How to Optimize Inductor Designs to Prevent Coil Whine?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Inductor Coil Whine Background and Objectives

Coil whine is a persistent challenge in the design and operation of inductors, affecting various electronic devices and systems. This phenomenon, characterized by audible noise emanating from inductors under certain operating conditions, has become increasingly significant as electronic devices continue to shrink in size while demanding higher power efficiency. The background of coil whine traces back to the fundamental principles of electromagnetism and the physical properties of materials used in inductor construction.

Historically, coil whine was often overlooked or considered a minor issue in many applications. However, as consumer electronics have become more compact and performance-driven, the audible noise from inductors has emerged as a critical concern for manufacturers and end-users alike. The problem is particularly pronounced in high-frequency switching applications, such as those found in power supplies, voltage regulators, and modern computing devices.

The primary mechanism behind coil whine involves the interaction between magnetic fields and the physical structure of the inductor. As alternating current flows through the coil, it generates a fluctuating magnetic field. This field, in turn, causes minute physical deformations in the inductor's windings and core material. When these deformations occur at frequencies within the audible range (typically 20 Hz to 20 kHz), they produce the characteristic whine or buzz associated with the phenomenon.

The objectives of optimizing inductor designs to prevent coil whine are multifaceted. Primarily, the goal is to minimize or eliminate the audible noise without compromising the electrical performance of the inductor. This involves addressing several key aspects of inductor design and construction, including material selection, winding techniques, core geometry, and overall structural integrity.

Another critical objective is to develop design methodologies that can predict and mitigate coil whine early in the product development cycle. This proactive approach aims to reduce the need for costly redesigns and improve time-to-market for new electronic products. Additionally, there is a growing emphasis on creating inductor designs that remain quiet across a wide range of operating conditions, including varying frequencies, currents, and temperatures.

Furthermore, the optimization efforts seek to balance the reduction of coil whine with other important factors such as power efficiency, thermal management, and electromagnetic interference (EMI) suppression. This holistic approach recognizes that inductor design is a complex interplay of various performance parameters, and improvements in one area must not come at the expense of others.

As the electronics industry continues to evolve, with trends towards higher switching frequencies and more compact designs, the importance of addressing coil whine becomes even more pronounced. The ongoing research and development in this field aim not only to solve current challenges but also to anticipate and prevent future issues as technology advances.

Historically, coil whine was often overlooked or considered a minor issue in many applications. However, as consumer electronics have become more compact and performance-driven, the audible noise from inductors has emerged as a critical concern for manufacturers and end-users alike. The problem is particularly pronounced in high-frequency switching applications, such as those found in power supplies, voltage regulators, and modern computing devices.

The primary mechanism behind coil whine involves the interaction between magnetic fields and the physical structure of the inductor. As alternating current flows through the coil, it generates a fluctuating magnetic field. This field, in turn, causes minute physical deformations in the inductor's windings and core material. When these deformations occur at frequencies within the audible range (typically 20 Hz to 20 kHz), they produce the characteristic whine or buzz associated with the phenomenon.

The objectives of optimizing inductor designs to prevent coil whine are multifaceted. Primarily, the goal is to minimize or eliminate the audible noise without compromising the electrical performance of the inductor. This involves addressing several key aspects of inductor design and construction, including material selection, winding techniques, core geometry, and overall structural integrity.

Another critical objective is to develop design methodologies that can predict and mitigate coil whine early in the product development cycle. This proactive approach aims to reduce the need for costly redesigns and improve time-to-market for new electronic products. Additionally, there is a growing emphasis on creating inductor designs that remain quiet across a wide range of operating conditions, including varying frequencies, currents, and temperatures.

Furthermore, the optimization efforts seek to balance the reduction of coil whine with other important factors such as power efficiency, thermal management, and electromagnetic interference (EMI) suppression. This holistic approach recognizes that inductor design is a complex interplay of various performance parameters, and improvements in one area must not come at the expense of others.

