How to Cultivate Expertise in Coil Whine Management?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Fundamentals

Coil whine is an audible noise produced by electromagnetic components, particularly inductors and transformers, in electronic devices. This phenomenon occurs when these components vibrate at frequencies within the human audible range, typically between 20 Hz and 20 kHz. The vibrations are caused by electromagnetic forces acting on the windings of the coil, which can be exacerbated by varying electrical currents passing through them.

The fundamental cause of coil whine lies in the interaction between magnetic fields and electrical currents. As alternating current flows through a coil, it generates a fluctuating magnetic field. This field interacts with the coil's windings, causing them to vibrate. When these vibrations occur at frequencies within the audible spectrum, they produce the characteristic high-pitched noise associated with coil whine.

Several factors contribute to the severity and frequency of coil whine. The design and quality of the components play a crucial role, with poorly constructed or low-quality inductors and transformers being more susceptible to this issue. The operating frequency of the device, power supply ripple, and overall circuit design can also influence the occurrence and intensity of coil whine.

Coil whine is particularly prevalent in high-performance electronic devices, such as computers, power supplies, and audio equipment. In these applications, rapid changes in power demand can lead to sudden fluctuations in current, exacerbating the problem. The issue is often more noticeable in quiet environments or when devices are under heavy load, as the increased current flow amplifies the electromagnetic forces acting on the coils.

Understanding the physics behind coil whine is essential for developing effective management strategies. The resonant frequency of the coil, determined by its physical properties and construction, plays a significant role in the manifestation of coil whine. When the frequency of the electrical current matches or harmonizes with the coil's natural resonant frequency, the resulting vibrations can be particularly pronounced.

To effectively manage coil whine, engineers must consider various approaches. These may include optimizing component selection, improving circuit design to minimize current fluctuations, and implementing damping techniques to reduce mechanical vibrations. Advanced materials and manufacturing processes can also be employed to create more stable and resilient electromagnetic components that are less prone to producing audible noise.

Expertise in coil whine management requires a multidisciplinary approach, combining knowledge from electrical engineering, materials science, and acoustics. Professionals in this field must stay abreast of the latest developments in component design, power management techniques, and noise reduction strategies to effectively address this persistent challenge in electronic device manufacturing.

The fundamental cause of coil whine lies in the interaction between magnetic fields and electrical currents. As alternating current flows through a coil, it generates a fluctuating magnetic field. This field interacts with the coil's windings, causing them to vibrate. When these vibrations occur at frequencies within the audible spectrum, they produce the characteristic high-pitched noise associated with coil whine.

Several factors contribute to the severity and frequency of coil whine. The design and quality of the components play a crucial role, with poorly constructed or low-quality inductors and transformers being more susceptible to this issue. The operating frequency of the device, power supply ripple, and overall circuit design can also influence the occurrence and intensity of coil whine.

Coil whine is particularly prevalent in high-performance electronic devices, such as computers, power supplies, and audio equipment. In these applications, rapid changes in power demand can lead to sudden fluctuations in current, exacerbating the problem. The issue is often more noticeable in quiet environments or when devices are under heavy load, as the increased current flow amplifies the electromagnetic forces acting on the coils.

Understanding the physics behind coil whine is essential for developing effective management strategies. The resonant frequency of the coil, determined by its physical properties and construction, plays a significant role in the manifestation of coil whine. When the frequency of the electrical current matches or harmonizes with the coil's natural resonant frequency, the resulting vibrations can be particularly pronounced.

To effectively manage coil whine, engineers must consider various approaches. These may include optimizing component selection, improving circuit design to minimize current fluctuations, and implementing damping techniques to reduce mechanical vibrations. Advanced materials and manufacturing processes can also be employed to create more stable and resilient electromagnetic components that are less prone to producing audible noise.

Expertise in coil whine management requires a multidisciplinary approach, combining knowledge from electrical engineering, materials science, and acoustics. Professionals in this field must stay abreast of the latest developments in component design, power management techniques, and noise reduction strategies to effectively address this persistent challenge in electronic device manufacturing.

