Comparing Metasurfaces And Optical Phased Arrays For LiDAR Beam Control

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiDAR Beam Control Technology Evolution and Objectives

LiDAR technology has evolved significantly since its inception in the 1960s, transitioning from bulky, expensive systems primarily used in specialized applications to more compact, cost-effective solutions deployed across various industries. The evolution of beam control mechanisms represents a critical aspect of this technological progression, with traditional mechanical scanning gradually giving way to solid-state approaches that offer enhanced reliability, reduced form factors, and improved performance characteristics.

The emergence of metasurfaces and optical phased arrays (OPAs) marks a pivotal advancement in LiDAR beam control technology. These technologies address fundamental limitations of mechanical systems, including susceptibility to vibration, limited scanning speeds, and reliability concerns in harsh environments. Metasurfaces—engineered surfaces with subwavelength structures—manipulate light through phase, amplitude, and polarization control at the nanoscale, enabling unprecedented beam steering capabilities without moving parts.

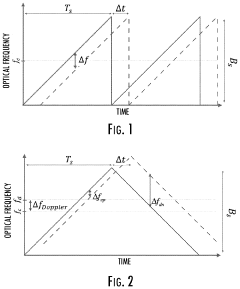

Optical phased arrays, conversely, leverage principles from radio frequency phased arrays, utilizing arrays of optical emitters with individually controllable phases to achieve constructive and destructive interference patterns that direct light beams. This approach offers dynamic beam steering with potentially microsecond response times, representing a significant improvement over mechanical alternatives that typically operate at millisecond timescales.

The technological trajectory indicates a clear shift toward solid-state beam control solutions, driven by demands for higher resolution, extended range, and reduced system complexity in autonomous vehicles, robotics, and industrial automation applications. Current research focuses on overcoming challenges related to field of view limitations, power efficiency, and manufacturing scalability for both metasurfaces and OPAs.

The primary objectives for advancing LiDAR beam control technology include achieving wide-angle scanning (>120° in both azimuth and elevation), microsecond-level scanning speeds, high optical efficiency (>80%), and compatibility with mass production techniques. Additionally, there is significant emphasis on developing solutions that maintain performance across varying environmental conditions while meeting stringent size, weight, and power consumption requirements.

Recent technological breakthroughs, including the development of reconfigurable metasurfaces and silicon photonics-based OPAs, have accelerated progress toward these objectives. These innovations suggest potential convergence of multiple beam control technologies in future LiDAR systems, combining the advantages of different approaches to overcome individual limitations.

The evolution of LiDAR beam control technology continues to be shaped by interdisciplinary collaboration across photonics, materials science, and electrical engineering, with significant contributions from both academic research institutions and industrial R&D centers. This collaborative ecosystem has been instrumental in addressing complex technical challenges and accelerating the path toward commercially viable solid-state LiDAR solutions.

The emergence of metasurfaces and optical phased arrays (OPAs) marks a pivotal advancement in LiDAR beam control technology. These technologies address fundamental limitations of mechanical systems, including susceptibility to vibration, limited scanning speeds, and reliability concerns in harsh environments. Metasurfaces—engineered surfaces with subwavelength structures—manipulate light through phase, amplitude, and polarization control at the nanoscale, enabling unprecedented beam steering capabilities without moving parts.

Optical phased arrays, conversely, leverage principles from radio frequency phased arrays, utilizing arrays of optical emitters with individually controllable phases to achieve constructive and destructive interference patterns that direct light beams. This approach offers dynamic beam steering with potentially microsecond response times, representing a significant improvement over mechanical alternatives that typically operate at millisecond timescales.

The technological trajectory indicates a clear shift toward solid-state beam control solutions, driven by demands for higher resolution, extended range, and reduced system complexity in autonomous vehicles, robotics, and industrial automation applications. Current research focuses on overcoming challenges related to field of view limitations, power efficiency, and manufacturing scalability for both metasurfaces and OPAs.