As the electronics industry continues to evolve, with trends towards higher switching frequencies and more compact designs, the importance of addressing coil whine becomes even more pronounced. The ongoing research and development in this field aim not only to solve current challenges but also to anticipate and prevent future issues as technology advances.

Market Demand for Quiet Electronic Devices

The market demand for quiet electronic devices has been steadily increasing in recent years, driven by consumer preferences for more comfortable and less intrusive technology. This trend is particularly evident in the consumer electronics sector, where devices like laptops, smartphones, and home appliances are expected to operate silently or with minimal noise. The growing awareness of noise pollution and its impact on health and productivity has further fueled this demand.

In the professional and industrial sectors, there is a significant push for quieter equipment in office environments, data centers, and manufacturing facilities. The need for noise reduction in these settings is not just a matter of comfort but also compliance with workplace safety regulations and environmental standards. This has led to a surge in demand for components and design solutions that can effectively mitigate issues like coil whine in electronic devices.

The automotive industry has also become a key driver in the market for quiet electronic components. With the rise of electric and hybrid vehicles, which are inherently quieter than traditional combustion engine vehicles, any extraneous noise from electronic components becomes more noticeable and less tolerable. This has prompted automotive manufacturers to seek advanced solutions for noise reduction in their electrical systems.

Consumer surveys and market research indicate that noise levels are increasingly becoming a deciding factor in purchasing decisions for electronic products. Users are willing to pay a premium for devices that offer quieter operation, especially in personal computing and home entertainment systems. This consumer behavior has prompted manufacturers to prioritize noise reduction in their product development cycles.

The healthcare sector presents another significant market for quiet electronic devices. Hospitals and medical facilities require equipment that operates with minimal noise to maintain a calm environment for patients and to prevent disruptions in sensitive procedures. This has created a niche market for specialized, low-noise medical equipment and devices.

As urban populations grow and living spaces become more compact, the demand for quiet electronic devices in residential settings has also increased. Consumers are seeking appliances and entertainment systems that do not disturb the peace of their homes or neighbors, especially in apartment buildings and shared living spaces.

The market trend towards miniaturization and increased power density in electronic devices has paradoxically increased the challenge of noise reduction. As components are packed more tightly and operate at higher frequencies, issues like coil whine become more prevalent. This has created a strong market pull for innovative solutions in inductor design and other noise-reducing technologies.

In the professional and industrial sectors, there is a significant push for quieter equipment in office environments, data centers, and manufacturing facilities. The need for noise reduction in these settings is not just a matter of comfort but also compliance with workplace safety regulations and environmental standards. This has led to a surge in demand for components and design solutions that can effectively mitigate issues like coil whine in electronic devices.

The automotive industry has also become a key driver in the market for quiet electronic components. With the rise of electric and hybrid vehicles, which are inherently quieter than traditional combustion engine vehicles, any extraneous noise from electronic components becomes more noticeable and less tolerable. This has prompted automotive manufacturers to seek advanced solutions for noise reduction in their electrical systems.

Consumer surveys and market research indicate that noise levels are increasingly becoming a deciding factor in purchasing decisions for electronic products. Users are willing to pay a premium for devices that offer quieter operation, especially in personal computing and home entertainment systems. This consumer behavior has prompted manufacturers to prioritize noise reduction in their product development cycles.

The healthcare sector presents another significant market for quiet electronic devices. Hospitals and medical facilities require equipment that operates with minimal noise to maintain a calm environment for patients and to prevent disruptions in sensitive procedures. This has created a niche market for specialized, low-noise medical equipment and devices.

As urban populations grow and living spaces become more compact, the demand for quiet electronic devices in residential settings has also increased. Consumers are seeking appliances and entertainment systems that do not disturb the peace of their homes or neighbors, especially in apartment buildings and shared living spaces.

The market trend towards miniaturization and increased power density in electronic devices has paradoxically increased the challenge of noise reduction. As components are packed more tightly and operate at higher frequencies, issues like coil whine become more prevalent. This has created a strong market pull for innovative solutions in inductor design and other noise-reducing technologies.

