System-Level Calibration Methods For Metasurface LiDAR Modules

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface LiDAR Calibration Background and Objectives

Metasurface LiDAR technology represents a significant advancement in the field of light detection and ranging systems, offering unprecedented capabilities in terms of miniaturization, beam steering precision, and system integration. The evolution of this technology can be traced back to conventional LiDAR systems, which have been fundamental in applications ranging from autonomous vehicles to environmental monitoring. However, traditional LiDAR systems face limitations in size, power consumption, and manufacturing complexity that metasurface-based solutions aim to overcome.

The development trajectory of metasurface LiDAR has been accelerated by breakthroughs in nanophotonics and metamaterial research over the past decade. These engineered surfaces, composed of subwavelength optical elements, enable manipulation of light properties including phase, amplitude, and polarization with exceptional spatial resolution. This capability has opened new possibilities for beam forming and steering that were previously unattainable with conventional optical components.

System-level calibration represents a critical challenge in the practical implementation of metasurface LiDAR modules. Unlike traditional optical systems where calibration methods are well-established, metasurface-based systems introduce unique complexities due to their nanoscale features, material properties, and integration requirements. The interdependence between metasurface design parameters and overall system performance necessitates novel calibration approaches that address both optical and electronic subsystems simultaneously.

The primary technical objectives for metasurface LiDAR calibration include achieving sub-millimeter ranging accuracy, angular resolution better than 0.1 degrees, and maintaining performance stability across varying environmental conditions. Additionally, calibration methods must be scalable for mass production while remaining cost-effective to support commercial viability. These objectives align with the broader industry requirements for next-generation sensing technologies in autonomous systems.

Current calibration approaches typically involve a combination of factory pre-calibration and in-field adjustment algorithms. However, these methods often fail to account for the unique characteristics of metasurface components, such as temperature-dependent phase responses and fabrication variations. This gap highlights the need for specialized calibration protocols that incorporate metasurface-specific parameters into the calibration workflow.

The technical goal of this research is to develop comprehensive system-level calibration methodologies specifically tailored for metasurface LiDAR modules. These methods should address the entire signal chain from optical emission through detection and processing, with particular emphasis on the metasurface-specific distortions and variations. Ultimately, successful calibration approaches will enable metasurface LiDAR technology to achieve its theoretical performance limits while maintaining reliability in real-world deployment scenarios.

The development trajectory of metasurface LiDAR has been accelerated by breakthroughs in nanophotonics and metamaterial research over the past decade. These engineered surfaces, composed of subwavelength optical elements, enable manipulation of light properties including phase, amplitude, and polarization with exceptional spatial resolution. This capability has opened new possibilities for beam forming and steering that were previously unattainable with conventional optical components.

System-level calibration represents a critical challenge in the practical implementation of metasurface LiDAR modules. Unlike traditional optical systems where calibration methods are well-established, metasurface-based systems introduce unique complexities due to their nanoscale features, material properties, and integration requirements. The interdependence between metasurface design parameters and overall system performance necessitates novel calibration approaches that address both optical and electronic subsystems simultaneously.

The primary technical objectives for metasurface LiDAR calibration include achieving sub-millimeter ranging accuracy, angular resolution better than 0.1 degrees, and maintaining performance stability across varying environmental conditions. Additionally, calibration methods must be scalable for mass production while remaining cost-effective to support commercial viability. These objectives align with the broader industry requirements for next-generation sensing technologies in autonomous systems.

Current calibration approaches typically involve a combination of factory pre-calibration and in-field adjustment algorithms. However, these methods often fail to account for the unique characteristics of metasurface components, such as temperature-dependent phase responses and fabrication variations. This gap highlights the need for specialized calibration protocols that incorporate metasurface-specific parameters into the calibration workflow.

The technical goal of this research is to develop comprehensive system-level calibration methodologies specifically tailored for metasurface LiDAR modules. These methods should address the entire signal chain from optical emission through detection and processing, with particular emphasis on the metasurface-specific distortions and variations. Ultimately, successful calibration approaches will enable metasurface LiDAR technology to achieve its theoretical performance limits while maintaining reliability in real-world deployment scenarios.

