Coil Whine Management: Techniques for R&D

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an electromagnetic phenomenon that occurs in electronic devices, particularly in power supplies and other components with inductors or transformers. This high-frequency noise is generated by the vibration of electromagnetic coils or other electrical components under alternating current. The issue has become increasingly prevalent in modern electronics due to the miniaturization of components and the push for higher efficiency in power delivery systems.

The phenomenon of coil whine has been observed since the early days of electronics, but it has gained more attention in recent years as consumers become more sensitive to noise pollution from their devices. The sound produced by coil whine can range from a barely audible high-pitched tone to a more noticeable buzzing or whining noise, depending on the specific components and operating conditions.

In the context of research and development, coil whine management has become a critical area of focus for manufacturers of electronic devices, particularly in industries such as computing, gaming, and audio equipment. The challenge lies in balancing the need for high-performance, efficient components with the desire for quiet operation, which is increasingly important in both consumer and professional environments.

The root causes of coil whine are complex and multifaceted. They can include factors such as the quality of materials used in the components, the design of the circuit board layout, the characteristics of the power supply, and even the specific frequencies at which the device operates. Environmental factors, such as temperature and humidity, can also play a role in exacerbating or mitigating coil whine issues.

As technology continues to advance, the importance of addressing coil whine has grown. This is particularly true in the realm of high-performance computing and gaming, where powerful components can generate significant electromagnetic noise. Additionally, the rise of silent computing and the increasing use of electronics in noise-sensitive environments have further emphasized the need for effective coil whine management techniques.

Research and development efforts in this area have focused on various approaches, including improved component design, advanced materials science, innovative circuit layouts, and sophisticated noise cancellation technologies. The goal is to develop solutions that can effectively reduce or eliminate coil whine without compromising the performance or efficiency of the electronic devices.

The phenomenon of coil whine has been observed since the early days of electronics, but it has gained more attention in recent years as consumers become more sensitive to noise pollution from their devices. The sound produced by coil whine can range from a barely audible high-pitched tone to a more noticeable buzzing or whining noise, depending on the specific components and operating conditions.

In the context of research and development, coil whine management has become a critical area of focus for manufacturers of electronic devices, particularly in industries such as computing, gaming, and audio equipment. The challenge lies in balancing the need for high-performance, efficient components with the desire for quiet operation, which is increasingly important in both consumer and professional environments.

The root causes of coil whine are complex and multifaceted. They can include factors such as the quality of materials used in the components, the design of the circuit board layout, the characteristics of the power supply, and even the specific frequencies at which the device operates. Environmental factors, such as temperature and humidity, can also play a role in exacerbating or mitigating coil whine issues.

As technology continues to advance, the importance of addressing coil whine has grown. This is particularly true in the realm of high-performance computing and gaming, where powerful components can generate significant electromagnetic noise. Additionally, the rise of silent computing and the increasing use of electronics in noise-sensitive environments have further emphasized the need for effective coil whine management techniques.

Research and development efforts in this area have focused on various approaches, including improved component design, advanced materials science, innovative circuit layouts, and sophisticated noise cancellation technologies. The goal is to develop solutions that can effectively reduce or eliminate coil whine without compromising the performance or efficiency of the electronic devices.

Market Impact Analysis

Coil whine management techniques have a significant impact on various market segments, particularly in consumer electronics, automotive, and industrial sectors. The demand for quieter and more efficient electronic devices has driven manufacturers to prioritize noise reduction technologies, including coil whine management.

In the consumer electronics market, coil whine management has become a crucial factor in product differentiation. High-end laptops, gaming consoles, and power supplies that effectively mitigate coil whine command premium prices and enjoy higher customer satisfaction rates. This has led to increased investment in research and development of advanced coil whine reduction techniques by major electronics manufacturers.

The automotive industry has also seen a growing emphasis on coil whine management, especially with the rise of electric and hybrid vehicles. As these vehicles rely heavily on power electronics, the reduction of coil whine contributes to a more comfortable and quieter driving experience. This has become a key selling point for many electric vehicle manufacturers, influencing consumer purchasing decisions and market share.

