Coil Whine and Echo Reduction: Performance Strategies

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Origins

Coil whine is an audible electromagnetic phenomenon that occurs in electronic devices, particularly in power supplies and other components with inductors or transformers. This high-frequency noise is primarily caused by the vibration of electromagnetic coils or other magnetic components when subjected to rapidly changing electrical currents. The origins of coil whine can be traced back to the fundamental principles of electromagnetism and the design of modern electronic circuits.

At its core, coil whine is a result of magnetostriction, a property of ferromagnetic materials that causes them to change shape when exposed to a magnetic field. In electronic components, such as inductors and transformers, the rapid switching of electrical currents creates fluctuating magnetic fields. These fields cause the ferromagnetic cores to expand and contract at high frequencies, producing audible vibrations.

The prevalence of coil whine has increased with the advancement of power electronics and the widespread adoption of switch-mode power supplies (SMPS). These efficient power conversion systems operate at high frequencies, typically in the range of 20 kHz to 1 MHz, to reduce the size of magnetic components. However, this high-frequency operation also increases the likelihood of audible coil whine, especially when harmonics fall within the human hearing range of 20 Hz to 20 kHz.

Several factors contribute to the severity and perception of coil whine. The physical construction of the coil, including its winding technique and the materials used, plays a crucial role. Poorly designed or manufactured coils are more susceptible to vibration and, consequently, coil whine. Additionally, the electrical characteristics of the circuit, such as the switching frequency and current waveform, can exacerbate the issue.

Environmental factors also influence coil whine. Temperature fluctuations can affect the physical properties of the magnetic materials, potentially altering their vibrational characteristics. Moreover, the acoustic properties of the device enclosure and surrounding environment can amplify or attenuate the perceived noise.

The impact of coil whine extends beyond mere annoyance. In sensitive electronic equipment, such as audio recording devices or medical imaging systems, coil whine can introduce unwanted noise and interference, potentially compromising the quality of output or data. In consumer electronics, particularly in quiet environments, coil whine can significantly degrade the user experience, leading to customer dissatisfaction and product returns.

Understanding the origins of coil whine is crucial for developing effective mitigation strategies. Engineers and designers must consider the complex interplay between electrical, magnetic, and mechanical factors when addressing this issue. This knowledge forms the foundation for implementing performance strategies aimed at reducing coil whine and its associated echoes in electronic devices.

At its core, coil whine is a result of magnetostriction, a property of ferromagnetic materials that causes them to change shape when exposed to a magnetic field. In electronic components, such as inductors and transformers, the rapid switching of electrical currents creates fluctuating magnetic fields. These fields cause the ferromagnetic cores to expand and contract at high frequencies, producing audible vibrations.

The prevalence of coil whine has increased with the advancement of power electronics and the widespread adoption of switch-mode power supplies (SMPS). These efficient power conversion systems operate at high frequencies, typically in the range of 20 kHz to 1 MHz, to reduce the size of magnetic components. However, this high-frequency operation also increases the likelihood of audible coil whine, especially when harmonics fall within the human hearing range of 20 Hz to 20 kHz.

Several factors contribute to the severity and perception of coil whine. The physical construction of the coil, including its winding technique and the materials used, plays a crucial role. Poorly designed or manufactured coils are more susceptible to vibration and, consequently, coil whine. Additionally, the electrical characteristics of the circuit, such as the switching frequency and current waveform, can exacerbate the issue.

Environmental factors also influence coil whine. Temperature fluctuations can affect the physical properties of the magnetic materials, potentially altering their vibrational characteristics. Moreover, the acoustic properties of the device enclosure and surrounding environment can amplify or attenuate the perceived noise.

The impact of coil whine extends beyond mere annoyance. In sensitive electronic equipment, such as audio recording devices or medical imaging systems, coil whine can introduce unwanted noise and interference, potentially compromising the quality of output or data. In consumer electronics, particularly in quiet environments, coil whine can significantly degrade the user experience, leading to customer dissatisfaction and product returns.

