements tuned to specific frequency bands, enabling wavelength-dependent control of polarization and beam direction. This approach is particularly valuable in applications requiring multiplexing of signals across different frequency bands while maintaining polarization control, such as in advanced communication systems and spectroscopic instruments.

- Fabrication techniques for high-precision metasurface polarization controllers: Advanced fabrication methods are crucial for creating metasurfaces with precise control over polarization and beam steering properties. These techniques include nanolithography, self-assembly processes, and multi-layer deposition approaches that enable the creation of complex three-dimensional nanostructures with the required optical characteristics. The fabrication processes focus on achieving high uniformity, structural integrity, and reproducibility to ensure consistent performance in polarization manipulation and beam steering applications across large surface areas.

02 Reconfigurable metasurfaces for dynamic beam steering

Reconfigurable metasurfaces incorporate active elements that can dynamically change their optical properties in response to external stimuli such as electrical signals, temperature changes, or mechanical deformation. These adaptive metasurfaces enable real-time control of beam steering and polarization manipulation, allowing for applications in beam scanning, adaptive optics, and programmable photonics. The reconfigurability offers significant advantages over static metasurfaces for applications requiring adjustable beam direction.Expand Specific Solutions03 Integration of metasurfaces in optical communication systems

Metasurfaces are being integrated into optical communication systems to enhance signal processing capabilities through polarization control and beam steering. These integrated systems can manipulate light beams with high precision, enabling efficient multiplexing, demultiplexing, and routing of optical signals. The compact nature of metasurfaces allows for miniaturization of optical components, making them suitable for space-constrained applications in telecommunications infrastructure and satellite communications.Expand Specific Solutions04 Multi-functional metasurfaces combining polarization control and beam steering

Advanced metasurface designs incorporate multiple functionalities within a single device, simultaneously controlling polarization states and beam direction. These multi-functional metasurfaces utilize complex unit cell geometries that can manipulate multiple properties of light simultaneously. By engineering the phase, amplitude, and polarization responses of the metasurface elements, these devices can perform tasks such as polarization conversion, beam splitting, and directional emission, reducing the need for multiple optical components in complex systems.Expand Specific Solutions05 Fabrication techniques for high-performance metasurfaces

Advanced fabrication methods are crucial for creating high-performance metasurfaces with precise control over polarization and beam steering. These techniques include electron beam lithography, nanoimprint lithography, and self-assembly processes that enable the creation of nanoscale structures with the required precision. The development of scalable manufacturing approaches is essential for transitioning metasurface technology from laboratory demonstrations to practical applications in consumer electronics, automotive sensors, and telecommunications equipment.Expand Specific Solutions

Leading Research Groups and Companies in Metasurface Technology

Polarization Management in Metasurface-Based Beam Steering is currently in an early growth phase, with the market expanding as applications in optical communications, sensing, and imaging gain traction. The global market for metasurface technologies is projected to reach $500 million by 2025, driven by increasing demand for miniaturized optical components. Technologically, the field is transitioning from research to commercialization, with companies like Metalenz leading innovation through their semiconductor-based meta-optics that simplify complex optical systems into single flat devices. Meadowlark Optics and Boulder Nonlinear Systems have established expertise in polarization control technologies, while research institutions such as Harvard University and the Institute of Optics and Electronics (CAS) continue to advance fundamental capabilities. Major corporations including Sony and Raytheon are investing in this technology for next-generation sensing and defense applications.

President & Fellows of Harvard College

Technical Solution: Harvard's research teams have pioneered fundamental approaches to polarization management in metasurface-based beam steering through their work at the Harvard John A. Paulson School of Engineering and Applied Sciences. Their technology utilizes dielectric metasurfaces composed of nanopillars with elliptical or rectangular cross-sections that exhibit form birefringence, allowing for simultaneous control of phase and polarization. Harvard researchers have developed metasurfaces that can perform polarization-dependent beam steering, where orthogonal polarization states are directed to different angles with high efficiency. Their approach includes cascaded metasurface designs where the first surface acts as a polarization converter while the second performs the beam steering function. This separation allows for independent optimization of each optical process. Harvard has also demonstrated metasurfaces with spatially varying birefringence that can generate complex polarization profiles while steering the beam, enabling applications in quantum optics and advanced sensing[5]. Their recent work has focused on achromatic metasurfaces that maintain polarization control across broad wavelength ranges, addressing a key limitation of earlier designs that exhibited strong chromatic aberrations.

