Coil Whine in Signal Processing Applications: Advanced Methods

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an electromagnetic phenomenon that occurs in electronic devices, particularly in power supplies and other components with inductors or transformers. This high-frequency noise is generated by the vibration of coil windings in response to fluctuating electromagnetic fields. While coil whine has been a known issue in electronics for decades, it has become increasingly problematic in modern signal processing applications due to the growing demand for high-performance, compact devices.

The origins of coil whine can be traced back to the early days of electronics, but its significance has evolved with technological advancements. As devices have become more powerful and miniaturized, the potential for coil whine has increased. This is particularly evident in signal processing applications, where the precision and clarity of signals are paramount.

In signal processing, coil whine can introduce unwanted noise into the system, potentially degrading the quality of audio output, interfering with sensitive measurements, or compromising the accuracy of data acquisition. The challenge is exacerbated by the fact that coil whine often occurs at frequencies within the human audible range, making it not only a technical issue but also a user experience concern.

The impact of coil whine on signal processing applications is multifaceted. In audio systems, it can manifest as an annoying high-pitched sound, reducing the overall quality of sound reproduction. In measurement and instrumentation applications, coil whine can introduce errors in readings, potentially leading to inaccurate results or false interpretations of data.

As the field of signal processing continues to advance, addressing coil whine has become increasingly important. The push for higher clock speeds, more efficient power delivery, and smaller form factors in electronic devices has inadvertently created conditions that are more conducive to coil whine. This has led to a growing focus on developing advanced methods to mitigate or eliminate coil whine in signal processing applications.

The technological evolution driving the need for advanced coil whine reduction methods includes the widespread adoption of switched-mode power supplies, the increasing use of high-frequency digital circuits, and the integration of multiple complex systems within confined spaces. These factors have collectively contributed to making coil whine a more prevalent and challenging issue in modern signal processing environments.

Understanding the background of coil whine in signal processing applications is crucial for developing effective solutions. It requires a comprehensive approach that considers not only the physical principles behind the phenomenon but also the specific requirements and constraints of signal processing systems. This holistic understanding forms the foundation for exploring advanced methods to combat coil whine and improve the overall performance and reliability of signal processing applications.

The origins of coil whine can be traced back to the early days of electronics, but its significance has evolved with technological advancements. As devices have become more powerful and miniaturized, the potential for coil whine has increased. This is particularly evident in signal processing applications, where the precision and clarity of signals are paramount.

In signal processing, coil whine can introduce unwanted noise into the system, potentially degrading the quality of audio output, interfering with sensitive measurements, or compromising the accuracy of data acquisition. The challenge is exacerbated by the fact that coil whine often occurs at frequencies within the human audible range, making it not only a technical issue but also a user experience concern.

The impact of coil whine on signal processing applications is multifaceted. In audio systems, it can manifest as an annoying high-pitched sound, reducing the overall quality of sound reproduction. In measurement and instrumentation applications, coil whine can introduce errors in readings, potentially leading to inaccurate results or false interpretations of data.

As the field of signal processing continues to advance, addressing coil whine has become increasingly important. The push for higher clock speeds, more efficient power delivery, and smaller form factors in electronic devices has inadvertently created conditions that are more conducive to coil whine. This has led to a growing focus on developing advanced methods to mitigate or eliminate coil whine in signal processing applications.

The technological evolution driving the need for advanced coil whine reduction methods includes the widespread adoption of switched-mode power supplies, the increasing use of high-frequency digital circuits, and the integration of multiple complex systems within confined spaces. These factors have collectively contributed to making coil whine a more prevalent and challenging issue in modern signal processing environments.

Understanding the background of coil whine in signal processing applications is crucial for developing effective solutions. It requires a comprehensive approach that considers not only the physical principles behind the phenomenon but also the specific requirements and constraints of signal processing systems. This holistic understanding forms the foundation for exploring advanced methods to combat coil whine and improve the overall performance and reliability of signal processing applications.