Current Challenges in Inductor Noise Reduction

Coil whine, a persistent challenge in inductor design, continues to pose significant obstacles for engineers and manufacturers in the power electronics industry. This high-frequency noise, typically ranging from 1 kHz to 20 kHz, is not only a nuisance but can also impact the overall performance and reliability of electronic devices. The primary source of this issue lies in the magnetostriction effect, where magnetic materials change shape under the influence of magnetic fields.

One of the main challenges in addressing coil whine is the complex interplay between various design parameters. Factors such as core material selection, winding technique, and overall inductor geometry all contribute to the noise generation process. Engineers must balance these elements while maintaining the inductor's electrical performance, making optimization a multifaceted problem.

The selection of core materials presents a particular challenge. While materials with low magnetostriction, such as certain ferrites or powdered iron cores, can help reduce coil whine, they may not always provide the optimal magnetic properties required for specific applications. This trade-off between noise reduction and electrical performance often necessitates compromises in design.

Another significant hurdle is the difficulty in predicting and modeling coil whine accurately. The noise generation mechanism involves complex interactions between electromagnetic fields, mechanical vibrations, and acoustic phenomena. Current simulation tools often struggle to capture these interactions comprehensively, leading to discrepancies between predicted and actual performance.

Manufacturing tolerances and consistency also play a crucial role in coil whine reduction. Even small variations in core geometry, air gaps, or winding tension can significantly impact noise generation. Achieving tight tolerances consistently across large production volumes remains a challenge for many manufacturers.

The operating environment of the inductor further complicates noise reduction efforts. Factors such as temperature fluctuations, mechanical stress, and electromagnetic interference from surrounding components can all influence coil whine characteristics. Designing inductors that maintain low noise performance across a wide range of operating conditions is a significant engineering challenge.

As electronic devices continue to shrink in size while increasing in power density, the space available for inductors becomes increasingly constrained. This miniaturization trend exacerbates the coil whine issue, as smaller inductors are generally more prone to noise generation. Balancing size reduction with effective noise suppression represents a ongoing challenge for designers.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, electromagnetic theory, mechanical engineering, and acoustic analysis. As the demand for quieter and more efficient power electronics grows, overcoming these obstacles in inductor noise reduction remains a critical focus for research and development in the field.

One of the main challenges in addressing coil whine is the complex interplay between various design parameters. Factors such as core material selection, winding technique, and overall inductor geometry all contribute to the noise generation process. Engineers must balance these elements while maintaining the inductor's electrical performance, making optimization a multifaceted problem.

The selection of core materials presents a particular challenge. While materials with low magnetostriction, such as certain ferrites or powdered iron cores, can help reduce coil whine, they may not always provide the optimal magnetic properties required for specific applications. This trade-off between noise reduction and electrical performance often necessitates compromises in design.

Another significant hurdle is the difficulty in predicting and modeling coil whine accurately. The noise generation mechanism involves complex interactions between electromagnetic fields, mechanical vibrations, and acoustic phenomena. Current simulation tools often struggle to capture these interactions comprehensively, leading to discrepancies between predicted and actual performance.

Manufacturing tolerances and consistency also play a crucial role in coil whine reduction. Even small variations in core geometry, air gaps, or winding tension can significantly impact noise generation. Achieving tight tolerances consistently across large production volumes remains a challenge for many manufacturers.

The operating environment of the inductor further complicates noise reduction efforts. Factors such as temperature fluctuations, mechanical stress, and electromagnetic interference from surrounding components can all influence coil whine characteristics. Designing inductors that maintain low noise performance across a wide range of operating conditions is a significant engineering challenge.

As electronic devices continue to shrink in size while increasing in power density, the space available for inductors becomes increasingly constrained. This miniaturization trend exacerbates the coil whine issue, as smaller inductors are generally more prone to noise generation. Balancing size reduction with effective noise suppression represents a ongoing challenge for designers.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, electromagnetic theory, mechanical engineering, and acoustic analysis. As the demand for quieter and more efficient power electronics grows, overcoming these obstacles in inductor noise reduction remains a critical focus for research and development in the field.

