Metasurface Testing Protocols: Angular, Spectral, And Power Metrics

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Testing Background and Objectives

Metasurfaces represent a revolutionary class of engineered surfaces that manipulate electromagnetic waves in unprecedented ways. These two-dimensional arrays of subwavelength structures have emerged as transformative optical components capable of controlling amplitude, phase, and polarization of light with exceptional precision. The evolution of metasurfaces began in the early 2000s, building upon the foundation of metamaterials research, but offering significant advantages in terms of fabrication simplicity and integration potential.

The technological trajectory of metasurfaces has accelerated dramatically over the past decade, moving from theoretical concepts to practical implementations across multiple electromagnetic spectrum bands. Initial developments focused primarily on proof-of-concept demonstrations, while recent advances have enabled complex wavefront shaping, holographic displays, and computational imaging systems. This rapid progression has created an urgent need for standardized testing protocols to accurately characterize metasurface performance.

Despite their tremendous potential, the metasurface field currently lacks universally accepted measurement standards and testing methodologies. This absence of standardization creates significant challenges for comparing research results across different laboratories and impedes the transition from laboratory demonstrations to commercial applications. The primary objective of this technical investigation is to establish comprehensive testing protocols specifically addressing angular response, spectral characteristics, and power handling metrics for metasurfaces.

Angular measurements are critical for characterizing how metasurfaces interact with electromagnetic waves arriving from or departing to different directions. This aspect is particularly important for applications such as beam steering, wide-angle lenses, and cloaking devices. Spectral characterization provides essential information about wavelength-dependent behavior, bandwidth limitations, and chromatic aberrations that affect real-world performance.

Power metrics represent perhaps the most overlooked yet crucial aspect of metasurface testing. Understanding how these devices respond under varying power conditions is essential for applications ranging from telecommunications to high-power laser systems. Current literature often neglects to report power handling capabilities, thermal effects, and nonlinear responses that emerge at higher intensities.

The technical goal of this investigation is to develop a unified framework for metasurface characterization that addresses these three critical dimensions: angular, spectral, and power metrics. By establishing standardized measurement protocols, we aim to facilitate meaningful comparisons between different metasurface designs, accelerate technological maturation, and provide industry with reliable benchmarks for evaluating commercial potential.

The technological trajectory of metasurfaces has accelerated dramatically over the past decade, moving from theoretical concepts to practical implementations across multiple electromagnetic spectrum bands. Initial developments focused primarily on proof-of-concept demonstrations, while recent advances have enabled complex wavefront shaping, holographic displays, and computational imaging systems. This rapid progression has created an urgent need for standardized testing protocols to accurately characterize metasurface performance.

Despite their tremendous potential, the metasurface field currently lacks universally accepted measurement standards and testing methodologies. This absence of standardization creates significant challenges for comparing research results across different laboratories and impedes the transition from laboratory demonstrations to commercial applications. The primary objective of this technical investigation is to establish comprehensive testing protocols specifically addressing angular response, spectral characteristics, and power handling metrics for metasurfaces.

Angular measurements are critical for characterizing how metasurfaces interact with electromagnetic waves arriving from or departing to different directions. This aspect is particularly important for applications such as beam steering, wide-angle lenses, and cloaking devices. Spectral characterization provides essential information about wavelength-dependent behavior, bandwidth limitations, and chromatic aberrations that affect real-world performance.

Power metrics represent perhaps the most overlooked yet crucial aspect of metasurface testing. Understanding how these devices respond under varying power conditions is essential for applications ranging from telecommunications to high-power laser systems. Current literature often neglects to report power handling capabilities, thermal effects, and nonlinear responses that emerge at higher intensities.

The technical goal of this investigation is to develop a unified framework for metasurface characterization that addresses these three critical dimensions: angular, spectral, and power metrics. By establishing standardized measurement protocols, we aim to facilitate meaningful comparisons between different metasurface designs, accelerate technological maturation, and provide industry with reliable benchmarks for evaluating commercial potential.

Market Applications and Demand Analysis for Metasurfaces

The metasurface market is experiencing significant growth driven by emerging applications across multiple industries. The global metasurface market is projected to reach $1.5 billion by 2027, with a compound annual growth rate exceeding 35% from 2022 to 2027. This rapid expansion underscores the critical need for standardized testing protocols that can accurately measure angular, spectral, and power metrics.

Telecommunications represents the largest market segment, with 5G and upcoming 6G networks requiring advanced antenna technologies. Metasurfaces enable beamforming, signal focusing, and frequency-selective surfaces that can significantly enhance network performance. Industry analysts estimate that metasurface-enhanced antennas could improve signal strength by up to 20% while reducing power consumption by 30% compared to conventional solutions.

The aerospace and defense sectors show robust demand for metasurfaces in radar systems, stealth technology, and satellite communications. Military applications particularly value the ability to precisely control electromagnetic wave propagation across multiple frequency bands. The defense metasurface market segment alone is expected to grow at 40% annually through 2026.

Consumer electronics manufacturers are increasingly incorporating metasurfaces into smartphones, augmented reality displays, and wearable devices. Apple, Samsung, and Google have all filed patents related to metasurface applications for camera lenses, display technologies, and sensing capabilities. The consumer electronics segment represents approximately 25% of the current metasurface market.

