Coil Whine Analysis Techniques in Complex Systems

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an electromagnetic phenomenon that occurs in electronic devices, particularly in complex systems with high-frequency switching components. This audible noise is generated by the vibration of electromagnetic coils or other components due to fluctuating magnetic fields. The issue has become increasingly prevalent in modern electronics as devices become more compact and operate at higher frequencies.

The phenomenon was first observed in early electrical systems but gained significant attention with the advent of switched-mode power supplies and high-performance computing devices. As electronic systems evolved, the demand for more efficient and powerful components led to increased switching frequencies, inadvertently exacerbating the coil whine problem.

In complex systems, coil whine can originate from various sources, including power supply units, voltage regulators, inductors, and transformers. The noise is typically characterized by a high-pitched buzzing or whining sound, which can vary in intensity and frequency depending on the system's operational state and load conditions.

The impact of coil whine extends beyond mere annoyance. In sensitive electronic equipment, such as audio systems or medical devices, it can introduce unwanted interference and compromise performance. In consumer electronics, it often leads to user dissatisfaction and increased product returns, posing significant challenges for manufacturers.

Understanding and mitigating coil whine has become crucial in the design and development of modern electronic systems. Engineers and researchers have been exploring various techniques to analyze and address this issue, ranging from improved component selection and circuit design to advanced noise cancellation methods.

The complexity of coil whine analysis lies in its multifaceted nature. It involves intricate interactions between electrical, mechanical, and acoustic phenomena. Factors such as circuit layout, component quality, thermal management, and even environmental conditions can influence the occurrence and severity of coil whine.

As electronic devices continue to evolve, with trends towards higher power densities and miniaturization, the challenges associated with coil whine are expected to persist. This has led to increased focus on developing sophisticated analysis techniques that can accurately identify, characterize, and mitigate coil whine in complex systems.

The field of coil whine analysis has seen significant advancements in recent years, driven by the need for quieter and more reliable electronic products. These developments have spanned across various disciplines, including electrical engineering, materials science, and acoustic engineering, highlighting the interdisciplinary nature of this technological challenge.

The phenomenon was first observed in early electrical systems but gained significant attention with the advent of switched-mode power supplies and high-performance computing devices. As electronic systems evolved, the demand for more efficient and powerful components led to increased switching frequencies, inadvertently exacerbating the coil whine problem.

In complex systems, coil whine can originate from various sources, including power supply units, voltage regulators, inductors, and transformers. The noise is typically characterized by a high-pitched buzzing or whining sound, which can vary in intensity and frequency depending on the system's operational state and load conditions.

The impact of coil whine extends beyond mere annoyance. In sensitive electronic equipment, such as audio systems or medical devices, it can introduce unwanted interference and compromise performance. In consumer electronics, it often leads to user dissatisfaction and increased product returns, posing significant challenges for manufacturers.

Understanding and mitigating coil whine has become crucial in the design and development of modern electronic systems. Engineers and researchers have been exploring various techniques to analyze and address this issue, ranging from improved component selection and circuit design to advanced noise cancellation methods.

The complexity of coil whine analysis lies in its multifaceted nature. It involves intricate interactions between electrical, mechanical, and acoustic phenomena. Factors such as circuit layout, component quality, thermal management, and even environmental conditions can influence the occurrence and severity of coil whine.

As electronic devices continue to evolve, with trends towards higher power densities and miniaturization, the challenges associated with coil whine are expected to persist. This has led to increased focus on developing sophisticated analysis techniques that can accurately identify, characterize, and mitigate coil whine in complex systems.

The field of coil whine analysis has seen significant advancements in recent years, driven by the need for quieter and more reliable electronic products. These developments have spanned across various disciplines, including electrical engineering, materials science, and acoustic engineering, highlighting the interdisciplinary nature of this technological challenge.

Market Impact Analysis

The market impact of coil whine analysis techniques in complex systems is significant and multifaceted. As electronic devices become increasingly prevalent and sophisticated, the demand for quieter and more efficient systems has grown substantially. This has led to a heightened focus on identifying and mitigating coil whine, a high-frequency noise produced by electromagnetic components under certain operating conditions.

In the consumer electronics sector, coil whine analysis techniques have become crucial for manufacturers seeking to maintain a competitive edge. High-end laptops, gaming consoles, and power supplies are particularly susceptible to coil whine issues, which can negatively impact user experience and brand reputation. As a result, companies that can effectively implement these analysis techniques are better positioned to deliver premium products that meet consumer expectations for silent operation.