Existing Solutions for Coil Whine Mitigation

01 Coil design optimization

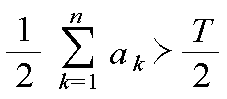

Optimizing the design of inductor coils can help reduce coil whine. This includes adjusting the winding pattern, core material selection, and overall geometry of the coil to minimize vibrations and resonance frequencies that contribute to audible noise.- Coil design optimization: Optimizing the design of inductor coils can help reduce coil whine. This includes adjusting the winding pattern, core material selection, and overall geometry of the coil to minimize vibrations and resonance frequencies that contribute to audible noise.

- Vibration dampening techniques: Implementing vibration dampening techniques can significantly reduce coil whine. This may involve using specialized materials or structures to absorb or dissipate mechanical vibrations generated by the inductor coil during operation.

- Encapsulation and insulation methods: Encapsulating or insulating the inductor coil can help minimize coil whine by reducing the transmission of vibrations to surrounding components and the environment. This may include using potting compounds, specialized coatings, or isolation materials.

- Frequency modulation and control: Implementing frequency modulation or control techniques can help reduce coil whine by avoiding resonant frequencies or distributing the noise across a wider frequency spectrum, making it less noticeable to human ears.

- Magnetic field shaping: Shaping the magnetic field generated by the inductor coil can help reduce coil whine. This may involve using specialized core geometries, magnetic shielding materials, or field-focusing techniques to minimize stray magnetic fields that can contribute to vibrations and noise.

02 Vibration dampening techniques

Implementing vibration dampening techniques can significantly reduce coil whine. This may involve using specialized materials or structures to absorb and dissipate mechanical vibrations, or incorporating isolation mechanisms to prevent the transmission of vibrations to surrounding components.Expand Specific Solutions03 Electromagnetic shielding

Applying electromagnetic shielding to inductor coils can help mitigate coil whine by reducing electromagnetic interference and stray fields. This may involve using shielding materials or designing enclosures that contain and redirect electromagnetic energy.Expand Specific Solutions04 Frequency modulation and control

Implementing frequency modulation and control techniques can help reduce audible coil whine. This may involve adjusting the operating frequency of the circuit or using spread spectrum techniques to distribute the energy across a wider frequency range, making the noise less noticeable.Expand Specific Solutions05 Advanced manufacturing processes

Utilizing advanced manufacturing processes can improve the quality and consistency of inductor coils, reducing the likelihood of coil whine. This may include precision winding techniques, improved core material processing, or novel assembly methods that minimize mechanical stress and potential sources of vibration.Expand Specific Solutions

Key Players in Inductor Manufacturing

The competition landscape for optimizing inductor designs to prevent coil whine is characterized by a mature market with established players and ongoing technological advancements. The market size is substantial, driven by the increasing demand for high-performance electronic devices across various industries. Companies like Murata Manufacturing, TDK Corp., and Panasonic Holdings are at the forefront, leveraging their extensive experience in electronic component manufacturing. The technology is relatively mature, with continuous improvements focused on noise reduction, efficiency, and miniaturization. Emerging players such as Shenzhen Sunlord Electronics and TongFu Microelectronics are also contributing to innovation in this field, particularly in the areas of automotive and consumer electronics applications.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata's approach to optimizing inductor designs to prevent coil whine focuses on advanced materials and innovative construction techniques. They utilize high-performance ferrite materials with optimized magnetic properties to reduce core losses and minimize vibrations[1]. Their patented multi-layer winding technology distributes the magnetic field more evenly, reducing mechanical stress on the coil[2]. Additionally, Murata implements a unique encapsulation process that uses specialized resins to dampen vibrations and absorb acoustic energy[3]. This comprehensive approach addresses both the electromagnetic and mechanical aspects of coil whine, resulting in inductors with significantly reduced noise emissions.