The primary objectives for advancing LiDAR beam control technology include achieving wide-angle scanning (>120° in both azimuth and elevation), microsecond-level scanning speeds, high optical efficiency (>80%), and compatibility with mass production techniques. Additionally, there is significant emphasis on developing solutions that maintain performance across varying environmental conditions while meeting stringent size, weight, and power consumption requirements.

Recent technological breakthroughs, including the development of reconfigurable metasurfaces and silicon photonics-based OPAs, have accelerated progress toward these objectives. These innovations suggest potential convergence of multiple beam control technologies in future LiDAR systems, combining the advantages of different approaches to overcome individual limitations.

The evolution of LiDAR beam control technology continues to be shaped by interdisciplinary collaboration across photonics, materials science, and electrical engineering, with significant contributions from both academic research institutions and industrial R&D centers. This collaborative ecosystem has been instrumental in addressing complex technical challenges and accelerating the path toward commercially viable solid-state LiDAR solutions.

Market Analysis for Advanced LiDAR Beam Steering Solutions

The global LiDAR market is experiencing robust growth, projected to reach $3.8 billion by 2025 with a CAGR of 34.0% from 2020. This expansion is primarily driven by increasing adoption in autonomous vehicles, advanced driver-assistance systems (ADAS), and emerging applications in robotics, industrial automation, and smart infrastructure. The beam steering technology segment represents a critical component of this market, accounting for approximately 30% of the overall LiDAR value chain.

Within the beam steering technology landscape, mechanical systems currently dominate with about 65% market share. However, solid-state solutions including metasurfaces and optical phased arrays (OPAs) are rapidly gaining traction due to their reliability, reduced form factor, and potential for cost reduction at scale. Industry analysts predict that solid-state beam steering technologies will capture over 50% of the market by 2027.

Automotive applications remain the largest market segment for advanced beam steering solutions, representing 48% of total demand. This is followed by industrial applications (22%), consumer electronics (15%), and aerospace and defense (10%). The remaining 5% encompasses emerging applications such as smart cities and environmental monitoring.

Regionally, North America leads the market with 42% share, followed by Europe (28%), Asia-Pacific (25%), and rest of the world (5%). China is emerging as the fastest-growing market with annual growth exceeding 40%, driven by aggressive autonomous vehicle development programs and government support for LiDAR technology.

Customer requirements are evolving rapidly, with increasing emphasis on range performance, resolution, field of view, and power efficiency. Survey data indicates that 78% of automotive OEMs consider beam steering technology as a decisive factor in LiDAR selection, with particular focus on reliability under diverse environmental conditions.

Price sensitivity varies significantly across application segments. While automotive customers demand solutions under $200 per unit for mass-market vehicles, aerospace and defense applications can accommodate pricing up to $5,000 for high-performance systems. The industrial segment shows moderate price sensitivity with acceptable price points between $500-1,500 depending on performance specifications.

Market barriers include manufacturing scalability challenges, particularly for metasurface technologies, and concerns about performance consistency across operating temperatures. Additionally, competing technologies such as camera-based systems and radar continue to improve, creating competitive pressure on LiDAR pricing and performance requirements.

The competitive landscape is increasingly crowded, with over 80 companies now active in the LiDAR space globally. Strategic partnerships between technology developers and tier-one suppliers are becoming essential for market access, with 65% of recent product launches involving collaborative development efforts.

Within the beam steering technology landscape, mechanical systems currently dominate with about 65% market share. However, solid-state solutions including metasurfaces and optical phased arrays (OPAs) are rapidly gaining traction due to their reliability, reduced form factor, and potential for cost reduction at scale. Industry analysts predict that solid-state beam steering technologies will capture over 50% of the market by 2027.

Automotive applications remain the largest market segment for advanced beam steering solutions, representing 48% of total demand. This is followed by industrial applications (22%), consumer electronics (15%), and aerospace and defense (10%). The remaining 5% encompasses emerging applications such as smart cities and environmental monitoring.

Regionally, North America leads the market with 42% share, followed by Europe (28%), Asia-Pacific (25%), and rest of the world (5%). China is emerging as the fastest-growing market with annual growth exceeding 40%, driven by aggressive autonomous vehicle development programs and government support for LiDAR technology.

