Coil Whine in Smart Devices: Strategies for Mitigation

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an electromagnetic phenomenon that has become increasingly prevalent in modern smart devices. This high-frequency noise is produced by the rapid vibration of electronic components, particularly inductors and transformers, when subjected to fluctuating electrical currents. The issue has gained prominence as devices have become more compact and powerful, leading to higher power densities and increased electromagnetic interference.

The phenomenon of coil whine has its roots in the fundamental principles of electromagnetism. When an alternating current flows through a coil, it generates a fluctuating magnetic field. This field can cause the coil's windings to vibrate at frequencies within the audible range, resulting in the characteristic high-pitched noise. The problem is exacerbated in switch-mode power supplies and voltage regulators, which are common in modern electronic devices due to their efficiency and compact size.

As smart devices have evolved, the demand for higher performance and energy efficiency has led to the widespread adoption of advanced power management techniques. These often involve rapid switching of currents at high frequencies, which can inadvertently contribute to coil whine. The miniaturization of components has also played a role, as smaller inductors and transformers are more susceptible to vibration and may produce more noticeable acoustic emissions.

The impact of coil whine extends beyond mere annoyance. In professional environments, such as recording studios or quiet workspaces, even low levels of electronic noise can be disruptive. For consumers, the presence of coil whine in personal devices like smartphones, laptops, or gaming consoles can significantly detract from the user experience, potentially affecting brand perception and customer satisfaction.

Historically, coil whine was primarily associated with desktop computers and power supplies. However, the proliferation of smart devices has broadened the scope of this issue. From wearable technology to smart home appliances, the integration of sophisticated electronics into everyday objects has introduced coil whine into a wide array of consumer products. This expansion has necessitated a renewed focus on noise mitigation strategies across various industries.

Understanding the background of coil whine is crucial for developing effective mitigation strategies. The complex interplay between electrical design, component selection, and device architecture all contribute to the manifestation of this phenomenon. As such, addressing coil whine requires a multidisciplinary approach, combining expertise in electrical engineering, materials science, and acoustic design to create quieter, more refined smart devices.

The phenomenon of coil whine has its roots in the fundamental principles of electromagnetism. When an alternating current flows through a coil, it generates a fluctuating magnetic field. This field can cause the coil's windings to vibrate at frequencies within the audible range, resulting in the characteristic high-pitched noise. The problem is exacerbated in switch-mode power supplies and voltage regulators, which are common in modern electronic devices due to their efficiency and compact size.

As smart devices have evolved, the demand for higher performance and energy efficiency has led to the widespread adoption of advanced power management techniques. These often involve rapid switching of currents at high frequencies, which can inadvertently contribute to coil whine. The miniaturization of components has also played a role, as smaller inductors and transformers are more susceptible to vibration and may produce more noticeable acoustic emissions.

The impact of coil whine extends beyond mere annoyance. In professional environments, such as recording studios or quiet workspaces, even low levels of electronic noise can be disruptive. For consumers, the presence of coil whine in personal devices like smartphones, laptops, or gaming consoles can significantly detract from the user experience, potentially affecting brand perception and customer satisfaction.

Historically, coil whine was primarily associated with desktop computers and power supplies. However, the proliferation of smart devices has broadened the scope of this issue. From wearable technology to smart home appliances, the integration of sophisticated electronics into everyday objects has introduced coil whine into a wide array of consumer products. This expansion has necessitated a renewed focus on noise mitigation strategies across various industries.

Understanding the background of coil whine is crucial for developing effective mitigation strategies. The complex interplay between electrical design, component selection, and device architecture all contribute to the manifestation of this phenomenon. As such, addressing coil whine requires a multidisciplinary approach, combining expertise in electrical engineering, materials science, and acoustic design to create quieter, more refined smart devices.

Market Impact Analysis

The impact of coil whine on the smart device market is multifaceted and increasingly significant. As consumers become more aware of this issue, it has begun to influence purchasing decisions and brand perception. High-end smartphones, tablets, and laptops are particularly susceptible to scrutiny, as users expect premium devices to offer a seamless and noise-free experience. Manufacturers that fail to address coil whine effectively may face decreased sales, negative reviews, and potential damage to their brand reputation.

