Coil Whine Optimization Methods: Advanced Research Insights

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine, a phenomenon characterized by high-frequency vibrations in electronic components, has been a persistent challenge in the electronics industry for decades. This audible noise, typically emanating from inductors, transformers, or capacitors, is caused by magnetostriction or electrostatic forces acting on these components during operation. The issue gained prominence in the 1970s with the widespread adoption of switched-mode power supplies in consumer electronics.

As electronic devices became more compact and powerful, the problem of coil whine intensified. The miniaturization of components and the increase in switching frequencies led to more pronounced electromagnetic effects, exacerbating the audible noise. This trend has continued into the modern era, with high-performance computing systems, graphics cards, and power-hungry mobile devices all susceptible to coil whine.

The evolution of coil whine as a technical challenge mirrors the advancement of electronic technology. Early solutions focused on mechanical damping and component selection. However, as devices became more complex, these approaches proved insufficient. The industry began exploring more sophisticated methods, including advanced materials science, electromagnetic shielding techniques, and innovative circuit designs.

In recent years, the push for energy efficiency has inadvertently contributed to the prevalence of coil whine. The adoption of high-frequency switching regulators, while improving power efficiency, has also increased the likelihood of audible noise generation. This has led to a renewed focus on coil whine optimization, particularly in consumer electronics and high-performance computing sectors.

The technical goals in addressing coil whine have evolved from simple noise reduction to a more holistic approach. Modern objectives include not only minimizing audible noise but also optimizing power efficiency, thermal management, and electromagnetic compatibility. This multifaceted approach reflects the growing complexity of electronic systems and the interdependence of various performance factors.

As we look towards future technological trends, the importance of coil whine optimization is likely to increase. The advent of 5G technology, the proliferation of Internet of Things (IoT) devices, and the continued growth of high-performance computing all present new challenges in managing electromagnetic noise. These developments underscore the need for continued research and innovation in coil whine mitigation strategies, positioning it as a critical area of focus in the ongoing evolution of electronic design and engineering.

As electronic devices became more compact and powerful, the problem of coil whine intensified. The miniaturization of components and the increase in switching frequencies led to more pronounced electromagnetic effects, exacerbating the audible noise. This trend has continued into the modern era, with high-performance computing systems, graphics cards, and power-hungry mobile devices all susceptible to coil whine.

The evolution of coil whine as a technical challenge mirrors the advancement of electronic technology. Early solutions focused on mechanical damping and component selection. However, as devices became more complex, these approaches proved insufficient. The industry began exploring more sophisticated methods, including advanced materials science, electromagnetic shielding techniques, and innovative circuit designs.

In recent years, the push for energy efficiency has inadvertently contributed to the prevalence of coil whine. The adoption of high-frequency switching regulators, while improving power efficiency, has also increased the likelihood of audible noise generation. This has led to a renewed focus on coil whine optimization, particularly in consumer electronics and high-performance computing sectors.

The technical goals in addressing coil whine have evolved from simple noise reduction to a more holistic approach. Modern objectives include not only minimizing audible noise but also optimizing power efficiency, thermal management, and electromagnetic compatibility. This multifaceted approach reflects the growing complexity of electronic systems and the interdependence of various performance factors.

As we look towards future technological trends, the importance of coil whine optimization is likely to increase. The advent of 5G technology, the proliferation of Internet of Things (IoT) devices, and the continued growth of high-performance computing all present new challenges in managing electromagnetic noise. These developments underscore the need for continued research and innovation in coil whine mitigation strategies, positioning it as a critical area of focus in the ongoing evolution of electronic design and engineering.

Market Impact Analysis

The market impact of coil whine optimization methods extends far beyond the realm of electronics manufacturing, influencing various sectors and consumer behaviors. As electronic devices become increasingly prevalent in both personal and professional settings, the demand for quieter, more efficient products has grown significantly. This shift in consumer preferences has prompted manufacturers to prioritize coil whine reduction techniques, leading to a ripple effect across the electronics industry.

In the consumer electronics market, the implementation of advanced coil whine optimization methods has become a key differentiator for high-end products. Manufacturers who successfully minimize or eliminate coil whine in their devices can command premium prices and gain a competitive edge. This trend is particularly evident in the gaming and professional computing sectors, where users are willing to pay more for silent operation and improved performance.