In the industrial sector, coil whine management techniques have found applications in power distribution systems, industrial machinery, and renewable energy installations. The implementation of effective coil whine reduction methods has led to improved equipment reliability, reduced maintenance costs, and enhanced workplace safety by minimizing noise-induced stress on workers.

The market for coil whine management solutions has experienced steady growth, with specialized component manufacturers and acoustic engineering firms seeing increased demand for their expertise. This has led to the development of new materials, design techniques, and testing methodologies specifically tailored to address coil whine issues.

The adoption of coil whine management techniques has also influenced supply chain dynamics. Manufacturers are increasingly prioritizing suppliers who can provide components with superior noise characteristics, leading to shifts in supplier relationships and potentially reshaping the competitive landscape in component manufacturing.

Furthermore, the focus on coil whine management has spurred innovation in related fields, such as electromagnetic compatibility (EMC) and thermal management. This cross-pollination of technologies has created new market opportunities for companies that can offer integrated solutions addressing multiple aspects of electronic device performance.

As awareness of coil whine issues grows among consumers and regulatory bodies, there is potential for new standards and regulations to emerge. This could further drive market demand for coil whine management solutions and create opportunities for companies that can quickly adapt to evolving requirements.

In the consumer electronics market, coil whine management has become a crucial factor in product differentiation. High-end laptops, gaming consoles, and power supplies that effectively mitigate coil whine command premium prices and enjoy higher customer satisfaction rates. This has led to increased investment in research and development of advanced coil whine reduction techniques by major electronics manufacturers.

The automotive industry has also seen a growing emphasis on coil whine management, especially with the rise of electric and hybrid vehicles. As these vehicles rely heavily on power electronics, the reduction of coil whine contributes to a more comfortable and quieter driving experience. This has become a key selling point for many electric vehicle manufacturers, influencing consumer purchasing decisions and market share.

In the industrial sector, coil whine management techniques have found applications in power distribution systems, industrial machinery, and renewable energy installations. The implementation of effective coil whine reduction methods has led to improved equipment reliability, reduced maintenance costs, and enhanced workplace safety by minimizing noise-induced stress on workers.

The market for coil whine management solutions has experienced steady growth, with specialized component manufacturers and acoustic engineering firms seeing increased demand for their expertise. This has led to the development of new materials, design techniques, and testing methodologies specifically tailored to address coil whine issues.

The adoption of coil whine management techniques has also influenced supply chain dynamics. Manufacturers are increasingly prioritizing suppliers who can provide components with superior noise characteristics, leading to shifts in supplier relationships and potentially reshaping the competitive landscape in component manufacturing.

Furthermore, the focus on coil whine management has spurred innovation in related fields, such as electromagnetic compatibility (EMC) and thermal management. This cross-pollination of technologies has created new market opportunities for companies that can offer integrated solutions addressing multiple aspects of electronic device performance.

As awareness of coil whine issues grows among consumers and regulatory bodies, there is potential for new standards and regulations to emerge. This could further drive market demand for coil whine management solutions and create opportunities for companies that can quickly adapt to evolving requirements.

Technical Challenges

Coil whine management presents several significant technical challenges in the field of research and development. One of the primary obstacles is the complex nature of electromagnetic interactions within electronic devices. The high-frequency vibrations that cause coil whine are often a result of intricate interplays between various components, making it difficult to isolate and address the root cause.

Another major challenge lies in the diversity of electronic devices and their unique configurations. Each device may exhibit different coil whine characteristics due to variations in design, materials, and manufacturing processes. This heterogeneity complicates the development of universal solutions and necessitates tailored approaches for different product categories.

The miniaturization trend in electronics further exacerbates the coil whine issue. As devices become smaller and more compact, the proximity of components increases, leading to greater electromagnetic interference and potentially more pronounced coil whine effects. This trend challenges engineers to develop innovative solutions that can effectively manage coil whine within increasingly constrained spaces.