Customer requirements are evolving rapidly, with increasing emphasis on range performance, resolution, field of view, and power efficiency. Survey data indicates that 78% of automotive OEMs consider beam steering technology as a decisive factor in LiDAR selection, with particular focus on reliability under diverse environmental conditions.

Price sensitivity varies significantly across application segments. While automotive customers demand solutions under $200 per unit for mass-market vehicles, aerospace and defense applications can accommodate pricing up to $5,000 for high-performance systems. The industrial segment shows moderate price sensitivity with acceptable price points between $500-1,500 depending on performance specifications.

Market barriers include manufacturing scalability challenges, particularly for metasurface technologies, and concerns about performance consistency across operating temperatures. Additionally, competing technologies such as camera-based systems and radar continue to improve, creating competitive pressure on LiDAR pricing and performance requirements.

The competitive landscape is increasingly crowded, with over 80 companies now active in the LiDAR space globally. Strategic partnerships between technology developers and tier-one suppliers are becoming essential for market access, with 65% of recent product launches involving collaborative development efforts.

Metasurfaces vs OPAs: Current Capabilities and Limitations

Metasurfaces and Optical Phased Arrays (OPAs) represent two competing technologies for LiDAR beam steering applications, each with distinct capabilities and limitations that define their current technological readiness and application potential.

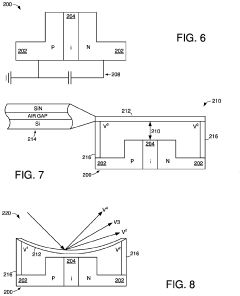

Metasurfaces excel in their compact form factor, typically measuring just a few micrometers in thickness. This ultra-thin profile enables integration possibilities that traditional optical components cannot match. Current metasurface implementations demonstrate high efficiency in static beam steering applications, with some designs achieving diffraction efficiencies exceeding 80% at specific wavelengths. Their fabrication leverages established semiconductor manufacturing techniques, allowing for precise nanostructure creation through processes like electron-beam lithography.

However, metasurfaces face significant limitations in dynamic beam steering applications. Most current designs are passive and fixed after fabrication, requiring mechanical movement of the entire structure for beam redirection. Recent advancements in tunable metasurfaces using phase-change materials or liquid crystals show promise but remain limited in steering range (typically <20°) and switching speed (milliseconds rather than microseconds).

In contrast, OPAs offer superior dynamic beam steering capabilities. Current silicon photonics-based OPAs demonstrate steering ranges up to 80° in one dimension and refresh rates in the microsecond regime. Their active control mechanism allows for rapid, precise beam positioning without moving parts. Additionally, OPAs can simultaneously generate multiple beams, enabling advanced scanning patterns not possible with conventional mechanical systems.

OPAs face their own set of challenges, particularly in power efficiency and scalability. Current implementations suffer from significant optical losses, with system efficiencies often below 10%. The requirement for individual phase control of numerous optical elements increases system complexity and power consumption. Fabrication challenges also persist in creating large-scale arrays with consistent performance across all elements.

Resolution capabilities differ significantly between the technologies. Metasurfaces currently achieve higher spatial resolution due to their subwavelength element spacing, enabling precise beam forming with minimal side lobes. OPAs typically have element spacing limited by fabrication constraints, resulting in unwanted diffraction orders that restrict their effective field of view.

Temperature stability represents another critical difference. Metasurfaces generally demonstrate better thermal stability once fabricated, while OPAs require active temperature compensation to maintain phase relationships between elements, adding complexity to deployment in automotive environments.

The wavelength dependence of both technologies presents challenges for broadband operation, with metasurfaces typically exhibiting higher wavelength sensitivity than OPAs, limiting their effectiveness in applications requiring operation across multiple wavelengths.