Strengths: Cutting-edge designs based on rigorous theoretical foundations; achieves near-unity efficiency for specific polarization states; enables novel functionalities like polarization-dependent focusing and holography alongside beam steering. Weaknesses: Complex fabrication requirements with tight tolerance specifications; current designs primarily optimized for operation at discrete wavelengths rather than broadband; limited scalability for mass production with current nanofabrication techniques.

Metalenz, Inc.

Technical Solution: Metalenz has developed a revolutionary approach to polarization management in metasurface-based beam steering through their proprietary PolarEyes™ technology. Their solution utilizes a single-layer metasurface design that simultaneously manipulates both polarization states and wavefront control. The metasurfaces consist of subwavelength nanostructures arranged in patterns that can selectively interact with different polarization components of light. By engineering the geometry, orientation, and spacing of these nanostructures, Metalenz achieves precise control over polarization-dependent beam steering. Their technology enables polarization-insensitive operation by implementing polarization diversity schemes where the metasurface responds uniformly regardless of incident polarization state. For polarization-selective applications, they've developed metasurfaces with anisotropic optical responses that can separate orthogonal polarization components and steer them independently[1]. This approach eliminates the need for bulky polarization optics while maintaining high efficiency across the operating bandwidth.

Strengths: Enables miniaturization of optical systems by eliminating the need for separate polarization components; achieves high optical efficiency (>80%) across broadband operation; compatible with standard semiconductor manufacturing processes allowing for cost-effective mass production. Weaknesses: Performance may degrade at extreme angles of incidence; temperature sensitivity can affect phase response in some implementations; limited power handling capability compared to traditional bulk optics.

Key Patents and Publications in Metasurface Polarization Control

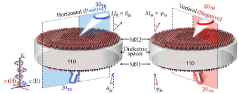

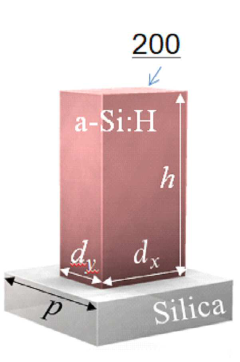

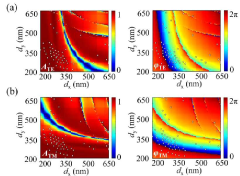

All-dielectric metasurface doublelet device enabling polarization-controllable enhanced beam steering

PatentActiveKR1020230147888A

Innovation

- A dielectric metasurface doublet device is developed, comprising hydrogenated amorphous silicon nanopost arrays on both sides of a silica spacer, with distinct nanopost configurations for TE and TM mode polarizations, enabling bidirectional beam steering and adjustable angular magnification through polarization control.

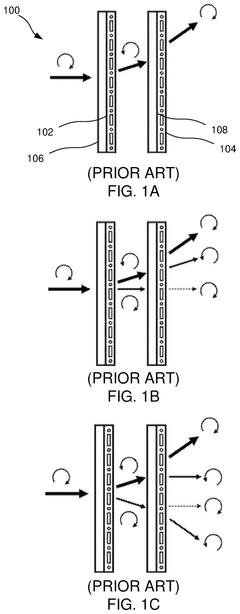

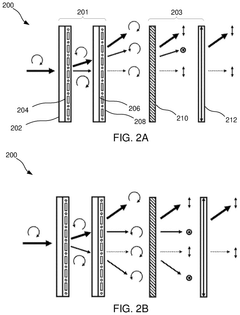

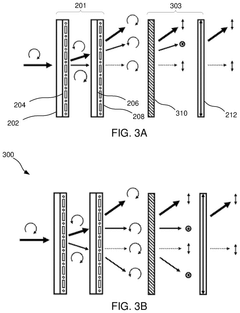

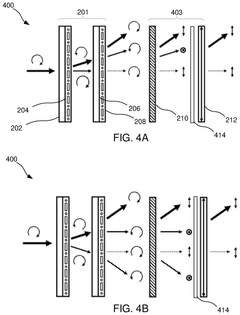

Reducing stray light in beam steering systems using polarization gratings

PatentInactiveUS20240329491A1

Innovation

- The implementation of an optical assembly with a beam steering system comprising multiple stages of polarization-controlling switches and gratings, followed by a retarder and linear polarizer to convert circularly polarized light to linear polarization, allowing for selective filtering and reduction of stray light by blocking unwanted polarizations.