Thermal management also poses a significant challenge in coil whine reduction. Many techniques for mitigating coil whine, such as using dampening materials or altering component designs, can impact heat dissipation. Balancing the need for effective coil whine management with proper thermal regulation requires careful consideration and often involves complex trade-offs.

The dynamic nature of coil whine presents another hurdle. The frequency and intensity of coil whine can vary depending on the device's operational state, power load, and environmental conditions. Developing solutions that can adapt to these changing conditions and provide consistent performance across various scenarios is a complex undertaking.

Cost considerations add another layer of complexity to coil whine management. While some advanced solutions may be highly effective, they may also be prohibitively expensive for mass-market products. Finding cost-effective techniques that can be implemented at scale without significantly impacting product pricing is a persistent challenge for R&D teams.

Lastly, the subjective nature of coil whine perception complicates the evaluation and validation of potential solutions. What may be an acceptable level of coil whine for one user might be intolerable for another. This subjectivity makes it challenging to establish universal standards and benchmarks for coil whine management, necessitating a more nuanced approach to solution development and testing.

Another major challenge lies in the diversity of electronic devices and their unique configurations. Each device may exhibit different coil whine characteristics due to variations in design, materials, and manufacturing processes. This heterogeneity complicates the development of universal solutions and necessitates tailored approaches for different product categories.

The miniaturization trend in electronics further exacerbates the coil whine issue. As devices become smaller and more compact, the proximity of components increases, leading to greater electromagnetic interference and potentially more pronounced coil whine effects. This trend challenges engineers to develop innovative solutions that can effectively manage coil whine within increasingly constrained spaces.

Thermal management also poses a significant challenge in coil whine reduction. Many techniques for mitigating coil whine, such as using dampening materials or altering component designs, can impact heat dissipation. Balancing the need for effective coil whine management with proper thermal regulation requires careful consideration and often involves complex trade-offs.

The dynamic nature of coil whine presents another hurdle. The frequency and intensity of coil whine can vary depending on the device's operational state, power load, and environmental conditions. Developing solutions that can adapt to these changing conditions and provide consistent performance across various scenarios is a complex undertaking.

Cost considerations add another layer of complexity to coil whine management. While some advanced solutions may be highly effective, they may also be prohibitively expensive for mass-market products. Finding cost-effective techniques that can be implemented at scale without significantly impacting product pricing is a persistent challenge for R&D teams.

Lastly, the subjective nature of coil whine perception complicates the evaluation and validation of potential solutions. What may be an acceptable level of coil whine for one user might be intolerable for another. This subjectivity makes it challenging to establish universal standards and benchmarks for coil whine management, necessitating a more nuanced approach to solution development and testing.

Current Mitigation

01 Electromagnetic shielding techniques

Implementing electromagnetic shielding techniques to reduce coil whine by containing electromagnetic fields generated by electronic components. This can involve using conductive materials or specialized coatings to create a barrier that prevents electromagnetic interference from escaping or entering sensitive areas.- Electromagnetic shielding techniques: Implementing electromagnetic shielding techniques to reduce coil whine by containing electromagnetic interference. This can involve using specialized materials or coatings to encase the coils or other components, effectively blocking the transmission of electromagnetic waves that contribute to the audible noise.

- Vibration dampening and isolation: Employing vibration dampening and isolation methods to minimize the transmission of mechanical vibrations that cause coil whine. This can include using rubber or silicone mounts, foam padding, or other shock-absorbing materials to isolate the coils from the surrounding structure.

- Coil design optimization: Optimizing the design of the coils themselves to reduce the likelihood of whine. This can involve adjusting the winding pattern, using different wire gauges, or implementing alternative core materials to minimize resonance and vibration during operation.

- Active noise cancellation: Implementing active noise cancellation techniques to counteract coil whine. This involves using sensors to detect the frequency and amplitude of the whine, then generating an inverse sound wave to cancel out the unwanted noise.

- Power supply and signal filtering: Improving power supply quality and implementing signal filtering to reduce electrical noise that can contribute to coil whine. This can include using higher quality capacitors, implementing low-pass filters, or employing advanced voltage regulation techniques to provide cleaner power to the coils.

