Thermal And Mechanical Stability Considerations For Automotive Use

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automotive Thermal-Mechanical Stability Background and Objectives

The evolution of automotive thermal and mechanical stability considerations has undergone significant transformation since the early days of automobile manufacturing. Initially focused primarily on basic engine cooling systems and structural integrity, this field has expanded dramatically with the advancement of materials science, computational modeling, and increasingly stringent performance requirements. Modern vehicles operate in extreme temperature ranges from arctic cold to desert heat while maintaining structural integrity under diverse mechanical stresses, making thermal-mechanical stability a cornerstone of automotive engineering.

The automotive industry's shift toward electrification, lightweight materials, and advanced electronics has fundamentally altered thermal management paradigms. Electric vehicles generate different heat patterns than internal combustion engines, requiring novel cooling strategies for battery systems and power electronics. Simultaneously, the integration of lightweight materials like carbon fiber composites and high-strength aluminum alloys introduces new thermal expansion challenges and mechanical stress considerations that were largely absent in traditional steel-based designs.

Global regulatory frameworks have significantly influenced this technical domain. Emissions standards, fuel efficiency requirements, and safety regulations have pushed manufacturers to develop increasingly sophisticated thermal management systems that optimize performance while meeting compliance standards. These regulatory pressures, combined with consumer expectations for reliability in extreme conditions, have accelerated innovation in thermal-mechanical stability solutions.

The primary objective in this field is to develop integrated systems and materials that maintain optimal performance across the vehicle's operational temperature range while ensuring structural integrity throughout the product lifecycle. This includes preventing thermal degradation of components, managing thermal expansion and contraction, mitigating vibration effects, and ensuring durability under cyclical thermal and mechanical loading conditions.

Key technical goals include developing predictive models for thermal-mechanical behavior, creating advanced materials with tailored thermal expansion properties, designing more efficient cooling systems, and implementing smart thermal management strategies that adapt to changing conditions. The industry aims to achieve these objectives while reducing weight, cost, and complexity—a challenging multi-variable optimization problem.

The convergence of computational fluid dynamics, finite element analysis, and real-world testing methodologies has enabled unprecedented accuracy in predicting thermal-mechanical interactions. This technical evolution continues to accelerate as vehicles become more complex, incorporating autonomous systems, advanced driver assistance features, and connectivity solutions that introduce additional thermal management challenges and mechanical design considerations.

The automotive industry's shift toward electrification, lightweight materials, and advanced electronics has fundamentally altered thermal management paradigms. Electric vehicles generate different heat patterns than internal combustion engines, requiring novel cooling strategies for battery systems and power electronics. Simultaneously, the integration of lightweight materials like carbon fiber composites and high-strength aluminum alloys introduces new thermal expansion challenges and mechanical stress considerations that were largely absent in traditional steel-based designs.

Global regulatory frameworks have significantly influenced this technical domain. Emissions standards, fuel efficiency requirements, and safety regulations have pushed manufacturers to develop increasingly sophisticated thermal management systems that optimize performance while meeting compliance standards. These regulatory pressures, combined with consumer expectations for reliability in extreme conditions, have accelerated innovation in thermal-mechanical stability solutions.

The primary objective in this field is to develop integrated systems and materials that maintain optimal performance across the vehicle's operational temperature range while ensuring structural integrity throughout the product lifecycle. This includes preventing thermal degradation of components, managing thermal expansion and contraction, mitigating vibration effects, and ensuring durability under cyclical thermal and mechanical loading conditions.

Key technical goals include developing predictive models for thermal-mechanical behavior, creating advanced materials with tailored thermal expansion properties, designing more efficient cooling systems, and implementing smart thermal management strategies that adapt to changing conditions. The industry aims to achieve these objectives while reducing weight, cost, and complexity—a challenging multi-variable optimization problem.

The convergence of computational fluid dynamics, finite element analysis, and real-world testing methodologies has enabled unprecedented accuracy in predicting thermal-mechanical interactions. This technical evolution continues to accelerate as vehicles become more complex, incorporating autonomous systems, advanced driver assistance features, and connectivity solutions that introduce additional thermal management challenges and mechanical design considerations.