The prevalence of coil whine has led to a growing demand for quieter electronic components, creating new opportunities for suppliers specializing in low-noise inductors and power management solutions. This shift has sparked innovation in the component manufacturing sector, with companies investing in research and development to produce more efficient and quieter electronic parts. As a result, the market for specialized, low-noise components is expanding, potentially leading to increased competition and technological advancements in this niche area.

Consumer electronics retailers and repair services have also been affected by the coil whine phenomenon. Some retailers report an increase in product returns due to noise complaints, while repair shops have seen a rise in requests for coil whine mitigation services. This trend has led to the emergence of specialized repair services focusing on noise reduction in smart devices, creating a new sub-sector within the electronics repair industry.

The issue of coil whine has implications for the broader Internet of Things (IoT) market as well. As smart home devices become more prevalent, consumers are increasingly sensitive to noise pollution in their living spaces. This concern extends to a wide range of products, from smart speakers and displays to connected appliances and security systems. Manufacturers in the IoT space are now prioritizing acoustic design alongside other features, recognizing that noise levels can be a key differentiator in a competitive market.

In the enterprise sector, coil whine in data centers and office equipment has become a focus for IT managers and facility planners. The cumulative effect of coil whine from multiple devices can contribute to workplace noise pollution, potentially affecting employee productivity and well-being. This has led to increased demand for quieter server racks, network switches, and other IT infrastructure components, influencing purchasing decisions for large-scale deployments.

The market impact of coil whine extends to regulatory considerations as well. Some regions have begun to explore the inclusion of noise emissions in their electronic device standards and energy efficiency regulations. This regulatory attention could lead to new compliance requirements for manufacturers, potentially affecting product design, testing procedures, and certification processes across the smart device industry.

The prevalence of coil whine has led to a growing demand for quieter electronic components, creating new opportunities for suppliers specializing in low-noise inductors and power management solutions. This shift has sparked innovation in the component manufacturing sector, with companies investing in research and development to produce more efficient and quieter electronic parts. As a result, the market for specialized, low-noise components is expanding, potentially leading to increased competition and technological advancements in this niche area.

Consumer electronics retailers and repair services have also been affected by the coil whine phenomenon. Some retailers report an increase in product returns due to noise complaints, while repair shops have seen a rise in requests for coil whine mitigation services. This trend has led to the emergence of specialized repair services focusing on noise reduction in smart devices, creating a new sub-sector within the electronics repair industry.

The issue of coil whine has implications for the broader Internet of Things (IoT) market as well. As smart home devices become more prevalent, consumers are increasingly sensitive to noise pollution in their living spaces. This concern extends to a wide range of products, from smart speakers and displays to connected appliances and security systems. Manufacturers in the IoT space are now prioritizing acoustic design alongside other features, recognizing that noise levels can be a key differentiator in a competitive market.

In the enterprise sector, coil whine in data centers and office equipment has become a focus for IT managers and facility planners. The cumulative effect of coil whine from multiple devices can contribute to workplace noise pollution, potentially affecting employee productivity and well-being. This has led to increased demand for quieter server racks, network switches, and other IT infrastructure components, influencing purchasing decisions for large-scale deployments.

The market impact of coil whine extends to regulatory considerations as well. Some regions have begun to explore the inclusion of noise emissions in their electronic device standards and energy efficiency regulations. This regulatory attention could lead to new compliance requirements for manufacturers, potentially affecting product design, testing procedures, and certification processes across the smart device industry.

Technical Challenges

Coil whine in smart devices presents a significant technical challenge for manufacturers and engineers. This high-frequency noise, typically ranging from 2 kHz to 20 kHz, is caused by electromagnetic forces acting on components, particularly inductors and transformers in power supply circuits. The primary difficulty lies in the fact that coil whine is not a malfunction but rather an inherent characteristic of certain electronic components under specific operating conditions.