The automotive industry has also seen a growing need for coil whine analysis, especially with the rise of electric and hybrid vehicles. The quiet operation of these vehicles makes any electromagnetic noise more noticeable, necessitating advanced analysis techniques to ensure passenger comfort and vehicle quality. This has created new opportunities for suppliers specializing in noise, vibration, and harshness (NVH) testing and mitigation.

In the industrial sector, coil whine analysis techniques are becoming increasingly important for improving the reliability and efficiency of power systems and large-scale machinery. By identifying and addressing coil whine issues, companies can reduce maintenance costs, extend equipment lifespan, and improve overall system performance. This has led to the development of specialized analysis tools and services, creating a niche market within the broader industrial testing and measurement industry.

The adoption of coil whine analysis techniques has also spurred innovation in materials science and component design. Manufacturers are investing in research and development to create new materials and designs that inherently reduce coil whine, leading to advancements in transformer and inductor technologies. This has created opportunities for material suppliers and component manufacturers to differentiate their products and capture market share.

The market for coil whine analysis techniques has also been influenced by regulatory pressures. As governments worldwide implement stricter noise pollution standards, industries are compelled to invest in more sophisticated analysis and mitigation strategies. This regulatory environment has driven demand for advanced testing equipment and expertise, benefiting companies that specialize in acoustic and electromagnetic analysis.

In the consumer electronics sector, coil whine analysis techniques have become crucial for manufacturers seeking to maintain a competitive edge. High-end laptops, gaming consoles, and power supplies are particularly susceptible to coil whine issues, which can negatively impact user experience and brand reputation. As a result, companies that can effectively implement these analysis techniques are better positioned to deliver premium products that meet consumer expectations for silent operation.

The automotive industry has also seen a growing need for coil whine analysis, especially with the rise of electric and hybrid vehicles. The quiet operation of these vehicles makes any electromagnetic noise more noticeable, necessitating advanced analysis techniques to ensure passenger comfort and vehicle quality. This has created new opportunities for suppliers specializing in noise, vibration, and harshness (NVH) testing and mitigation.

In the industrial sector, coil whine analysis techniques are becoming increasingly important for improving the reliability and efficiency of power systems and large-scale machinery. By identifying and addressing coil whine issues, companies can reduce maintenance costs, extend equipment lifespan, and improve overall system performance. This has led to the development of specialized analysis tools and services, creating a niche market within the broader industrial testing and measurement industry.

The adoption of coil whine analysis techniques has also spurred innovation in materials science and component design. Manufacturers are investing in research and development to create new materials and designs that inherently reduce coil whine, leading to advancements in transformer and inductor technologies. This has created opportunities for material suppliers and component manufacturers to differentiate their products and capture market share.

The market for coil whine analysis techniques has also been influenced by regulatory pressures. As governments worldwide implement stricter noise pollution standards, industries are compelled to invest in more sophisticated analysis and mitigation strategies. This regulatory environment has driven demand for advanced testing equipment and expertise, benefiting companies that specialize in acoustic and electromagnetic analysis.

Technical Challenges

Coil whine analysis in complex systems presents several significant technical challenges that researchers and engineers must overcome. One of the primary difficulties lies in isolating the coil whine signal from other noise sources within the system. Complex systems often contain multiple components that generate various types of electromagnetic interference, making it challenging to identify and isolate the specific frequency and amplitude characteristics of coil whine.

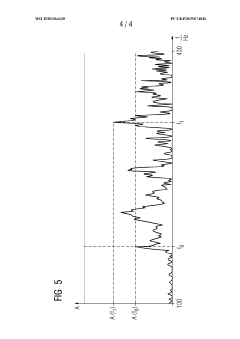

Another major challenge is the variability of coil whine across different operating conditions. The intensity and frequency of coil whine can change dramatically based on factors such as system load, temperature, and voltage fluctuations. This variability makes it difficult to develop consistent and reliable analysis techniques that can accurately characterize coil whine under all possible operating scenarios.

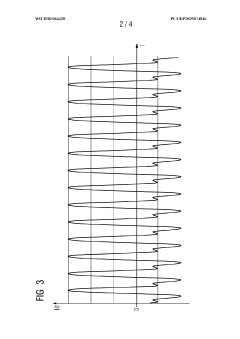

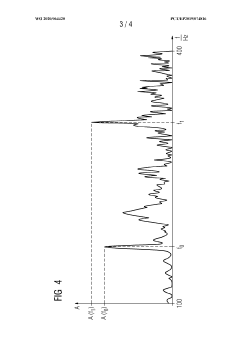

The non-linear nature of coil whine poses additional complications for analysis. Unlike many other forms of electromagnetic noise, coil whine often exhibits complex harmonic structures and frequency modulations. These non-linear characteristics require sophisticated signal processing techniques and advanced mathematical models to accurately capture and analyze the behavior of coil whine in complex systems.