Market Analysis for Calibrated Metasurface LiDAR Systems

The global market for LiDAR systems is experiencing robust growth, with the metasurface LiDAR segment emerging as a particularly promising area. Current market valuations place the overall LiDAR market at approximately $2.1 billion in 2023, with projections indicating growth to reach $5.7 billion by 2028, representing a compound annual growth rate (CAGR) of 21.8%.

Metasurface LiDAR technology, specifically systems with advanced calibration capabilities, addresses critical market needs across multiple sectors. The automotive industry remains the largest consumer, accounting for roughly 35% of the market share, driven by increasing adoption of advanced driver-assistance systems (ADAS) and autonomous vehicle development. Properly calibrated metasurface LiDAR modules offer superior performance in varying environmental conditions, a crucial factor for automotive applications.

Industrial automation represents the second-largest market segment at 22%, where high-precision distance measurement and object detection capabilities are essential for manufacturing processes and warehouse automation. The construction and infrastructure sectors follow at 18%, utilizing these systems for building information modeling (BIM) and digital twin creation.

Regional analysis reveals North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (26%). China specifically has shown the fastest growth rate in adoption, with domestic production capacity increasing by 45% over the past two years.

Market demand is increasingly focused on systems offering superior calibration capabilities, with 76% of enterprise customers citing calibration accuracy and reliability as "very important" or "critical" factors in purchasing decisions. This represents a significant shift from 2018, when only 52% of customers prioritized these features.

Key market drivers include regulatory requirements for vehicle safety systems, decreasing component costs (metasurface manufacturing costs have declined by 32% since 2020), and increasing demand for high-resolution 3D mapping applications. The integration of AI-based calibration methods has created a new premium segment, with these systems commanding price premiums of 40-60% over conventional LiDAR solutions.

Market barriers include high initial system costs, technical complexity of calibration processes, and interoperability challenges with existing sensor ecosystems. Additionally, the shortage of specialized engineering talent familiar with metasurface technology and calibration methods represents a significant constraint on market growth, with industry surveys indicating a 35% gap between available positions and qualified candidates.

Metasurface LiDAR technology, specifically systems with advanced calibration capabilities, addresses critical market needs across multiple sectors. The automotive industry remains the largest consumer, accounting for roughly 35% of the market share, driven by increasing adoption of advanced driver-assistance systems (ADAS) and autonomous vehicle development. Properly calibrated metasurface LiDAR modules offer superior performance in varying environmental conditions, a crucial factor for automotive applications.

Industrial automation represents the second-largest market segment at 22%, where high-precision distance measurement and object detection capabilities are essential for manufacturing processes and warehouse automation. The construction and infrastructure sectors follow at 18%, utilizing these systems for building information modeling (BIM) and digital twin creation.

Regional analysis reveals North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (26%). China specifically has shown the fastest growth rate in adoption, with domestic production capacity increasing by 45% over the past two years.

Market demand is increasingly focused on systems offering superior calibration capabilities, with 76% of enterprise customers citing calibration accuracy and reliability as "very important" or "critical" factors in purchasing decisions. This represents a significant shift from 2018, when only 52% of customers prioritized these features.

Key market drivers include regulatory requirements for vehicle safety systems, decreasing component costs (metasurface manufacturing costs have declined by 32% since 2020), and increasing demand for high-resolution 3D mapping applications. The integration of AI-based calibration methods has created a new premium segment, with these systems commanding price premiums of 40-60% over conventional LiDAR solutions.

Market barriers include high initial system costs, technical complexity of calibration processes, and interoperability challenges with existing sensor ecosystems. Additionally, the shortage of specialized engineering talent familiar with metasurface technology and calibration methods represents a significant constraint on market growth, with industry surveys indicating a 35% gap between available positions and qualified candidates.

Technical Challenges in System-Level Calibration

System-level calibration for metasurface LiDAR modules presents several significant technical challenges that must be addressed to ensure optimal performance. The integration of metasurfaces into LiDAR systems introduces complex optical interactions that require precise calibration across multiple components simultaneously, rather than individual component calibration.

One primary challenge is the temperature sensitivity of metasurface elements. These nanostructured optical components exhibit thermal expansion and refractive index changes that can significantly alter beam steering angles and focal properties. Current calibration methods struggle to compensate for these thermal effects in real-time, especially in automotive applications where temperature variations can be extreme and rapid.