Medical imaging and diagnostics present another high-growth application area, with metasurfaces enabling higher-resolution imaging, more precise targeting in treatments, and miniaturized diagnostic tools. The healthcare metasurface market is projected to grow at 45% annually, the fastest among all segments.

Automotive applications are emerging rapidly, particularly for advanced driver assistance systems (ADAS) and autonomous vehicles. Metasurfaces can enhance radar and lidar performance while reducing size and power requirements. Major automotive suppliers including Bosch, Continental, and Aptiv have established research programs focused on metasurface integration.

The energy sector is exploring metasurfaces for solar panel efficiency improvements, with laboratory demonstrations showing potential efficiency gains of 15-20% through better light absorption and reduced reflection losses.

This diverse market landscape highlights the critical importance of developing standardized testing protocols for angular, spectral, and power metrics. Without reliable measurement standards, market adoption may be hindered by inconsistent performance claims and difficulty in comparing solutions across manufacturers and applications.

Telecommunications represents the largest market segment, with 5G and upcoming 6G networks requiring advanced antenna technologies. Metasurfaces enable beamforming, signal focusing, and frequency-selective surfaces that can significantly enhance network performance. Industry analysts estimate that metasurface-enhanced antennas could improve signal strength by up to 20% while reducing power consumption by 30% compared to conventional solutions.

The aerospace and defense sectors show robust demand for metasurfaces in radar systems, stealth technology, and satellite communications. Military applications particularly value the ability to precisely control electromagnetic wave propagation across multiple frequency bands. The defense metasurface market segment alone is expected to grow at 40% annually through 2026.

Consumer electronics manufacturers are increasingly incorporating metasurfaces into smartphones, augmented reality displays, and wearable devices. Apple, Samsung, and Google have all filed patents related to metasurface applications for camera lenses, display technologies, and sensing capabilities. The consumer electronics segment represents approximately 25% of the current metasurface market.

Medical imaging and diagnostics present another high-growth application area, with metasurfaces enabling higher-resolution imaging, more precise targeting in treatments, and miniaturized diagnostic tools. The healthcare metasurface market is projected to grow at 45% annually, the fastest among all segments.

Automotive applications are emerging rapidly, particularly for advanced driver assistance systems (ADAS) and autonomous vehicles. Metasurfaces can enhance radar and lidar performance while reducing size and power requirements. Major automotive suppliers including Bosch, Continental, and Aptiv have established research programs focused on metasurface integration.

The energy sector is exploring metasurfaces for solar panel efficiency improvements, with laboratory demonstrations showing potential efficiency gains of 15-20% through better light absorption and reduced reflection losses.

This diverse market landscape highlights the critical importance of developing standardized testing protocols for angular, spectral, and power metrics. Without reliable measurement standards, market adoption may be hindered by inconsistent performance claims and difficulty in comparing solutions across manufacturers and applications.

Current Metasurface Testing Challenges and Limitations

Despite significant advancements in metasurface technology, current testing methodologies face substantial challenges that impede standardized evaluation and comparison across different research groups and applications. The absence of universally accepted testing protocols creates inconsistencies in reported performance metrics, making it difficult to validate claims and benchmark innovations effectively.

One primary limitation is the lack of standardized angular measurement procedures. Different research groups employ varying angular resolutions, measurement distances, and detection methodologies, resulting in incomparable data sets. Some laboratories utilize goniometric setups with high angular precision but limited spectral capabilities, while others employ wide-field imaging techniques that sacrifice angular resolution for measurement speed.

Spectral characterization presents another significant challenge. The broadband response of metasurfaces often requires measurements across extensive wavelength ranges, from visible to infrared. Current testing approaches frequently employ different light sources, detectors, and spectral resolutions, leading to discrepancies in reported spectral performance. Additionally, many facilities lack the capability to simultaneously measure angular and spectral responses, forcing researchers to conduct separate measurements that may not capture the complex interdependencies between these parameters.

Power handling metrics remain particularly underdeveloped in metasurface testing. While theoretical designs may promise exceptional efficiency, practical implementations often suffer from thermal management issues, nonlinear responses at high intensities, and degradation over time. Current testing protocols rarely address these aspects systematically, leaving significant gaps in understanding operational limitations under real-world conditions.

Reproducibility challenges further complicate metasurface evaluation. Fabrication variations, even within the same batch, can significantly alter performance characteristics. Without standardized testing methodologies that account for sample-to-sample variations, reported results often represent best-case scenarios rather than statistically significant performance metrics.

Environmental stability testing represents another critical gap. Metasurfaces intended for outdoor applications or harsh environments require evaluation under varying temperature, humidity, and exposure conditions. Current testing approaches typically characterize devices under controlled laboratory conditions, failing to predict long-term performance degradation or environmental sensitivity.

Lastly, the integration of metasurfaces into complex optical systems introduces additional testing challenges. System-level performance metrics often differ substantially from component-level measurements, yet standardized protocols for evaluating metasurfaces within their intended application environments remain largely undeveloped. This disconnect between isolated device testing and practical implementation requirements represents a significant barrier to commercial adoption.