Strengths: Superior noise reduction, high-performance materials, and innovative construction techniques. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic's approach to optimizing inductor designs for coil whine prevention centers on advanced simulation techniques and precision manufacturing. They employ sophisticated finite element analysis (FEA) models to predict and mitigate electromagnetic-induced vibrations at the design stage[7]. Their proprietary winding technique utilizes ultra-thin, high-purity copper wire with optimized tensioning to minimize mechanical resonances[8]. Panasonic also implements a unique core structure with strategically placed air gaps to reduce flux concentration and associated vibrations. Additionally, they use a specialized potting compound with tailored viscoelastic properties to absorb vibrations across a wide frequency spectrum[9]. This comprehensive approach results in inductors with exceptional noise performance and reliability.

Strengths: Advanced simulation capabilities, precision manufacturing techniques, and innovative core designs. Weaknesses: Potentially longer design cycles and higher initial development costs.

Core Innovations in Quiet Inductor Technology

Optimal inductor

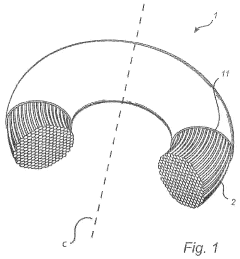

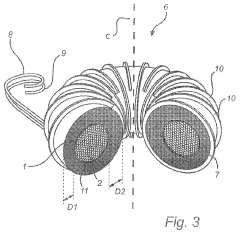

PatentInactiveUS20200243241A1

Innovation

- A toroidal coil with a high thermal heat conduction and a soft magnetic composite core, where the coil is wound with insulated strands and coated with resin to minimize voids and enhance thermal conductivity, and the core is magnetically aligned with the H-field to optimize magnetic field distribution and reduce losses.

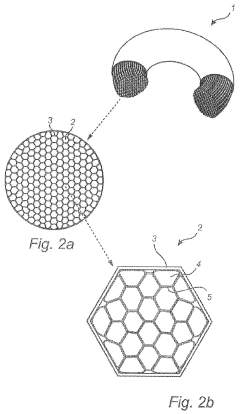

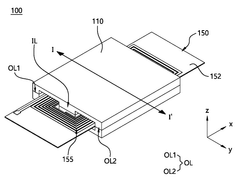

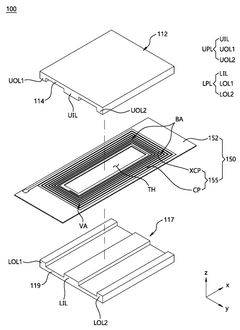

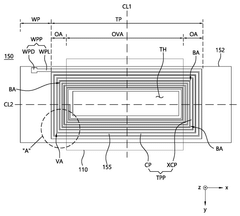

Inductor

PatentWO2023121021A1

Innovation

- The design features a spiral coil pattern with increasing width from the inner to the outer magnetic core, incorporating overlapping and non-overlapping coil patterns with varying widths and spacings, connected via holes, to enhance inductance and reduce resistance.

Electromagnetic Compatibility Regulations

Electromagnetic Compatibility (EMC) regulations play a crucial role in the optimization of inductor designs to prevent coil whine. These regulations are established to ensure that electronic devices do not interfere with each other or with other electrical systems. In the context of inductor design, compliance with EMC regulations is essential to minimize electromagnetic interference (EMI) and maintain the overall performance of electronic systems.

The International Electrotechnical Commission (IEC) sets global standards for EMC, with IEC 61000 being the primary series of standards addressing electromagnetic compatibility. These standards define limits for electromagnetic emissions and immunity levels for various types of equipment. For inductor designs, particularly relevant are the IEC 61000-3 series, which focus on emission limits, and the IEC 61000-4 series, which deal with testing and measurement techniques.