The non-linear response characteristics of metasurfaces present another substantial hurdle. Unlike conventional optical components, metasurfaces often display non-linear phase responses across their operating spectrum, making traditional linear calibration models insufficient. This necessitates the development of complex mathematical models that can accurately represent these non-linearities across various operating conditions.

Manufacturing variations introduce additional calibration difficulties. Even minor fabrication inconsistencies in metasurface structures can lead to significant performance deviations between theoretically identical modules. This requires each module to undergo individual calibration, dramatically increasing production costs and complexity compared to conventional optical systems.

Cross-talk between adjacent metasurface elements creates interference patterns that degrade system performance. Current calibration methods typically treat each element independently, failing to account for these interactions. Developing calibration approaches that model and compensate for these inter-element effects remains an unsolved challenge.

The dynamic reconfigurability of advanced metasurface LiDAR systems adds another layer of complexity. As these systems increasingly incorporate tunable metasurfaces that can change their optical properties on demand, calibration must account for the full range of possible configurations rather than a single static state.

Data fusion challenges also emerge when integrating metasurface LiDAR with other sensing modalities. Calibration must ensure consistent spatial and temporal alignment between the metasurface LiDAR data and information from complementary sensors, particularly challenging given the unique beam steering mechanisms of metasurface technology.

Finally, the computational burden of system-level calibration for metasurface LiDAR is substantial. Real-time calibration requires efficient algorithms that can process complex optical interactions without introducing latency that would compromise the system's ability to detect and track objects in dynamic environments.

One primary challenge is the temperature sensitivity of metasurface elements. These nanostructured optical components exhibit thermal expansion and refractive index changes that can significantly alter beam steering angles and focal properties. Current calibration methods struggle to compensate for these thermal effects in real-time, especially in automotive applications where temperature variations can be extreme and rapid.

The non-linear response characteristics of metasurfaces present another substantial hurdle. Unlike conventional optical components, metasurfaces often display non-linear phase responses across their operating spectrum, making traditional linear calibration models insufficient. This necessitates the development of complex mathematical models that can accurately represent these non-linearities across various operating conditions.

Manufacturing variations introduce additional calibration difficulties. Even minor fabrication inconsistencies in metasurface structures can lead to significant performance deviations between theoretically identical modules. This requires each module to undergo individual calibration, dramatically increasing production costs and complexity compared to conventional optical systems.

Cross-talk between adjacent metasurface elements creates interference patterns that degrade system performance. Current calibration methods typically treat each element independently, failing to account for these interactions. Developing calibration approaches that model and compensate for these inter-element effects remains an unsolved challenge.

The dynamic reconfigurability of advanced metasurface LiDAR systems adds another layer of complexity. As these systems increasingly incorporate tunable metasurfaces that can change their optical properties on demand, calibration must account for the full range of possible configurations rather than a single static state.

Data fusion challenges also emerge when integrating metasurface LiDAR with other sensing modalities. Calibration must ensure consistent spatial and temporal alignment between the metasurface LiDAR data and information from complementary sensors, particularly challenging given the unique beam steering mechanisms of metasurface technology.

Finally, the computational burden of system-level calibration for metasurface LiDAR is substantial. Real-time calibration requires efficient algorithms that can process complex optical interactions without introducing latency that would compromise the system's ability to detect and track objects in dynamic environments.

Current System-Level Calibration Approaches

01 Metasurface-based LiDAR calibration techniques

Metasurfaces can be used to enhance LiDAR calibration by providing precise optical control. These engineered surfaces with subwavelength structures enable manipulation of light properties such as phase, amplitude, and polarization, which is crucial for accurate LiDAR measurements. Calibration techniques using metasurfaces can compensate for manufacturing variations and environmental factors, ensuring consistent performance across different operating conditions.- Metasurface-based LiDAR calibration techniques: Metasurfaces can be used to calibrate LiDAR modules by providing precise optical reference patterns. These engineered surfaces with subwavelength structures enable accurate alignment and calibration of LiDAR systems by manipulating light wavefronts in predetermined ways. The calibration process typically involves using metasurfaces as reference targets with known optical properties to adjust and verify the accuracy of LiDAR measurements, ensuring consistent performance across different environmental conditions.