Miniaturization trends in modern electronics further exacerbate the challenges of coil whine analysis. As systems become more compact and densely packed, the proximity of components increases the likelihood of electromagnetic coupling and interference. This makes it harder to isolate individual noise sources and increases the complexity of the overall electromagnetic environment within the system.

The low-frequency nature of coil whine also presents unique measurement challenges. Many traditional high-frequency noise measurement techniques are not well-suited for capturing and analyzing the low-frequency vibrations associated with coil whine. This necessitates the development of specialized measurement equipment and methodologies specifically tailored to low-frequency acoustic and electromagnetic phenomena.

Furthermore, the impact of manufacturing variations on coil whine characteristics adds another layer of complexity to the analysis process. Slight differences in component tolerances, assembly techniques, and material properties can lead to significant variations in coil whine behavior between nominally identical systems. This variability makes it difficult to develop generalized analysis techniques that can be applied consistently across a range of products or system configurations.

Lastly, the interdisciplinary nature of coil whine analysis presents challenges in terms of expertise and collaboration. Effective analysis requires a combination of skills from various fields, including electromagnetics, acoustics, signal processing, and mechanical engineering. Integrating these diverse areas of knowledge and fostering collaboration between specialists can be a significant hurdle in developing comprehensive coil whine analysis techniques for complex systems.

Another major challenge is the variability of coil whine across different operating conditions. The intensity and frequency of coil whine can change dramatically based on factors such as system load, temperature, and voltage fluctuations. This variability makes it difficult to develop consistent and reliable analysis techniques that can accurately characterize coil whine under all possible operating scenarios.

The non-linear nature of coil whine poses additional complications for analysis. Unlike many other forms of electromagnetic noise, coil whine often exhibits complex harmonic structures and frequency modulations. These non-linear characteristics require sophisticated signal processing techniques and advanced mathematical models to accurately capture and analyze the behavior of coil whine in complex systems.

Miniaturization trends in modern electronics further exacerbate the challenges of coil whine analysis. As systems become more compact and densely packed, the proximity of components increases the likelihood of electromagnetic coupling and interference. This makes it harder to isolate individual noise sources and increases the complexity of the overall electromagnetic environment within the system.

The low-frequency nature of coil whine also presents unique measurement challenges. Many traditional high-frequency noise measurement techniques are not well-suited for capturing and analyzing the low-frequency vibrations associated with coil whine. This necessitates the development of specialized measurement equipment and methodologies specifically tailored to low-frequency acoustic and electromagnetic phenomena.

Furthermore, the impact of manufacturing variations on coil whine characteristics adds another layer of complexity to the analysis process. Slight differences in component tolerances, assembly techniques, and material properties can lead to significant variations in coil whine behavior between nominally identical systems. This variability makes it difficult to develop generalized analysis techniques that can be applied consistently across a range of products or system configurations.

Lastly, the interdisciplinary nature of coil whine analysis presents challenges in terms of expertise and collaboration. Effective analysis requires a combination of skills from various fields, including electromagnetics, acoustics, signal processing, and mechanical engineering. Integrating these diverse areas of knowledge and fostering collaboration between specialists can be a significant hurdle in developing comprehensive coil whine analysis techniques for complex systems.

Current Solutions

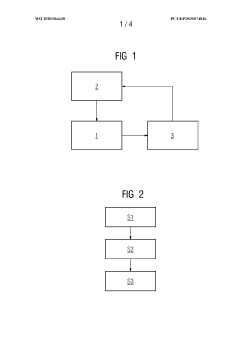

01 Noise reduction techniques for electronic devices

Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.- Noise reduction techniques for electronic devices: Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.

- Coil design and construction for noise reduction: Innovative coil designs and construction methods are developed to mitigate coil whine noise. These include using specialized winding techniques, incorporating noise-dampening materials, and optimizing the physical structure of the coils. By focusing on the coil itself, these approaches aim to reduce vibrations and resonances that contribute to the whine noise.

- Power supply and voltage regulation for noise reduction: Improvements in power supply design and voltage regulation techniques are implemented to minimize coil whine noise. These methods focus on stabilizing power delivery, reducing electromagnetic interference, and optimizing voltage levels to prevent or reduce the conditions that lead to coil whine in electronic devices.