One of the main technical hurdles is the unpredictability of coil whine occurrence. It can vary greatly between seemingly identical devices due to minor manufacturing variations or differences in operating environments. This inconsistency makes it challenging to implement universal solutions across product lines.

Another significant challenge is the trade-off between performance and noise reduction. Many strategies for mitigating coil whine, such as using larger inductors or implementing more robust shielding, can negatively impact device size, weight, and overall performance. This is particularly problematic for smart devices where miniaturization and efficiency are key design priorities.

The dynamic nature of smart device usage further complicates the issue. Coil whine can become more pronounced under certain load conditions or during specific operations, making it difficult to address comprehensively without compromising functionality. Engineers must consider a wide range of use cases and power states when developing mitigation strategies.

Material selection presents another technical obstacle. While certain materials may be more effective at dampening vibrations or absorbing electromagnetic energy, they may not meet other crucial requirements such as cost-effectiveness, durability, or environmental sustainability. Finding materials that balance acoustic properties with other essential characteristics remains a significant challenge.

Moreover, the increasing complexity of smart devices, with their multiple integrated circuits and power management systems, creates more potential sources of coil whine. This complexity makes isolating and addressing individual noise sources more difficult, often requiring a holistic approach to device design and component layout.

Thermal management also plays a critical role in coil whine mitigation. As devices become more powerful and compact, managing heat dissipation becomes increasingly challenging. Thermal stress can exacerbate coil whine issues, creating a complex interplay between thermal design and acoustic performance that engineers must carefully balance.

Lastly, the cost implications of implementing advanced coil whine mitigation techniques pose a significant challenge for manufacturers. Developing and integrating effective solutions while maintaining competitive pricing in the consumer electronics market requires innovative approaches and careful cost-benefit analysis.

One of the main technical hurdles is the unpredictability of coil whine occurrence. It can vary greatly between seemingly identical devices due to minor manufacturing variations or differences in operating environments. This inconsistency makes it challenging to implement universal solutions across product lines.

Another significant challenge is the trade-off between performance and noise reduction. Many strategies for mitigating coil whine, such as using larger inductors or implementing more robust shielding, can negatively impact device size, weight, and overall performance. This is particularly problematic for smart devices where miniaturization and efficiency are key design priorities.

The dynamic nature of smart device usage further complicates the issue. Coil whine can become more pronounced under certain load conditions or during specific operations, making it difficult to address comprehensively without compromising functionality. Engineers must consider a wide range of use cases and power states when developing mitigation strategies.

Material selection presents another technical obstacle. While certain materials may be more effective at dampening vibrations or absorbing electromagnetic energy, they may not meet other crucial requirements such as cost-effectiveness, durability, or environmental sustainability. Finding materials that balance acoustic properties with other essential characteristics remains a significant challenge.

Moreover, the increasing complexity of smart devices, with their multiple integrated circuits and power management systems, creates more potential sources of coil whine. This complexity makes isolating and addressing individual noise sources more difficult, often requiring a holistic approach to device design and component layout.

Thermal management also plays a critical role in coil whine mitigation. As devices become more powerful and compact, managing heat dissipation becomes increasingly challenging. Thermal stress can exacerbate coil whine issues, creating a complex interplay between thermal design and acoustic performance that engineers must carefully balance.

Lastly, the cost implications of implementing advanced coil whine mitigation techniques pose a significant challenge for manufacturers. Developing and integrating effective solutions while maintaining competitive pricing in the consumer electronics market requires innovative approaches and careful cost-benefit analysis.

Mitigation Techniques

01 Noise reduction techniques for electronic devices

Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. The focus is on minimizing electromagnetic vibrations that cause audible noise in components like transformers and inductors.- Noise reduction techniques for electronic devices: Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.

- Magnetic field shielding for coil whine reduction: Magnetic field shielding is utilized to mitigate coil whine noise. This involves the use of materials and structures that can contain or redirect magnetic fields generated by coils and transformers. By reducing the interaction between these fields and surrounding components, the likelihood of coil whine occurrence is decreased, resulting in quieter operation of electronic devices.