- Integration of metasurfaces in LiDAR beam steering systems: Metasurfaces can be integrated into LiDAR modules to enhance beam steering capabilities, requiring specialized calibration methods. These optical components enable precise control of laser beam direction without mechanical moving parts, improving scanning speed and reliability. Calibration of such systems involves adjusting the phase modulation parameters of the metasurface to ensure accurate beam positioning and wavefront shaping, which is essential for maintaining high-resolution 3D mapping capabilities in autonomous vehicles and other applications.

- Environmental compensation in metasurface LiDAR calibration: Calibration methods for metasurface LiDAR systems must account for environmental factors such as temperature variations, humidity, and atmospheric conditions. These factors can affect the optical properties of metasurfaces and the accuracy of LiDAR measurements. Advanced calibration techniques incorporate environmental sensors and adaptive algorithms to compensate for these variations in real-time, ensuring consistent performance across diverse operating conditions and extending the functional range of LiDAR systems.

- Factory and field calibration procedures for metasurface LiDAR: Comprehensive calibration of metasurface LiDAR modules involves both factory calibration and field calibration procedures. Factory calibration establishes baseline performance parameters under controlled conditions, while field calibration addresses system-specific variations and environmental factors. These procedures typically include geometric calibration to align optical components, radiometric calibration to ensure consistent signal intensity measurements, and temporal calibration to synchronize multiple sensors. Automated calibration tools and reference targets with known optical properties facilitate these processes.

- Multi-sensor fusion calibration with metasurface LiDAR: Calibration techniques for systems integrating metasurface LiDAR with other sensors such as cameras, radar, and conventional LiDAR require specialized approaches to ensure accurate data fusion. These methods establish spatial and temporal relationships between different sensor modalities, enabling precise alignment of data from multiple sources. Calibration targets with features detectable by all sensor types facilitate this process, while machine learning algorithms can be employed to optimize the calibration parameters and compensate for systematic errors in the integrated sensing system.

02 Real-time calibration methods for metasurface LiDAR systems

Real-time calibration methods enable continuous adjustment of metasurface LiDAR modules during operation. These methods involve dynamic parameter optimization based on feedback from the environment and system performance metrics. By implementing real-time calibration algorithms, metasurface LiDAR systems can maintain high accuracy despite changing conditions such as temperature fluctuations, vibration, or aging of components, ultimately improving the reliability of distance measurements and object detection.Expand Specific Solutions03 Integration of metasurfaces with beam steering for LiDAR calibration

Metasurfaces can be integrated with beam steering mechanisms to enhance LiDAR calibration. This approach allows for precise control of the laser beam direction and shape, enabling more accurate scanning patterns and improved spatial resolution. The combination of metasurface technology with advanced beam steering techniques facilitates calibration processes that account for optical aberrations and distortions, resulting in more reliable distance measurements and object detection capabilities.Expand Specific Solutions04 Temperature compensation in metasurface LiDAR calibration

Temperature variations can significantly affect the performance of metasurface LiDAR modules. Advanced calibration techniques incorporate temperature compensation mechanisms that adjust the optical properties of metasurfaces based on thermal conditions. These methods may include integrated temperature sensors, thermal modeling algorithms, and adaptive control systems that maintain calibration accuracy across a wide range of operating temperatures, ensuring consistent LiDAR performance in varying environmental conditions.Expand Specific Solutions05 Factory and field calibration protocols for metasurface LiDAR

Comprehensive calibration protocols for metasurface LiDAR modules include both factory and field calibration procedures. Factory calibration establishes baseline performance parameters under controlled conditions, while field calibration addresses environmental factors and system-specific variations. These protocols may involve reference targets, automated calibration fixtures, and software algorithms that characterize and compensate for systematic errors. The combination of factory and field calibration ensures optimal performance throughout the lifecycle of metasurface LiDAR systems.Expand Specific Solutions

Leading Companies in Metasurface LiDAR Technology

The metasurface LiDAR calibration technology market is in its early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is projected to expand rapidly as autonomous driving and robotics applications mature, potentially reaching several billion dollars by 2030. From a technical maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Hesai Technology and RoboSense (Suteng Innovation) have made substantial progress in commercializing metasurface LiDAR modules, while automotive giants such as Ford, Toyota, and Bosch are integrating these technologies into their autonomous vehicle platforms. Academic institutions including Beihang University and Harbin Institute of Technology are contributing fundamental research, while technology companies like Huawei, Velodyne, and Aurora are developing proprietary calibration methods to enhance system-level performance and reliability across diverse operating conditions.