Market Demand Analysis

The market demand for coil whine management expertise has been steadily increasing in recent years, driven by the growing complexity of electronic devices and the rising consumer expectations for quiet, high-performance products. As electronic components become more powerful and compact, the issue of coil whine has become more prevalent, affecting a wide range of industries including consumer electronics, automotive, and industrial equipment.

In the consumer electronics sector, there is a significant demand for coil whine management in high-end gaming PCs, laptops, and graphics cards. Gamers and enthusiasts are particularly sensitive to noise issues, and manufacturers are under pressure to deliver silent yet powerful systems. This has led to a surge in demand for engineers and designers who can effectively mitigate coil whine without compromising performance.

The automotive industry is another key driver of market demand for coil whine expertise. With the rapid growth of electric and hybrid vehicles, managing electromagnetic noise from power electronics and electric motors has become crucial. Automakers are investing heavily in noise, vibration, and harshness (NVH) reduction technologies, creating opportunities for specialists in coil whine management.

In the industrial sector, the push for more energy-efficient and compact equipment has resulted in increased power densities, exacerbating coil whine issues. Manufacturers of industrial power supplies, variable frequency drives, and other power electronics are seeking solutions to reduce electromagnetic noise and improve overall system reliability.

The market for coil whine management solutions is also expanding in the renewable energy sector, particularly in solar and wind power systems. As these systems become more widespread and integrated into residential and commercial settings, the need for quiet operation has become more critical.

The global trend towards miniaturization and increased power efficiency in electronic devices is expected to further drive the demand for coil whine management expertise. This trend is particularly evident in the development of 5G infrastructure, Internet of Things (IoT) devices, and wearable technology, where compact, high-performance components are essential.

As a result of these market demands, there is a growing need for specialized training programs, research initiatives, and industry collaborations focused on coil whine management. Companies are increasingly recognizing the value of investing in this expertise to gain a competitive edge in their respective markets.

In the consumer electronics sector, there is a significant demand for coil whine management in high-end gaming PCs, laptops, and graphics cards. Gamers and enthusiasts are particularly sensitive to noise issues, and manufacturers are under pressure to deliver silent yet powerful systems. This has led to a surge in demand for engineers and designers who can effectively mitigate coil whine without compromising performance.

The automotive industry is another key driver of market demand for coil whine expertise. With the rapid growth of electric and hybrid vehicles, managing electromagnetic noise from power electronics and electric motors has become crucial. Automakers are investing heavily in noise, vibration, and harshness (NVH) reduction technologies, creating opportunities for specialists in coil whine management.

In the industrial sector, the push for more energy-efficient and compact equipment has resulted in increased power densities, exacerbating coil whine issues. Manufacturers of industrial power supplies, variable frequency drives, and other power electronics are seeking solutions to reduce electromagnetic noise and improve overall system reliability.

The market for coil whine management solutions is also expanding in the renewable energy sector, particularly in solar and wind power systems. As these systems become more widespread and integrated into residential and commercial settings, the need for quiet operation has become more critical.

The global trend towards miniaturization and increased power efficiency in electronic devices is expected to further drive the demand for coil whine management expertise. This trend is particularly evident in the development of 5G infrastructure, Internet of Things (IoT) devices, and wearable technology, where compact, high-performance components are essential.

As a result of these market demands, there is a growing need for specialized training programs, research initiatives, and industry collaborations focused on coil whine management. Companies are increasingly recognizing the value of investing in this expertise to gain a competitive edge in their respective markets.

Current Challenges

Coil whine management presents several significant challenges in the current technological landscape. One of the primary obstacles is the complexity of identifying the root cause of coil whine in electronic devices. The phenomenon can stem from various sources, including power supply units, graphics cards, and motherboards, making it difficult to pinpoint the exact origin without extensive testing and analysis.

Another major challenge lies in the variability of coil whine across different units of the same product. Even devices from the same production batch can exhibit varying levels of coil whine, complicating quality control processes and customer satisfaction management. This inconsistency makes it challenging for manufacturers to implement standardized solutions across their product lines.

The subjective nature of coil whine perception further compounds the issue. What may be an acceptable level of noise for one user could be highly disruptive for another, making it difficult to establish universal standards for coil whine management. This subjectivity also complicates the development of effective testing methodologies and benchmarks for evaluating coil whine severity.