- Acoustic isolation and dampening methods: Various acoustic isolation and dampening techniques are employed to reduce the transmission of coil whine noise. These methods include using sound-absorbing materials, implementing vibration isolation systems, and designing enclosures that minimize sound propagation. By focusing on containing and absorbing the noise, these approaches aim to reduce the perceived coil whine in electronic devices.

- Detection and analysis of coil whine noise: Advanced detection and analysis techniques are developed to identify and characterize coil whine noise in electronic devices. These methods involve using specialized sensors, signal processing algorithms, and acoustic analysis tools to pinpoint the sources and characteristics of the noise. By accurately identifying the problem, these techniques enable more targeted and effective noise reduction solutions.

02 Coil design and construction for noise reduction

Innovative coil designs and construction methods are developed to mitigate coil whine noise. These include using specialized winding techniques, incorporating noise-dampening materials, and optimizing the physical structure of the coils. By focusing on the coil itself, these approaches aim to reduce vibrations and resonances that contribute to the whine noise.Expand Specific Solutions03 Power supply and voltage regulation improvements

Enhancements in power supply design and voltage regulation systems are implemented to address coil whine noise. These improvements focus on stabilizing power delivery, reducing electromagnetic interference, and optimizing current flow. By refining the power management aspects of electronic devices, these techniques aim to minimize the conditions that lead to coil whine.Expand Specific Solutions04 Acoustic isolation and dampening solutions

Various acoustic isolation and dampening methods are employed to reduce the perception of coil whine noise. These solutions include using sound-absorbing materials, implementing vibration isolation techniques, and designing enclosures that minimize sound transmission. By focusing on containing and absorbing the noise, these approaches aim to improve the overall acoustic performance of electronic devices.Expand Specific Solutions05 Detection and measurement of coil whine noise

Advanced detection and measurement techniques are developed to identify and quantify coil whine noise in electronic devices. These methods include using specialized sensors, implementing signal processing algorithms, and developing testing protocols. By accurately detecting and measuring coil whine, manufacturers can better address the issue during the design and quality control processes.Expand Specific Solutions

Industry Leaders

The competitive landscape for Coil Whine Analysis Techniques in Complex Systems is evolving rapidly, with the market in its growth phase. The industry is experiencing increased demand due to the rising complexity of electronic systems across various sectors. Key players like Siemens AG, IBM, and Robert Bosch GmbH are investing heavily in research and development to enhance their technological capabilities. The market size is expanding, driven by the need for noise reduction in high-performance computing and power electronics. Technological maturity varies, with companies like Halliburton Energy Services and Schlumberger focusing on specialized applications in the energy sector, while others like National Instruments and Murata Manufacturing are developing more broadly applicable solutions.

Siemens AG

Technical Solution: Siemens AG has developed advanced Coil Whine Analysis Techniques for complex systems, focusing on their industrial and energy sector applications. Their approach combines acoustic measurement with advanced signal processing algorithms. They utilize high-precision microphones and accelerometers to capture coil whine signals, which are then processed using proprietary software that employs machine learning algorithms for pattern recognition[1]. This system can detect and analyze coil whine frequencies as high as 20 kHz, allowing for early identification of potential issues in electrical components[3]. Siemens has also integrated this technology into their predictive maintenance solutions, enabling real-time monitoring and analysis of coil whine in large-scale industrial equipment[5].

Strengths: Comprehensive solution integrating hardware and software, applicable to large-scale industrial systems, and integration with existing predictive maintenance platforms. Weaknesses: May require significant initial investment and specialized training for implementation.

International Business Machines Corp.

Technical Solution: IBM has developed a sophisticated Coil Whine Analysis system leveraging their expertise in AI and machine learning. Their approach uses a network of distributed sensors to capture coil whine data across complex systems. This data is then processed using IBM's Watson AI platform, which employs advanced acoustic analysis algorithms and deep learning models to identify patterns and anomalies in the coil whine signatures[2]. The system can detect subtle changes in coil whine characteristics, potentially indicating impending component failures or system inefficiencies. IBM's solution also incorporates cloud-based data storage and analysis, allowing for long-term trend analysis and cross-system comparisons[4]. This enables predictive maintenance strategies and can help optimize system performance across large-scale operations.

Strengths: Powerful AI-driven analysis, scalable cloud-based solution, and potential for cross-system insights. Weaknesses: May require significant computational resources and ongoing cloud service costs.