The automotive industry has also been significantly impacted by advancements in coil whine optimization. As electric vehicles (EVs) gain market share, the reduction of electromagnetic noise has become crucial for enhancing the driving experience and meeting stringent noise regulations. Manufacturers who can effectively minimize coil whine in their EV components are better positioned to capture market share and meet consumer expectations for quiet, smooth operation.

In the industrial sector, the adoption of coil whine optimization methods has led to improved efficiency and reduced maintenance costs for heavy machinery and manufacturing equipment. By minimizing electromagnetic noise and vibration, companies can extend the lifespan of their equipment, reduce downtime, and enhance overall productivity. This has resulted in a growing market for specialized coil whine reduction solutions in industrial applications.

The impact of coil whine optimization has also been felt in the renewable energy sector, particularly in wind turbine manufacturing. As wind farms expand and move closer to populated areas, the need for quieter operation has become paramount. Advanced coil whine reduction techniques have enabled manufacturers to develop more efficient and less disruptive wind turbines, facilitating the growth of wind energy adoption and improving public acceptance of renewable energy projects.

The healthcare industry has seen notable benefits from coil whine optimization in medical imaging equipment. Reduced electromagnetic noise in MRI machines, for example, has led to improved image quality and patient comfort. This has driven demand for advanced coil whine reduction technologies in medical device manufacturing, creating new market opportunities for specialized component suppliers and engineering firms.

As the importance of coil whine optimization grows across industries, a new market for specialized testing and certification services has emerged. Companies offering acoustic and electromagnetic compatibility testing have seen increased demand for their services, as manufacturers seek to validate their coil whine reduction efforts and comply with increasingly stringent noise regulations.

In the consumer electronics market, the implementation of advanced coil whine optimization methods has become a key differentiator for high-end products. Manufacturers who successfully minimize or eliminate coil whine in their devices can command premium prices and gain a competitive edge. This trend is particularly evident in the gaming and professional computing sectors, where users are willing to pay more for silent operation and improved performance.

The automotive industry has also been significantly impacted by advancements in coil whine optimization. As electric vehicles (EVs) gain market share, the reduction of electromagnetic noise has become crucial for enhancing the driving experience and meeting stringent noise regulations. Manufacturers who can effectively minimize coil whine in their EV components are better positioned to capture market share and meet consumer expectations for quiet, smooth operation.

In the industrial sector, the adoption of coil whine optimization methods has led to improved efficiency and reduced maintenance costs for heavy machinery and manufacturing equipment. By minimizing electromagnetic noise and vibration, companies can extend the lifespan of their equipment, reduce downtime, and enhance overall productivity. This has resulted in a growing market for specialized coil whine reduction solutions in industrial applications.

The impact of coil whine optimization has also been felt in the renewable energy sector, particularly in wind turbine manufacturing. As wind farms expand and move closer to populated areas, the need for quieter operation has become paramount. Advanced coil whine reduction techniques have enabled manufacturers to develop more efficient and less disruptive wind turbines, facilitating the growth of wind energy adoption and improving public acceptance of renewable energy projects.

The healthcare industry has seen notable benefits from coil whine optimization in medical imaging equipment. Reduced electromagnetic noise in MRI machines, for example, has led to improved image quality and patient comfort. This has driven demand for advanced coil whine reduction technologies in medical device manufacturing, creating new market opportunities for specialized component suppliers and engineering firms.

As the importance of coil whine optimization grows across industries, a new market for specialized testing and certification services has emerged. Companies offering acoustic and electromagnetic compatibility testing have seen increased demand for their services, as manufacturers seek to validate their coil whine reduction efforts and comply with increasingly stringent noise regulations.

Current Challenges

Coil whine, a persistent challenge in electronic devices, continues to pose significant obstacles for manufacturers and engineers. This high-frequency noise, emanating from electromagnetic components, not only affects user experience but also impacts device performance and longevity. The current state of coil whine optimization faces several key challenges that demand innovative solutions.

One of the primary hurdles is the increasing miniaturization of electronic devices. As components are packed more tightly into smaller spaces, the potential for electromagnetic interference and resonance increases, exacerbating the coil whine issue. This trend towards compact design conflicts with traditional mitigation techniques that often rely on physical separation or bulky shielding materials.

Another significant challenge lies in the diverse range of frequencies at which coil whine can occur. Different components and operating conditions can produce varying frequencies of noise, making it difficult to develop a one-size-fits-all solution. Engineers must contend with a spectrum of frequencies, often requiring multiple optimization strategies to address the full range of potential coil whine sources.