Market Requirements for Automotive Thermal-Mechanical Performance

The automotive industry is witnessing unprecedented demands for thermal and mechanical performance as vehicles evolve toward electrification, autonomous capabilities, and enhanced safety features. Current market requirements indicate that components must withstand operating temperatures ranging from -40°C to 125°C for standard applications, with specialized under-hood components requiring stability up to 150°C. These temperature extremes represent a significant expansion from previous generations of vehicles, where typical requirements rarely exceeded 105°C for most components.

Mechanical stability requirements have similarly intensified, with vibration resistance now commonly specified at 10-500 Hz with acceleration forces up to 30g for critical components. Impact resistance standards have increased by approximately 30% over the past decade, reflecting the industry's heightened focus on passenger safety and component longevity. These specifications are particularly stringent for electric vehicles, where battery systems must maintain structural integrity during collision events while preventing thermal runaway.

Market analysis reveals regional variations in requirements, with European OEMs typically demanding the most rigorous thermal cycling tests (up to 1,000 cycles), while North American manufacturers emphasize mechanical shock resistance. The Asia-Pacific market, particularly China and Japan, leads in requirements for humidity resistance combined with thermal stability, reflecting their diverse climate conditions.

Consumer expectations are driving many of these enhanced requirements, with vehicle warranties now commonly extending to 7-10 years. This extended lifecycle necessitates materials and components that maintain performance characteristics despite thousands of thermal cycles and continuous vibration exposure. Fleet operators and ride-sharing companies have further elevated these demands, expecting vehicles to maintain reliability through significantly higher utilization rates than traditional consumer vehicles.

Regulatory frameworks are also reshaping thermal-mechanical requirements. The UN ECE R100 regulation for electric vehicle safety has established stringent thermal management standards, while the EU's End-of-Life Vehicle Directive necessitates thermal stability of components to facilitate recycling processes. In North America, NHTSA standards increasingly address thermal management as a safety consideration, particularly for autonomous driving systems where sensor and computing hardware must maintain precise operation across extreme temperature conditions.

The market increasingly values solutions that address multiple requirements simultaneously, such as materials that provide both thermal insulation and vibration damping, or structural components that serve as thermal management systems. This integration trend is expected to accelerate as vehicle architectures continue to evolve toward more compact, multifunctional designs.

Mechanical stability requirements have similarly intensified, with vibration resistance now commonly specified at 10-500 Hz with acceleration forces up to 30g for critical components. Impact resistance standards have increased by approximately 30% over the past decade, reflecting the industry's heightened focus on passenger safety and component longevity. These specifications are particularly stringent for electric vehicles, where battery systems must maintain structural integrity during collision events while preventing thermal runaway.

Market analysis reveals regional variations in requirements, with European OEMs typically demanding the most rigorous thermal cycling tests (up to 1,000 cycles), while North American manufacturers emphasize mechanical shock resistance. The Asia-Pacific market, particularly China and Japan, leads in requirements for humidity resistance combined with thermal stability, reflecting their diverse climate conditions.

Consumer expectations are driving many of these enhanced requirements, with vehicle warranties now commonly extending to 7-10 years. This extended lifecycle necessitates materials and components that maintain performance characteristics despite thousands of thermal cycles and continuous vibration exposure. Fleet operators and ride-sharing companies have further elevated these demands, expecting vehicles to maintain reliability through significantly higher utilization rates than traditional consumer vehicles.

Regulatory frameworks are also reshaping thermal-mechanical requirements. The UN ECE R100 regulation for electric vehicle safety has established stringent thermal management standards, while the EU's End-of-Life Vehicle Directive necessitates thermal stability of components to facilitate recycling processes. In North America, NHTSA standards increasingly address thermal management as a safety consideration, particularly for autonomous driving systems where sensor and computing hardware must maintain precise operation across extreme temperature conditions.

The market increasingly values solutions that address multiple requirements simultaneously, such as materials that provide both thermal insulation and vibration damping, or structural components that serve as thermal management systems. This integration trend is expected to accelerate as vehicle architectures continue to evolve toward more compact, multifunctional designs.

Current Challenges in Automotive Material Stability

The automotive industry faces unprecedented challenges in material stability as vehicles are subjected to increasingly extreme operating conditions. Modern automobiles must withstand temperatures ranging from -40°C in arctic environments to over 150°C near engine components, creating significant thermal expansion and contraction cycles that stress material integrity. These thermal fluctuations are particularly problematic for composite materials and adhesive bonds used in lightweight vehicle construction, where differential expansion rates between dissimilar materials can lead to delamination and structural failure.