Key Innovations

Reducing interference noises and/or vibrations during the operation of an electric machine

PatentWO2020064420A1

Innovation

- A method involving the determination of a compensation current for the d component of the three-phase coil winding current, which is added to the setpoint to reduce noise and vibrations, utilizing a d/q transformation and parameterizing frequency components independently to create a compensation current that can be optimized using measurements and mathematical procedures, allowing for a software-based solution without hardware changes.

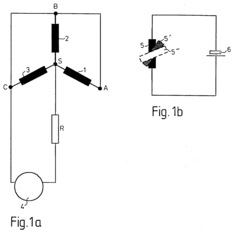

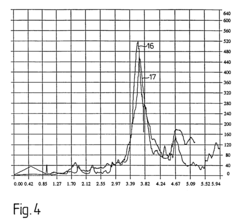

Method and means for noise measurement of electric machines and apparatus

PatentInactiveEP0838669A2

Innovation

- An electrical excitation of the coil winding generates an alternating magnetic field and associated mechanical vibrations, allowing for noise simulation and quality testing without the need for a powerful drive, using an AC voltage frequency corresponding to desired speeds and a variable frequency source for precise noise analysis.

Noise Regulations

Noise regulations play a crucial role in the analysis and mitigation of coil whine in complex systems. These regulations set the standards for acceptable noise levels in various environments, including industrial, commercial, and residential settings. The International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) are among the leading organizations that establish and maintain these standards globally.

In the context of coil whine analysis, noise regulations typically specify maximum permissible sound pressure levels (SPLs) for different frequency ranges. These regulations often use A-weighted decibel scales (dBA) to measure noise levels, as this scale closely approximates human hearing sensitivity. For complex systems, the regulations may also consider factors such as tonal components, impulsive noise, and low-frequency noise, which are particularly relevant to coil whine issues.

Many countries have adopted their own noise regulations based on international standards. For instance, the European Union's Environmental Noise Directive (END) sets common approaches to avoid, prevent, or reduce harmful effects of environmental noise exposure. In the United States, the Occupational Safety and Health Administration (OSHA) establishes noise exposure limits for workplace environments, which can impact the design and operation of complex systems that may produce coil whine.

Compliance with these regulations often requires manufacturers to implement noise control measures during the design and production phases of complex systems. This may involve techniques such as acoustic enclosures, vibration isolation, and active noise control systems. Additionally, regular noise monitoring and reporting may be mandated to ensure ongoing compliance with applicable regulations.

The impact of noise regulations on coil whine analysis techniques is significant. These regulations drive the development of more sensitive and accurate measurement methodologies. For example, the need to detect and quantify tonal components in noise emissions has led to the refinement of frequency analysis techniques, such as Fast Fourier Transform (FFT) and narrowband analysis.

Furthermore, noise regulations have spurred innovation in predictive modeling and simulation tools for coil whine. These tools allow engineers to anticipate potential noise issues early in the design process, reducing the need for costly retrofits or redesigns to meet regulatory requirements. Advanced computational methods, such as finite element analysis (FEA) and boundary element method (BEM), are increasingly used to model the acoustic behavior of complex systems and predict compliance with noise regulations.

As noise regulations continue to evolve, becoming more stringent and comprehensive, the field of coil whine analysis in complex systems must adapt accordingly. This ongoing process drives continuous improvement in measurement techniques, analysis methodologies, and noise reduction strategies, ultimately leading to quieter and more efficient complex systems across various industries.

In the context of coil whine analysis, noise regulations typically specify maximum permissible sound pressure levels (SPLs) for different frequency ranges. These regulations often use A-weighted decibel scales (dBA) to measure noise levels, as this scale closely approximates human hearing sensitivity. For complex systems, the regulations may also consider factors such as tonal components, impulsive noise, and low-frequency noise, which are particularly relevant to coil whine issues.

Many countries have adopted their own noise regulations based on international standards. For instance, the European Union's Environmental Noise Directive (END) sets common approaches to avoid, prevent, or reduce harmful effects of environmental noise exposure. In the United States, the Occupational Safety and Health Administration (OSHA) establishes noise exposure limits for workplace environments, which can impact the design and operation of complex systems that may produce coil whine.

Compliance with these regulations often requires manufacturers to implement noise control measures during the design and production phases of complex systems. This may involve techniques such as acoustic enclosures, vibration isolation, and active noise control systems. Additionally, regular noise monitoring and reporting may be mandated to ensure ongoing compliance with applicable regulations.