Hesai Technology Co. Ltd.

Technical Solution: Hesai has developed a comprehensive system-level calibration approach for their metasurface LiDAR modules that integrates both factory and field calibration processes. Their solution employs a multi-stage calibration pipeline including intrinsic parameter calibration, extrinsic parameter calibration, and dynamic environmental compensation. The factory calibration utilizes precision-controlled environments with reference targets at known distances to establish baseline performance metrics. For field deployment, Hesai implements an adaptive self-calibration algorithm that continuously monitors sensor performance and environmental conditions to adjust calibration parameters in real-time. Their AT128 LiDAR incorporates proprietary metasurface technology with 128 scanning lines and utilizes a hybrid solid-state/mechanical design that requires specialized calibration techniques to account for the unique optical properties of metasurfaces.

Strengths: Industry-leading precision with documented accuracy of ±2cm at 100m range; comprehensive calibration ecosystem that supports both initial and continuous calibration; proprietary algorithms for temperature and vibration compensation. Weaknesses: Calibration process requires specialized equipment; field calibration may require periodic maintenance interventions; system complexity increases integration challenges for some applications.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an advanced system-level calibration methodology for metasurface LiDAR modules that leverages their expertise in telecommunications and optical systems. Their approach utilizes a hierarchical calibration framework that addresses multiple levels of the sensor system, from individual metasurface elements to full system integration. The calibration process begins with characterization of the metasurface optical properties using interferometric techniques, followed by module-level calibration that accounts for assembly variations. Huawei's system incorporates machine learning algorithms that continuously refine calibration parameters based on operational data, enabling adaptive compensation for aging effects and environmental variations. Their solution includes specialized calibration hardware that can be deployed in production environments, as well as field-portable calibration tools for maintenance operations. Huawei has implemented a digital twin approach where a virtual model of each sensor maintains calibration history and predicts maintenance requirements based on operational conditions.

Strengths: Integration of advanced machine learning techniques for continuous calibration improvement; comprehensive digital twin approach that enables predictive maintenance; leverages extensive optical engineering expertise from telecommunications applications. Weaknesses: System complexity requires significant computational resources; calibration approach may be optimized for specific applications rather than general-purpose use; relatively new entrant to the LiDAR market compared to specialized manufacturers.

Key Patents and Research in Metasurface Calibration

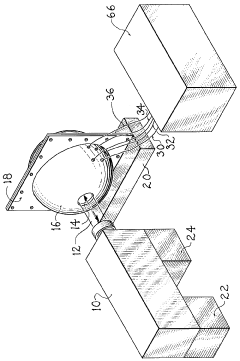

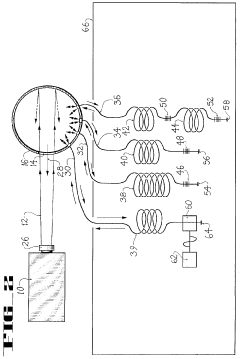

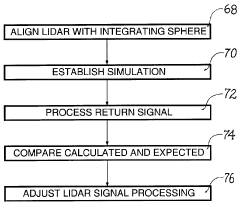

Calibration system and method for lidar systems

PatentInactiveUS5825464A

Innovation

- A calibration system using an integrating sphere to diffuse high-intensity light and optical fibers with Bragg gratings to simulate remote objects and Doppler shifts, allowing for precise calibration of LIDAR systems without the need for extensive alignment or outdoor testing, and enabling 'end-to-end' testing of signal processing hardware and software.

Range Calibration of Light Detectors

PatentActiveUS20230280452A1

Innovation

- A calibration method using a target with varying reflectivity regions is employed to generate walk-error calibration data by emitting light signals towards different regions and detecting reflections, allowing for the adjustment of calibration data to compensate for intensity-related errors in distance measurements.