02 Vibration dampening and isolation

Employing vibration dampening and isolation methods to minimize coil whine by reducing mechanical resonance. This can include using specialized materials or mounting techniques to absorb vibrations from coils and other components, preventing them from propagating through the device structure.Expand Specific Solutions03 Coil design optimization

Optimizing the design of coils to reduce the likelihood of whine generation. This can involve adjusting coil geometry, winding techniques, or core materials to minimize vibrations and electromagnetic emissions that contribute to coil whine.Expand Specific Solutions04 Active noise cancellation

Implementing active noise cancellation techniques to counteract coil whine. This approach involves using sensors to detect the whine and generating opposing sound waves or electromagnetic fields to cancel out the unwanted noise.Expand Specific Solutions05 Power supply and circuit design improvements

Enhancing power supply and circuit designs to minimize electrical fluctuations that can cause coil whine. This can include implementing better voltage regulation, filtering techniques, or redesigning circuit layouts to reduce electromagnetic interference and resonance.Expand Specific Solutions

Industry Leaders

The coil whine management technology landscape is in a mature phase, with established players and ongoing innovation. The market size is substantial, driven by the widespread use of electronic devices across industries. Companies like Toyota Motor Corp., Murata Manufacturing Co. Ltd., and TOKIN Corp. are at the forefront of technological advancements in this field. These firms have demonstrated high levels of technical maturity, leveraging their extensive R&D capabilities to develop sophisticated solutions for coil whine reduction. The competitive landscape is characterized by a mix of automotive, electronics, and specialized component manufacturers, each contributing unique expertise to address this persistent engineering challenge.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced noise suppression techniques for coil whine management in electronic components. Their approach involves the use of specialized magnetic materials and innovative winding techniques to minimize electromagnetic noise. They have implemented a multi-layer shielding technology that effectively reduces electromagnetic interference (EMI) and coil whine in power inductors and transformers[1]. Additionally, Murata has introduced a series of noise suppression filters specifically designed to address coil whine issues in various electronic devices, including power supplies and motor drivers[2]. These filters utilize a combination of capacitive and inductive elements to attenuate high-frequency noise associated with coil whine.

Strengths: Expertise in magnetic materials and EMI suppression. Comprehensive range of noise suppression solutions. Weaknesses: May require additional space in compact designs. Potential cost increase for high-performance solutions.

TOKIN Corp.

Technical Solution: TOKIN has developed a proprietary Noise Suppression Sheet technology for coil whine management. This innovative solution utilizes a thin, flexible sheet embedded with magnetic particles that can be easily applied to various electronic components. The sheet effectively absorbs and dissipates electromagnetic noise, including coil whine, across a wide frequency range[3]. TOKIN's approach also includes the development of advanced ferrite cores with optimized geometries and material compositions to minimize core losses and reduce coil whine in power inductors[4]. Furthermore, they have implemented a hybrid noise suppression technique that combines their sheet technology with active noise cancellation circuits, providing a comprehensive solution for complex electronic systems.

Strengths: Flexible and easy-to-apply noise suppression solution. Effective across a wide frequency range. Weaknesses: May require periodic replacement in high-stress environments. Potential thermal management challenges in some applications.

Key Innovations

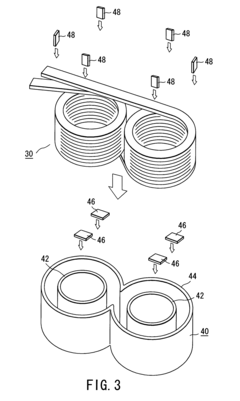

Coil component and fabrication method of the same

PatentInactiveUS7427909B2

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin, embedded within a magnetic core composed of a mixture of resin and magnetic powder, which provides enhanced structural integrity and noise suppression.

Liquid crystal panel

PatentInactiveEP2405297A1

Innovation

- A liquid crystal panel structure with a coil formed by allowing parts of the counter signal line or power supply line to make loops on the active matrix substrate, eliminating noise without the need for anti-noise components by inserting the coil in series with these lines, thereby stabilizing the liquid crystal applied voltage.