Market Impact Analysis

The impact of advanced methods for coil whine reduction in signal processing applications is poised to significantly reshape various market segments within the electronics and technology industries. As consumer demand for high-performance, low-noise electronic devices continues to grow, manufacturers are increasingly prioritizing coil whine mitigation techniques to enhance product quality and user experience.

In the consumer electronics sector, the implementation of advanced coil whine reduction methods is expected to drive innovation in premium audio equipment, high-end gaming peripherals, and professional-grade computing hardware. This trend is likely to create a new tier of premium products that command higher profit margins, potentially altering the competitive landscape in favor of companies that can effectively implement these advanced techniques.

The automotive industry stands to benefit substantially from improved coil whine reduction in signal processing applications. As vehicles become more electrified and autonomous, the need for quiet, high-performance electronic systems becomes paramount. Advanced methods for coil whine reduction could become a key differentiator in the electric vehicle market, where noise reduction is a critical factor in consumer satisfaction and brand perception.

In the telecommunications sector, the deployment of 5G and future network technologies requires increasingly sophisticated signal processing equipment. The adoption of advanced coil whine reduction methods in this field could lead to improved network performance, reduced maintenance costs, and enhanced reliability of communication infrastructure. This may accelerate the rollout of next-generation networks and create new opportunities for equipment manufacturers and service providers.

The industrial automation and robotics markets are also likely to be impacted by advancements in coil whine reduction. As factories and manufacturing processes become more automated and reliant on precision electronics, the demand for low-noise, high-accuracy signal processing components is expected to rise. This could lead to the development of new product lines specifically tailored for industrial applications, potentially opening up new revenue streams for companies specializing in noise reduction technologies.

In the medical technology sector, the integration of advanced coil whine reduction methods could enhance the accuracy and reliability of diagnostic equipment, particularly in imaging and monitoring devices. This improvement may lead to more precise diagnoses, better patient outcomes, and potentially reduce healthcare costs associated with equipment-related errors or inefficiencies.

The overall market for signal processing components and systems is likely to see a shift towards higher-value products incorporating advanced coil whine reduction techniques. This trend may lead to increased research and development investments, as companies seek to gain a competitive edge through superior noise reduction capabilities. Additionally, it could spur the growth of specialized suppliers and consultancies focused on noise reduction solutions, creating a new sub-sector within the broader electronics industry.

In the consumer electronics sector, the implementation of advanced coil whine reduction methods is expected to drive innovation in premium audio equipment, high-end gaming peripherals, and professional-grade computing hardware. This trend is likely to create a new tier of premium products that command higher profit margins, potentially altering the competitive landscape in favor of companies that can effectively implement these advanced techniques.

The automotive industry stands to benefit substantially from improved coil whine reduction in signal processing applications. As vehicles become more electrified and autonomous, the need for quiet, high-performance electronic systems becomes paramount. Advanced methods for coil whine reduction could become a key differentiator in the electric vehicle market, where noise reduction is a critical factor in consumer satisfaction and brand perception.

In the telecommunications sector, the deployment of 5G and future network technologies requires increasingly sophisticated signal processing equipment. The adoption of advanced coil whine reduction methods in this field could lead to improved network performance, reduced maintenance costs, and enhanced reliability of communication infrastructure. This may accelerate the rollout of next-generation networks and create new opportunities for equipment manufacturers and service providers.

The industrial automation and robotics markets are also likely to be impacted by advancements in coil whine reduction. As factories and manufacturing processes become more automated and reliant on precision electronics, the demand for low-noise, high-accuracy signal processing components is expected to rise. This could lead to the development of new product lines specifically tailored for industrial applications, potentially opening up new revenue streams for companies specializing in noise reduction technologies.

In the medical technology sector, the integration of advanced coil whine reduction methods could enhance the accuracy and reliability of diagnostic equipment, particularly in imaging and monitoring devices. This improvement may lead to more precise diagnoses, better patient outcomes, and potentially reduce healthcare costs associated with equipment-related errors or inefficiencies.