From a design perspective, engineers face the challenge of balancing performance requirements with coil whine reduction. High-performance components often operate at frequencies that are more prone to generating audible coil whine, creating a trade-off between device capabilities and acoustic comfort. This balance becomes increasingly difficult to achieve as consumer expectations for both performance and quietness continue to rise.

The miniaturization trend in electronics also poses significant challenges for coil whine management. As devices become smaller and more compact, there is less space for implementing traditional noise reduction techniques, such as physical dampening or component isolation. This limitation requires innovative approaches to coil whine mitigation that can be effective within constrained form factors.

Additionally, the cost implications of implementing advanced coil whine reduction techniques present a significant hurdle. High-quality components and sophisticated design solutions that minimize coil whine can substantially increase production costs, potentially affecting product pricing and market competitiveness. Manufacturers must carefully weigh the benefits of improved acoustic performance against the economic impact on their product lines.

Lastly, the lack of comprehensive industry standards and guidelines specifically addressing coil whine management creates challenges in establishing best practices and benchmarks. While general acoustic standards exist, they often do not adequately address the unique characteristics of coil whine, leaving manufacturers without clear directives for improvement and compliance.

Another major challenge lies in the variability of coil whine across different units of the same product. Even devices from the same production batch can exhibit varying levels of coil whine, complicating quality control processes and customer satisfaction management. This inconsistency makes it challenging for manufacturers to implement standardized solutions across their product lines.

The subjective nature of coil whine perception further compounds the issue. What may be an acceptable level of noise for one user could be highly disruptive for another, making it difficult to establish universal standards for coil whine management. This subjectivity also complicates the development of effective testing methodologies and benchmarks for evaluating coil whine severity.

From a design perspective, engineers face the challenge of balancing performance requirements with coil whine reduction. High-performance components often operate at frequencies that are more prone to generating audible coil whine, creating a trade-off between device capabilities and acoustic comfort. This balance becomes increasingly difficult to achieve as consumer expectations for both performance and quietness continue to rise.

The miniaturization trend in electronics also poses significant challenges for coil whine management. As devices become smaller and more compact, there is less space for implementing traditional noise reduction techniques, such as physical dampening or component isolation. This limitation requires innovative approaches to coil whine mitigation that can be effective within constrained form factors.

Additionally, the cost implications of implementing advanced coil whine reduction techniques present a significant hurdle. High-quality components and sophisticated design solutions that minimize coil whine can substantially increase production costs, potentially affecting product pricing and market competitiveness. Manufacturers must carefully weigh the benefits of improved acoustic performance against the economic impact on their product lines.

Lastly, the lack of comprehensive industry standards and guidelines specifically addressing coil whine management creates challenges in establishing best practices and benchmarks. While general acoustic standards exist, they often do not adequately address the unique characteristics of coil whine, leaving manufacturers without clear directives for improvement and compliance.

Existing Mitigation

01 Electromagnetic shielding techniques

Implementing electromagnetic shielding techniques to reduce coil whine by containing electromagnetic fields generated by electronic components. This can involve using conductive materials or specialized coatings to create a barrier that prevents electromagnetic interference and reduces audible noise.- Electromagnetic shielding techniques: Implementing electromagnetic shielding techniques to reduce coil whine by containing electromagnetic fields generated by electronic components. This can involve using conductive materials or specialized coatings to create a barrier that prevents electromagnetic interference from escaping or entering the device.

- Vibration dampening and isolation: Employing vibration dampening and isolation methods to minimize coil whine by reducing mechanical resonance. This can include using specialized materials or mounting techniques to absorb vibrations from coils and other components, preventing them from propagating through the device structure.

- Coil design optimization: Optimizing the design of coils and transformers to reduce the likelihood of coil whine. This can involve adjusting winding techniques, core materials, or overall geometry to minimize vibrations and electromagnetic emissions that contribute to audible noise.

- Active noise cancellation: Implementing active noise cancellation techniques to counteract coil whine. This approach involves using sensors to detect the frequency and amplitude of the whine, then generating an inverse waveform to cancel out the unwanted noise.