- Acoustic dampening and isolation methods: Acoustic dampening and isolation techniques are implemented to minimize the propagation of coil whine noise. These methods involve using sound-absorbing materials, isolating vibrating components, and designing enclosures that prevent noise transmission. By addressing the acoustic aspects of coil whine, these approaches help to reduce the perceived noise levels in electronic devices.

- Frequency modulation and control for coil whine reduction: Frequency modulation and control strategies are employed to address coil whine issues. These techniques involve adjusting the operating frequencies of electronic components to avoid resonance and reduce audible noise. By carefully managing the frequency characteristics of power supplies and other components, the intensity and perceptibility of coil whine can be significantly reduced.

- Advanced materials and component design for noise reduction: The use of advanced materials and innovative component designs plays a crucial role in minimizing coil whine noise. This includes the development of low-noise transformers, specialized coil winding techniques, and the integration of noise-reducing features directly into electronic components. By addressing noise generation at the source, these approaches contribute to overall quieter operation of electronic devices.

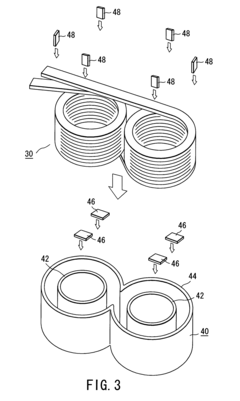

02 Coil design and construction for noise reduction

Innovative coil designs and construction methods are developed to mitigate whine noise. This includes using specific winding techniques, core materials, and insulation to dampen vibrations. The goal is to create coils that maintain performance while significantly reducing audible noise emissions.Expand Specific Solutions03 Power supply and voltage regulation improvements

Advancements in power supply design and voltage regulation techniques are implemented to address coil whine. This involves optimizing power delivery, filtering, and stabilization methods to reduce electrical fluctuations that contribute to audible noise in coils and transformers.Expand Specific Solutions04 Acoustic isolation and dampening solutions

Methods for isolating and dampening coil whine noise are developed. These include using acoustic materials, enclosures, and vibration-absorbing mounts to prevent noise propagation. The focus is on containing and absorbing the vibrations at their source to minimize audible emissions.Expand Specific Solutions05 Diagnostic and testing methods for coil whine

Advanced diagnostic and testing techniques are developed to identify and characterize coil whine noise. These methods involve specialized equipment and procedures to measure, analyze, and locate sources of electromagnetic noise in electronic devices, enabling more effective noise reduction strategies.Expand Specific Solutions

Industry Leaders

The coil whine mitigation strategies in smart devices market is in a growth phase, with increasing demand for quieter electronics driving innovation. The global market size for noise reduction technologies in consumer electronics is expanding, estimated to reach several billion dollars by 2025. Technologically, solutions are advancing but not yet fully mature. Leading players like Samsung, LG, and Apple are investing heavily in R&D to develop proprietary noise reduction techniques. Smaller specialized firms such as Murata and TDK are also making significant contributions with their expertise in electronic components. The competitive landscape is characterized by a mix of large consumer electronics manufacturers and niche component suppliers collaborating to address this growing concern in smart devices.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a multi-layered approach to mitigate coil whine in smart devices. Their strategy includes advanced circuit design techniques, such as implementing spread spectrum clocking (SSC) to distribute electromagnetic emissions over a wider frequency range, reducing peak emissions [1]. They also utilize high-quality, low-noise power supplies and voltage regulators to minimize electrical noise. Samsung's engineers have implemented active noise cancellation techniques, using microphones to detect coil whine and generate inverse waveforms to cancel out the unwanted noise [3]. Additionally, they employ careful component selection and placement, using shielded inductors and strategically positioning noise-generating components away from sensitive areas [2].

Strengths: Comprehensive approach addressing multiple aspects of coil whine. Advanced noise cancellation techniques. Weaknesses: Potential increased cost and complexity in device manufacturing.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a comprehensive strategy to address coil whine in their smart devices. Their approach includes the use of advanced materials science, implementing nano-composite materials in their device construction to dampen vibrations and reduce acoustic emissions [1]. Huawei's engineers have also developed sophisticated power management systems that utilize dynamic voltage and frequency scaling (DVFS) to optimize power delivery and minimize electrical noise [2]. They employ advanced electromagnetic interference (EMI) shielding techniques, including the use of ferrite materials and specialized coatings to contain electromagnetic emissions [3]. Additionally, Huawei has implemented AI-driven noise detection and suppression algorithms that continuously monitor and adjust device parameters to minimize coil whine in real-time.

