Addressing Coil Whine in Dense Electronic Environments

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Origins

Coil whine is an audible electromagnetic phenomenon that occurs in electronic devices, particularly in dense electronic environments. This high-frequency noise is primarily caused by the vibration of electromagnetic components, most commonly inductors and transformers, under varying electrical loads. The origin of coil whine can be traced back to the fundamental principles of electromagnetism and the design of modern electronic circuits.

At its core, coil whine is a result of magnetostriction, a property of ferromagnetic materials that causes them to change shape when subjected to a magnetic field. In electronic components like inductors and transformers, the alternating current flowing through the windings creates a fluctuating magnetic field. This field causes the core material to expand and contract rapidly, producing mechanical vibrations that manifest as audible noise.

The frequency of coil whine typically falls within the range of human hearing, usually between 1 kHz and 20 kHz. The intensity and pitch of the noise can vary depending on the specific electrical characteristics of the circuit and the load conditions. In dense electronic environments, where multiple components are packed closely together, the problem can be exacerbated due to resonance effects and the cumulative impact of multiple sources.

The prevalence of coil whine has increased in recent years due to several factors in modern electronics design. The trend towards higher switching frequencies in power supplies and voltage regulators has pushed the vibrations into more audible ranges. Additionally, the miniaturization of electronic devices has led to denser circuit layouts, which can amplify the issue by creating resonant cavities and reducing the effectiveness of traditional damping methods.

Another contributing factor to the prominence of coil whine is the widespread adoption of pulse-width modulation (PWM) techniques for power management. While PWM is highly efficient, it introduces rapid changes in current flow, which can excite electromagnetic components and produce more noticeable coil whine. This is particularly evident in devices with variable power demands, such as computers and smartphones, where the constant adjustment of power delivery can lead to fluctuating noise levels.

The materials used in electronic components also play a crucial role in the generation of coil whine. Ferrite cores, commonly used in inductors and transformers, are particularly susceptible to magnetostriction. The choice of core material, winding technique, and overall component design can significantly influence the likelihood and severity of coil whine in a given circuit.

Understanding the origins of coil whine is essential for developing effective mitigation strategies. By recognizing the fundamental physical principles at play, engineers can approach the problem from multiple angles, including material selection, circuit design, and system-level considerations. This comprehensive understanding forms the basis for innovative solutions to address coil whine in increasingly complex and compact electronic environments.

At its core, coil whine is a result of magnetostriction, a property of ferromagnetic materials that causes them to change shape when subjected to a magnetic field. In electronic components like inductors and transformers, the alternating current flowing through the windings creates a fluctuating magnetic field. This field causes the core material to expand and contract rapidly, producing mechanical vibrations that manifest as audible noise.

The frequency of coil whine typically falls within the range of human hearing, usually between 1 kHz and 20 kHz. The intensity and pitch of the noise can vary depending on the specific electrical characteristics of the circuit and the load conditions. In dense electronic environments, where multiple components are packed closely together, the problem can be exacerbated due to resonance effects and the cumulative impact of multiple sources.

The prevalence of coil whine has increased in recent years due to several factors in modern electronics design. The trend towards higher switching frequencies in power supplies and voltage regulators has pushed the vibrations into more audible ranges. Additionally, the miniaturization of electronic devices has led to denser circuit layouts, which can amplify the issue by creating resonant cavities and reducing the effectiveness of traditional damping methods.

Another contributing factor to the prominence of coil whine is the widespread adoption of pulse-width modulation (PWM) techniques for power management. While PWM is highly efficient, it introduces rapid changes in current flow, which can excite electromagnetic components and produce more noticeable coil whine. This is particularly evident in devices with variable power demands, such as computers and smartphones, where the constant adjustment of power delivery can lead to fluctuating noise levels.

The materials used in electronic components also play a crucial role in the generation of coil whine. Ferrite cores, commonly used in inductors and transformers, are particularly susceptible to magnetostriction. The choice of core material, winding technique, and overall component design can significantly influence the likelihood and severity of coil whine in a given circuit.

Understanding the origins of coil whine is essential for developing effective mitigation strategies. By recognizing the fundamental physical principles at play, engineers can approach the problem from multiple angles, including material selection, circuit design, and system-level considerations. This comprehensive understanding forms the basis for innovative solutions to address coil whine in increasingly complex and compact electronic environments.

Market Impact Analysis

The market impact of addressing coil whine in dense electronic environments is significant and multifaceted. As electronic devices continue to shrink in size while increasing in power and complexity, the issue of coil whine has become more prevalent and problematic. This phenomenon not only affects user experience but also has implications for product design, manufacturing costs, and market competitiveness.

In the consumer electronics sector, coil whine has become a notable concern, particularly in high-performance devices such as gaming laptops, graphics cards, and power supplies. The presence of audible coil whine can lead to customer dissatisfaction, increased product returns, and negative brand perception. Manufacturers who successfully mitigate this issue gain a competitive edge, potentially increasing their market share and customer loyalty.