The dynamic nature of electronic loads further complicates coil whine optimization efforts. Modern devices frequently switch between different power states and operating modes, leading to fluctuating electromagnetic fields. This variability makes it challenging to predict and mitigate coil whine consistently across all usage scenarios, necessitating adaptive solutions that can respond to changing conditions in real-time.

Cost considerations present another substantial obstacle. While effective solutions may exist, they often come at a premium that can significantly impact product pricing and market competitiveness. Balancing the need for coil whine reduction with economic viability remains a delicate task for manufacturers, particularly in consumer electronics where price sensitivity is high.

Environmental factors also play a crucial role in the complexity of coil whine optimization. Temperature variations, humidity, and even physical stress on components can influence the occurrence and intensity of coil whine. Developing solutions that remain effective across a wide range of environmental conditions adds another layer of difficulty to the optimization process.

Regulatory compliance presents an additional challenge, as electromagnetic emissions standards become increasingly stringent. Engineers must not only address the audible aspects of coil whine but also ensure that their solutions do not inadvertently increase electromagnetic interference, potentially violating regulatory limits.

Lastly, the interdisciplinary nature of coil whine optimization poses a challenge in itself. Effective solutions often require expertise from various fields, including electrical engineering, materials science, and acoustic engineering. Coordinating these diverse skill sets and integrating their insights into cohesive optimization strategies remains a complex undertaking for many organizations.

One of the primary hurdles is the increasing miniaturization of electronic devices. As components are packed more tightly into smaller spaces, the potential for electromagnetic interference and resonance increases, exacerbating the coil whine issue. This trend towards compact design conflicts with traditional mitigation techniques that often rely on physical separation or bulky shielding materials.

Another significant challenge lies in the diverse range of frequencies at which coil whine can occur. Different components and operating conditions can produce varying frequencies of noise, making it difficult to develop a one-size-fits-all solution. Engineers must contend with a spectrum of frequencies, often requiring multiple optimization strategies to address the full range of potential coil whine sources.

The dynamic nature of electronic loads further complicates coil whine optimization efforts. Modern devices frequently switch between different power states and operating modes, leading to fluctuating electromagnetic fields. This variability makes it challenging to predict and mitigate coil whine consistently across all usage scenarios, necessitating adaptive solutions that can respond to changing conditions in real-time.

Cost considerations present another substantial obstacle. While effective solutions may exist, they often come at a premium that can significantly impact product pricing and market competitiveness. Balancing the need for coil whine reduction with economic viability remains a delicate task for manufacturers, particularly in consumer electronics where price sensitivity is high.

Environmental factors also play a crucial role in the complexity of coil whine optimization. Temperature variations, humidity, and even physical stress on components can influence the occurrence and intensity of coil whine. Developing solutions that remain effective across a wide range of environmental conditions adds another layer of difficulty to the optimization process.

Regulatory compliance presents an additional challenge, as electromagnetic emissions standards become increasingly stringent. Engineers must not only address the audible aspects of coil whine but also ensure that their solutions do not inadvertently increase electromagnetic interference, potentially violating regulatory limits.

Lastly, the interdisciplinary nature of coil whine optimization poses a challenge in itself. Effective solutions often require expertise from various fields, including electrical engineering, materials science, and acoustic engineering. Coordinating these diverse skill sets and integrating their insights into cohesive optimization strategies remains a complex undertaking for many organizations.

Existing Solutions

01 Electromagnetic shielding techniques

Implementing electromagnetic shielding techniques to reduce coil whine by isolating the source of electromagnetic interference. This can involve using conductive materials or specialized coatings to create a barrier that prevents electromagnetic waves from escaping or entering sensitive components.- Electromagnetic shielding techniques: Implementing electromagnetic shielding techniques can help reduce coil whine by minimizing electromagnetic interference. This may involve using conductive materials to encase the coil or incorporating shielding layers within the device's design. Proper shielding can contain the electromagnetic fields generated by the coil, reducing audible noise.

- Optimizing coil design and materials: Improving the design and materials of the coil itself can significantly reduce whine. This may include using high-quality core materials, optimizing winding techniques, or employing specialized coil shapes. Advanced materials and precise manufacturing processes can minimize vibrations and resonances that contribute to coil whine.

- Active noise cancellation: Implementing active noise cancellation techniques can help counteract coil whine. This involves using sensors to detect the whine and generating an inverse sound wave to cancel it out. Advanced signal processing algorithms can be employed to adapt to varying whine frequencies and intensities in real-time.