Mechanical stability presents equally formidable challenges, with materials required to maintain performance under constant vibration, shock loading, and cyclic stress. Road-induced vibrations typically occur at frequencies between 10-100 Hz, while engine vibrations can reach 200 Hz or higher, creating complex resonance patterns throughout the vehicle structure. These conditions accelerate fatigue failure mechanisms, particularly in critical safety components and lightweight structural elements designed to meet stringent fuel efficiency standards.

Environmental factors compound these challenges, with materials simultaneously exposed to UV radiation, moisture, road salt, and chemical contaminants. The increasing adoption of electric vehicles introduces new stability concerns, as battery systems generate unique thermal management requirements and electromagnetic interference patterns that can affect material performance. High-voltage components require insulation materials with exceptional thermal stability and dielectric strength maintained over the vehicle's entire lifecycle.

Manufacturing inconsistencies further complicate material stability, with variations in production processes leading to unpredictable material behavior under stress. Quality control data indicates that even minor deviations in curing temperatures or cooling rates can reduce a material's thermal stability by 15-20%, significantly impacting long-term durability. The industry's shift toward automated manufacturing has improved consistency but introduced new challenges in detecting subtle material defects that may compromise stability.

Regulatory pressures add another dimension to these challenges, with increasingly stringent safety and environmental standards requiring materials to maintain stability while meeting sustainability goals. The push toward recyclable and bio-based materials often involves compromises in thermal and mechanical stability, creating difficult engineering tradeoffs. Additionally, the extended warranty periods now common in the automotive market (often 7-10 years) require materials to maintain stability far longer than historically expected.

Cost constraints remain perhaps the most persistent challenge, with automotive manufacturers continuously seeking materials that offer enhanced stability without significant price premiums. This economic pressure often forces compromises in material selection, with engineers balancing optimal performance against budgetary realities. The result is a complex optimization problem where thermal and mechanical stability must be achieved within strict financial parameters.

Mechanical stability presents equally formidable challenges, with materials required to maintain performance under constant vibration, shock loading, and cyclic stress. Road-induced vibrations typically occur at frequencies between 10-100 Hz, while engine vibrations can reach 200 Hz or higher, creating complex resonance patterns throughout the vehicle structure. These conditions accelerate fatigue failure mechanisms, particularly in critical safety components and lightweight structural elements designed to meet stringent fuel efficiency standards.

Environmental factors compound these challenges, with materials simultaneously exposed to UV radiation, moisture, road salt, and chemical contaminants. The increasing adoption of electric vehicles introduces new stability concerns, as battery systems generate unique thermal management requirements and electromagnetic interference patterns that can affect material performance. High-voltage components require insulation materials with exceptional thermal stability and dielectric strength maintained over the vehicle's entire lifecycle.

Manufacturing inconsistencies further complicate material stability, with variations in production processes leading to unpredictable material behavior under stress. Quality control data indicates that even minor deviations in curing temperatures or cooling rates can reduce a material's thermal stability by 15-20%, significantly impacting long-term durability. The industry's shift toward automated manufacturing has improved consistency but introduced new challenges in detecting subtle material defects that may compromise stability.

Regulatory pressures add another dimension to these challenges, with increasingly stringent safety and environmental standards requiring materials to maintain stability while meeting sustainability goals. The push toward recyclable and bio-based materials often involves compromises in thermal and mechanical stability, creating difficult engineering tradeoffs. Additionally, the extended warranty periods now common in the automotive market (often 7-10 years) require materials to maintain stability far longer than historically expected.

Cost constraints remain perhaps the most persistent challenge, with automotive manufacturers continuously seeking materials that offer enhanced stability without significant price premiums. This economic pressure often forces compromises in material selection, with engineers balancing optimal performance against budgetary realities. The result is a complex optimization problem where thermal and mechanical stability must be achieved within strict financial parameters.