One primary limitation is the lack of standardized angular measurement procedures. Different research groups employ varying angular resolutions, measurement distances, and detection methodologies, resulting in incomparable data sets. Some laboratories utilize goniometric setups with high angular precision but limited spectral capabilities, while others employ wide-field imaging techniques that sacrifice angular resolution for measurement speed.

Spectral characterization presents another significant challenge. The broadband response of metasurfaces often requires measurements across extensive wavelength ranges, from visible to infrared. Current testing approaches frequently employ different light sources, detectors, and spectral resolutions, leading to discrepancies in reported spectral performance. Additionally, many facilities lack the capability to simultaneously measure angular and spectral responses, forcing researchers to conduct separate measurements that may not capture the complex interdependencies between these parameters.

Power handling metrics remain particularly underdeveloped in metasurface testing. While theoretical designs may promise exceptional efficiency, practical implementations often suffer from thermal management issues, nonlinear responses at high intensities, and degradation over time. Current testing protocols rarely address these aspects systematically, leaving significant gaps in understanding operational limitations under real-world conditions.

Reproducibility challenges further complicate metasurface evaluation. Fabrication variations, even within the same batch, can significantly alter performance characteristics. Without standardized testing methodologies that account for sample-to-sample variations, reported results often represent best-case scenarios rather than statistically significant performance metrics.

Environmental stability testing represents another critical gap. Metasurfaces intended for outdoor applications or harsh environments require evaluation under varying temperature, humidity, and exposure conditions. Current testing approaches typically characterize devices under controlled laboratory conditions, failing to predict long-term performance degradation or environmental sensitivity.

Lastly, the integration of metasurfaces into complex optical systems introduces additional testing challenges. System-level performance metrics often differ substantially from component-level measurements, yet standardized protocols for evaluating metasurfaces within their intended application environments remain largely undeveloped. This disconnect between isolated device testing and practical implementation requirements represents a significant barrier to commercial adoption.

Established Angular, Spectral, and Power Measurement Methodologies

01 Angular measurement protocols for metasurfaces

Testing protocols for metasurfaces include angular measurement techniques to characterize their performance across different incident angles. These protocols involve measuring the reflection, transmission, and diffraction properties as functions of incident angle to evaluate the metasurface's angular response. Advanced goniometric setups are used to precisely control and measure the angular dependencies, which is crucial for applications requiring specific angular selectivity or wide-angle performance.- Angular measurement protocols for metasurfaces: Testing protocols for metasurfaces include angular measurement techniques to characterize their directional properties. These methods involve measuring the response of metasurfaces at different incident and reflection angles to evaluate beam steering capabilities, angular selectivity, and phase shifts. Angular measurements are crucial for applications requiring precise control of electromagnetic wave propagation and can be performed using goniometric setups with controlled rotation stages.

- Spectral characterization methods: Spectral testing protocols for metasurfaces involve measuring their frequency-dependent responses across relevant wavelength ranges. These methods characterize how metasurfaces interact with electromagnetic radiation at different frequencies, including transmission, reflection, and absorption spectra. Spectral measurements help evaluate bandwidth performance, resonance characteristics, and frequency selectivity, which are essential for applications in communications, sensing, and filtering.

- Power efficiency measurement techniques: Testing protocols for metasurface power metrics focus on quantifying energy conversion efficiency, power handling capabilities, and losses. These measurements evaluate how effectively metasurfaces manipulate electromagnetic energy, including transmission efficiency, reflection losses, and absorption characteristics. Power metrics are critical for practical applications where energy conservation is important, and testing methods may include calorimetric measurements, power meters, and comparative analysis against reference standards.

- Integrated testing systems for metasurfaces: Comprehensive testing protocols for metasurfaces often employ integrated measurement systems that simultaneously evaluate multiple performance metrics. These systems combine various measurement techniques to characterize angular, spectral, and power properties in a coordinated manner. Integrated testing approaches may include automated measurement platforms with multiple sensors, data acquisition systems, and analysis software to provide holistic performance evaluation of metasurface devices.

- Quality control and standardization of metasurface testing: Standardized testing protocols for metasurfaces establish consistent methods for quality control and performance verification. These protocols define reference measurements, calibration procedures, and reporting formats to ensure reproducibility and comparability of results across different laboratories and manufacturing processes. Standardization efforts address challenges in metasurface characterization, including measurement accuracy, environmental factors, and test condition specifications.

02 Spectral characterization methods

Spectral testing protocols for metasurfaces involve measuring their response across different wavelengths to evaluate wavelength-dependent behaviors. These methods include spectrophotometric analysis, spectroscopic ellipsometry, and hyperspectral imaging techniques to characterize transmission, reflection, and absorption spectra. The protocols enable assessment of metasurface performance across targeted frequency ranges, which is essential for applications in optical filtering, sensing, and wavelength-selective devices.Expand Specific Solutions03 Power efficiency measurement techniques

Testing protocols for evaluating the power metrics of metasurfaces focus on measuring energy conversion efficiency, power transmission, reflection ratios, and absorption characteristics. These techniques involve calibrated power measurements before and after interaction with the metasurface to determine power distribution across different diffraction orders or modes. The protocols are crucial for applications requiring high efficiency such as energy harvesting, beam steering, and wavefront manipulation devices.Expand Specific Solutions04 Integrated testing systems for metasurfaces