The enterprise and data center markets are also significantly impacted by coil whine solutions. With the increasing density of server racks and the push for energy efficiency, addressing coil whine becomes crucial for maintaining a suitable working environment and meeting noise level regulations. Companies that offer quieter, more efficient hardware solutions are likely to see increased demand from data center operators and enterprises with large-scale computing needs.

In the automotive industry, the transition to electric vehicles (EVs) has brought coil whine to the forefront of design considerations. As EVs rely heavily on power electronics, addressing coil whine is essential for maintaining cabin comfort and meeting noise, vibration, and harshness (NVH) standards. Manufacturers who excel in this area can differentiate their products in a rapidly growing and competitive market.

The impact extends to the component supply chain as well. Suppliers who develop innovative materials, designs, or manufacturing techniques to reduce coil whine stand to gain significant market share. This includes manufacturers of inductors, transformers, and other magnetic components, as well as producers of specialized coatings and encapsulation materials.

From a regulatory perspective, addressing coil whine aligns with increasingly stringent electromagnetic compatibility (EMC) and noise emission standards. Products that effectively manage coil whine are more likely to pass regulatory requirements, facilitating easier market entry and reducing compliance-related costs.

The financial implications of addressing coil whine are substantial. While implementing solutions may increase production costs in the short term, the long-term benefits in terms of reduced warranty claims, improved product reliability, and enhanced brand reputation can lead to significant cost savings and revenue growth. Companies that invest in research and development to tackle this issue are likely to see returns in the form of increased sales and market leadership.

In the consumer electronics sector, coil whine has become a notable concern, particularly in high-performance devices such as gaming laptops, graphics cards, and power supplies. The presence of audible coil whine can lead to customer dissatisfaction, increased product returns, and negative brand perception. Manufacturers who successfully mitigate this issue gain a competitive edge, potentially increasing their market share and customer loyalty.

The enterprise and data center markets are also significantly impacted by coil whine solutions. With the increasing density of server racks and the push for energy efficiency, addressing coil whine becomes crucial for maintaining a suitable working environment and meeting noise level regulations. Companies that offer quieter, more efficient hardware solutions are likely to see increased demand from data center operators and enterprises with large-scale computing needs.

In the automotive industry, the transition to electric vehicles (EVs) has brought coil whine to the forefront of design considerations. As EVs rely heavily on power electronics, addressing coil whine is essential for maintaining cabin comfort and meeting noise, vibration, and harshness (NVH) standards. Manufacturers who excel in this area can differentiate their products in a rapidly growing and competitive market.

The impact extends to the component supply chain as well. Suppliers who develop innovative materials, designs, or manufacturing techniques to reduce coil whine stand to gain significant market share. This includes manufacturers of inductors, transformers, and other magnetic components, as well as producers of specialized coatings and encapsulation materials.

From a regulatory perspective, addressing coil whine aligns with increasingly stringent electromagnetic compatibility (EMC) and noise emission standards. Products that effectively manage coil whine are more likely to pass regulatory requirements, facilitating easier market entry and reducing compliance-related costs.

The financial implications of addressing coil whine are substantial. While implementing solutions may increase production costs in the short term, the long-term benefits in terms of reduced warranty claims, improved product reliability, and enhanced brand reputation can lead to significant cost savings and revenue growth. Companies that invest in research and development to tackle this issue are likely to see returns in the form of increased sales and market leadership.

Technical Challenges

Coil whine in dense electronic environments presents a significant challenge for engineers and manufacturers. This high-frequency noise, typically ranging from 2 kHz to 20 kHz, is caused by electromagnetic forces acting on components, particularly inductors and transformers. As electronic devices become more compact and powerful, the issue of coil whine becomes increasingly prevalent and difficult to mitigate.

One of the primary technical challenges in addressing coil whine is the complex interplay between electrical, mechanical, and acoustic factors. The vibrations causing the whine are often a result of magnetostriction, where magnetic materials change shape under the influence of magnetic fields. This phenomenon is particularly problematic in switching power supplies and voltage regulators, which are essential components in modern electronics.

The miniaturization trend in electronics exacerbates the coil whine issue. As devices shrink, components are packed more tightly, leading to increased electromagnetic interference (EMI) and reduced space for implementing traditional noise reduction techniques. This densification also results in higher operating frequencies, which can push coil whine into more audible ranges.

Another significant challenge is the variability of coil whine across different units of the same product. Factors such as manufacturing tolerances, component quality, and even ambient temperature can influence the intensity and frequency of the noise. This inconsistency makes it difficult to implement a one-size-fits-all solution and necessitates a more comprehensive approach to noise reduction.

The thermal management of dense electronic environments further complicates coil whine mitigation. Higher power densities lead to increased heat generation, which can affect the mechanical properties of components and exacerbate vibrations. Balancing thermal management with noise reduction often requires trade-offs that can impact overall system performance.