Strengths: Innovative use of advanced materials. AI-driven noise suppression. Weaknesses: Potential increased manufacturing costs due to specialized materials and components.

Key Innovations

Coil component and fabrication method of the same

PatentInactiveUS7427909B2

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin, embedded within a magnetic core composed of a mixture of resin and magnetic powder, which provides enhanced structural integrity and noise suppression.

Printed circuit board with vibration-generating electronic component

PatentActiveEP2044817A1

Innovation

- Incorporating slots in the circuit board, specifically designed to interrupt the propagation of vibrations by positioning them parallel to the electronic components, effectively breaking the surface waves and transverse vibrations, thereby suppressing sound radiation.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of strategies to mitigate coil whine in smart devices. As manufacturers and developers work to address this issue, they must navigate a complex landscape of regulations and standards that govern electromagnetic compatibility (EMC) and noise emissions.

In the United States, the Federal Communications Commission (FCC) sets strict guidelines for electronic devices through its Part 15 regulations. These rules specifically address unintentional radiators, which include devices that may produce coil whine. Manufacturers must ensure that their smart devices comply with FCC limits on conducted and radiated emissions to obtain certification and enter the market.

The European Union enforces similar regulations through the EMC Directive (2014/30/EU). This directive mandates that all electronic equipment sold within the EU must meet specific EMC requirements, including limits on electromagnetic interference. Coil whine, as a form of audible electromagnetic noise, falls under the purview of these regulations.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide additional guidance for manufacturers. The IEC 61000 series of standards, particularly IEC 61000-3-2 and IEC 61000-3-3, address harmonic current emissions and voltage fluctuations, which can be related to coil whine phenomena.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct EMC tests in certified laboratories to demonstrate that their devices meet the required standards. This process typically involves measuring electromagnetic emissions across a wide frequency range and ensuring that they fall below specified limits.

The regulatory landscape also extends to workplace safety and environmental noise regulations. In some jurisdictions, persistent coil whine could potentially be considered a workplace hazard if it exceeds certain decibel levels or causes discomfort to users over extended periods. This consideration adds another layer of complexity to the compliance process for smart device manufacturers.

As technology evolves, regulatory bodies continue to update their standards to address new challenges. For instance, the increasing prevalence of high-frequency switching in modern power supplies has led to more stringent regulations on high-frequency emissions. Manufacturers must stay informed about these evolving standards and adapt their mitigation strategies accordingly.

Failure to comply with regulatory requirements can result in significant consequences, including product recalls, fines, and damage to brand reputation. Therefore, addressing coil whine is not just a matter of improving user experience but also a critical aspect of ensuring regulatory compliance and maintaining market access for smart devices.

In the United States, the Federal Communications Commission (FCC) sets strict guidelines for electronic devices through its Part 15 regulations. These rules specifically address unintentional radiators, which include devices that may produce coil whine. Manufacturers must ensure that their smart devices comply with FCC limits on conducted and radiated emissions to obtain certification and enter the market.

The European Union enforces similar regulations through the EMC Directive (2014/30/EU). This directive mandates that all electronic equipment sold within the EU must meet specific EMC requirements, including limits on electromagnetic interference. Coil whine, as a form of audible electromagnetic noise, falls under the purview of these regulations.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide additional guidance for manufacturers. The IEC 61000 series of standards, particularly IEC 61000-3-2 and IEC 61000-3-3, address harmonic current emissions and voltage fluctuations, which can be related to coil whine phenomena.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct EMC tests in certified laboratories to demonstrate that their devices meet the required standards. This process typically involves measuring electromagnetic emissions across a wide frequency range and ensuring that they fall below specified limits.