Understanding the origins of coil whine is crucial for developing effective mitigation strategies. Engineers and designers must consider the complex interplay between electrical, magnetic, and mechanical factors when addressing this issue. This knowledge forms the foundation for implementing performance strategies aimed at reducing coil whine and its associated echoes in electronic devices.

Market Demand Analysis

The market demand for coil whine and echo reduction technologies has been steadily increasing in recent years, driven by the growing consumer electronics industry and the rising expectations for high-quality audio experiences. As electronic devices become more compact and powerful, the issue of coil whine has become more prevalent, affecting a wide range of products from smartphones and laptops to gaming consoles and power supplies.

In the consumer electronics sector, manufacturers are facing increasing pressure to address coil whine issues, as they can significantly impact user experience and product perception. The demand for effective solutions is particularly high in the gaming and high-performance computing markets, where powerful components and intensive workloads often exacerbate the problem. This has led to a surge in research and development efforts aimed at mitigating coil whine through innovative design techniques and materials.

The automotive industry has also emerged as a significant market for coil whine reduction technologies. With the rapid growth of electric and hybrid vehicles, the need for quiet and efficient power electronics has become paramount. Consumers expect a silent and comfortable driving experience, making coil whine reduction a critical factor in vehicle design and manufacturing.

Echo reduction technologies, on the other hand, have seen substantial demand growth in the telecommunications and smart home device markets. The proliferation of voice-controlled devices and virtual assistants has created a need for advanced echo cancellation algorithms to improve speech recognition accuracy and overall user experience. This trend is expected to continue as voice-based interfaces become more prevalent in various applications, from smart speakers to automotive infotainment systems.

The professional audio and video conferencing markets have also contributed significantly to the demand for echo reduction solutions. With the global shift towards remote work and virtual meetings, there has been a surge in the adoption of video conferencing platforms. This has highlighted the importance of clear, echo-free audio communication, driving investments in advanced echo cancellation technologies.

In the industrial sector, the demand for coil whine reduction is growing in power electronics applications, particularly in renewable energy systems and industrial automation. As these systems become more sophisticated and widespread, the need for quiet and efficient operation has become a key consideration for manufacturers and end-users alike.

The market for coil whine and echo reduction technologies is expected to continue its growth trajectory in the coming years, driven by ongoing technological advancements and the increasing integration of electronic devices in various aspects of daily life. This presents significant opportunities for companies specializing in acoustic engineering, signal processing, and materials science to develop innovative solutions that address these challenges and meet the evolving demands of diverse industries.

In the consumer electronics sector, manufacturers are facing increasing pressure to address coil whine issues, as they can significantly impact user experience and product perception. The demand for effective solutions is particularly high in the gaming and high-performance computing markets, where powerful components and intensive workloads often exacerbate the problem. This has led to a surge in research and development efforts aimed at mitigating coil whine through innovative design techniques and materials.

The automotive industry has also emerged as a significant market for coil whine reduction technologies. With the rapid growth of electric and hybrid vehicles, the need for quiet and efficient power electronics has become paramount. Consumers expect a silent and comfortable driving experience, making coil whine reduction a critical factor in vehicle design and manufacturing.

Echo reduction technologies, on the other hand, have seen substantial demand growth in the telecommunications and smart home device markets. The proliferation of voice-controlled devices and virtual assistants has created a need for advanced echo cancellation algorithms to improve speech recognition accuracy and overall user experience. This trend is expected to continue as voice-based interfaces become more prevalent in various applications, from smart speakers to automotive infotainment systems.

The professional audio and video conferencing markets have also contributed significantly to the demand for echo reduction solutions. With the global shift towards remote work and virtual meetings, there has been a surge in the adoption of video conferencing platforms. This has highlighted the importance of clear, echo-free audio communication, driving investments in advanced echo cancellation technologies.

In the industrial sector, the demand for coil whine reduction is growing in power electronics applications, particularly in renewable energy systems and industrial automation. As these systems become more sophisticated and widespread, the need for quiet and efficient operation has become a key consideration for manufacturers and end-users alike.