Current Engineering Approaches for Thermal-Mechanical Stability

01 Materials with enhanced thermal stability

Various materials can be engineered to exhibit improved thermal stability properties, allowing them to maintain structural integrity and performance under high-temperature conditions. These materials include specialized polymers, composites, and alloys that resist degradation, deformation, or phase changes when exposed to elevated temperatures. The enhanced thermal stability is achieved through specific molecular structures, cross-linking, or the addition of stabilizing compounds that prevent thermal breakdown.- Materials with enhanced thermal stability: Various materials can be engineered to provide improved thermal stability for applications requiring resistance to temperature fluctuations. These materials include specialized polymers, composite structures, and thermally resistant compounds that maintain their structural integrity and functional properties across a wide temperature range. The enhanced thermal stability enables these materials to be used in high-temperature environments without degradation or loss of performance.

- Mechanical stability enhancement techniques: Techniques for improving mechanical stability focus on strengthening materials against physical stresses, vibrations, and deformations. These include structural reinforcement methods, incorporation of stabilizing additives, and specialized manufacturing processes that enhance durability. By improving resistance to mechanical forces, these techniques extend the operational lifespan of components and systems under stress conditions.

- Testing and measurement methods for stability: Advanced testing methodologies have been developed to evaluate and quantify both thermal and mechanical stability of materials and systems. These include accelerated aging tests, thermal cycling, mechanical stress testing, and analytical techniques that can predict long-term stability performance. Such testing protocols help in validating material performance under various environmental and operational conditions.

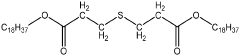

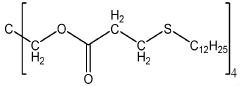

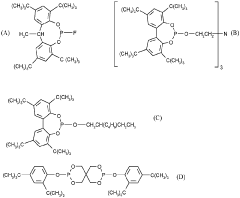

- Stabilization additives and compounds: Specific additives and compounds can be incorporated into materials to significantly improve their thermal and mechanical stability. These include heat stabilizers, antioxidants, reinforcing fillers, and cross-linking agents that prevent degradation under extreme conditions. The strategic use of these stabilizing components can tailor materials for specific environmental challenges while maintaining desired performance characteristics.

- Integrated stability solutions for electronic devices: Electronic devices require specialized approaches to ensure both thermal and mechanical stability in increasingly compact designs. These solutions include advanced thermal management systems, shock-absorbing structures, and materials with balanced thermal and mechanical properties. Such integrated approaches protect sensitive electronic components from environmental stresses while maintaining operational reliability under various usage conditions.

02 Testing methods for thermal and mechanical stability

Various testing methodologies have been developed to evaluate the thermal and mechanical stability of materials and components. These include accelerated aging tests, thermal cycling, mechanical stress testing, and combined thermomechanical analysis. Such testing protocols help in predicting the long-term performance and reliability of materials under various operating conditions, enabling better selection of materials for specific applications where stability is critical.Expand Specific Solutions03 Semiconductor device packaging with improved stability

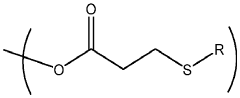

Advanced packaging techniques for semiconductor devices focus on enhancing both thermal and mechanical stability to ensure reliable operation under varying conditions. These techniques include specialized encapsulation materials, thermal interface materials, and structural designs that minimize thermal expansion mismatch. The improved packaging helps in heat dissipation while maintaining mechanical integrity, thereby extending device lifespan and performance reliability in electronic applications.Expand Specific Solutions04 Stabilization additives for polymeric materials

Chemical additives can be incorporated into polymeric materials to enhance their thermal and mechanical stability. These stabilizers include antioxidants, heat stabilizers, UV absorbers, and mechanical reinforcing agents. By preventing degradation mechanisms such as oxidation, chain scission, and cross-linking, these additives significantly extend the service life of polymeric materials under challenging environmental conditions and mechanical stresses.Expand Specific Solutions05 Nanostructured materials for enhanced stability

Nanostructured materials offer superior thermal and mechanical stability compared to their conventional counterparts. By controlling material structure at the nanoscale, properties such as thermal conductivity, mechanical strength, and resistance to deformation can be significantly enhanced. These materials include nanocomposites, nanocrystalline metals, and ceramics with engineered grain boundaries that impede crack propagation and thermal degradation, making them suitable for extreme environment applications.Expand Specific Solutions

Leading Manufacturers and Suppliers in Automotive Stability Solutions

The automotive thermal and mechanical stability market is in a mature growth phase, with increasing demand driven by vehicle electrification and stringent safety regulations. The global market size is estimated at $12-15 billion annually, growing at 5-7% CAGR. Leading players represent diverse specializations: traditional automotive manufacturers (Ford, Volkswagen, Audi, Volvo) focus on integration; materials specialists (ArcelorMittal, BASF, DuPont) develop advanced composites; while thermal management specialists (Hanon Systems, Gentherm) offer dedicated solutions. Chinese manufacturers like BYD and CRRC are rapidly advancing, particularly in EV applications. Technology maturity varies by application, with conventional thermal management systems being highly mature while advanced materials and EV-specific solutions remain in active development phases.