Regulatory compliance adds another layer of complexity to addressing coil whine. Electronic devices must meet stringent electromagnetic compatibility (EMC) standards, which limit both conducted and radiated emissions. Solutions to coil whine must not only reduce audible noise but also ensure that the device remains compliant with these regulations.

The cost-effectiveness of coil whine solutions is a critical consideration for manufacturers. High-end techniques such as active noise cancellation or the use of premium, low-noise components can significantly increase production costs. Finding a balance between effective noise reduction and economic viability is a persistent challenge in the industry.

Lastly, the interdisciplinary nature of coil whine mitigation requires expertise across multiple domains, including electrical engineering, mechanical engineering, materials science, and acoustics. Developing comprehensive solutions often necessitates collaboration between specialists from these diverse fields, adding to the complexity of addressing this technical challenge in dense electronic environments.

One of the primary technical challenges in addressing coil whine is the complex interplay between electrical, mechanical, and acoustic factors. The vibrations causing the whine are often a result of magnetostriction, where magnetic materials change shape under the influence of magnetic fields. This phenomenon is particularly problematic in switching power supplies and voltage regulators, which are essential components in modern electronics.

The miniaturization trend in electronics exacerbates the coil whine issue. As devices shrink, components are packed more tightly, leading to increased electromagnetic interference (EMI) and reduced space for implementing traditional noise reduction techniques. This densification also results in higher operating frequencies, which can push coil whine into more audible ranges.

Another significant challenge is the variability of coil whine across different units of the same product. Factors such as manufacturing tolerances, component quality, and even ambient temperature can influence the intensity and frequency of the noise. This inconsistency makes it difficult to implement a one-size-fits-all solution and necessitates a more comprehensive approach to noise reduction.

The thermal management of dense electronic environments further complicates coil whine mitigation. Higher power densities lead to increased heat generation, which can affect the mechanical properties of components and exacerbate vibrations. Balancing thermal management with noise reduction often requires trade-offs that can impact overall system performance.

Regulatory compliance adds another layer of complexity to addressing coil whine. Electronic devices must meet stringent electromagnetic compatibility (EMC) standards, which limit both conducted and radiated emissions. Solutions to coil whine must not only reduce audible noise but also ensure that the device remains compliant with these regulations.

The cost-effectiveness of coil whine solutions is a critical consideration for manufacturers. High-end techniques such as active noise cancellation or the use of premium, low-noise components can significantly increase production costs. Finding a balance between effective noise reduction and economic viability is a persistent challenge in the industry.

Lastly, the interdisciplinary nature of coil whine mitigation requires expertise across multiple domains, including electrical engineering, mechanical engineering, materials science, and acoustics. Developing comprehensive solutions often necessitates collaboration between specialists from these diverse fields, adding to the complexity of addressing this technical challenge in dense electronic environments.

Mitigation Techniques

01 Noise reduction techniques for electronic devices

Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.- Noise reduction techniques for electronic devices: Various methods are employed to reduce coil whine noise in electronic devices. These include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. Such techniques aim to minimize electromagnetic vibrations that cause the audible whine, improving overall device performance and user experience.

- Coil design and construction for noise reduction: Innovative coil designs and construction methods are developed to mitigate coil whine. This includes using different winding techniques, core materials, and insulation methods. The goal is to reduce mechanical vibrations and electromagnetic interactions that contribute to the whine noise, resulting in quieter operation of electronic components.

- Power supply and voltage regulation improvements: Advancements in power supply design and voltage regulation techniques are implemented to address coil whine issues. These improvements focus on stabilizing power delivery, reducing electrical fluctuations, and optimizing current flow. By enhancing power management, the occurrence and intensity of coil whine can be significantly reduced in various electronic devices.

- Acoustic isolation and damping solutions: Acoustic isolation and damping techniques are applied to minimize the propagation of coil whine noise. This involves using specialized materials and designs to absorb or redirect sound waves generated by coil vibrations. These solutions can be implemented at the component level or integrated into the overall device enclosure design.

- Detection and measurement of coil whine: Advanced methods for detecting and measuring coil whine are developed to aid in diagnosis and mitigation efforts. These techniques involve specialized sensors, acoustic analysis tools, and testing procedures to accurately identify and characterize coil whine noise. Such methods enable more effective troubleshooting and targeted noise reduction strategies in electronic devices.