- Frequency modulation and spread spectrum techniques: Applying frequency modulation or spread spectrum techniques to the coil's driving signals can help distribute the acoustic energy over a wider frequency range. This can make the whine less noticeable to human ears by reducing the concentration of energy at specific frequencies that are more easily perceived.

- Mechanical damping and isolation: Incorporating mechanical damping and isolation methods can reduce the transmission of vibrations from the coil to other parts of the device. This may involve using specialized mounting materials, vibration-absorbing compounds, or designing the device's structure to minimize resonance. Proper isolation can significantly reduce the audible manifestation of coil whine.

02 Optimizing coil design and materials

Improving coil design and selecting appropriate materials to minimize vibrations that cause coil whine. This includes using high-quality core materials, optimizing winding techniques, and implementing damping mechanisms to reduce resonance frequencies.Expand Specific Solutions03 Advanced control algorithms

Developing and implementing advanced control algorithms to regulate power delivery and minimize sudden changes in current that can lead to coil whine. These algorithms can include adaptive frequency modulation and intelligent power management techniques.Expand Specific Solutions04 Thermal management solutions

Implementing effective thermal management solutions to control temperature fluctuations that can contribute to coil whine. This includes using advanced cooling systems, heat-dissipating materials, and optimized component layouts to maintain stable operating temperatures.Expand Specific Solutions05 Vibration dampening and isolation

Employing vibration dampening and isolation techniques to reduce the transmission of mechanical vibrations that contribute to coil whine. This can involve using specialized mounting systems, vibration-absorbing materials, and strategic component placement to minimize resonance effects.Expand Specific Solutions

Industry Leaders

The coil whine optimization market is in a growth phase, driven by increasing demand for quieter electronic devices across various industries. The market size is expanding as more manufacturers prioritize noise reduction in their products. Technologically, the field is advancing rapidly, with companies like Toyota Motor Corp., Siemens AG, and Robert Bosch GmbH leading innovation. These firms are developing sophisticated solutions, including advanced materials and design techniques, to mitigate coil whine. The technology's maturity varies, with some established methods and emerging cutting-edge approaches. Companies such as Halliburton Energy Services and Kongsberg Maritime are adapting these technologies for specific industrial applications, further driving market growth and technological refinement.

Siemens AG

Technical Solution: Siemens AG has developed advanced coil whine optimization methods focusing on electromagnetic design and material science. Their approach includes using advanced magnetic materials with lower magnetostriction, such as amorphous alloys, to reduce vibrations[1]. They've also implemented active noise control systems that use piezoelectric actuators to generate counter-vibrations, effectively cancelling out coil whine[3]. Siemens has further refined their coil designs using finite element analysis to optimize winding patterns and reduce electromagnetic forces that cause vibrations[5]. Additionally, they've developed innovative cooling solutions to maintain consistent temperatures, as thermal fluctuations can exacerbate coil whine[7].

Strengths: Comprehensive approach combining material science, active control, and thermal management. Weaknesses: Potentially higher costs due to advanced materials and complex control systems.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has focused on coil whine optimization through innovative manufacturing techniques and advanced control algorithms. They've developed a precision winding technique that ensures uniform wire tension and spacing, reducing asymmetries that can lead to vibrations[2]. Bosch has also implemented adaptive PWM (Pulse Width Modulation) control strategies that dynamically adjust switching frequencies to avoid resonant frequencies that cause coil whine[4]. Their research includes the use of multi-layer PCB coils with optimized trace layouts to minimize stray magnetic fields[6]. Furthermore, Bosch has explored the use of magnetorheological fluids in coil encapsulation, which can change stiffness under magnetic fields to dampen vibrations[8].

Strengths: Focus on manufacturing precision and adaptive control strategies. Weaknesses: Some solutions may be complex to implement in mass production.

Key Innovations

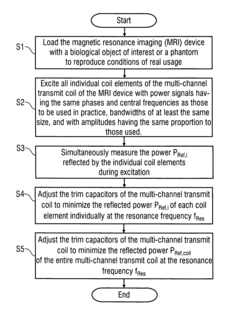

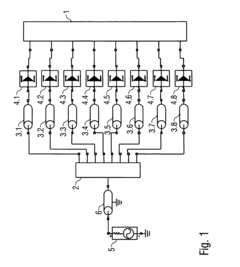

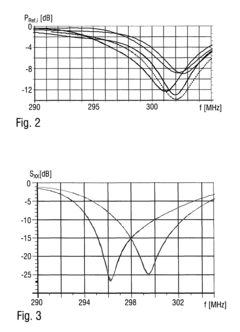

Method for optimization of a multi-channel coil

PatentActiveUS9024636B2

Innovation

- A method that directly minimizes the power reflected by the entire coil at resonance frequency by measuring and adjusting the insertion impedance of each coil element, using reflected power measurement devices to simplify the optimization process and reduce measurement effort, allowing for real-time coil performance optimization.