The market for coil whine and echo reduction technologies is expected to continue its growth trajectory in the coming years, driven by ongoing technological advancements and the increasing integration of electronic devices in various aspects of daily life. This presents significant opportunities for companies specializing in acoustic engineering, signal processing, and materials science to develop innovative solutions that address these challenges and meet the evolving demands of diverse industries.

Current Challenges

Coil whine and echo reduction present significant challenges in modern electronic systems, particularly in high-performance computing and audio equipment. These issues stem from electromagnetic interactions and acoustic reflections, respectively, and can severely impact user experience and device functionality.

One of the primary challenges in addressing coil whine is its inherent connection to the fundamental operation of electronic components. As current flows through coils and inductors, it generates electromagnetic fields that can cause vibrations in nearby materials. This phenomenon is especially prevalent in power supply units, graphics cards, and other high-power components. The difficulty lies in mitigating these vibrations without compromising the performance or efficiency of the device.

Another obstacle in coil whine reduction is the variability of its occurrence. The intensity and frequency of coil whine can differ significantly between individual units of the same product, making it challenging to implement a universal solution. This variability is often due to minor differences in component quality, assembly tolerances, and environmental factors.

Echo reduction faces its own set of challenges, particularly in the realm of audio processing and telecommunications. The primary difficulty lies in distinguishing between desired audio signals and unwanted echoes or reflections. This task becomes increasingly complex in environments with multiple sound sources or in scenarios with rapidly changing acoustic conditions.

Real-time processing requirements pose another significant hurdle in echo reduction. Many applications, such as video conferencing and live audio production, demand instantaneous echo cancellation with minimal latency. Achieving this while maintaining high audio quality and preserving the nuances of the original sound is a delicate balancing act.

The computational complexity of advanced echo reduction algorithms presents an additional challenge. Sophisticated techniques often require substantial processing power, which can be a limiting factor in mobile devices or systems with constrained resources. Striking a balance between algorithm effectiveness and computational efficiency is crucial for widespread implementation.

Furthermore, the integration of coil whine and echo reduction strategies into existing product designs can be problematic. Retrofitting solutions into established architectures may require significant redesigns, potentially impacting production costs and timelines. This challenge is particularly acute in industries with long product development cycles or those bound by strict regulatory requirements.

Lastly, the interdisciplinary nature of these issues compounds the difficulty in finding comprehensive solutions. Effective strategies often require expertise from various fields, including electrical engineering, acoustics, signal processing, and materials science. Coordinating efforts across these disciplines and translating theoretical advancements into practical, manufacturable solutions remains a persistent challenge in the industry.

One of the primary challenges in addressing coil whine is its inherent connection to the fundamental operation of electronic components. As current flows through coils and inductors, it generates electromagnetic fields that can cause vibrations in nearby materials. This phenomenon is especially prevalent in power supply units, graphics cards, and other high-power components. The difficulty lies in mitigating these vibrations without compromising the performance or efficiency of the device.

Another obstacle in coil whine reduction is the variability of its occurrence. The intensity and frequency of coil whine can differ significantly between individual units of the same product, making it challenging to implement a universal solution. This variability is often due to minor differences in component quality, assembly tolerances, and environmental factors.

Echo reduction faces its own set of challenges, particularly in the realm of audio processing and telecommunications. The primary difficulty lies in distinguishing between desired audio signals and unwanted echoes or reflections. This task becomes increasingly complex in environments with multiple sound sources or in scenarios with rapidly changing acoustic conditions.

Real-time processing requirements pose another significant hurdle in echo reduction. Many applications, such as video conferencing and live audio production, demand instantaneous echo cancellation with minimal latency. Achieving this while maintaining high audio quality and preserving the nuances of the original sound is a delicate balancing act.

The computational complexity of advanced echo reduction algorithms presents an additional challenge. Sophisticated techniques often require substantial processing power, which can be a limiting factor in mobile devices or systems with constrained resources. Striking a balance between algorithm effectiveness and computational efficiency is crucial for widespread implementation.