Regulatory Compliance

Regulatory compliance is a critical aspect of coil whine management in research and development. As electronic devices become increasingly prevalent in various industries, manufacturers must adhere to strict regulations governing electromagnetic compatibility (EMC) and noise emissions. These regulations are designed to ensure that electronic products do not interfere with other devices or cause undue discomfort to users.

In the context of coil whine, regulatory bodies such as the Federal Communications Commission (FCC) in the United States and the European Union's CE marking system have established specific limits on electromagnetic emissions. These limits cover a wide range of frequencies, including those associated with coil whine. Manufacturers must demonstrate compliance with these standards through rigorous testing and certification processes.

The International Electrotechnical Commission (IEC) has developed several standards relevant to coil whine management, including IEC 61000-3-2 for harmonic current emissions and IEC 61000-3-3 for voltage fluctuations and flicker. These standards provide guidelines for measuring and limiting electromagnetic disturbances, which can be directly applicable to coil whine issues.

Additionally, occupational health and safety regulations often include provisions for noise exposure in the workplace. While coil whine typically falls below the threshold for hearing damage, it can still contribute to overall noise levels and potentially impact worker comfort and productivity. As such, manufacturers may need to consider these regulations when designing products for use in professional environments.

Environmental regulations also play a role in coil whine management. The European Union's Restriction of Hazardous Substances (RoHS) directive, for example, limits the use of certain materials in electronic products. This can impact the selection of components and materials used in coil construction, potentially affecting their acoustic properties and the likelihood of coil whine occurrence.

To ensure regulatory compliance, R&D teams must integrate compliance considerations into the early stages of product development. This may involve conducting pre-compliance testing, utilizing specialized EMC simulation software, and collaborating with regulatory experts. By addressing potential coil whine issues proactively, manufacturers can avoid costly redesigns and delays in the product certification process.

Furthermore, as regulations continue to evolve, staying informed about upcoming changes and participating in industry standards development can provide a competitive advantage. This proactive approach allows companies to anticipate future requirements and incorporate them into their R&D strategies for coil whine management.

In the context of coil whine, regulatory bodies such as the Federal Communications Commission (FCC) in the United States and the European Union's CE marking system have established specific limits on electromagnetic emissions. These limits cover a wide range of frequencies, including those associated with coil whine. Manufacturers must demonstrate compliance with these standards through rigorous testing and certification processes.

The International Electrotechnical Commission (IEC) has developed several standards relevant to coil whine management, including IEC 61000-3-2 for harmonic current emissions and IEC 61000-3-3 for voltage fluctuations and flicker. These standards provide guidelines for measuring and limiting electromagnetic disturbances, which can be directly applicable to coil whine issues.

Additionally, occupational health and safety regulations often include provisions for noise exposure in the workplace. While coil whine typically falls below the threshold for hearing damage, it can still contribute to overall noise levels and potentially impact worker comfort and productivity. As such, manufacturers may need to consider these regulations when designing products for use in professional environments.

Environmental regulations also play a role in coil whine management. The European Union's Restriction of Hazardous Substances (RoHS) directive, for example, limits the use of certain materials in electronic products. This can impact the selection of components and materials used in coil construction, potentially affecting their acoustic properties and the likelihood of coil whine occurrence.

To ensure regulatory compliance, R&D teams must integrate compliance considerations into the early stages of product development. This may involve conducting pre-compliance testing, utilizing specialized EMC simulation software, and collaborating with regulatory experts. By addressing potential coil whine issues proactively, manufacturers can avoid costly redesigns and delays in the product certification process.

Furthermore, as regulations continue to evolve, staying informed about upcoming changes and participating in industry standards development can provide a competitive advantage. This proactive approach allows companies to anticipate future requirements and incorporate them into their R&D strategies for coil whine management.

Acoustic Testing

Acoustic testing plays a crucial role in the management of coil whine, providing essential data for R&D efforts to mitigate this common issue in electronic devices. The process involves sophisticated measurement techniques and analysis to quantify and characterize the acoustic emissions produced by electromagnetic coils under various operating conditions.