Method for reducing of whine noise for continuously variable transmission entails carrying out pretensioning of elements in thrust component bands by hot assembly of ring packs

PatentInactiveDE10354702A1

Innovation

- Implementing a method to prestress the elements in the CVT belt by a hot assembly of ring packs, utilizing thermal expansion to create a larger space requirement for the elements, ensuring they are under tension even when the transmission is unloaded, thereby reducing noise when under load.

Acoustic Standards

Acoustic standards play a crucial role in the optimization of coil whine, providing a framework for measuring, evaluating, and mitigating this unwanted noise in electronic devices. These standards are developed by various international organizations and regulatory bodies to ensure consistency and reliability in acoustic measurements across different industries and applications.

The International Electrotechnical Commission (IEC) has established several standards relevant to coil whine optimization. IEC 60268-16, for instance, focuses on the objective rating of speech intelligibility by speech transmission index, which can be applied to assess the impact of coil whine on audio quality in communication devices. Additionally, IEC 61672-1 specifies performance requirements for sound level meters, essential tools in measuring and quantifying coil whine emissions.

The International Organization for Standardization (ISO) also contributes significantly to acoustic standards applicable to coil whine optimization. ISO 3744 provides guidelines for determining sound power levels of noise sources using sound pressure, which is particularly useful in characterizing the acoustic output of electronic components. ISO 7779, developed in conjunction with ECMA-74, outlines methods for measuring airborne noise emitted by information technology and telecommunications equipment, including procedures that can be adapted for coil whine assessment.

In the automotive industry, where coil whine can be a significant concern in electric and hybrid vehicles, standards such as ISO 5128 for measuring interior noise levels and SAE J1030 for measuring exterior sound levels of vehicles are particularly relevant. These standards help manufacturers ensure that coil whine from various components does not exceed acceptable limits within the vehicle cabin or contribute to overall environmental noise pollution.

For consumer electronics, ENERGY STAR program requirements often include acoustic noise limits, indirectly addressing coil whine issues. While not exclusively focused on coil whine, these standards encourage manufacturers to implement noise reduction techniques that can mitigate the problem.

Compliance with these acoustic standards often necessitates sophisticated measurement techniques and equipment. Anechoic chambers, precision microphones, and advanced signal processing software are typically employed to accurately characterize coil whine emissions in accordance with standardized procedures. The use of these standards not only ensures regulatory compliance but also facilitates the comparison of different optimization techniques and their effectiveness across various devices and industries.

As technology evolves, acoustic standards continue to be updated to address emerging challenges in noise control, including those related to coil whine. Ongoing research in psychoacoustics and advancements in measurement technologies are likely to influence future revisions of these standards, potentially leading to more stringent requirements and innovative approaches to coil whine optimization.

The International Electrotechnical Commission (IEC) has established several standards relevant to coil whine optimization. IEC 60268-16, for instance, focuses on the objective rating of speech intelligibility by speech transmission index, which can be applied to assess the impact of coil whine on audio quality in communication devices. Additionally, IEC 61672-1 specifies performance requirements for sound level meters, essential tools in measuring and quantifying coil whine emissions.

The International Organization for Standardization (ISO) also contributes significantly to acoustic standards applicable to coil whine optimization. ISO 3744 provides guidelines for determining sound power levels of noise sources using sound pressure, which is particularly useful in characterizing the acoustic output of electronic components. ISO 7779, developed in conjunction with ECMA-74, outlines methods for measuring airborne noise emitted by information technology and telecommunications equipment, including procedures that can be adapted for coil whine assessment.

In the automotive industry, where coil whine can be a significant concern in electric and hybrid vehicles, standards such as ISO 5128 for measuring interior noise levels and SAE J1030 for measuring exterior sound levels of vehicles are particularly relevant. These standards help manufacturers ensure that coil whine from various components does not exceed acceptable limits within the vehicle cabin or contribute to overall environmental noise pollution.