BYD Co., Ltd.

Technical Solution: BYD has developed an integrated thermal management approach for their electric vehicles that emphasizes battery longevity and performance optimization. Their "Blade Battery" technology incorporates innovative thermal management features that maintain cell-to-cell temperature differentials below 3°C even under extreme charging and discharging scenarios. BYD's thermal solution includes a liquid cooling system with intelligent flow distribution that adapts to both ambient conditions and battery state of charge. For mechanical stability, BYD employs a cell-to-pack design that eliminates traditional module housings, reducing thermal barriers while enhancing structural integrity. Their battery packs undergo vibration testing that simulates over 200,000 km of diverse road conditions while monitoring thermal performance. BYD's approach to thermal interface materials focuses on long-term stability, using silicon-based compounds that maintain consistent performance despite thousands of thermal cycles. Their electronic components are protected by thermal management systems that incorporate both active and passive cooling strategies, with redundant thermal protection mechanisms for safety-critical systems.

Strengths: Cell-to-pack design provides excellent thermal uniformity while reducing weight and improving energy density. Integrated approach to thermal and mechanical design results in simplified manufacturing and improved reliability. Weaknesses: Some proprietary thermal management components may create service challenges outside BYD's dealer network. The system optimization for battery longevity occasionally sacrifices peak performance in extreme conditions.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced thermal management systems for automotive applications that integrate multiple cooling circuits with intelligent control algorithms. Their solution includes a comprehensive thermal architecture that manages heat across the powertrain, battery systems, and cabin climate control. For mechanical stability, GM employs computer-aided engineering (CAE) with finite element analysis to simulate thermal expansion, vibration, and structural integrity under extreme conditions. Their vehicles undergo rigorous testing in temperature ranges from -40°C to +85°C to ensure component durability. GM's thermal stability approach includes phase-change materials in battery packs that absorb excess heat during high-load operations and specialized thermal interface materials that maintain consistent contact pressure despite thermal cycling. Their mechanical stability considerations incorporate vibration isolation systems that adapt to different road conditions and operational states.

Strengths: Comprehensive integration of thermal and mechanical systems with predictive control algorithms provides excellent performance across diverse operating conditions. Extensive real-world validation data from millions of vehicles enhances reliability. Weaknesses: Complex thermal management systems increase manufacturing costs and potential points of failure. Some solutions are optimized for specific vehicle platforms, limiting cross-platform standardization.

Key Patents and Research in Automotive Material Science

Stabilizer composition

PatentWO2021021871A1

Innovation

- A stabilizer additive composition comprising a combination of thioester additives, phenolic antioxidants, and phosphite stabilizers, or Hindered Amine Light Stabilizers (HALS), which are incorporated into a thermoplastic olefin substrate to enhance thermal stability, weathering resistance, and gas fade performance, particularly at elevated temperatures.

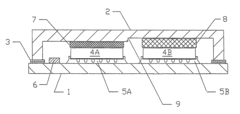

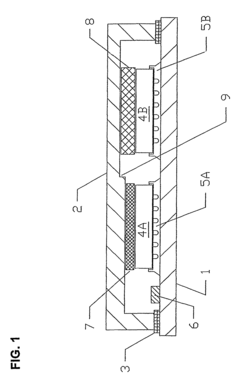

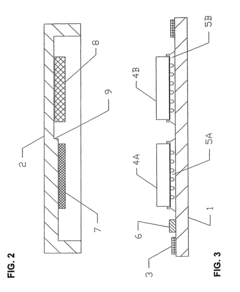

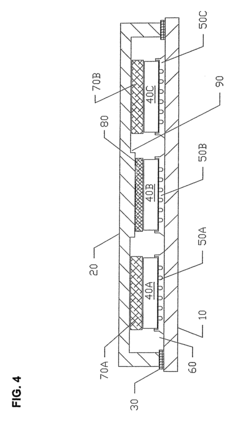

Achieving mechanical and thermal stability in a multi-chip package

PatentActiveUS8421217B2

Innovation

- A system utilizing a stepped lid with multiple thermal interface materials (TIMs) of varying properties, where a thin, high-performance TIM is used over high-power chips and a more robust, lower-performance TIM is used over low-power chips, along with a stepped lid configuration to control bond line thickness and capping load, providing structural support and thermal stability.