Furthermore, the integration of coil whine and echo reduction strategies into existing product designs can be problematic. Retrofitting solutions into established architectures may require significant redesigns, potentially impacting production costs and timelines. This challenge is particularly acute in industries with long product development cycles or those bound by strict regulatory requirements.

Lastly, the interdisciplinary nature of these issues compounds the difficulty in finding comprehensive solutions. Effective strategies often require expertise from various fields, including electrical engineering, acoustics, signal processing, and materials science. Coordinating efforts across these disciplines and translating theoretical advancements into practical, manufacturable solutions remains a persistent challenge in the industry.

Existing Solutions

01 Active noise cancellation techniques

Active noise cancellation techniques are employed to reduce coil whine and echo. These methods involve generating anti-noise signals that are opposite in phase to the unwanted noise, effectively canceling it out. This approach can be particularly effective for reducing persistent, low-frequency noises like coil whine.- Active noise cancellation techniques: Active noise cancellation techniques are employed to reduce coil whine and echo. These methods involve generating anti-noise signals that are opposite in phase to the unwanted noise, effectively canceling it out. This approach can be particularly effective for reducing persistent, low-frequency noises like coil whine.

- Digital signal processing for echo reduction: Advanced digital signal processing algorithms are used to identify and suppress echo in audio signals. These techniques may involve adaptive filtering, spectral subtraction, or other signal processing methods to separate the desired audio from unwanted echoes or reverberations.

- Acoustic design and shielding: Careful acoustic design and shielding of electronic components can help minimize coil whine at the source. This may include using specialized materials to dampen vibrations, redesigning circuit layouts to reduce electromagnetic interference, or implementing physical barriers to contain and absorb unwanted noise.

- Frequency analysis and selective filtering: Techniques involving frequency analysis are used to identify specific frequencies associated with coil whine or echo. Once identified, these frequencies can be selectively filtered or attenuated to reduce their impact on the overall audio quality without significantly affecting the desired sound.

- Adaptive echo cancellation algorithms: Adaptive algorithms are employed to dynamically adjust echo cancellation parameters based on the changing acoustic environment. These algorithms continuously analyze the audio input and output to optimize echo reduction in real-time, improving performance in various acoustic conditions.

02 Digital signal processing for echo reduction

Advanced digital signal processing algorithms are utilized to identify and suppress echo in audio signals. These techniques often involve adaptive filtering, which can dynamically adjust to changing acoustic environments, effectively minimizing echo without degrading the quality of the desired audio signal.Expand Specific Solutions03 Acoustic design optimization

Optimizing the acoustic design of electronic devices can significantly reduce coil whine and echo. This includes careful placement of components, use of sound-absorbing materials, and implementation of resonance-reducing structures within the device. Such design considerations can prevent or minimize the generation and propagation of unwanted noise.Expand Specific Solutions04 Frequency-selective noise suppression

Implementing frequency-selective noise suppression techniques allows for targeted reduction of coil whine, which typically occurs at specific frequencies. This approach involves identifying the problematic frequencies and applying selective filtering or cancellation methods to address them without affecting the overall audio quality.Expand Specific Solutions05 Adaptive echo cancellation algorithms

Adaptive echo cancellation algorithms are employed to dynamically adjust to changing acoustic conditions and effectively reduce echo. These algorithms continuously analyze the audio signal, estimate the echo path, and apply appropriate cancellation techniques in real-time, ensuring optimal echo reduction across various environments and use cases.Expand Specific Solutions