Fabrication Techniques for Advanced Metasurface Structures

The fabrication of advanced metasurfaces for polarization management in beam steering applications requires sophisticated manufacturing techniques that balance precision, scalability, and cost-effectiveness. Current fabrication methods can be categorized into several primary approaches, each with distinct advantages for specific polarization control requirements.

Electron beam lithography (EBL) remains the gold standard for high-precision metasurface fabrication, offering nanometer-scale resolution crucial for creating the complex subwavelength structures needed for effective polarization manipulation. This technique enables the creation of anisotropic meta-atoms with precisely controlled geometric parameters that determine polarization conversion efficiency. However, EBL's serial nature limits throughput for large-area applications.

Nanoimprint lithography has emerged as a promising alternative that combines high resolution with improved throughput. This technique utilizes pre-patterned molds to transfer nanoscale features onto resist materials, making it particularly suitable for manufacturing polarization-sensitive metasurfaces that require consistent reproduction of complex geometries across large areas.

Focused ion beam milling offers exceptional flexibility for prototyping polarization-controlling metasurfaces, allowing direct writing of sophisticated structures without masks. This technique excels in creating three-dimensional nanostructures with varying heights and sidewall profiles that can manipulate different polarization states simultaneously.

For industrial-scale production, deep ultraviolet lithography has been adapted for metasurface fabrication, though with resolution limitations compared to EBL. Recent advances in multiple-exposure techniques have improved its capability to produce polarization-sensitive structures with feature sizes down to 50-100 nm.

Material deposition techniques play a crucial role in determining the optical performance of polarization-managing metasurfaces. Atomic layer deposition enables precise control of film thickness with atomic-level precision, while oblique angle deposition creates anisotropic nanostructures with inherent polarization sensitivity through controlled directional growth.

Self-assembly approaches represent an emerging direction for cost-effective fabrication, utilizing block copolymers or colloidal assembly to create periodic nanostructures. While these methods offer excellent scalability, achieving the precise geometric control needed for advanced polarization management remains challenging.

The integration of multiple fabrication techniques has proven particularly effective for creating hierarchical metasurfaces that can simultaneously control multiple polarization properties. Combined approaches, such as EBL patterning followed by directional etching and selective material deposition, enable the creation of complex three-dimensional architectures with sophisticated polarization response profiles.

Electron beam lithography (EBL) remains the gold standard for high-precision metasurface fabrication, offering nanometer-scale resolution crucial for creating the complex subwavelength structures needed for effective polarization manipulation. This technique enables the creation of anisotropic meta-atoms with precisely controlled geometric parameters that determine polarization conversion efficiency. However, EBL's serial nature limits throughput for large-area applications.

Nanoimprint lithography has emerged as a promising alternative that combines high resolution with improved throughput. This technique utilizes pre-patterned molds to transfer nanoscale features onto resist materials, making it particularly suitable for manufacturing polarization-sensitive metasurfaces that require consistent reproduction of complex geometries across large areas.

Focused ion beam milling offers exceptional flexibility for prototyping polarization-controlling metasurfaces, allowing direct writing of sophisticated structures without masks. This technique excels in creating three-dimensional nanostructures with varying heights and sidewall profiles that can manipulate different polarization states simultaneously.

For industrial-scale production, deep ultraviolet lithography has been adapted for metasurface fabrication, though with resolution limitations compared to EBL. Recent advances in multiple-exposure techniques have improved its capability to produce polarization-sensitive structures with feature sizes down to 50-100 nm.

Material deposition techniques play a crucial role in determining the optical performance of polarization-managing metasurfaces. Atomic layer deposition enables precise control of film thickness with atomic-level precision, while oblique angle deposition creates anisotropic nanostructures with inherent polarization sensitivity through controlled directional growth.

Self-assembly approaches represent an emerging direction for cost-effective fabrication, utilizing block copolymers or colloidal assembly to create periodic nanostructures. While these methods offer excellent scalability, achieving the precise geometric control needed for advanced polarization management remains challenging.