Environmental Impact and Sustainability Considerations

The environmental impact of automotive thermal and mechanical stability solutions has become increasingly significant as the industry faces stricter regulations and growing consumer awareness. Materials used in thermal management systems often contain metals and chemicals that pose environmental challenges throughout their lifecycle. Traditional thermal interface materials (TIMs) containing silicones, metals, and ceramics present disposal difficulties and can contribute to electronic waste problems when vehicles reach end-of-life.

Emerging sustainable alternatives include bio-based thermal interface materials derived from renewable resources such as cellulose, plant oils, and agricultural waste products. These materials demonstrate promising thermal conductivity while significantly reducing carbon footprint compared to conventional petroleum-based options. Research indicates that bio-based TIMs can achieve up to 30% reduction in environmental impact while maintaining acceptable thermal performance parameters.

The manufacturing processes for thermal stability components also present environmental considerations. Energy-intensive production methods for high-temperature ceramics and specialized alloys contribute substantially to the carbon footprint of automotive thermal management systems. Innovations in low-energy manufacturing techniques, including room-temperature curing adhesives and additive manufacturing approaches, are showing potential for reducing production-related emissions by 15-25%.

Water consumption represents another critical environmental factor, particularly in the production of specialized cooling systems and heat-resistant materials. Advanced water recycling systems and dry manufacturing processes are being implemented by industry leaders, achieving water usage reductions of up to 40% compared to conventional manufacturing methods.

End-of-life considerations for thermal and mechanical stability components present both challenges and opportunities. The complex material compositions of many heat-resistant components make recycling difficult, with only 20-30% of these materials currently being recovered effectively. Design for disassembly approaches and material selection strategies that prioritize recyclability are emerging as best practices among forward-thinking manufacturers.

Carbon emissions associated with the operational phase of thermal management systems must also be considered. More efficient thermal management can reduce vehicle fuel consumption by 2-5%, translating to significant lifetime emissions reductions. However, this benefit must be balanced against the embodied carbon in increasingly complex thermal management solutions.

Regulatory frameworks worldwide are evolving to address these environmental concerns, with the European Union's End-of-Life Vehicle Directive and similar regulations in other regions placing greater responsibility on manufacturers to consider full lifecycle impacts. Companies demonstrating leadership in sustainable thermal management solutions are gaining competitive advantages through improved brand reputation and preparedness for future regulatory requirements.

Emerging sustainable alternatives include bio-based thermal interface materials derived from renewable resources such as cellulose, plant oils, and agricultural waste products. These materials demonstrate promising thermal conductivity while significantly reducing carbon footprint compared to conventional petroleum-based options. Research indicates that bio-based TIMs can achieve up to 30% reduction in environmental impact while maintaining acceptable thermal performance parameters.

The manufacturing processes for thermal stability components also present environmental considerations. Energy-intensive production methods for high-temperature ceramics and specialized alloys contribute substantially to the carbon footprint of automotive thermal management systems. Innovations in low-energy manufacturing techniques, including room-temperature curing adhesives and additive manufacturing approaches, are showing potential for reducing production-related emissions by 15-25%.

Water consumption represents another critical environmental factor, particularly in the production of specialized cooling systems and heat-resistant materials. Advanced water recycling systems and dry manufacturing processes are being implemented by industry leaders, achieving water usage reductions of up to 40% compared to conventional manufacturing methods.

End-of-life considerations for thermal and mechanical stability components present both challenges and opportunities. The complex material compositions of many heat-resistant components make recycling difficult, with only 20-30% of these materials currently being recovered effectively. Design for disassembly approaches and material selection strategies that prioritize recyclability are emerging as best practices among forward-thinking manufacturers.