Metasurfaces excel in their compact form factor, typically measuring just a few micrometers in thickness. This ultra-thin profile enables integration possibilities that traditional optical components cannot match. Current metasurface implementations demonstrate high efficiency in static beam steering applications, with some designs achieving diffraction efficiencies exceeding 80% at specific wavelengths. Their fabrication leverages established semiconductor manufacturing techniques, allowing for precise nanostructure creation through processes like electron-beam lithography.

However, metasurfaces face significant limitations in dynamic beam steering applications. Most current designs are passive and fixed after fabrication, requiring mechanical movement of the entire structure for beam redirection. Recent advancements in tunable metasurfaces using phase-change materials or liquid crystals show promise but remain limited in steering range (typically <20°) and switching speed (milliseconds rather than microseconds).

In contrast, OPAs offer superior dynamic beam steering capabilities. Current silicon photonics-based OPAs demonstrate steering ranges up to 80° in one dimension and refresh rates in the microsecond regime. Their active control mechanism allows for rapid, precise beam positioning without moving parts. Additionally, OPAs can simultaneously generate multiple beams, enabling advanced scanning patterns not possible with conventional mechanical systems.

OPAs face their own set of challenges, particularly in power efficiency and scalability. Current implementations suffer from significant optical losses, with system efficiencies often below 10%. The requirement for individual phase control of numerous optical elements increases system complexity and power consumption. Fabrication challenges also persist in creating large-scale arrays with consistent performance across all elements.

Resolution capabilities differ significantly between the technologies. Metasurfaces currently achieve higher spatial resolution due to their subwavelength element spacing, enabling precise beam forming with minimal side lobes. OPAs typically have element spacing limited by fabrication constraints, resulting in unwanted diffraction orders that restrict their effective field of view.

Temperature stability represents another critical difference. Metasurfaces generally demonstrate better thermal stability once fabricated, while OPAs require active temperature compensation to maintain phase relationships between elements, adding complexity to deployment in automotive environments.

The wavelength dependence of both technologies presents challenges for broadband operation, with metasurfaces typically exhibiting higher wavelength sensitivity than OPAs, limiting their effectiveness in applications requiring operation across multiple wavelengths.

Comparative Analysis of Existing Beam Steering Implementations

01 Metasurface design for beam steering and control

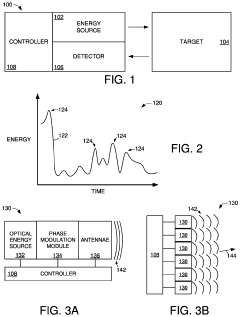

Metasurfaces can be designed with specific nanostructures to manipulate electromagnetic waves for precise beam steering and control. These engineered surfaces consist of subwavelength elements that can modify the phase, amplitude, and polarization of incident light. By carefully designing the geometry and arrangement of these elements, metasurfaces can achieve dynamic beam steering, focusing, and other wavefront manipulations with high efficiency and compact form factors.- Metasurface design for beam steering and control: Metasurfaces can be designed with specific patterns and structures to manipulate electromagnetic waves for precise beam steering and control. These engineered surfaces consist of subwavelength elements that can modify the phase, amplitude, and polarization of incident light. By carefully designing the geometry and arrangement of these elements, metasurfaces can achieve dynamic beam control with high precision and efficiency for various applications including communications, sensing, and imaging systems.

- Optical phased array architectures for beam forming: Optical phased arrays utilize multiple optical elements arranged in specific configurations to control the direction and shape of light beams. These systems employ phase shifters to adjust the relative phase between array elements, enabling constructive interference in desired directions. Advanced architectures incorporate tunable components that allow for real-time beam steering without mechanical movement, offering advantages in speed, reliability, and precision for applications such as LiDAR, free-space optical communications, and advanced sensing systems.

- Integration of metasurfaces with active control elements: The integration of metasurfaces with active control elements enables dynamic and reconfigurable beam control capabilities. These systems incorporate tunable materials or electronic components that can modify the properties of the metasurface in response to external stimuli such as voltage, temperature, or optical signals. This integration allows for adaptive beam steering, focusing, and shaping, enhancing the functionality and versatility of optical systems for applications in telecommunications, autonomous vehicles, and advanced imaging.