02 Coil design and construction for noise reduction

Innovative coil designs and construction methods are developed to mitigate coil whine noise. These may include using specialized winding techniques, incorporating dampening materials, or modifying the physical structure of the coils. The goal is to reduce mechanical vibrations and electromagnetic interactions that contribute to the whine noise.Expand Specific Solutions03 Power supply and voltage regulation improvements

Enhancements in power supply design and voltage regulation systems are implemented to address coil whine issues. These improvements focus on stabilizing power delivery, reducing electrical fluctuations, and optimizing current flow to minimize the conditions that lead to coil whine in electronic components.Expand Specific Solutions04 Acoustic isolation and dampening solutions

Various acoustic isolation and dampening techniques are employed to contain and reduce coil whine noise. These may include using sound-absorbing materials, implementing vibration isolation mounts, or designing enclosures that minimize sound transmission. The aim is to prevent the propagation of coil whine noise from the source to the user.Expand Specific Solutions05 Detection and measurement of coil whine

Advanced methods for detecting and measuring coil whine are developed to aid in diagnosis and mitigation efforts. These techniques may involve specialized sensors, acoustic analysis tools, or electromagnetic field detection systems. Accurate measurement helps in identifying the sources of coil whine and evaluating the effectiveness of noise reduction strategies.Expand Specific Solutions

Industry Leaders

The market for addressing coil whine in dense electronic environments is in a growth phase, driven by increasing demand for compact, high-performance devices. The global market size is expanding, with major players like TDK Corp., Murata Manufacturing, and Robert Bosch GmbH leading innovation. These companies are investing heavily in R&D to develop advanced solutions, indicating a moderate to high level of technological maturity. Emerging players such as WiTs Co., Ltd. and Elephantech Inc. are also contributing to the competitive landscape, focusing on niche applications and novel approaches to mitigate coil whine issues in various electronic products.

TDK Corp.

Technical Solution: TDK Corp. has developed advanced noise suppression technologies to address coil whine in dense electronic environments. Their approach includes the use of specialized magnetic materials and innovative coil designs. TDK's multilayer power inductors feature a unique internal structure that minimizes magnetic flux leakage, reducing electromagnetic interference and coil whine[1]. They have also implemented advanced shielding techniques, incorporating ferrite materials to contain electromagnetic fields and reduce audible noise[2]. Additionally, TDK has developed thin-film power inductors with high current ratings and low DC resistance, which help to minimize power losses and heat generation, further reducing the likelihood of coil whine[3].

Strengths: Expertise in magnetic materials, innovative coil designs, and advanced shielding techniques. Weaknesses: Potential higher costs due to specialized materials and manufacturing processes.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed a comprehensive approach to mitigate coil whine in dense electronic environments. Their solution incorporates advanced materials science and innovative design techniques. Murata's power inductors utilize a proprietary core material that exhibits low magnetostriction, significantly reducing mechanical vibrations that cause coil whine[1]. They have also implemented a unique winding technique that minimizes gaps between wire turns, reducing the potential for wire movement and associated noise[2]. Furthermore, Murata has developed a series of low-profile, high-current inductors with integrated shielding, which not only addresses space constraints in dense electronic environments but also contains electromagnetic fields to reduce interference and noise[3].

Strengths: Advanced materials science, innovative winding techniques, and integrated shielding solutions. Weaknesses: Possible limitations in extreme high-frequency applications.