In the United States, the Federal Communications Commission (FCC) enforces EMC regulations. Part 15 of the FCC rules is particularly relevant for inductor designs, as it covers unintentional radiators. These regulations set limits on the amount of electromagnetic energy that devices can emit, which directly impacts the design considerations for inductors to prevent coil whine.

The European Union enforces EMC regulations through the EMC Directive (2014/30/EU). This directive requires all electronic equipment sold in the EU to meet specific EMC standards, including those related to inductor performance and coil whine prevention. Manufacturers must ensure their products comply with these regulations before obtaining CE marking for market access.

To optimize inductor designs in compliance with EMC regulations, several key factors must be considered. These include the selection of core materials with low electromagnetic emissions, the implementation of shielding techniques to contain electromagnetic fields, and the careful design of winding patterns to minimize stray capacitance and mutual inductance.

Furthermore, EMC regulations often require specific testing procedures to verify compliance. These may include conducted emissions tests, radiated emissions tests, and immunity tests. Designers must consider these testing requirements during the optimization process to ensure that the final inductor design not only prevents coil whine but also meets all applicable EMC standards.

As technology advances and electronic devices become more complex, EMC regulations continue to evolve. This ongoing development necessitates a proactive approach in inductor design optimization. Designers must stay informed about the latest regulatory updates and anticipate future changes to ensure long-term compliance and product viability in the global market.

The International Electrotechnical Commission (IEC) sets global standards for EMC, with IEC 61000 being the primary series of standards addressing electromagnetic compatibility. These standards define limits for electromagnetic emissions and immunity levels for various types of equipment. For inductor designs, particularly relevant are the IEC 61000-3 series, which focus on emission limits, and the IEC 61000-4 series, which deal with testing and measurement techniques.

In the United States, the Federal Communications Commission (FCC) enforces EMC regulations. Part 15 of the FCC rules is particularly relevant for inductor designs, as it covers unintentional radiators. These regulations set limits on the amount of electromagnetic energy that devices can emit, which directly impacts the design considerations for inductors to prevent coil whine.

The European Union enforces EMC regulations through the EMC Directive (2014/30/EU). This directive requires all electronic equipment sold in the EU to meet specific EMC standards, including those related to inductor performance and coil whine prevention. Manufacturers must ensure their products comply with these regulations before obtaining CE marking for market access.

To optimize inductor designs in compliance with EMC regulations, several key factors must be considered. These include the selection of core materials with low electromagnetic emissions, the implementation of shielding techniques to contain electromagnetic fields, and the careful design of winding patterns to minimize stray capacitance and mutual inductance.

Furthermore, EMC regulations often require specific testing procedures to verify compliance. These may include conducted emissions tests, radiated emissions tests, and immunity tests. Designers must consider these testing requirements during the optimization process to ensure that the final inductor design not only prevents coil whine but also meets all applicable EMC standards.

As technology advances and electronic devices become more complex, EMC regulations continue to evolve. This ongoing development necessitates a proactive approach in inductor design optimization. Designers must stay informed about the latest regulatory updates and anticipate future changes to ensure long-term compliance and product viability in the global market.

Acoustic Testing Methods for Inductors

Acoustic testing methods for inductors play a crucial role in optimizing inductor designs to prevent coil whine. These methods involve a systematic approach to measure, analyze, and evaluate the acoustic performance of inductors under various operating conditions.

One of the primary acoustic testing methods for inductors is the anechoic chamber test. This method utilizes a specially designed room with sound-absorbing materials on all surfaces to create an echo-free environment. Inductors are placed in the chamber and subjected to different electrical loads while sensitive microphones capture the emitted sound. The anechoic chamber test provides accurate measurements of the inductor's acoustic emissions, allowing engineers to identify specific frequencies and intensities of coil whine.

Another commonly employed method is the near-field acoustic holography (NAH) technique. NAH involves using an array of microphones to measure the sound pressure field near the inductor's surface. By applying advanced signal processing algorithms, this method can reconstruct the three-dimensional sound field and pinpoint the exact locations on the inductor where acoustic emissions are most prominent. This information is invaluable for identifying design flaws and optimizing the inductor's structure to minimize coil whine.