Comprehensive testing systems that integrate angular, spectral, and power measurements for metasurfaces have been developed. These systems combine multiple measurement capabilities into unified testing platforms, allowing for simultaneous or sequential characterization across different metrics. The integrated approach enables more efficient testing workflows, correlation analysis between different performance parameters, and standardized evaluation protocols for research and manufacturing quality control.Expand Specific Solutions05 Automated calibration and verification methods

Advanced protocols for metasurface testing include automated calibration and verification methods to ensure measurement accuracy and repeatability. These methods incorporate reference standards, calibration algorithms, and uncertainty analysis to validate test results. Automated systems can perform self-calibration routines, detect measurement errors, and compensate for environmental factors, improving the reliability of angular, spectral, and power metrics for metasurface characterization.Expand Specific Solutions

Leading Research Groups and Industry Players in Metasurface Testing

Metasurface testing protocols are evolving within a rapidly maturing technological landscape, currently transitioning from research to commercial applications. The market is experiencing significant growth, projected to reach substantial scale as metasurfaces find applications in telecommunications, defense, and consumer electronics. Technologically, established players like ASML, Carl Zeiss SMT, and Samsung Electronics are advancing standardized testing methodologies, while research institutions including EPFL, Caltech, and KAUST are developing fundamental measurement protocols. Huawei and Nanohmics represent emerging commercial innovators. The field exhibits varying levels of maturity across angular, spectral, and power metrics, with companies like Nova Ltd. and Horiba developing specialized metrology solutions to address the complex characterization requirements of these advanced optical surfaces.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei Technologies has developed sophisticated metasurface testing protocols through their Advanced Materials and Devices Research Center, focusing on telecommunications and consumer electronics applications. Their approach integrates comprehensive angular, spectral, and power characterization methodologies optimized for metasurfaces operating in the visible to millimeter wave spectrum. Huawei's angular testing protocols utilize automated precision goniometric systems that measure optical responses across incident angles from 0-85° with 0.1° resolution, enabling detailed mapping of beam steering capabilities, angular selectivity, and phase discontinuities. Their spectral characterization methodology employs broadband (400nm-300GHz) measurement techniques including terahertz time-domain spectroscopy and vector network analysis to evaluate frequency-dependent amplitude, phase, and polarization responses with particular emphasis on communication-relevant metrics. For power metrics, Huawei has established standardized procedures for measuring insertion loss, power handling capabilities, and efficiency under varying signal strengths, with specialized protocols for assessing metasurface performance under modulated signals typical in communication systems. Their integrated testing approach includes automated characterization platforms that generate comprehensive performance maps correlating metasurface structural parameters with electromagnetic functionality across multiple dimensions[9][11].

Strengths: Exceptional breadth of testing capabilities spanning optical to millimeter wave frequencies; specialized protocols for communication-relevant metrics; advanced automation enabling high-throughput testing; comprehensive correlation between structural and electromagnetic performance. Weaknesses: Testing protocols primarily optimized for communication applications rather than general-purpose characterization; limited accessibility of proprietary testing methodologies; less extensive capabilities for ultrafast optical response characterization.

Carl Zeiss SMT GmbH

Technical Solution: Carl Zeiss SMT has developed comprehensive metasurface testing protocols that integrate angular, spectral, and power metrics through their advanced optical metrology systems. Their approach utilizes high-precision interferometric measurement techniques combined with specialized software algorithms to characterize metasurface performance across multiple dimensions simultaneously. The company's PROVE® metrology system incorporates multi-angle scatterometry and spectroscopic ellipsometry to evaluate phase shifts and amplitude modulation across different incident angles (0-70°) and wavelength ranges (visible to near-IR). Their testing protocols include standardized procedures for measuring diffraction efficiency, polarization conversion ratio, and wavefront manipulation capabilities with nanometer-scale precision. Zeiss has also pioneered automated testing sequences that generate comprehensive metasurface performance maps, correlating structural parameters with optical functionality across varying power conditions (from μW to several W/cm²) to assess thermal stability and nonlinear responses[1][3].

Strengths: Exceptional measurement accuracy (sub-nanometer resolution) and repeatability; comprehensive integration of angular, spectral and power measurements in unified systems; established industry standards for metasurface characterization. Weaknesses: High equipment costs; complex calibration requirements; testing protocols primarily optimized for semiconductor applications rather than all metasurface types.