- Beam control techniques for LIDAR and sensing applications: Advanced beam control techniques using metasurfaces and optical phased arrays are crucial for LIDAR and sensing applications. These technologies enable precise scanning patterns, variable focus capabilities, and adaptive beam shaping that can respond to changing environmental conditions. By implementing sophisticated control algorithms and specialized optical designs, these systems can achieve enhanced range, resolution, and reliability in detecting and tracking objects, making them valuable for autonomous navigation, environmental monitoring, and security applications.

- Fabrication methods for metasurfaces and optical phased arrays: Various fabrication methods are employed to create metasurfaces and optical phased arrays with precise control over their optical properties. These techniques include nanolithography, electron beam lithography, self-assembly processes, and advanced material deposition methods. The fabrication approaches focus on achieving nanoscale precision in the creation of subwavelength structures while maintaining scalability for practical applications. Innovations in manufacturing processes have enabled the development of more efficient, compact, and cost-effective beam control systems for commercial and research applications.

02 Optical phased array architectures for beam forming

Optical phased arrays (OPAs) utilize arrays of optical emitters with controlled phase relationships to achieve beam steering and forming. These systems can dynamically control the direction of light propagation without mechanical components by adjusting the relative phases between array elements. Various architectures have been developed including waveguide-based OPAs, MEMS-based systems, and liquid crystal-based designs, each offering different advantages in terms of steering range, speed, and power efficiency.Expand Specific Solutions03 Integration of metasurfaces with active control elements

Advanced beam control systems integrate metasurfaces with active control elements such as tunable materials, MEMS, or electronic components to enable dynamic beam manipulation. These hybrid systems combine the compact form factor of metasurfaces with real-time tunability, allowing for adaptive beam steering, focusing, and wavefront shaping. The integration enables applications in LiDAR, free-space optical communications, and advanced sensing with improved performance and reduced size compared to conventional optical systems.Expand Specific Solutions04 Beam control techniques for LiDAR and sensing applications

Specialized beam control techniques have been developed for LiDAR and sensing applications, enabling high-resolution 3D mapping and object detection. These techniques include fast beam scanning methods, multi-beam generation, and adaptive focusing to optimize detection range and resolution. By precisely controlling the direction and shape of optical beams, these systems can achieve improved detection capabilities, reduced interference, and enhanced performance in challenging environmental conditions.Expand Specific Solutions05 Phase control methods for wide-angle beam steering

Advanced phase control methods enable wide-angle beam steering in optical systems without mechanical components. These methods include progressive phase shifting, phase reset techniques, and multi-level phase control to achieve large steering angles while maintaining beam quality. Implementation approaches include the use of liquid crystals, electro-optic materials, and semiconductor-based phase shifters that can be electronically controlled to provide rapid and precise beam positioning across a wide field of view.Expand Specific Solutions

Leading Companies and Research Institutions in LiDAR Optics

The LiDAR beam control technology market is currently in a transitional growth phase, with metasurfaces and optical phased arrays (OPAs) emerging as competing solutions. The global LiDAR market is projected to reach $3.8 billion by 2025, with beam steering technologies representing a significant segment. Metasurfaces offer advantages in miniaturization and power efficiency, while OPAs provide more dynamic beam control capabilities. Leading companies like Lumotive and Analog Devices are advancing metasurface technology, while Raytheon, Samsung, and LG Innotek are developing OPA solutions. Academic institutions including Columbia University and Caltech are conducting foundational research, while companies like Bosch and RoboSense (Suteng Innovation) are integrating these technologies into automotive and robotics applications. The technology remains in early commercial deployment with significant R&D investment continuing across both approaches.