The regulatory landscape also extends to workplace safety and environmental noise regulations. In some jurisdictions, persistent coil whine could potentially be considered a workplace hazard if it exceeds certain decibel levels or causes discomfort to users over extended periods. This consideration adds another layer of complexity to the compliance process for smart device manufacturers.

As technology evolves, regulatory bodies continue to update their standards to address new challenges. For instance, the increasing prevalence of high-frequency switching in modern power supplies has led to more stringent regulations on high-frequency emissions. Manufacturers must stay informed about these evolving standards and adapt their mitigation strategies accordingly.

Failure to comply with regulatory requirements can result in significant consequences, including product recalls, fines, and damage to brand reputation. Therefore, addressing coil whine is not just a matter of improving user experience but also a critical aspect of ensuring regulatory compliance and maintaining market access for smart devices.

User Experience Impact

Coil whine in smart devices can significantly impact user experience, often leading to frustration and dissatisfaction among consumers. This high-frequency noise, typically emanating from electronic components such as inductors or transformers, can be particularly noticeable in quiet environments or during low-power operations.

The presence of coil whine can negatively affect the perceived quality of a device, regardless of its actual performance or features. Users may associate the noise with poor build quality or potential hardware issues, even when the device is functioning normally. This perception can lead to increased product returns, negative reviews, and damage to brand reputation.

In portable devices like smartphones and tablets, coil whine can be especially problematic during activities that require concentration or relaxation. For instance, users may find the noise distracting when reading e-books, watching videos, or trying to sleep with the device nearby. This interference can diminish the overall user experience and reduce the perceived value of the product.

The impact of coil whine on user experience can vary depending on individual sensitivity to high-frequency sounds. Some users may find the noise barely noticeable, while others may find it extremely irritating. This variability in perception presents a challenge for manufacturers in addressing the issue effectively across their entire user base.

Furthermore, coil whine can interfere with the audio quality of smart devices. In devices with built-in speakers or audio output, the high-frequency noise may be picked up by the audio system, resulting in unwanted background noise during media playback or voice calls. This interference can significantly degrade the audio experience, particularly in devices marketed for their sound quality.

The persistence of coil whine over time can also lead to user fatigue and decreased satisfaction with the device. What may initially be a minor annoyance can become increasingly bothersome with prolonged use, potentially leading users to seek alternative products or avoid future purchases from the same brand.

Addressing coil whine is crucial for maintaining a positive user experience and ensuring customer loyalty. Manufacturers must balance the need for efficient power management with the elimination of audible noise to create devices that not only perform well but also provide a pleasant and unobtrusive user experience.

The presence of coil whine can negatively affect the perceived quality of a device, regardless of its actual performance or features. Users may associate the noise with poor build quality or potential hardware issues, even when the device is functioning normally. This perception can lead to increased product returns, negative reviews, and damage to brand reputation.

In portable devices like smartphones and tablets, coil whine can be especially problematic during activities that require concentration or relaxation. For instance, users may find the noise distracting when reading e-books, watching videos, or trying to sleep with the device nearby. This interference can diminish the overall user experience and reduce the perceived value of the product.

The impact of coil whine on user experience can vary depending on individual sensitivity to high-frequency sounds. Some users may find the noise barely noticeable, while others may find it extremely irritating. This variability in perception presents a challenge for manufacturers in addressing the issue effectively across their entire user base.

Furthermore, coil whine can interfere with the audio quality of smart devices. In devices with built-in speakers or audio output, the high-frequency noise may be picked up by the audio system, resulting in unwanted background noise during media playback or voice calls. This interference can significantly degrade the audio experience, particularly in devices marketed for their sound quality.

The persistence of coil whine over time can also lead to user fatigue and decreased satisfaction with the device. What may initially be a minor annoyance can become increasingly bothersome with prolonged use, potentially leading users to seek alternative products or avoid future purchases from the same brand.

Addressing coil whine is crucial for maintaining a positive user experience and ensuring customer loyalty. Manufacturers must balance the need for efficient power management with the elimination of audible noise to create devices that not only perform well but also provide a pleasant and unobtrusive user experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!