Critical Metasurface Testing Patents and Scientific Literature

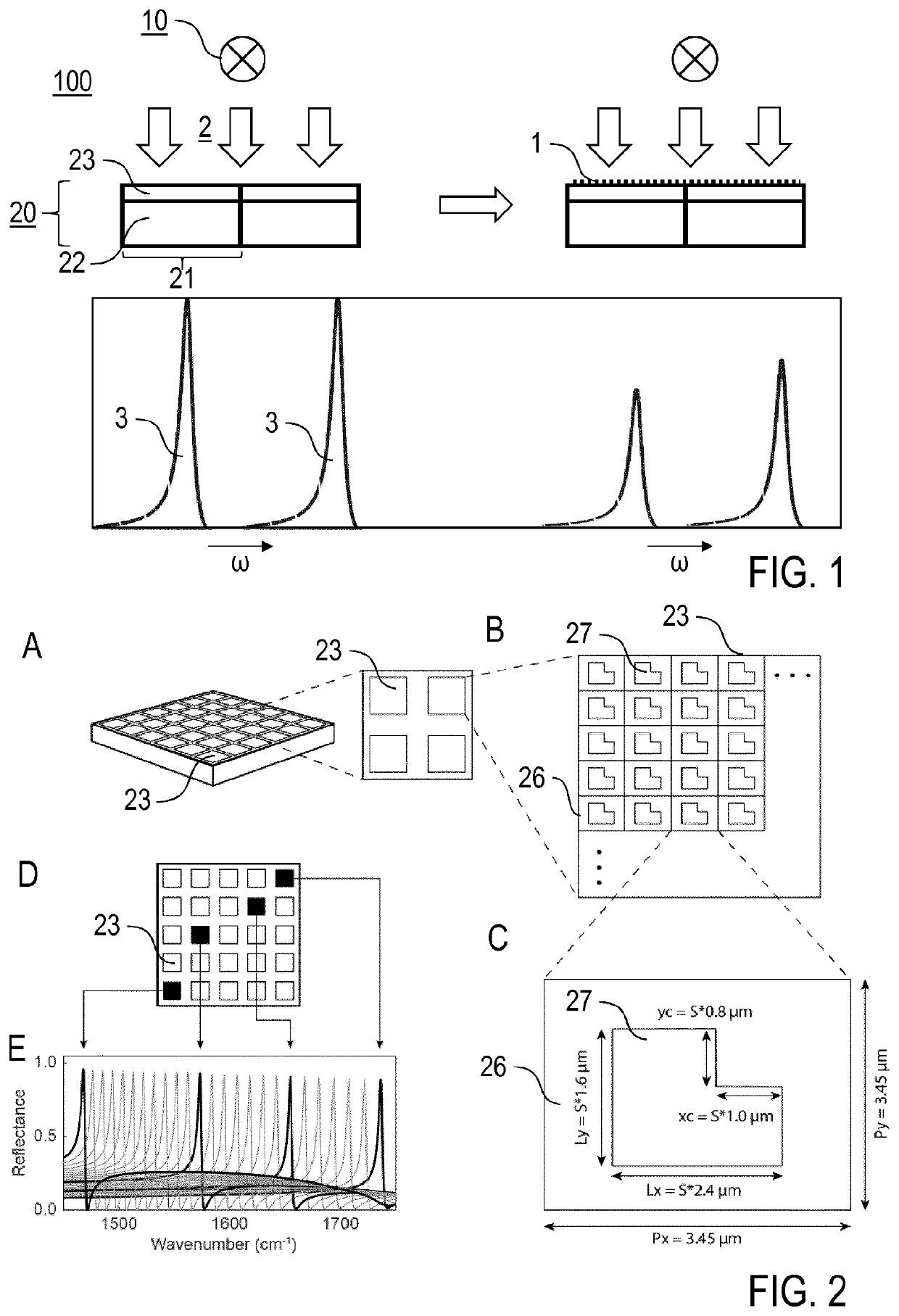

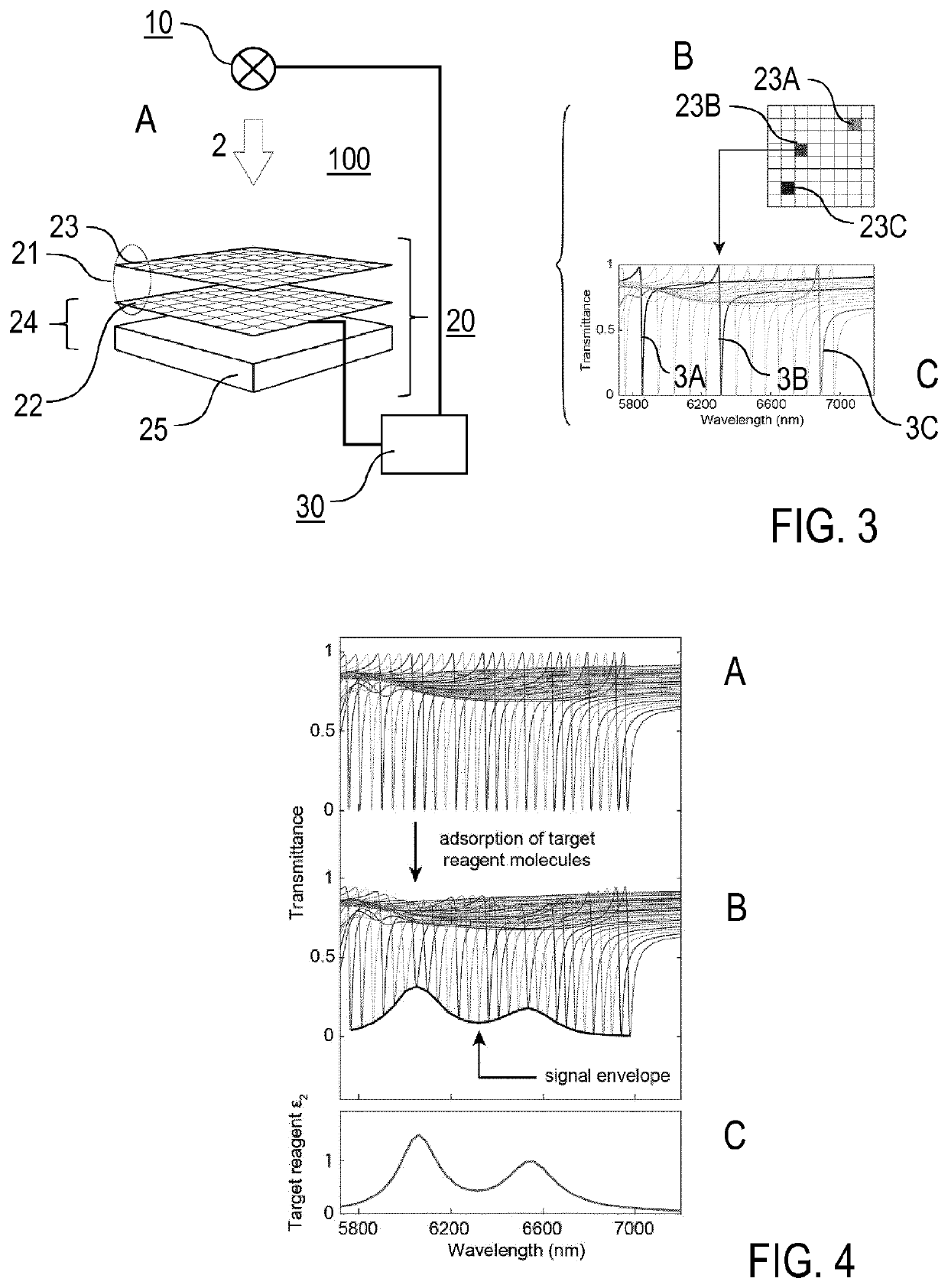

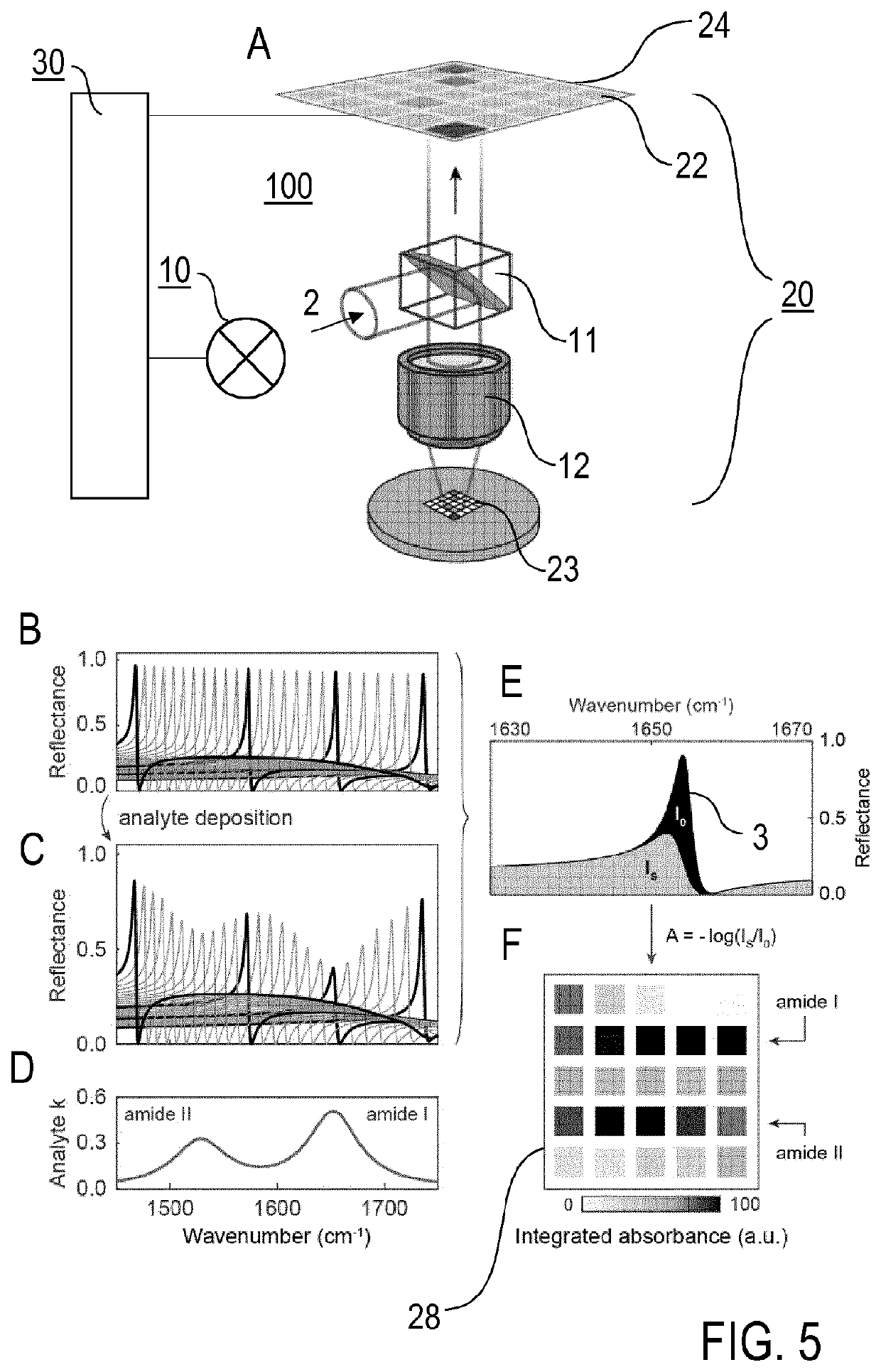

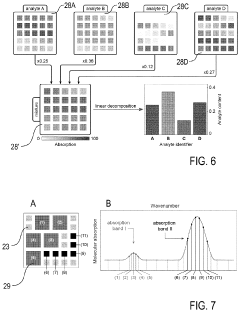

Method and spectrometer apparatus for investigating an infrared absorption of a sample

PatentActiveUS20210239605A1

Innovation

- A method and spectrometer apparatus utilizing a pixelated metasurface with dielectric metamaterial resonator sections, each with a specific spectral resonance line within the infrared range, enabling near-field coupling for enhanced sensitivity and allowing detection of molecular fingerprints without the need for light dispersive elements or moving parts, using broadband light sources and micro-bolometer cells for high spatial resolution.

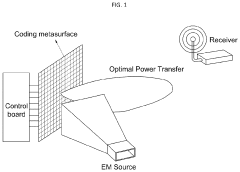

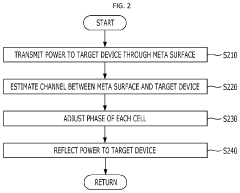

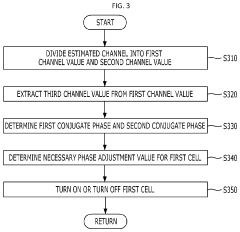

Method for transmitting power using metasurface in wireless communication system

PatentActiveUS11476896B2

Innovation

- A method utilizing a metasurface with N cells, where the metasurface estimates a channel based on received power and a property matrix, adjusts the phase of each cell, and reflects power to a target device using a phase adjusting unit that sets reflection coefficients to 0° or 180°, enabling efficient beamforming and power transmission.

International Standards and Certification Requirements

The standardization landscape for metasurface technologies remains fragmented, with various international bodies working to establish comprehensive testing protocols. Currently, the IEEE P1928 working group is developing standards specifically for electromagnetic metasurfaces, focusing on characterization methods and performance metrics. This initiative represents the first coordinated effort to standardize metasurface testing across angular, spectral, and power domains.