California Institute of Technology

Technical Solution: Caltech has pioneered innovative approaches to both metasurface and optical phased array technologies for LiDAR applications. Their research team has developed a silicon photonic wavelength-controlled OPA that achieves two-dimensional beam steering without the need for complex phase shifter arrays. This system utilizes a wavelength-sensitive optical grating coupled with an array of nano-antennas to create a compact, chip-scale beam steering solution. The wavelength-dependent beam steering achieves scanning rates up to 100 kHz with a field of view of approximately 70 degrees in one dimension. In parallel, Caltech researchers have developed dielectric metasurfaces using titanium dioxide nanostructures that demonstrate high efficiency beam control with simplified fabrication requirements compared to traditional OPAs. Their metasurface design achieves over 90% transmission efficiency while enabling precise beam forming capabilities. A notable innovation is their hybrid approach that combines the advantages of both technologies—using metasurfaces for wide-angle beam formation and OPAs for rapid, fine steering—resulting in a system that addresses the limitations of each individual technology.

Strengths: Innovative hybrid approach combining benefits of both technologies, high scanning rates (100 kHz), simplified control mechanisms through wavelength tuning, and high optical efficiency. Weaknesses: Limited commercial readiness as the technology remains primarily in research phase, potential challenges in scaling manufacturing for complex nanostructures, and wavelength-dependent steering may introduce chromatic aberrations.

Interuniversitair Micro-Electronica Centrum VZW

Technical Solution: IMEC has developed a silicon photonics-based optical phased array platform for LiDAR applications that integrates thousands of phase shifters on a single chip. Their approach utilizes a proprietary silicon nitride (SiN) waveguide technology that offers lower optical loss compared to traditional silicon photonics, enabling longer detection ranges. IMEC's OPA design incorporates thermo-optic phase shifters arranged in a two-dimensional array configuration, allowing for beam steering in both azimuth and elevation without mechanical components. The system achieves a field of view of approximately 80 degrees horizontally and 20 degrees vertically with steering speeds in the microsecond range. A key innovation in IMEC's approach is their advanced calibration algorithms that compensate for manufacturing variations in the phase shifters, resulting in more precise beam control. The platform operates at the 905nm wavelength band, balancing performance with cost considerations for automotive applications. IMEC has also explored hybrid integration approaches that combine their silicon photonics platform with III-V materials to enhance light emission and detection capabilities.

Strengths: Highly integrated solution with thousands of phase shifters on a single chip, lower optical losses through SiN waveguide technology, advanced calibration algorithms for manufacturing tolerance compensation, and compatibility with standard CMOS fabrication processes. Weaknesses: Thermal management challenges due to the use of thermo-optic phase shifters, limited vertical field of view compared to some metasurface alternatives, and higher power consumption requirements.

Key Patents and Research Breakthroughs in Beam Control

Lidar with metasurface beam steering

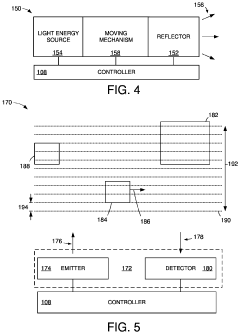

PatentPendingUS20220413103A1

Innovation

- A metasurface that continuously extends between electrical contacts, separated from a silicon substrate by an air gap, is used to create an electrostatic force that alters the air gap size in response to voltage bias, enabling efficient and accurate beam steering and optimization of light detection and ranging systems.

Techniques for Combining Optical Beams into Shared Spatial Mode

PatentActiveUS20220155426A1

Innovation

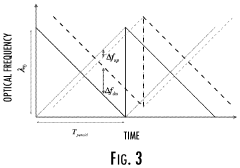

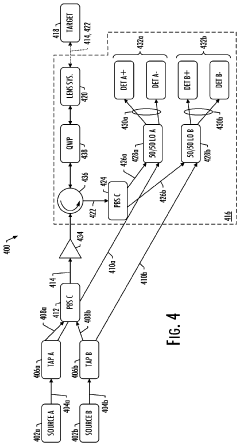

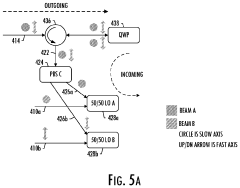

- A frequency-modulated LiDAR system with dual optical sources of opposite polarizations, split into high and low-power paths, combined and amplified, and mixed to produce beat frequencies for range and velocity determination, utilizing polarization beam splitters and balanced optical detectors, enabling compact and efficient simultaneous measurement.