- Power supply and circuit design improvements: Enhancing power supply and circuit designs to minimize factors that contribute to coil whine. This can include implementing better voltage regulation, filtering techniques, or redesigning circuit layouts to reduce electromagnetic interference and resonance issues.

02 Vibration dampening and isolation

Employing vibration dampening materials and isolation techniques to minimize the transmission of mechanical vibrations that contribute to coil whine. This can include using rubber mounts, silicone pads, or other shock-absorbing materials to isolate components and reduce resonance.Expand Specific Solutions03 Optimized coil design and construction

Improving the design and construction of coils to minimize the likelihood of whine. This can involve using different winding techniques, core materials, or geometries to reduce mechanical stress and electromagnetic fluctuations that lead to audible noise.Expand Specific Solutions04 Active noise cancellation systems

Implementing active noise cancellation systems that detect and counteract coil whine. These systems can use sensors to measure the frequency and amplitude of the whine and generate opposing sound waves or vibrations to cancel out the unwanted noise.Expand Specific Solutions05 Power supply and voltage regulation optimization

Optimizing power supply design and voltage regulation to reduce electrical fluctuations that can cause coil whine. This can include implementing more stable power delivery systems, improved filtering, and advanced voltage regulation techniques to minimize rapid changes in current that contribute to audible noise.Expand Specific Solutions

Key Industry Players

The coil whine management technology sector is in a growth phase, with increasing market size driven by the rising demand for quieter electronic devices. The market is characterized by moderate competition among established players and emerging specialists. Key companies like Robert Bosch GmbH, Continental Automotive GmbH, and DENSO Corp. are leveraging their automotive expertise to address coil whine issues. Nittoku Co., Ltd. stands out as a specialized player in coil winding technology. The technology's maturity is advancing, with companies like Huawei Technologies Co., Ltd. and Sumitomo Electric Industries Ltd. investing in research and development to improve coil designs and noise reduction techniques.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced coil whine management techniques for automotive applications. Their approach involves a combination of electromagnetic shielding, optimized circuit design, and innovative materials. They utilize specialized magnetic alloys and advanced winding techniques to minimize electromagnetic interference (EMI) and reduce coil whine in electric motors and power electronics[1]. Bosch has also implemented active noise cancellation systems that detect and counteract coil whine frequencies in real-time, significantly reducing audible noise in vehicle cabins[3].

Strengths: Comprehensive approach combining hardware and software solutions, extensive automotive industry experience. Weaknesses: Solutions may be costly for mass-market implementation, potentially complex integration with existing systems.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed innovative coil whine management solutions for their telecommunications and consumer electronics products. Their approach focuses on advanced PCB design techniques, including optimized trace routing and component placement to minimize electromagnetic interactions[2]. Huawei employs multi-layer PCB designs with dedicated power and ground planes to reduce EMI and coil whine. They have also implemented adaptive power management algorithms that dynamically adjust voltage and current levels to minimize coil vibrations while maintaining optimal performance[4]. Additionally, Huawei utilizes advanced materials such as specialized ferrite cores and low-noise capacitors to further reduce coil whine in their power supply units and other electronic components[5].

Strengths: Strong focus on software-based solutions, expertise in miniaturization for mobile devices. Weaknesses: May face challenges in adapting solutions to larger-scale industrial applications.

Innovative Solutions

Coil component

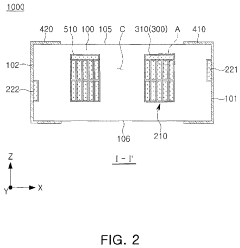

PatentActiveUS11875931B2

Innovation

- A coil component design featuring a winding-type coil with a noise removal portion having an open-loop pattern and an insulating layer, coupled with external electrodes, effectively discharges high-frequency noise by forming capacitance with the coil portion, enhancing noise removal capabilities.

Coil component and fabrication method of the same

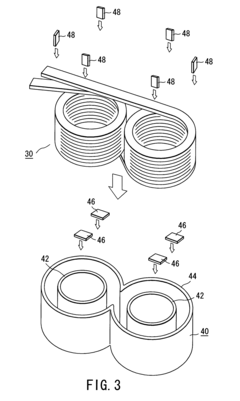

PatentInactiveUS7427909B2

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin, embedded within a magnetic core composed of a mixture of resin and magnetic powder, which provides enhanced structural integrity and noise suppression.