One of the primary methods employed in acoustic testing for coil whine is the use of anechoic chambers. These specialized rooms are designed to eliminate external noise and reflections, allowing for precise measurement of the sound produced by the device under test. Within these chambers, high-sensitivity microphones are strategically positioned to capture the acoustic signature of the coil whine across different frequencies and intensities.

Spectrum analysis is a key component of acoustic testing for coil whine. Fast Fourier Transform (FFT) algorithms are applied to the recorded audio data to decompose the complex waveforms into their constituent frequencies. This analysis helps identify the specific harmonic components that contribute to the perceived coil whine, enabling engineers to target their mitigation efforts more effectively.

Another important aspect of acoustic testing is the simulation of real-world operating conditions. Test setups often include variable power supplies and load simulators to replicate the dynamic electrical conditions that may trigger or exacerbate coil whine. This approach allows researchers to identify the correlation between electrical parameters and acoustic emissions, providing valuable insights for design optimization.

Psychoacoustic metrics are increasingly being incorporated into coil whine acoustic testing protocols. These metrics, such as loudness, sharpness, and tonality, take into account human perception of sound and help quantify the subjective annoyance factor of coil whine. By considering these psychoacoustic factors, R&D teams can prioritize their efforts on addressing the most perceptually significant aspects of the issue.

Advanced imaging techniques, such as acoustic cameras, are also being employed in coil whine research. These devices use arrays of microphones to create visual representations of sound fields, allowing engineers to pinpoint the exact sources of acoustic emissions within complex electronic assemblies. This spatial information is invaluable for identifying problematic components and optimizing PCB layouts to minimize coil whine.

Standardization of acoustic testing procedures for coil whine is an ongoing effort in the industry. Organizations such as the International Electrotechnical Commission (IEC) are working to develop uniform test methods and reporting standards. These standards aim to ensure consistency and comparability of results across different laboratories and manufacturers, facilitating more effective collaboration and benchmarking in the field of coil whine management.

One of the primary methods employed in acoustic testing for coil whine is the use of anechoic chambers. These specialized rooms are designed to eliminate external noise and reflections, allowing for precise measurement of the sound produced by the device under test. Within these chambers, high-sensitivity microphones are strategically positioned to capture the acoustic signature of the coil whine across different frequencies and intensities.

Spectrum analysis is a key component of acoustic testing for coil whine. Fast Fourier Transform (FFT) algorithms are applied to the recorded audio data to decompose the complex waveforms into their constituent frequencies. This analysis helps identify the specific harmonic components that contribute to the perceived coil whine, enabling engineers to target their mitigation efforts more effectively.

Another important aspect of acoustic testing is the simulation of real-world operating conditions. Test setups often include variable power supplies and load simulators to replicate the dynamic electrical conditions that may trigger or exacerbate coil whine. This approach allows researchers to identify the correlation between electrical parameters and acoustic emissions, providing valuable insights for design optimization.

Psychoacoustic metrics are increasingly being incorporated into coil whine acoustic testing protocols. These metrics, such as loudness, sharpness, and tonality, take into account human perception of sound and help quantify the subjective annoyance factor of coil whine. By considering these psychoacoustic factors, R&D teams can prioritize their efforts on addressing the most perceptually significant aspects of the issue.

Advanced imaging techniques, such as acoustic cameras, are also being employed in coil whine research. These devices use arrays of microphones to create visual representations of sound fields, allowing engineers to pinpoint the exact sources of acoustic emissions within complex electronic assemblies. This spatial information is invaluable for identifying problematic components and optimizing PCB layouts to minimize coil whine.

Standardization of acoustic testing procedures for coil whine is an ongoing effort in the industry. Organizations such as the International Electrotechnical Commission (IEC) are working to develop uniform test methods and reporting standards. These standards aim to ensure consistency and comparability of results across different laboratories and manufacturers, facilitating more effective collaboration and benchmarking in the field of coil whine management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!