Innovative Solutions

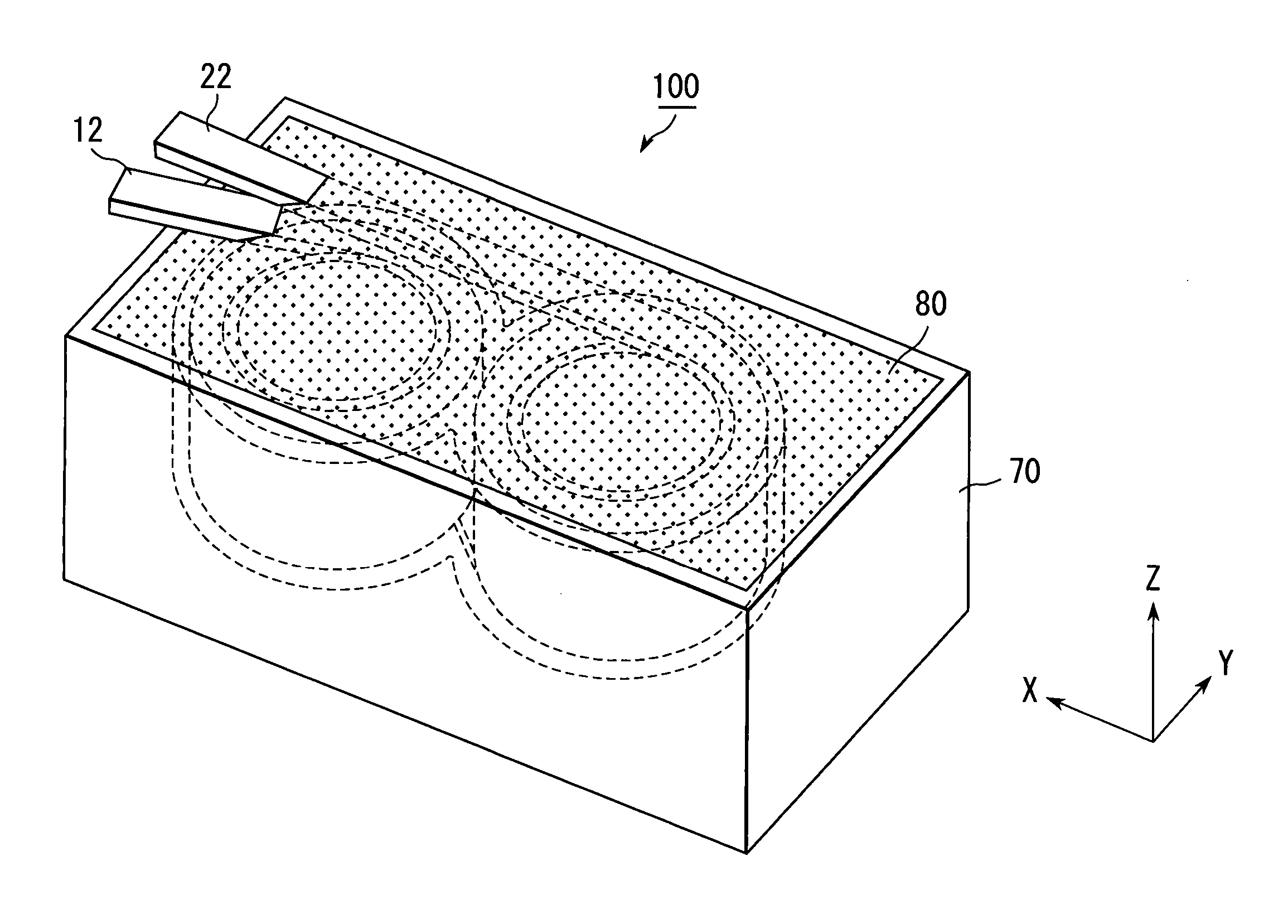

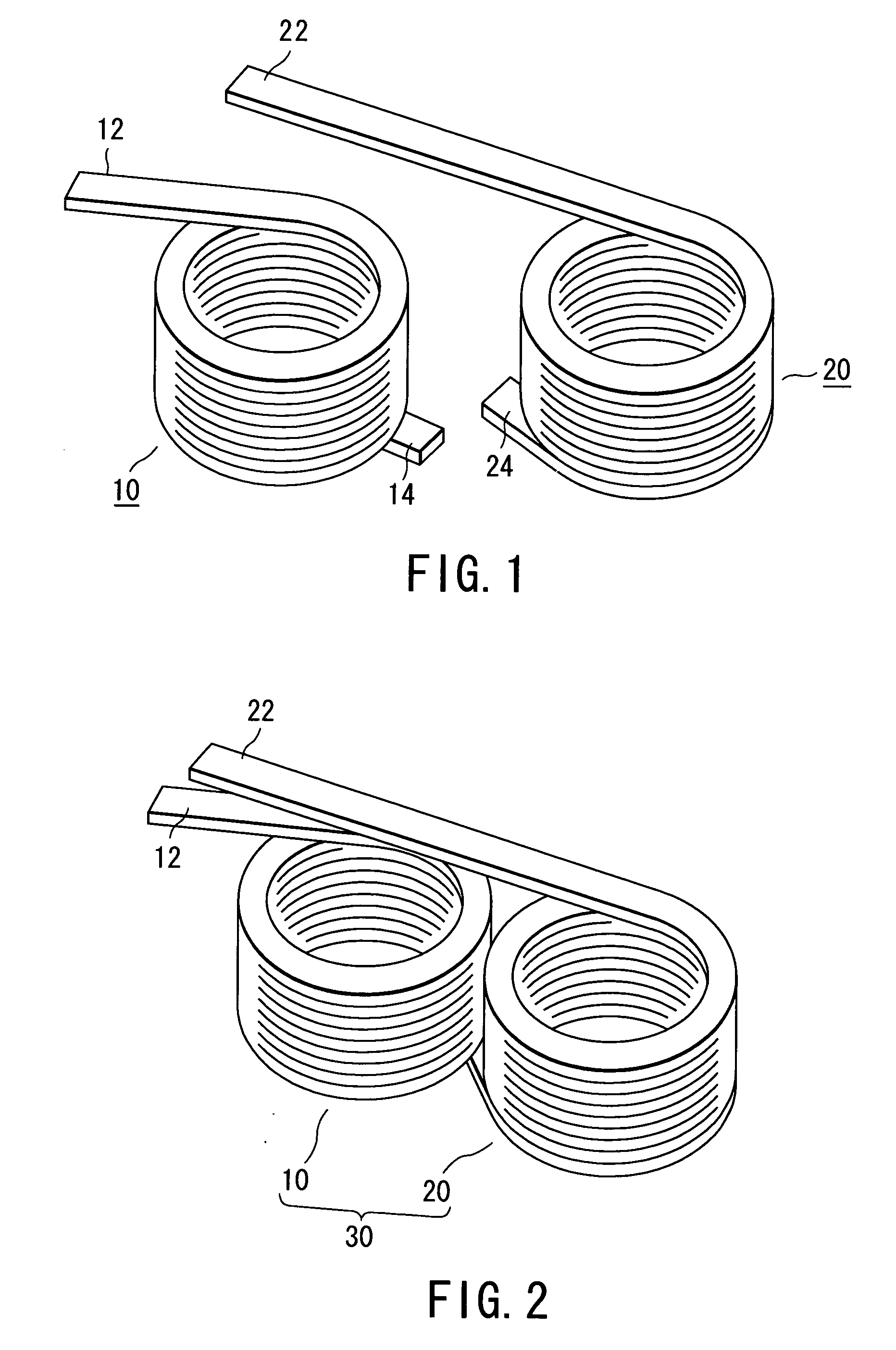

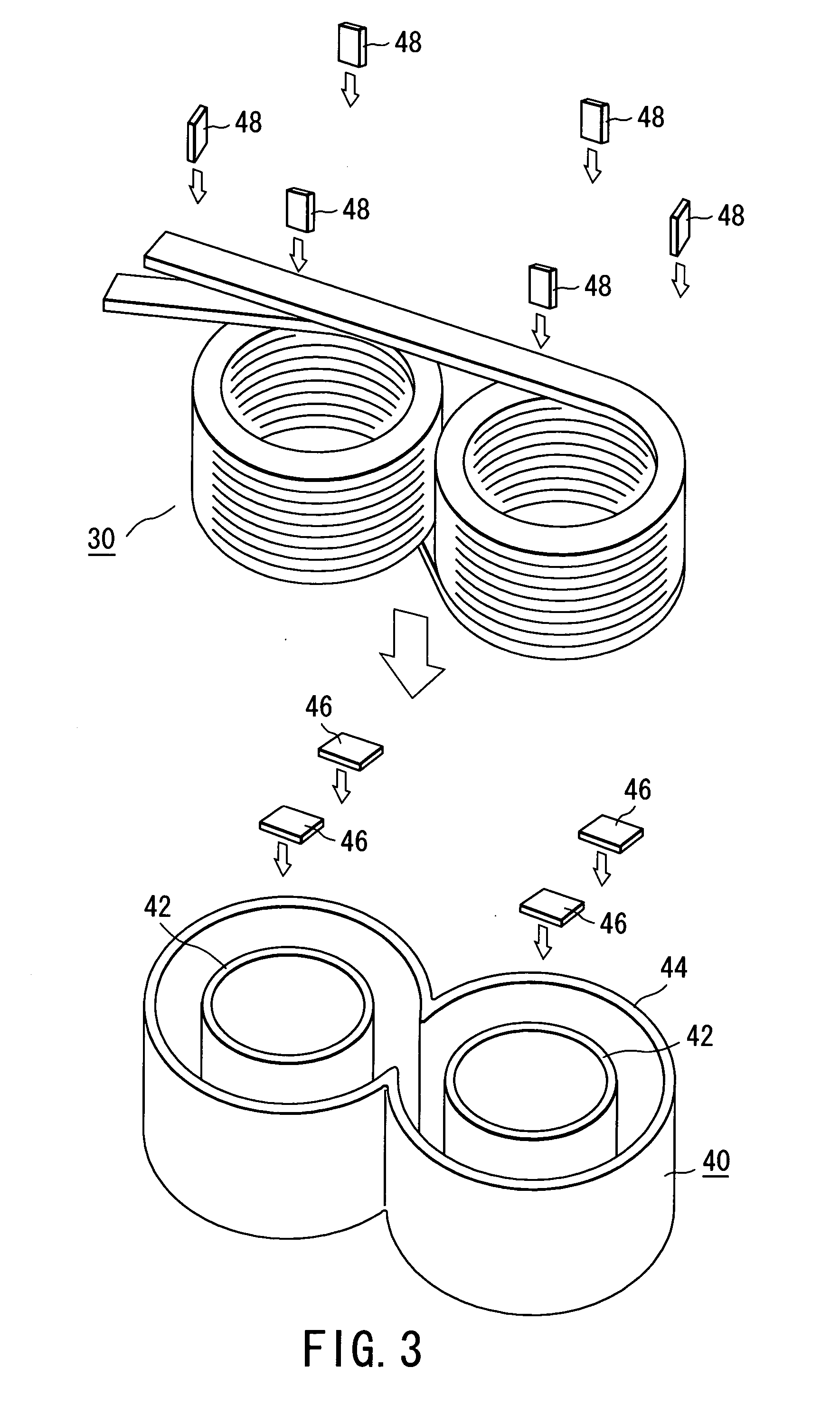

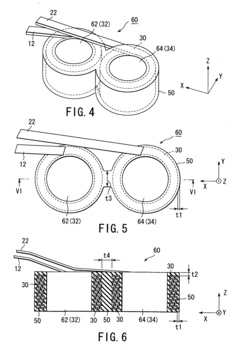

Coil component and fabricaiton method of the same

PatentInactiveUS20050012581A1

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin and a magnetic core composed of a mixture of resin and magnetic powder, where the insulator enclosure is embedded within the magnetic core, enhancing the component's structural integrity and noise suppression capabilities.