Regulatory Standards

Regulatory standards play a crucial role in managing coil whine issues across various industries. These standards are designed to ensure product safety, performance, and environmental compliance while addressing electromagnetic compatibility (EMC) concerns. The International Electrotechnical Commission (IEC) has established several standards that directly or indirectly relate to coil whine management.

IEC 61000-3-2 is a key standard that sets limits for harmonic current emissions in electrical and electronic equipment. This standard is particularly relevant to coil whine management as it addresses issues related to power supply harmonics, which can contribute to audible noise. Manufacturers must ensure their products comply with these limits to minimize potential coil whine issues.

Another important standard is IEC 61000-4-19, which focuses on test and measurement techniques for harmonic and interharmonic immunity tests for equipment with input current up to 16A per phase. This standard helps in assessing the susceptibility of equipment to harmonic distortions, which can be a contributing factor to coil whine.

The CISPR 32 standard, which deals with electromagnetic compatibility of multimedia equipment, also has implications for coil whine management. It sets limits for both conducted and radiated emissions, which can help in identifying and mitigating potential sources of electromagnetic interference that may lead to coil whine.

In the automotive industry, the ISO 26262 standard for functional safety of electrical and electronic systems in production automobiles includes considerations for electromagnetic compatibility. This standard indirectly addresses coil whine issues by ensuring that electronic components in vehicles meet stringent safety and performance requirements.

Regulatory bodies such as the Federal Communications Commission (FCC) in the United States and the European Union's CE marking system also enforce standards related to electromagnetic compatibility. These regulations often incorporate or reference the IEC standards mentioned above, creating a global framework for addressing coil whine and related EMC issues.

Compliance with these regulatory standards requires manufacturers to implement robust design practices and testing procedures. This includes conducting thorough EMC testing, employing shielding techniques, and optimizing circuit designs to minimize electromagnetic emissions and susceptibility. By adhering to these standards, manufacturers can not only reduce the likelihood of coil whine issues but also improve overall product quality and reliability.

As technology advances and new applications emerge, regulatory standards continue to evolve. Experts in coil whine management must stay informed about updates to existing standards and the introduction of new regulations. This ongoing process of adaptation and compliance is essential for maintaining expertise in the field and ensuring that products meet the latest requirements for electromagnetic compatibility and noise reduction.

IEC 61000-3-2 is a key standard that sets limits for harmonic current emissions in electrical and electronic equipment. This standard is particularly relevant to coil whine management as it addresses issues related to power supply harmonics, which can contribute to audible noise. Manufacturers must ensure their products comply with these limits to minimize potential coil whine issues.

Another important standard is IEC 61000-4-19, which focuses on test and measurement techniques for harmonic and interharmonic immunity tests for equipment with input current up to 16A per phase. This standard helps in assessing the susceptibility of equipment to harmonic distortions, which can be a contributing factor to coil whine.

The CISPR 32 standard, which deals with electromagnetic compatibility of multimedia equipment, also has implications for coil whine management. It sets limits for both conducted and radiated emissions, which can help in identifying and mitigating potential sources of electromagnetic interference that may lead to coil whine.

In the automotive industry, the ISO 26262 standard for functional safety of electrical and electronic systems in production automobiles includes considerations for electromagnetic compatibility. This standard indirectly addresses coil whine issues by ensuring that electronic components in vehicles meet stringent safety and performance requirements.

Regulatory bodies such as the Federal Communications Commission (FCC) in the United States and the European Union's CE marking system also enforce standards related to electromagnetic compatibility. These regulations often incorporate or reference the IEC standards mentioned above, creating a global framework for addressing coil whine and related EMC issues.

Compliance with these regulatory standards requires manufacturers to implement robust design practices and testing procedures. This includes conducting thorough EMC testing, employing shielding techniques, and optimizing circuit designs to minimize electromagnetic emissions and susceptibility. By adhering to these standards, manufacturers can not only reduce the likelihood of coil whine issues but also improve overall product quality and reliability.