The integration of multiple fabrication techniques has proven particularly effective for creating hierarchical metasurfaces that can simultaneously control multiple polarization properties. Combined approaches, such as EBL patterning followed by directional etching and selective material deposition, enable the creation of complex three-dimensional architectures with sophisticated polarization response profiles.

Integration Challenges with Existing Optical Systems

The integration of metasurface-based beam steering systems with existing optical infrastructure presents significant technical challenges that require careful consideration. Traditional optical systems are typically designed with fixed polarization states and lack the dynamic polarization management capabilities necessary for optimal metasurface operation. This fundamental mismatch creates a complex integration barrier that must be addressed through innovative approaches.

Existing optical systems often utilize components optimized for specific polarization states, such as linear or circular polarization. However, metasurfaces frequently require precise polarization control across multiple states to achieve desired beam steering functionality. This discrepancy necessitates the development of interface layers or adaptation modules that can effectively translate between the polarization requirements of legacy systems and advanced metasurface components.

Dimensional compatibility presents another critical challenge. Conventional optical systems typically operate at scales significantly larger than metasurfaces, which function at subwavelength dimensions. This scale mismatch requires careful design of transitional optics to efficiently couple light between macro-scale components and nano-scale metasurface structures without introducing excessive losses or aberrations.

Signal integrity must be maintained throughout the integrated system, particularly at the boundaries between conventional optics and metasurface elements. Polarization-dependent losses, cross-talk, and unwanted diffraction effects can significantly degrade system performance if not properly managed. These effects become especially pronounced when attempting to preserve the polarization states necessary for metasurface beam steering functionality.

Thermal management represents a substantial integration hurdle as well. Metasurfaces can be sensitive to temperature variations that affect their optical properties and polarization response. When integrated with existing systems that may generate significant heat or experience thermal fluctuations, additional thermal isolation or compensation mechanisms become necessary to maintain consistent polarization management performance.

Calibration and control systems present further integration challenges. Existing optical systems typically lack the sophisticated feedback mechanisms required to monitor and adjust polarization states for optimal metasurface beam steering. Implementing these control systems within legacy optical architectures requires careful consideration of space constraints, power requirements, and communication protocols to ensure seamless operation.

Manufacturing compatibility must also be addressed when integrating metasurface technology with conventional optics. The fabrication processes for metasurfaces often involve advanced nanolithography techniques that differ significantly from traditional optical manufacturing methods. Developing hybrid manufacturing approaches that can efficiently produce integrated systems remains a significant technical challenge requiring cross-disciplinary expertise.

Existing optical systems often utilize components optimized for specific polarization states, such as linear or circular polarization. However, metasurfaces frequently require precise polarization control across multiple states to achieve desired beam steering functionality. This discrepancy necessitates the development of interface layers or adaptation modules that can effectively translate between the polarization requirements of legacy systems and advanced metasurface components.

Dimensional compatibility presents another critical challenge. Conventional optical systems typically operate at scales significantly larger than metasurfaces, which function at subwavelength dimensions. This scale mismatch requires careful design of transitional optics to efficiently couple light between macro-scale components and nano-scale metasurface structures without introducing excessive losses or aberrations.

Signal integrity must be maintained throughout the integrated system, particularly at the boundaries between conventional optics and metasurface elements. Polarization-dependent losses, cross-talk, and unwanted diffraction effects can significantly degrade system performance if not properly managed. These effects become especially pronounced when attempting to preserve the polarization states necessary for metasurface beam steering functionality.

Thermal management represents a substantial integration hurdle as well. Metasurfaces can be sensitive to temperature variations that affect their optical properties and polarization response. When integrated with existing systems that may generate significant heat or experience thermal fluctuations, additional thermal isolation or compensation mechanisms become necessary to maintain consistent polarization management performance.

Calibration and control systems present further integration challenges. Existing optical systems typically lack the sophisticated feedback mechanisms required to monitor and adjust polarization states for optimal metasurface beam steering. Implementing these control systems within legacy optical architectures requires careful consideration of space constraints, power requirements, and communication protocols to ensure seamless operation.

Manufacturing compatibility must also be addressed when integrating metasurface technology with conventional optics. The fabrication processes for metasurfaces often involve advanced nanolithography techniques that differ significantly from traditional optical manufacturing methods. Developing hybrid manufacturing approaches that can efficiently produce integrated systems remains a significant technical challenge requiring cross-disciplinary expertise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!