Key Industry Players

The competitive landscape for coil whine and echo reduction technologies is evolving rapidly, with the market currently in a growth phase. As demand for quieter electronic devices increases, the global market size for noise reduction solutions is expanding. Major players like Robert Bosch GmbH, Siemens AG, and TDK Corp. are investing heavily in research and development to improve their offerings. The technology is maturing, with companies like LG Innotek and Murata Manufacturing Co. Ltd. introducing advanced solutions. However, there's still room for innovation, particularly in integrating AI and machine learning for more effective noise cancellation. Universities such as Southeast University and Zhejiang University are contributing to technological advancements, indicating a collaborative ecosystem between industry and academia.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Active Noise Control (ANC) system for coil whine reduction in electric vehicles. Their solution utilizes a combination of strategically placed microphones and accelerometers to detect and analyze coil whine frequencies. The system then generates anti-noise signals through the vehicle's audio system to cancel out the unwanted noise. Bosch's ANC technology adapts in real-time to changes in driving conditions and vehicle speed, ensuring optimal performance across various scenarios[1]. Additionally, they have implemented machine learning algorithms to continuously improve noise cancellation effectiveness over time, learning from different driving patterns and environmental conditions[3].

Strengths: Adaptive real-time noise cancellation, integration with existing vehicle audio systems, and continuous improvement through machine learning. Weaknesses: Potential for increased system complexity and cost, reliance on vehicle's audio system quality.

Siemens AG

Technical Solution: Siemens has pioneered a multi-faceted approach to coil whine and echo reduction in industrial equipment. Their strategy involves a combination of hardware and software solutions. On the hardware side, Siemens has developed specialized low-noise coil designs that utilize advanced materials and winding techniques to minimize electromagnetic vibrations at the source. These coils incorporate nano-crystalline core materials that reduce magnetic hysteresis losses by up to 70% compared to traditional silicon steel cores[2]. For echo reduction, Siemens employs active damping technologies in their motor control systems. This involves real-time monitoring of motor vibrations and applying counteracting forces through the motor's own electromagnetic fields, effectively canceling out unwanted resonances[4]. On the software front, Siemens has implemented advanced digital signal processing algorithms in their drive systems that can identify and mitigate coil whine frequencies in real-time, adapting to changing operational conditions.

Strengths: Comprehensive approach addressing both hardware and software aspects, significant noise reduction at the source, and adaptability to various industrial applications. Weaknesses: Potentially higher initial costs for specialized components and complex control systems.

Core Innovations

Method for reducing echo and related echo reducing device and voice apparatus thereof

PatentInactiveUS20090245528A1

Innovation

- A method and device that dynamically adjust the sensitivity of a sound input device based on detected output sound volume, using a sound volume detecting module and a sensitivity setting module to switch between designated sensitivity values when the output sound volume exceeds a threshold, implemented with an analog-to-digital converter and micro-processing control unit.

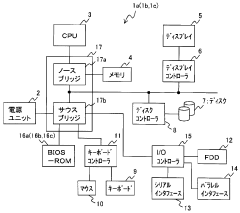

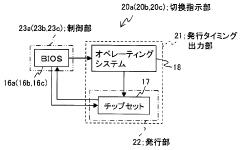

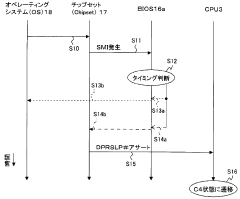

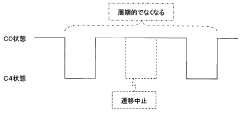

Information processing device, operation mode control program, and computer readable recording medium with the program recorded therein

PatentWO2007105270A1

Innovation

- An information processing apparatus and operation mode control program that aperiodically switch between operation modes with different power consumption, using a control unit to irregularly issue switching instructions and adjust the timing of these switches to prevent constant voltage changes, thereby reducing coil whine without compromising power saving effects.

Acoustic Testing Methods

Acoustic testing methods play a crucial role in evaluating and mitigating coil whine and echo issues in electronic devices. These methods involve a systematic approach to measuring, analyzing, and addressing unwanted acoustic emissions. The primary objective is to quantify the noise levels and identify their sources, enabling engineers to develop effective reduction strategies.

One of the fundamental acoustic testing methods is the use of anechoic chambers. These specialized rooms are designed to eliminate external noise and reflections, providing an ideal environment for precise sound measurements. Within these chambers, sensitive microphones are strategically placed to capture the acoustic emissions from the device under test. This setup allows for accurate measurement of sound pressure levels and frequency characteristics of coil whine and echoes.