As technology advances and new applications emerge, regulatory standards continue to evolve. Experts in coil whine management must stay informed about updates to existing standards and the introduction of new regulations. This ongoing process of adaptation and compliance is essential for maintaining expertise in the field and ensuring that products meet the latest requirements for electromagnetic compatibility and noise reduction.

Acoustic Testing Methods

Acoustic testing methods play a crucial role in the management and mitigation of coil whine in electronic devices. These methods involve a systematic approach to measuring, analyzing, and characterizing the acoustic emissions produced by electronic components, particularly inductors and transformers.

One of the primary acoustic testing methods used in coil whine management is anechoic chamber testing. This involves placing the device under test in a specially designed room that absorbs sound reflections, allowing for precise measurement of the acoustic emissions without interference from external noise sources. Anechoic chambers are equipped with high-sensitivity microphones and advanced data acquisition systems to capture and analyze the acoustic signature of the device.

Another important technique is near-field acoustic holography (NAH). This method uses an array of microphones to create a detailed map of the sound field near the surface of the device. By processing the data collected from these microphones, engineers can visualize the spatial distribution of sound sources and identify specific components contributing to coil whine.

Laser Doppler vibrometry is an advanced non-contact method that can be employed to measure surface vibrations associated with coil whine. This technique uses laser beams to detect minute vibrations on the surface of electronic components, providing valuable insights into the mechanical behavior that leads to acoustic emissions.

Spectral analysis is a fundamental tool in acoustic testing for coil whine. Fast Fourier Transform (FFT) algorithms are applied to the recorded audio signals to break down the complex waveforms into their constituent frequencies. This allows engineers to identify specific frequency components associated with coil whine and distinguish them from other noise sources.

Modal analysis is another valuable method used to understand the structural dynamics of electronic components that contribute to coil whine. By exciting the device with controlled vibrations and measuring its response, engineers can identify resonant frequencies and mode shapes that may exacerbate acoustic emissions.

To ensure repeatability and comparability of results, standardized test procedures such as those outlined in IEC 60076-10 for power transformers are often adapted for coil whine testing. These procedures specify measurement distances, environmental conditions, and reporting formats to maintain consistency across different testing scenarios.

In recent years, artificial intelligence and machine learning techniques have been integrated into acoustic testing methods. These advanced algorithms can analyze large datasets of acoustic measurements to identify patterns, predict potential coil whine issues, and suggest optimal design modifications to mitigate the problem.

One of the primary acoustic testing methods used in coil whine management is anechoic chamber testing. This involves placing the device under test in a specially designed room that absorbs sound reflections, allowing for precise measurement of the acoustic emissions without interference from external noise sources. Anechoic chambers are equipped with high-sensitivity microphones and advanced data acquisition systems to capture and analyze the acoustic signature of the device.

Another important technique is near-field acoustic holography (NAH). This method uses an array of microphones to create a detailed map of the sound field near the surface of the device. By processing the data collected from these microphones, engineers can visualize the spatial distribution of sound sources and identify specific components contributing to coil whine.

Laser Doppler vibrometry is an advanced non-contact method that can be employed to measure surface vibrations associated with coil whine. This technique uses laser beams to detect minute vibrations on the surface of electronic components, providing valuable insights into the mechanical behavior that leads to acoustic emissions.

Spectral analysis is a fundamental tool in acoustic testing for coil whine. Fast Fourier Transform (FFT) algorithms are applied to the recorded audio signals to break down the complex waveforms into their constituent frequencies. This allows engineers to identify specific frequency components associated with coil whine and distinguish them from other noise sources.

Modal analysis is another valuable method used to understand the structural dynamics of electronic components that contribute to coil whine. By exciting the device with controlled vibrations and measuring its response, engineers can identify resonant frequencies and mode shapes that may exacerbate acoustic emissions.

To ensure repeatability and comparability of results, standardized test procedures such as those outlined in IEC 60076-10 for power transformers are often adapted for coil whine testing. These procedures specify measurement distances, environmental conditions, and reporting formats to maintain consistency across different testing scenarios.

In recent years, artificial intelligence and machine learning techniques have been integrated into acoustic testing methods. These advanced algorithms can analyze large datasets of acoustic measurements to identify patterns, predict potential coil whine issues, and suggest optimal design modifications to mitigate the problem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!