For consumer electronics, ENERGY STAR program requirements often include acoustic noise limits, indirectly addressing coil whine issues. While not exclusively focused on coil whine, these standards encourage manufacturers to implement noise reduction techniques that can mitigate the problem.

Compliance with these acoustic standards often necessitates sophisticated measurement techniques and equipment. Anechoic chambers, precision microphones, and advanced signal processing software are typically employed to accurately characterize coil whine emissions in accordance with standardized procedures. The use of these standards not only ensures regulatory compliance but also facilitates the comparison of different optimization techniques and their effectiveness across various devices and industries.

As technology evolves, acoustic standards continue to be updated to address emerging challenges in noise control, including those related to coil whine. Ongoing research in psychoacoustics and advancements in measurement technologies are likely to influence future revisions of these standards, potentially leading to more stringent requirements and innovative approaches to coil whine optimization.

Energy Efficiency

Energy efficiency is a critical aspect of coil whine optimization methods, as it directly impacts the overall performance and sustainability of electronic devices. The reduction of coil whine not only improves user experience but also contributes to energy conservation and extended battery life in portable devices. Advanced research insights into energy efficiency focus on minimizing power losses and optimizing the conversion of electrical energy into useful work.

One of the primary approaches to enhancing energy efficiency in coil whine reduction is through the implementation of advanced power management techniques. These techniques involve dynamic voltage and frequency scaling (DVFS), which allows for real-time adjustments of power consumption based on the device's workload. By intelligently regulating voltage and frequency, DVFS can significantly reduce energy waste and mitigate coil whine without compromising performance.

Another area of focus is the development of more efficient power delivery networks (PDNs). Researchers are exploring novel materials and designs for power supply components, such as capacitors and inductors, to minimize parasitic losses and improve overall system efficiency. Advanced PDN designs also incorporate better voltage regulation and filtering techniques to reduce ripple and noise, which are often contributors to coil whine.

The optimization of switching frequencies in power converters is another key area of research. By carefully selecting and dynamically adjusting switching frequencies, engineers can balance between efficiency and electromagnetic interference (EMI) reduction. This approach not only helps in minimizing coil whine but also contributes to overall energy conservation by reducing switching losses and improving power conversion efficiency.

Thermal management plays a crucial role in energy efficiency and coil whine reduction. Advanced cooling solutions, such as phase-change materials and microfluidic cooling systems, are being investigated to maintain optimal operating temperatures for electronic components. Efficient thermal management not only reduces energy consumption but also extends the lifespan of components, indirectly contributing to sustainability and resource conservation.

Lastly, the integration of artificial intelligence and machine learning algorithms in power management systems is emerging as a promising direction for energy efficiency optimization. These intelligent systems can learn from usage patterns and environmental conditions to predict and proactively adjust power delivery, potentially leading to significant improvements in energy efficiency and coil whine reduction across various operating scenarios.

One of the primary approaches to enhancing energy efficiency in coil whine reduction is through the implementation of advanced power management techniques. These techniques involve dynamic voltage and frequency scaling (DVFS), which allows for real-time adjustments of power consumption based on the device's workload. By intelligently regulating voltage and frequency, DVFS can significantly reduce energy waste and mitigate coil whine without compromising performance.

Another area of focus is the development of more efficient power delivery networks (PDNs). Researchers are exploring novel materials and designs for power supply components, such as capacitors and inductors, to minimize parasitic losses and improve overall system efficiency. Advanced PDN designs also incorporate better voltage regulation and filtering techniques to reduce ripple and noise, which are often contributors to coil whine.

The optimization of switching frequencies in power converters is another key area of research. By carefully selecting and dynamically adjusting switching frequencies, engineers can balance between efficiency and electromagnetic interference (EMI) reduction. This approach not only helps in minimizing coil whine but also contributes to overall energy conservation by reducing switching losses and improving power conversion efficiency.

Thermal management plays a crucial role in energy efficiency and coil whine reduction. Advanced cooling solutions, such as phase-change materials and microfluidic cooling systems, are being investigated to maintain optimal operating temperatures for electronic components. Efficient thermal management not only reduces energy consumption but also extends the lifespan of components, indirectly contributing to sustainability and resource conservation.

Lastly, the integration of artificial intelligence and machine learning algorithms in power management systems is emerging as a promising direction for energy efficiency optimization. These intelligent systems can learn from usage patterns and environmental conditions to predict and proactively adjust power delivery, potentially leading to significant improvements in energy efficiency and coil whine reduction across various operating scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!