Laser vibrometry is an advanced acoustic testing method that utilizes laser technology to measure surface vibrations of the inductor. This non-contact technique can detect even the smallest vibrations with high precision, providing insights into the mechanical behavior of the inductor under different operating conditions. By correlating the vibration data with acoustic measurements, engineers can establish a clear relationship between the inductor's physical movement and the resulting coil whine.

Accelerometer-based testing is another effective method for evaluating inductor acoustics. Small, lightweight accelerometers are attached to various points on the inductor to measure its vibrations directly. This method is particularly useful for identifying resonant frequencies and mode shapes of the inductor, which are critical factors in coil whine generation.

To simulate real-world conditions, environmental chamber testing is often employed. Inductors are placed in chambers that can control temperature, humidity, and pressure while conducting acoustic measurements. This method helps engineers understand how environmental factors influence coil whine and allows them to design inductors that maintain low acoustic emissions across a wide range of operating conditions.

Acoustic imaging techniques, such as acoustic cameras, provide visual representations of sound fields around inductors. These methods use microphone arrays and sophisticated software to create color-coded maps of sound intensity, allowing engineers to visualize the spatial distribution of acoustic emissions and identify hotspots that require design modifications.

By combining these acoustic testing methods, engineers can gather comprehensive data on inductor performance, enabling them to make informed decisions in the design optimization process. The insights gained from these tests guide the development of innovative solutions, such as improved winding techniques, advanced core materials, and optimized geometries, all aimed at minimizing coil whine and enhancing the overall acoustic performance of inductors.

One of the primary acoustic testing methods for inductors is the anechoic chamber test. This method utilizes a specially designed room with sound-absorbing materials on all surfaces to create an echo-free environment. Inductors are placed in the chamber and subjected to different electrical loads while sensitive microphones capture the emitted sound. The anechoic chamber test provides accurate measurements of the inductor's acoustic emissions, allowing engineers to identify specific frequencies and intensities of coil whine.

Another commonly employed method is the near-field acoustic holography (NAH) technique. NAH involves using an array of microphones to measure the sound pressure field near the inductor's surface. By applying advanced signal processing algorithms, this method can reconstruct the three-dimensional sound field and pinpoint the exact locations on the inductor where acoustic emissions are most prominent. This information is invaluable for identifying design flaws and optimizing the inductor's structure to minimize coil whine.

Laser vibrometry is an advanced acoustic testing method that utilizes laser technology to measure surface vibrations of the inductor. This non-contact technique can detect even the smallest vibrations with high precision, providing insights into the mechanical behavior of the inductor under different operating conditions. By correlating the vibration data with acoustic measurements, engineers can establish a clear relationship between the inductor's physical movement and the resulting coil whine.

Accelerometer-based testing is another effective method for evaluating inductor acoustics. Small, lightweight accelerometers are attached to various points on the inductor to measure its vibrations directly. This method is particularly useful for identifying resonant frequencies and mode shapes of the inductor, which are critical factors in coil whine generation.

To simulate real-world conditions, environmental chamber testing is often employed. Inductors are placed in chambers that can control temperature, humidity, and pressure while conducting acoustic measurements. This method helps engineers understand how environmental factors influence coil whine and allows them to design inductors that maintain low acoustic emissions across a wide range of operating conditions.

Acoustic imaging techniques, such as acoustic cameras, provide visual representations of sound fields around inductors. These methods use microphone arrays and sophisticated software to create color-coded maps of sound intensity, allowing engineers to visualize the spatial distribution of acoustic emissions and identify hotspots that require design modifications.

By combining these acoustic testing methods, engineers can gather comprehensive data on inductor performance, enabling them to make informed decisions in the design optimization process. The insights gained from these tests guide the development of innovative solutions, such as improved winding techniques, advanced core materials, and optimized geometries, all aimed at minimizing coil whine and enhancing the overall acoustic performance of inductors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!