ISO/IEC has also begun incorporating metasurface considerations into their optical and electromagnetic standards framework, particularly through Technical Committee 172 for optical systems. These standards aim to establish uniform measurement methodologies for spectral response and angular dependency, ensuring consistency across research institutions and manufacturing facilities worldwide.

Certification requirements for metasurface technologies vary significantly by application domain. In telecommunications, the International Telecommunication Union (ITU) has introduced preliminary guidelines for metasurface-enhanced antenna systems, requiring specific performance verification across angular distributions and frequency bands. Similarly, for aerospace applications, both RTCA and EUROCAE have published certification guidance documents that include metasurface components, with particular emphasis on power handling capabilities and environmental resilience.

The European Telecommunications Standards Institute (ETSI) has established a specialized group focused on reconfigurable intelligent surfaces, which includes metasurface technologies. Their framework emphasizes the need for standardized testing protocols that address the dynamic nature of programmable metasurfaces, including response time measurements and reliability under varying environmental conditions.

For consumer electronics applications, the Consumer Technology Association (CTA) has begun developing certification requirements for devices incorporating metasurface components, particularly focusing on safety aspects related to electromagnetic radiation patterns and power densities. These requirements mandate comprehensive angular distribution testing to ensure compliance with human exposure limits.

Military and defense applications follow more stringent certification paths through organizations like NATO's STANAG system, which has recently updated its electromagnetic compatibility standards to include metasurface-specific testing protocols. These protocols emphasize robustness testing across extreme environmental conditions and operational scenarios.

The International Electrotechnical Commission (IEC) is currently developing a comprehensive framework under TC 106 that specifically addresses metasurface testing protocols, with publication expected within the next two years. This framework will likely become the definitive international standard for metasurface characterization, incorporating angular resolution requirements, spectral bandwidth specifications, and power handling metrics into a unified certification system.

ISO/IEC has also begun incorporating metasurface considerations into their optical and electromagnetic standards framework, particularly through Technical Committee 172 for optical systems. These standards aim to establish uniform measurement methodologies for spectral response and angular dependency, ensuring consistency across research institutions and manufacturing facilities worldwide.

Certification requirements for metasurface technologies vary significantly by application domain. In telecommunications, the International Telecommunication Union (ITU) has introduced preliminary guidelines for metasurface-enhanced antenna systems, requiring specific performance verification across angular distributions and frequency bands. Similarly, for aerospace applications, both RTCA and EUROCAE have published certification guidance documents that include metasurface components, with particular emphasis on power handling capabilities and environmental resilience.