Manufacturing Scalability and Cost Considerations

Manufacturing scalability and cost considerations represent critical factors in determining the commercial viability of both metasurfaces and optical phased arrays (OPAs) for LiDAR beam control applications. The manufacturing processes for these technologies differ significantly, directly impacting their adoption in automotive and consumer electronics markets.

Metasurfaces currently face substantial manufacturing challenges despite their promising optical performance. Traditional fabrication methods rely on electron beam lithography, which offers high precision but remains prohibitively expensive and time-consuming for mass production. Recent advances in nanoimprint lithography show potential for scaling metasurface production, potentially reducing unit costs by 60-70% compared to conventional methods. However, the technology still requires significant investment in specialized equipment and clean room facilities, with current estimates suggesting production costs of $50-100 per device at moderate volumes.

In contrast, OPAs benefit from compatibility with established semiconductor manufacturing processes. Silicon photonics-based OPAs can leverage existing CMOS fabrication infrastructure, enabling higher throughput and lower per-unit costs at scale. Industry analysts project that OPA manufacturing costs could decrease to $15-30 per unit at high volumes within 3-5 years, representing a significant advantage over metasurfaces in the near term.

Material considerations also impact manufacturing economics. Metasurfaces typically require exotic materials like titanium dioxide or silicon nitride with precise nanoscale features, increasing material costs and quality control requirements. OPAs primarily utilize silicon, which benefits from decades of manufacturing optimization and established supply chains, though they require more complex electronic control systems that add to overall costs.

Yield rates present another critical distinction. Current metasurface production processes achieve approximately 60-70% yield rates in laboratory settings, whereas OPA manufacturing leverages mature semiconductor processes with yields exceeding 90%. This yield differential significantly impacts final device costs and production scalability.

Looking forward, both technologies face different paths to cost reduction. Metasurfaces will likely see dramatic improvements through new manufacturing techniques like roll-to-roll nanoimprinting, potentially enabling high-volume production within 5-7 years. OPAs will benefit from continued semiconductor manufacturing advances and increasing integration density, with costs declining predictably following semiconductor industry learning curves. The technology that achieves the optimal balance between performance, manufacturing scalability, and cost will ultimately dominate the LiDAR beam control market.

Metasurfaces currently face substantial manufacturing challenges despite their promising optical performance. Traditional fabrication methods rely on electron beam lithography, which offers high precision but remains prohibitively expensive and time-consuming for mass production. Recent advances in nanoimprint lithography show potential for scaling metasurface production, potentially reducing unit costs by 60-70% compared to conventional methods. However, the technology still requires significant investment in specialized equipment and clean room facilities, with current estimates suggesting production costs of $50-100 per device at moderate volumes.

In contrast, OPAs benefit from compatibility with established semiconductor manufacturing processes. Silicon photonics-based OPAs can leverage existing CMOS fabrication infrastructure, enabling higher throughput and lower per-unit costs at scale. Industry analysts project that OPA manufacturing costs could decrease to $15-30 per unit at high volumes within 3-5 years, representing a significant advantage over metasurfaces in the near term.

Material considerations also impact manufacturing economics. Metasurfaces typically require exotic materials like titanium dioxide or silicon nitride with precise nanoscale features, increasing material costs and quality control requirements. OPAs primarily utilize silicon, which benefits from decades of manufacturing optimization and established supply chains, though they require more complex electronic control systems that add to overall costs.

Yield rates present another critical distinction. Current metasurface production processes achieve approximately 60-70% yield rates in laboratory settings, whereas OPA manufacturing leverages mature semiconductor processes with yields exceeding 90%. This yield differential significantly impacts final device costs and production scalability.

Looking forward, both technologies face different paths to cost reduction. Metasurfaces will likely see dramatic improvements through new manufacturing techniques like roll-to-roll nanoimprinting, potentially enabling high-volume production within 5-7 years. OPAs will benefit from continued semiconductor manufacturing advances and increasing integration density, with costs declining predictably following semiconductor industry learning curves. The technology that achieves the optimal balance between performance, manufacturing scalability, and cost will ultimately dominate the LiDAR beam control market.