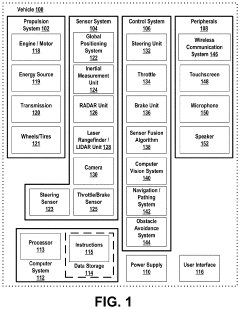

Integration Challenges with Autonomous Systems

The integration of metasurface LiDAR modules with autonomous systems presents significant challenges that require careful consideration and innovative solutions. Autonomous vehicles, drones, and robots rely on precise environmental sensing for navigation, obstacle avoidance, and decision-making. The calibration methods for metasurface LiDAR modules must therefore be compatible with the complex architecture of these autonomous systems.

One primary challenge lies in the real-time calibration requirements of autonomous systems. Unlike static applications, autonomous vehicles operate in dynamic environments where sensor calibration parameters may drift due to vibration, temperature fluctuations, and mechanical stress. Metasurface LiDAR modules must maintain accurate calibration despite these conditions, necessitating robust system-level calibration approaches that can operate continuously without compromising the autonomous system's performance.

Power consumption represents another critical integration challenge. Autonomous systems, particularly battery-powered platforms like drones and mobile robots, have strict energy budgets. While metasurface technology offers potential efficiency improvements over conventional LiDAR, the calibration processes themselves can be computationally intensive. Balancing calibration accuracy with power efficiency requires sophisticated algorithms that minimize processing overhead while maintaining sensing reliability.

Data fusion complexity increases substantially when integrating metasurface LiDAR with other sensing modalities common in autonomous systems, such as cameras, radar, and ultrasonic sensors. System-level calibration must account for temporal and spatial alignment between these diverse sensors, ensuring that the metasurface LiDAR data can be properly synchronized and referenced within the autonomous system's perception stack.

Size and weight constraints present additional integration hurdles. Autonomous platforms, especially aerial drones and compact robots, have limited payload capacity. While metasurfaces offer potential miniaturization advantages, the supporting calibration hardware (such as reference targets or auxiliary sensors) must also adhere to these constraints without compromising calibration quality.

Environmental adaptability poses perhaps the most significant integration challenge. Autonomous systems operate across diverse conditions—from urban environments with reflective buildings to rural areas with varying vegetation density. Calibration methods must adapt to these changing environments, potentially requiring dynamic adjustment of calibration parameters based on environmental context. This adaptability must function without requiring human intervention, as autonomous systems are expected to operate independently for extended periods.

One primary challenge lies in the real-time calibration requirements of autonomous systems. Unlike static applications, autonomous vehicles operate in dynamic environments where sensor calibration parameters may drift due to vibration, temperature fluctuations, and mechanical stress. Metasurface LiDAR modules must maintain accurate calibration despite these conditions, necessitating robust system-level calibration approaches that can operate continuously without compromising the autonomous system's performance.

Power consumption represents another critical integration challenge. Autonomous systems, particularly battery-powered platforms like drones and mobile robots, have strict energy budgets. While metasurface technology offers potential efficiency improvements over conventional LiDAR, the calibration processes themselves can be computationally intensive. Balancing calibration accuracy with power efficiency requires sophisticated algorithms that minimize processing overhead while maintaining sensing reliability.

Data fusion complexity increases substantially when integrating metasurface LiDAR with other sensing modalities common in autonomous systems, such as cameras, radar, and ultrasonic sensors. System-level calibration must account for temporal and spatial alignment between these diverse sensors, ensuring that the metasurface LiDAR data can be properly synchronized and referenced within the autonomous system's perception stack.

Size and weight constraints present additional integration hurdles. Autonomous platforms, especially aerial drones and compact robots, have limited payload capacity. While metasurfaces offer potential miniaturization advantages, the supporting calibration hardware (such as reference targets or auxiliary sensors) must also adhere to these constraints without compromising calibration quality.

Environmental adaptability poses perhaps the most significant integration challenge. Autonomous systems operate across diverse conditions—from urban environments with reflective buildings to rural areas with varying vegetation density. Calibration methods must adapt to these changing environments, potentially requiring dynamic adjustment of calibration parameters based on environmental context. This adaptability must function without requiring human intervention, as autonomous systems are expected to operate independently for extended periods.