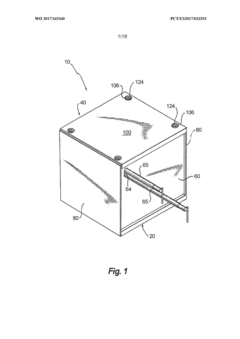

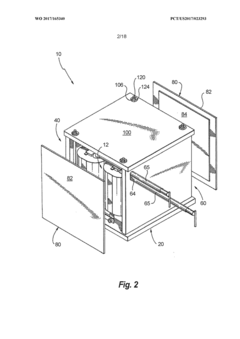

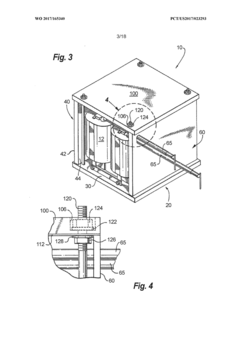

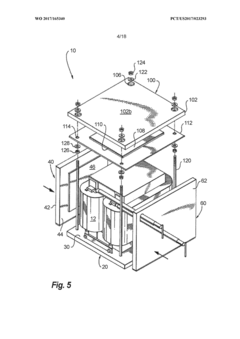

Noise reducing and cooling enclosure

PatentWO2017165340A1

Innovation

- The enclosure is constructed with multi-layered plate assemblies made of thermally conductive and acoustic quieting materials, which block and dissipate acoustic energy, using a combination of rigid acoustic blocking materials and thermally conductive materials to absorb and conduct heat away from the device.

EMC Regulations

Electromagnetic Compatibility (EMC) regulations play a crucial role in addressing coil whine issues in dense electronic environments. These regulations are designed to ensure that electronic devices can function without causing or experiencing electromagnetic interference. In the context of coil whine, EMC regulations are particularly relevant as they aim to limit the emission of electromagnetic noise and ensure the resilience of devices against external electromagnetic disturbances.

The International Electrotechnical Commission (IEC) sets global standards for EMC, with IEC 61000 being the primary series of standards addressing electromagnetic compatibility. These standards cover various aspects of EMC, including emission limits, immunity requirements, and testing methodologies. For coil whine specifically, the IEC 61000-3-2 standard is particularly relevant, as it deals with harmonic current emissions in low-voltage systems.

In the United States, the Federal Communications Commission (FCC) enforces EMC regulations through its Part 15 rules. These rules set limits on the electromagnetic emissions from electronic devices, including those that might contribute to coil whine. The FCC categorizes devices into Class A (for industrial and commercial use) and Class B (for residential use), with Class B having more stringent emission limits.

The European Union enforces EMC regulations through the EMC Directive (2014/30/EU). This directive requires all electronic equipment sold in the EU to meet specific EMC standards, ensuring that devices do not generate electromagnetic disturbances above a certain level and have an adequate level of immunity to external electromagnetic interference.

For manufacturers addressing coil whine in dense electronic environments, compliance with these regulations is not just a legal requirement but also a design imperative. EMC regulations often necessitate the implementation of specific design techniques and the use of specialized components to mitigate electromagnetic emissions. This may include the use of shielding materials, proper grounding techniques, and the strategic placement of components to minimize electromagnetic coupling.

Testing for EMC compliance is a critical part of the product development process. Manufacturers must conduct various tests, including radiated and conducted emissions tests, to ensure their products meet the required standards. For coil whine specifically, audio frequency magnetic field immunity tests (as per IEC 61000-4-8) may be particularly relevant.

As electronic devices become more compact and powerful, adhering to EMC regulations while addressing coil whine becomes increasingly challenging. This has led to ongoing research and development in EMC-compliant design techniques and materials, driving innovation in the field of electromagnetic compatibility.

The International Electrotechnical Commission (IEC) sets global standards for EMC, with IEC 61000 being the primary series of standards addressing electromagnetic compatibility. These standards cover various aspects of EMC, including emission limits, immunity requirements, and testing methodologies. For coil whine specifically, the IEC 61000-3-2 standard is particularly relevant, as it deals with harmonic current emissions in low-voltage systems.

In the United States, the Federal Communications Commission (FCC) enforces EMC regulations through its Part 15 rules. These rules set limits on the electromagnetic emissions from electronic devices, including those that might contribute to coil whine. The FCC categorizes devices into Class A (for industrial and commercial use) and Class B (for residential use), with Class B having more stringent emission limits.

The European Union enforces EMC regulations through the EMC Directive (2014/30/EU). This directive requires all electronic equipment sold in the EU to meet specific EMC standards, ensuring that devices do not generate electromagnetic disturbances above a certain level and have an adequate level of immunity to external electromagnetic interference.