The European Telecommunications Standards Institute (ETSI) has established a specialized group focused on reconfigurable intelligent surfaces, which includes metasurface technologies. Their framework emphasizes the need for standardized testing protocols that address the dynamic nature of programmable metasurfaces, including response time measurements and reliability under varying environmental conditions.

For consumer electronics applications, the Consumer Technology Association (CTA) has begun developing certification requirements for devices incorporating metasurface components, particularly focusing on safety aspects related to electromagnetic radiation patterns and power densities. These requirements mandate comprehensive angular distribution testing to ensure compliance with human exposure limits.

Military and defense applications follow more stringent certification paths through organizations like NATO's STANAG system, which has recently updated its electromagnetic compatibility standards to include metasurface-specific testing protocols. These protocols emphasize robustness testing across extreme environmental conditions and operational scenarios.

The International Electrotechnical Commission (IEC) is currently developing a comprehensive framework under TC 106 that specifically addresses metasurface testing protocols, with publication expected within the next two years. This framework will likely become the definitive international standard for metasurface characterization, incorporating angular resolution requirements, spectral bandwidth specifications, and power handling metrics into a unified certification system.

Equipment and Instrumentation for Advanced Metasurface Characterization

Advanced metasurface characterization requires sophisticated equipment and instrumentation to accurately measure and validate the complex electromagnetic responses across various parameters. The primary measurement apparatus typically includes vector network analyzers (VNAs) operating at frequencies ranging from microwave to terahertz, which enable precise measurement of amplitude and phase responses of metasurfaces.

Spectral characterization systems are essential components, incorporating tunable laser sources spanning visible to infrared wavelengths, coupled with high-resolution spectrometers capable of detecting nanometer-scale spectral shifts. These systems must maintain calibration accuracy within ±0.1nm to ensure reliable data collection across the operational bandwidth of metasurfaces.

Angular measurement platforms represent another critical instrumentation category, featuring automated goniometric stages with sub-degree precision. These platforms enable the systematic mapping of metasurface responses across incident angles ranging from normal incidence to grazing angles (0-85°). Modern systems incorporate computerized control systems that synchronize source positioning with detection equipment to generate comprehensive angular response profiles.

Power handling characterization requires specialized high-power sources with variable output capabilities, typically ranging from milliwatts to tens of watts, depending on the application domain. These are complemented by calibrated power meters and thermal imaging systems that can detect localized heating effects and potential failure modes under high-power conditions.

Near-field scanning optical microscopy (NSOM) and scanning electron microscopy (SEM) systems provide crucial capabilities for correlating electromagnetic performance with physical structure at nanometer resolution. These imaging technologies allow researchers to identify structural defects or fabrication inconsistencies that may impact metasurface performance.

Environmental testing chambers represent an often overlooked but essential component of comprehensive metasurface characterization. These chambers enable performance evaluation under controlled temperature, humidity, and pressure conditions, simulating real-world deployment scenarios ranging from aerospace to biomedical applications.

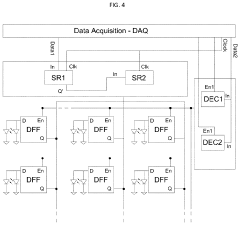

Data acquisition systems with high sampling rates (>10 GS/s) and advanced signal processing capabilities complete the instrumentation ecosystem, enabling real-time analysis of complex metasurface behaviors and facilitating the validation of theoretical models against experimental results.

Spectral characterization systems are essential components, incorporating tunable laser sources spanning visible to infrared wavelengths, coupled with high-resolution spectrometers capable of detecting nanometer-scale spectral shifts. These systems must maintain calibration accuracy within ±0.1nm to ensure reliable data collection across the operational bandwidth of metasurfaces.

Angular measurement platforms represent another critical instrumentation category, featuring automated goniometric stages with sub-degree precision. These platforms enable the systematic mapping of metasurface responses across incident angles ranging from normal incidence to grazing angles (0-85°). Modern systems incorporate computerized control systems that synchronize source positioning with detection equipment to generate comprehensive angular response profiles.

Power handling characterization requires specialized high-power sources with variable output capabilities, typically ranging from milliwatts to tens of watts, depending on the application domain. These are complemented by calibrated power meters and thermal imaging systems that can detect localized heating effects and potential failure modes under high-power conditions.

Near-field scanning optical microscopy (NSOM) and scanning electron microscopy (SEM) systems provide crucial capabilities for correlating electromagnetic performance with physical structure at nanometer resolution. These imaging technologies allow researchers to identify structural defects or fabrication inconsistencies that may impact metasurface performance.

Environmental testing chambers represent an often overlooked but essential component of comprehensive metasurface characterization. These chambers enable performance evaluation under controlled temperature, humidity, and pressure conditions, simulating real-world deployment scenarios ranging from aerospace to biomedical applications.

Data acquisition systems with high sampling rates (>10 GS/s) and advanced signal processing capabilities complete the instrumentation ecosystem, enabling real-time analysis of complex metasurface behaviors and facilitating the validation of theoretical models against experimental results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!