The impact of noise regulations on coil whine analysis techniques is significant. These regulations drive the development of more sensitive and accurate measurement methodologies. For example, the need to detect and quantify tonal components in noise emissions has led to the refinement of frequency analysis techniques, such as Fast Fourier Transform (FFT) and narrowband analysis.

Furthermore, noise regulations have spurred innovation in predictive modeling and simulation tools for coil whine. These tools allow engineers to anticipate potential noise issues early in the design process, reducing the need for costly retrofits or redesigns to meet regulatory requirements. Advanced computational methods, such as finite element analysis (FEA) and boundary element method (BEM), are increasingly used to model the acoustic behavior of complex systems and predict compliance with noise regulations.

As noise regulations continue to evolve, becoming more stringent and comprehensive, the field of coil whine analysis in complex systems must adapt accordingly. This ongoing process drives continuous improvement in measurement techniques, analysis methodologies, and noise reduction strategies, ultimately leading to quieter and more efficient complex systems across various industries.

User Experience Impact

Coil whine, a high-frequency noise produced by electronic components, can significantly impact user experience in complex systems. This phenomenon, often perceived as an annoying buzzing or squealing sound, can detract from the overall quality and satisfaction of product usage. In consumer electronics, such as laptops, graphics cards, and power supplies, coil whine can be particularly disruptive, potentially leading to decreased user comfort and productivity.

The impact of coil whine on user experience extends beyond mere auditory discomfort. In professional environments, such as recording studios or quiet office spaces, the presence of coil whine can interfere with work processes and concentration. This can result in reduced efficiency and increased stress levels among users, ultimately affecting their performance and well-being.

Moreover, the perception of coil whine can influence consumer purchasing decisions and brand loyalty. Products known for exhibiting coil whine may suffer from negative reviews and decreased sales, as users seek alternatives that offer a quieter operating experience. This underscores the importance of addressing coil whine issues in product design and quality control processes.

In gaming and multimedia applications, coil whine can be particularly detrimental to user immersion. The high-pitched noise can distract from the audio experience, breaking the sense of engagement and potentially impacting the overall enjoyment of games or media content. This is especially relevant in scenarios where users expect high-quality audio output, such as in premium gaming setups or home theater systems.

The impact of coil whine on user experience also varies depending on individual sensitivity to high-frequency sounds. Some users may find even low levels of coil whine intolerable, while others might not notice it at all. This variability in perception presents challenges for manufacturers in setting acceptable noise thresholds and highlights the need for comprehensive user testing during product development.

Addressing coil whine through improved analysis techniques can lead to significant enhancements in user experience. By identifying and mitigating sources of coil whine, manufacturers can create products that operate more quietly and smoothly. This not only improves immediate user satisfaction but also contributes to long-term brand reputation and customer loyalty. As such, the development of advanced coil whine analysis techniques in complex systems is crucial for delivering superior user experiences across a wide range of electronic devices and applications.

The impact of coil whine on user experience extends beyond mere auditory discomfort. In professional environments, such as recording studios or quiet office spaces, the presence of coil whine can interfere with work processes and concentration. This can result in reduced efficiency and increased stress levels among users, ultimately affecting their performance and well-being.

Moreover, the perception of coil whine can influence consumer purchasing decisions and brand loyalty. Products known for exhibiting coil whine may suffer from negative reviews and decreased sales, as users seek alternatives that offer a quieter operating experience. This underscores the importance of addressing coil whine issues in product design and quality control processes.

In gaming and multimedia applications, coil whine can be particularly detrimental to user immersion. The high-pitched noise can distract from the audio experience, breaking the sense of engagement and potentially impacting the overall enjoyment of games or media content. This is especially relevant in scenarios where users expect high-quality audio output, such as in premium gaming setups or home theater systems.

The impact of coil whine on user experience also varies depending on individual sensitivity to high-frequency sounds. Some users may find even low levels of coil whine intolerable, while others might not notice it at all. This variability in perception presents challenges for manufacturers in setting acceptable noise thresholds and highlights the need for comprehensive user testing during product development.

Addressing coil whine through improved analysis techniques can lead to significant enhancements in user experience. By identifying and mitigating sources of coil whine, manufacturers can create products that operate more quietly and smoothly. This not only improves immediate user satisfaction but also contributes to long-term brand reputation and customer loyalty. As such, the development of advanced coil whine analysis techniques in complex systems is crucial for delivering superior user experiences across a wide range of electronic devices and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!