For manufacturers addressing coil whine in dense electronic environments, compliance with these regulations is not just a legal requirement but also a design imperative. EMC regulations often necessitate the implementation of specific design techniques and the use of specialized components to mitigate electromagnetic emissions. This may include the use of shielding materials, proper grounding techniques, and the strategic placement of components to minimize electromagnetic coupling.

Testing for EMC compliance is a critical part of the product development process. Manufacturers must conduct various tests, including radiated and conducted emissions tests, to ensure their products meet the required standards. For coil whine specifically, audio frequency magnetic field immunity tests (as per IEC 61000-4-8) may be particularly relevant.

As electronic devices become more compact and powerful, adhering to EMC regulations while addressing coil whine becomes increasingly challenging. This has led to ongoing research and development in EMC-compliant design techniques and materials, driving innovation in the field of electromagnetic compatibility.

Acoustic Engineering

Acoustic engineering plays a crucial role in addressing coil whine issues in dense electronic environments. This field focuses on the study and manipulation of sound waves to control noise and vibration in various systems. In the context of coil whine, acoustic engineering principles are applied to identify, analyze, and mitigate the high-frequency noise produced by electromagnetic components in electronic devices.

One of the primary approaches in acoustic engineering for coil whine reduction is the implementation of advanced damping materials. These materials are specifically designed to absorb and dissipate vibrational energy, effectively reducing the amplitude of sound waves generated by coil vibrations. Engineers carefully select and position these damping materials within electronic devices to target the most problematic areas of noise generation.

Another key aspect of acoustic engineering in this context is the optimization of component placement and orientation. By strategically arranging electronic components and considering their interactions, engineers can minimize the propagation of vibrations and reduce the overall noise output. This may involve creating physical barriers or utilizing isolation techniques to prevent the transmission of vibrations between components.

Acoustic modeling and simulation tools are extensively employed in the design phase to predict and analyze the behavior of sound waves within electronic enclosures. These sophisticated software applications allow engineers to visualize sound propagation, identify resonance frequencies, and evaluate the effectiveness of various noise reduction strategies before physical prototyping.

Furthermore, acoustic engineering techniques extend to the design of enclosures and chassis for electronic devices. By incorporating acoustic treatments such as sound-absorbing materials, diffusers, and resonators into the device housing, engineers can significantly reduce the transmission of coil whine to the external environment. This approach not only addresses the immediate noise issue but also enhances the overall acoustic performance of the device.

Advanced signal processing techniques are also utilized in acoustic engineering to actively cancel or mask coil whine. This may involve the implementation of active noise control systems that generate anti-noise signals to destructively interfere with the unwanted sound waves. While more complex to implement, these active solutions can provide highly effective noise reduction in scenarios where passive methods alone are insufficient.

In conclusion, acoustic engineering offers a comprehensive toolkit for addressing coil whine in dense electronic environments. By combining passive and active noise control strategies, optimizing component layouts, and leveraging advanced materials and simulation tools, engineers can significantly reduce the impact of coil whine and improve the overall acoustic performance of electronic devices.

One of the primary approaches in acoustic engineering for coil whine reduction is the implementation of advanced damping materials. These materials are specifically designed to absorb and dissipate vibrational energy, effectively reducing the amplitude of sound waves generated by coil vibrations. Engineers carefully select and position these damping materials within electronic devices to target the most problematic areas of noise generation.

Another key aspect of acoustic engineering in this context is the optimization of component placement and orientation. By strategically arranging electronic components and considering their interactions, engineers can minimize the propagation of vibrations and reduce the overall noise output. This may involve creating physical barriers or utilizing isolation techniques to prevent the transmission of vibrations between components.

Acoustic modeling and simulation tools are extensively employed in the design phase to predict and analyze the behavior of sound waves within electronic enclosures. These sophisticated software applications allow engineers to visualize sound propagation, identify resonance frequencies, and evaluate the effectiveness of various noise reduction strategies before physical prototyping.

Furthermore, acoustic engineering techniques extend to the design of enclosures and chassis for electronic devices. By incorporating acoustic treatments such as sound-absorbing materials, diffusers, and resonators into the device housing, engineers can significantly reduce the transmission of coil whine to the external environment. This approach not only addresses the immediate noise issue but also enhances the overall acoustic performance of the device.

Advanced signal processing techniques are also utilized in acoustic engineering to actively cancel or mask coil whine. This may involve the implementation of active noise control systems that generate anti-noise signals to destructively interfere with the unwanted sound waves. While more complex to implement, these active solutions can provide highly effective noise reduction in scenarios where passive methods alone are insufficient.

In conclusion, acoustic engineering offers a comprehensive toolkit for addressing coil whine in dense electronic environments. By combining passive and active noise control strategies, optimizing component layouts, and leveraging advanced materials and simulation tools, engineers can significantly reduce the impact of coil whine and improve the overall acoustic performance of electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!