Integration Challenges with Autonomous Vehicle Systems

The integration of advanced beam steering technologies like metasurfaces and optical phased arrays (OPAs) into autonomous vehicle systems presents significant engineering challenges that must be addressed before widespread deployment. Current autonomous vehicle architectures are designed around conventional LiDAR systems with mechanical or MEMS-based scanning mechanisms, requiring substantial redesign to accommodate these emerging technologies. The electrical interfaces, power requirements, and thermal management systems differ considerably between traditional LiDAR and these new beam steering approaches.

Data processing pipelines represent another major integration hurdle. Metasurface-based LiDAR may generate different point cloud characteristics compared to conventional systems, necessitating modifications to perception algorithms and sensor fusion frameworks. The software stack that interprets LiDAR data for object detection, classification, and tracking would require recalibration and possibly fundamental redesign to fully leverage the unique capabilities of these advanced beam steering technologies.

Environmental robustness poses particular challenges for automotive implementation. Metasurfaces and OPAs must maintain reliable performance across extreme temperature ranges (-40°C to 85°C), withstand vibration, shock, and electromagnetic interference common in automotive environments. The optical surfaces must resist degradation from road debris, dust, rain, snow, and de-icing chemicals while maintaining calibration over the vehicle's operational lifetime.

Manufacturing scalability and supply chain considerations further complicate integration. Current metasurface fabrication processes rely on sophisticated nanofabrication techniques not yet optimized for automotive volumes and cost targets. The transition from laboratory prototypes to mass-produced automotive-grade components requires significant investment in manufacturing process development and quality control systems.

Regulatory compliance and safety certification represent additional integration challenges. Novel beam steering technologies must meet eye safety standards (IEC 60825), electromagnetic compatibility requirements, and functional safety specifications (ISO 26262). The certification process for these new technologies may be more complex than for established LiDAR systems, potentially extending development timelines and increasing costs.

System-level integration with other sensors (cameras, radar, ultrasonic) presents interoperability challenges. The different sensing modalities must work harmoniously without interference, sharing computational resources efficiently. Calibration procedures must account for the unique characteristics of metasurface or OPA-based LiDAR to ensure accurate sensor fusion and consistent environmental perception across the autonomous driving stack.

Data processing pipelines represent another major integration hurdle. Metasurface-based LiDAR may generate different point cloud characteristics compared to conventional systems, necessitating modifications to perception algorithms and sensor fusion frameworks. The software stack that interprets LiDAR data for object detection, classification, and tracking would require recalibration and possibly fundamental redesign to fully leverage the unique capabilities of these advanced beam steering technologies.

Environmental robustness poses particular challenges for automotive implementation. Metasurfaces and OPAs must maintain reliable performance across extreme temperature ranges (-40°C to 85°C), withstand vibration, shock, and electromagnetic interference common in automotive environments. The optical surfaces must resist degradation from road debris, dust, rain, snow, and de-icing chemicals while maintaining calibration over the vehicle's operational lifetime.

Manufacturing scalability and supply chain considerations further complicate integration. Current metasurface fabrication processes rely on sophisticated nanofabrication techniques not yet optimized for automotive volumes and cost targets. The transition from laboratory prototypes to mass-produced automotive-grade components requires significant investment in manufacturing process development and quality control systems.

Regulatory compliance and safety certification represent additional integration challenges. Novel beam steering technologies must meet eye safety standards (IEC 60825), electromagnetic compatibility requirements, and functional safety specifications (ISO 26262). The certification process for these new technologies may be more complex than for established LiDAR systems, potentially extending development timelines and increasing costs.

System-level integration with other sensors (cameras, radar, ultrasonic) presents interoperability challenges. The different sensing modalities must work harmoniously without interference, sharing computational resources efficiently. Calibration procedures must account for the unique characteristics of metasurface or OPA-based LiDAR to ensure accurate sensor fusion and consistent environmental perception across the autonomous driving stack.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!