Spectral analysis is another essential technique in acoustic testing. By employing Fast Fourier Transform (FFT) algorithms, engineers can decompose the recorded audio signals into their constituent frequencies. This analysis helps identify specific frequency components associated with coil whine, distinguishing them from other ambient noises. The resulting spectrograms provide valuable insights into the temporal and spectral characteristics of the acoustic emissions.

To simulate real-world conditions, acoustic testing often incorporates various operational scenarios. Devices are subjected to different load conditions, voltage levels, and environmental factors to assess how these variables impact coil whine and echo production. This comprehensive approach ensures that the testing covers a wide range of potential use cases and helps in developing robust reduction strategies.

Near-field acoustic holography (NAH) is an advanced technique used to map sound fields and locate noise sources with high spatial resolution. By using an array of microphones, NAH can create detailed 3D visualizations of sound propagation from electronic components. This method is particularly useful in identifying specific areas or components responsible for coil whine, allowing for targeted mitigation efforts.

Vibration analysis is often conducted in conjunction with acoustic testing. Accelerometers are attached to various parts of the device to measure mechanical vibrations that may contribute to or correlate with acoustic emissions. This integrated approach helps in understanding the relationship between structural vibrations and audible noise, leading to more comprehensive reduction strategies.

In recent years, artificial intelligence and machine learning techniques have been incorporated into acoustic testing methods. These advanced algorithms can analyze large datasets of acoustic measurements, identifying patterns and correlations that may not be immediately apparent to human observers. This data-driven approach enhances the efficiency and accuracy of noise source identification and characterization.

One of the fundamental acoustic testing methods is the use of anechoic chambers. These specialized rooms are designed to eliminate external noise and reflections, providing an ideal environment for precise sound measurements. Within these chambers, sensitive microphones are strategically placed to capture the acoustic emissions from the device under test. This setup allows for accurate measurement of sound pressure levels and frequency characteristics of coil whine and echoes.

Spectral analysis is another essential technique in acoustic testing. By employing Fast Fourier Transform (FFT) algorithms, engineers can decompose the recorded audio signals into their constituent frequencies. This analysis helps identify specific frequency components associated with coil whine, distinguishing them from other ambient noises. The resulting spectrograms provide valuable insights into the temporal and spectral characteristics of the acoustic emissions.

To simulate real-world conditions, acoustic testing often incorporates various operational scenarios. Devices are subjected to different load conditions, voltage levels, and environmental factors to assess how these variables impact coil whine and echo production. This comprehensive approach ensures that the testing covers a wide range of potential use cases and helps in developing robust reduction strategies.

Near-field acoustic holography (NAH) is an advanced technique used to map sound fields and locate noise sources with high spatial resolution. By using an array of microphones, NAH can create detailed 3D visualizations of sound propagation from electronic components. This method is particularly useful in identifying specific areas or components responsible for coil whine, allowing for targeted mitigation efforts.

Vibration analysis is often conducted in conjunction with acoustic testing. Accelerometers are attached to various parts of the device to measure mechanical vibrations that may contribute to or correlate with acoustic emissions. This integrated approach helps in understanding the relationship between structural vibrations and audible noise, leading to more comprehensive reduction strategies.

In recent years, artificial intelligence and machine learning techniques have been incorporated into acoustic testing methods. These advanced algorithms can analyze large datasets of acoustic measurements, identifying patterns and correlations that may not be immediately apparent to human observers. This data-driven approach enhances the efficiency and accuracy of noise source identification and characterization.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of coil whine and echo reduction strategies in electronic devices. As manufacturers strive to enhance performance and user experience, they must also navigate a complex landscape of regulations and standards set by various governing bodies.