Performance Metrics and Validation Standards

Establishing robust performance metrics and validation standards is crucial for the effective evaluation of metasurface LiDAR calibration methods. These standards must address both the optical performance of the metasurface components and the overall system-level accuracy of the LiDAR module.

The primary performance metrics for metasurface LiDAR calibration include absolute ranging accuracy, angular resolution, point cloud density, and calibration stability over time and environmental conditions. Industry standards typically require ranging accuracy within ±2cm at 100m distance, with angular resolution better than 0.1 degrees for high-performance automotive and industrial applications. These metrics must be measurable through standardized testing procedures to ensure consistency across different calibration methods.

Validation protocols for metasurface LiDAR calibration should incorporate multi-stage testing across controlled laboratory environments and real-world scenarios. Laboratory validation typically employs precision optical benches with calibrated targets at known distances and angles, allowing for the isolation of specific calibration parameters. Field validation extends this to dynamic environments with varying reflectivity surfaces, atmospheric conditions, and motion scenarios.

Statistical validation frameworks are essential for quantifying calibration performance. These frameworks should include metrics such as root mean square error (RMSE) for point cloud accuracy, temporal stability measurements over extended operation periods, and cross-validation against ground truth data obtained from reference systems. The IEEE P2020 standard for automotive image quality and ASPRS LiDAR calibration guidelines provide foundational frameworks that can be adapted specifically for metasurface LiDAR systems.

Environmental robustness testing constitutes another critical aspect of validation standards. Calibration methods must demonstrate resilience to temperature variations (-40°C to +85°C for automotive applications), vibration, humidity, and electromagnetic interference. The calibration stability should be maintained within specified tolerances across these environmental variables, with degradation characteristics well-documented.

Traceability to national and international measurement standards is necessary for establishing credible validation protocols. This includes regular calibration against NIST-traceable reference instruments and participation in round-robin testing programs among industry participants to establish comparative benchmarks for different calibration methodologies.

The development of simulation-based validation tools represents an emerging trend in metasurface LiDAR calibration validation. These digital twins enable the evaluation of calibration algorithms against synthetic but physically accurate data, allowing for the exploration of edge cases and failure modes that might be impractical to test physically. Such simulation frameworks must themselves be validated against physical measurements to ensure their fidelity.

The primary performance metrics for metasurface LiDAR calibration include absolute ranging accuracy, angular resolution, point cloud density, and calibration stability over time and environmental conditions. Industry standards typically require ranging accuracy within ±2cm at 100m distance, with angular resolution better than 0.1 degrees for high-performance automotive and industrial applications. These metrics must be measurable through standardized testing procedures to ensure consistency across different calibration methods.

Validation protocols for metasurface LiDAR calibration should incorporate multi-stage testing across controlled laboratory environments and real-world scenarios. Laboratory validation typically employs precision optical benches with calibrated targets at known distances and angles, allowing for the isolation of specific calibration parameters. Field validation extends this to dynamic environments with varying reflectivity surfaces, atmospheric conditions, and motion scenarios.

Statistical validation frameworks are essential for quantifying calibration performance. These frameworks should include metrics such as root mean square error (RMSE) for point cloud accuracy, temporal stability measurements over extended operation periods, and cross-validation against ground truth data obtained from reference systems. The IEEE P2020 standard for automotive image quality and ASPRS LiDAR calibration guidelines provide foundational frameworks that can be adapted specifically for metasurface LiDAR systems.

Environmental robustness testing constitutes another critical aspect of validation standards. Calibration methods must demonstrate resilience to temperature variations (-40°C to +85°C for automotive applications), vibration, humidity, and electromagnetic interference. The calibration stability should be maintained within specified tolerances across these environmental variables, with degradation characteristics well-documented.

Traceability to national and international measurement standards is necessary for establishing credible validation protocols. This includes regular calibration against NIST-traceable reference instruments and participation in round-robin testing programs among industry participants to establish comparative benchmarks for different calibration methodologies.

The development of simulation-based validation tools represents an emerging trend in metasurface LiDAR calibration validation. These digital twins enable the evaluation of calibration algorithms against synthetic but physically accurate data, allowing for the exploration of edge cases and failure modes that might be impractical to test physically. Such simulation frameworks must themselves be validated against physical measurements to ensure their fidelity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!