Carbon emissions associated with the operational phase of thermal management systems must also be considered. More efficient thermal management can reduce vehicle fuel consumption by 2-5%, translating to significant lifetime emissions reductions. However, this benefit must be balanced against the embodied carbon in increasingly complex thermal management solutions.

Regulatory frameworks worldwide are evolving to address these environmental concerns, with the European Union's End-of-Life Vehicle Directive and similar regulations in other regions placing greater responsibility on manufacturers to consider full lifecycle impacts. Companies demonstrating leadership in sustainable thermal management solutions are gaining competitive advantages through improved brand reputation and preparedness for future regulatory requirements.

Safety Standards and Compliance Requirements

Automotive safety standards and compliance requirements form a critical framework for thermal and mechanical stability considerations in vehicle design and manufacturing. The automotive industry is governed by stringent regulations that vary across global markets, with key standards including FMVSS (Federal Motor Vehicle Safety Standards) in the United States, UN ECE regulations in Europe, and equivalent frameworks in other major automotive markets like China, Japan, and India.

These standards specifically address thermal stability through requirements such as FMVSS 302 for flammability of interior materials, which mandates that components must maintain integrity under specified heat conditions. Similarly, ECE R118 establishes comprehensive burning behavior parameters for materials used in vehicle construction, particularly focusing on their performance under thermal stress.

Mechanical stability compliance is primarily governed by standards like FMVSS 207/210 for seating systems and seat belt anchorages, which require components to withstand specific force loads without failure. ISO 16750 provides detailed environmental condition testing protocols, including mechanical shock, vibration resistance, and thermal cycling that automotive components must endure.

The compliance landscape is further complicated by emerging standards for electric and autonomous vehicles. SAE J2929 and UN GTR No. 20 address battery thermal management and thermal runaway protection, while ISO 26262 establishes functional safety requirements with implications for thermal and mechanical stability in safety-critical systems.

Manufacturers must implement comprehensive testing regimes that simulate extreme operating conditions. These include thermal shock testing (cycling between -40°C and 125°C), vibration testing at various frequencies and amplitudes, and combined environmental stress testing that simultaneously applies thermal, mechanical, and electrical stresses to validate component integrity.

Documentation requirements represent another critical aspect of compliance. Manufacturers must maintain detailed records of material properties, test results, and validation procedures. This documentation serves as evidence of compliance during regulatory audits and is essential for product liability protection.

The compliance landscape continues to evolve, with increasing focus on harmonizing global standards through initiatives like the 1998 Agreement under the United Nations Economic Commission for Europe. This evolution aims to reduce regulatory fragmentation while maintaining or enhancing safety requirements for thermal and mechanical stability across international markets.

These standards specifically address thermal stability through requirements such as FMVSS 302 for flammability of interior materials, which mandates that components must maintain integrity under specified heat conditions. Similarly, ECE R118 establishes comprehensive burning behavior parameters for materials used in vehicle construction, particularly focusing on their performance under thermal stress.

Mechanical stability compliance is primarily governed by standards like FMVSS 207/210 for seating systems and seat belt anchorages, which require components to withstand specific force loads without failure. ISO 16750 provides detailed environmental condition testing protocols, including mechanical shock, vibration resistance, and thermal cycling that automotive components must endure.

The compliance landscape is further complicated by emerging standards for electric and autonomous vehicles. SAE J2929 and UN GTR No. 20 address battery thermal management and thermal runaway protection, while ISO 26262 establishes functional safety requirements with implications for thermal and mechanical stability in safety-critical systems.

Manufacturers must implement comprehensive testing regimes that simulate extreme operating conditions. These include thermal shock testing (cycling between -40°C and 125°C), vibration testing at various frequencies and amplitudes, and combined environmental stress testing that simultaneously applies thermal, mechanical, and electrical stresses to validate component integrity.

Documentation requirements represent another critical aspect of compliance. Manufacturers must maintain detailed records of material properties, test results, and validation procedures. This documentation serves as evidence of compliance during regulatory audits and is essential for product liability protection.

The compliance landscape continues to evolve, with increasing focus on harmonizing global standards through initiatives like the 1998 Agreement under the United Nations Economic Commission for Europe. This evolution aims to reduce regulatory fragmentation while maintaining or enhancing safety requirements for thermal and mechanical stability across international markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!