In the context of coil whine and echo reduction, several regulatory frameworks come into play. The Federal Communications Commission (FCC) in the United States and the European Union's Electromagnetic Compatibility (EMC) Directive are two primary regulatory bodies that set standards for electromagnetic interference (EMI) and electromagnetic compatibility. These regulations aim to ensure that electronic devices do not emit excessive electromagnetic radiation that could interfere with other devices or pose health risks to users.

Manufacturers must adhere to specific limits on electromagnetic emissions, including those that may contribute to coil whine. This often necessitates the implementation of advanced shielding techniques and careful circuit design to minimize electromagnetic interference. Additionally, acoustic noise regulations, such as those set by the International Organization for Standardization (ISO), may apply to devices where coil whine is audible to users.

Echo reduction strategies must also comply with telecommunications standards, particularly for devices used in voice communication. The International Telecommunication Union (ITU) provides recommendations for echo cancellation in telecommunications equipment, which manufacturers must consider when developing their products.

Compliance testing is a critical aspect of the regulatory process. Devices must undergo rigorous testing in certified laboratories to ensure they meet all applicable standards before they can be marketed and sold. This testing often includes measurements of electromagnetic emissions, acoustic noise levels, and the effectiveness of echo cancellation algorithms.

As technology evolves, so do regulatory requirements. Manufacturers must stay abreast of changes in regulations and adapt their coil whine and echo reduction strategies accordingly. This may involve continuous research and development efforts to improve existing technologies or develop new ones that can meet increasingly stringent regulatory standards.

Moreover, global market access requires compliance with regulations in multiple jurisdictions. Manufacturers aiming for international distribution must ensure their coil whine and echo reduction solutions meet the most stringent standards across different regions, often necessitating a harmonized approach to product design and testing.

In conclusion, regulatory compliance is an integral part of developing effective coil whine and echo reduction strategies. It not only ensures that products meet legal requirements but also contributes to overall product quality and user satisfaction. Manufacturers must balance performance optimization with regulatory adherence, often leading to innovative solutions that push the boundaries of technology while maintaining compliance with global standards.

In the context of coil whine and echo reduction, several regulatory frameworks come into play. The Federal Communications Commission (FCC) in the United States and the European Union's Electromagnetic Compatibility (EMC) Directive are two primary regulatory bodies that set standards for electromagnetic interference (EMI) and electromagnetic compatibility. These regulations aim to ensure that electronic devices do not emit excessive electromagnetic radiation that could interfere with other devices or pose health risks to users.

Manufacturers must adhere to specific limits on electromagnetic emissions, including those that may contribute to coil whine. This often necessitates the implementation of advanced shielding techniques and careful circuit design to minimize electromagnetic interference. Additionally, acoustic noise regulations, such as those set by the International Organization for Standardization (ISO), may apply to devices where coil whine is audible to users.

Echo reduction strategies must also comply with telecommunications standards, particularly for devices used in voice communication. The International Telecommunication Union (ITU) provides recommendations for echo cancellation in telecommunications equipment, which manufacturers must consider when developing their products.

Compliance testing is a critical aspect of the regulatory process. Devices must undergo rigorous testing in certified laboratories to ensure they meet all applicable standards before they can be marketed and sold. This testing often includes measurements of electromagnetic emissions, acoustic noise levels, and the effectiveness of echo cancellation algorithms.

As technology evolves, so do regulatory requirements. Manufacturers must stay abreast of changes in regulations and adapt their coil whine and echo reduction strategies accordingly. This may involve continuous research and development efforts to improve existing technologies or develop new ones that can meet increasingly stringent regulatory standards.

Moreover, global market access requires compliance with regulations in multiple jurisdictions. Manufacturers aiming for international distribution must ensure their coil whine and echo reduction solutions meet the most stringent standards across different regions, often necessitating a harmonized approach to product design and testing.

In conclusion, regulatory compliance is an integral part of developing effective coil whine and echo reduction strategies. It not only ensures that products meet legal requirements but also contributes to overall product quality and user satisfaction. Manufacturers must balance performance optimization with regulatory adherence, often leading to innovative solutions that push the boundaries of technology while maintaining compliance with global standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!