The overall market for signal processing components and systems is likely to see a shift towards higher-value products incorporating advanced coil whine reduction techniques. This trend may lead to increased research and development investments, as companies seek to gain a competitive edge through superior noise reduction capabilities. Additionally, it could spur the growth of specialized suppliers and consultancies focused on noise reduction solutions, creating a new sub-sector within the broader electronics industry.

Technical Challenges

Coil whine in signal processing applications presents several significant technical challenges that researchers and engineers must address. One of the primary obstacles is the inherent nature of coil whine itself, which is a high-frequency noise generated by electromagnetic components under varying electrical loads. This noise can interfere with sensitive signal processing operations, particularly in applications requiring high precision and low noise floors.

The complexity of coil whine mitigation is further compounded by its variability across different devices and operating conditions. Environmental factors, such as temperature and humidity, can influence the intensity and frequency of coil whine, making it difficult to implement universally effective solutions. Additionally, the miniaturization trend in electronic devices has led to more compact designs, which can exacerbate coil whine issues due to increased component density and reduced space for isolation measures.

Another significant challenge lies in the frequency range of coil whine, which often overlaps with the operational frequencies of many signal processing applications. This overlap makes it challenging to filter out the noise without affecting the desired signals. Traditional filtering techniques may not be sufficient, as they can introduce phase shifts or distortions that are unacceptable in high-fidelity signal processing scenarios.

The power supply design presents another hurdle in coil whine reduction. Modern switch-mode power supplies, while efficient, can contribute to coil whine through their high-frequency switching operations. Balancing power efficiency with noise reduction becomes a critical design consideration, often requiring complex trade-offs between performance, cost, and electromagnetic compatibility.

Advanced methods for coil whine reduction must also contend with the limitations of current materials and manufacturing processes. While specialized materials and construction techniques can help mitigate coil whine, they often come at a premium cost and may not be feasible for mass-produced consumer electronics. Developing cost-effective materials and manufacturing methods that inherently reduce coil whine remains an ongoing challenge.

The integration of digital and analog components in modern signal processing systems introduces additional complexities. Digital circuits can generate high-frequency noise that couples with analog components, potentially exacerbating coil whine issues. Effective isolation and grounding strategies become crucial but are increasingly difficult to implement in compact, multi-layered circuit designs.

Lastly, the regulatory landscape poses its own set of challenges. As electronic devices become more prevalent and operate at higher frequencies, electromagnetic compatibility (EMC) standards are becoming more stringent. Addressing coil whine is not just a matter of improving signal quality but also of ensuring compliance with evolving regulatory requirements, which can vary across different regions and applications.

The complexity of coil whine mitigation is further compounded by its variability across different devices and operating conditions. Environmental factors, such as temperature and humidity, can influence the intensity and frequency of coil whine, making it difficult to implement universally effective solutions. Additionally, the miniaturization trend in electronic devices has led to more compact designs, which can exacerbate coil whine issues due to increased component density and reduced space for isolation measures.

Another significant challenge lies in the frequency range of coil whine, which often overlaps with the operational frequencies of many signal processing applications. This overlap makes it challenging to filter out the noise without affecting the desired signals. Traditional filtering techniques may not be sufficient, as they can introduce phase shifts or distortions that are unacceptable in high-fidelity signal processing scenarios.

The power supply design presents another hurdle in coil whine reduction. Modern switch-mode power supplies, while efficient, can contribute to coil whine through their high-frequency switching operations. Balancing power efficiency with noise reduction becomes a critical design consideration, often requiring complex trade-offs between performance, cost, and electromagnetic compatibility.

Advanced methods for coil whine reduction must also contend with the limitations of current materials and manufacturing processes. While specialized materials and construction techniques can help mitigate coil whine, they often come at a premium cost and may not be feasible for mass-produced consumer electronics. Developing cost-effective materials and manufacturing methods that inherently reduce coil whine remains an ongoing challenge.

The integration of digital and analog components in modern signal processing systems introduces additional complexities. Digital circuits can generate high-frequency noise that couples with analog components, potentially exacerbating coil whine issues. Effective isolation and grounding strategies become crucial but are increasingly difficult to implement in compact, multi-layered circuit designs.

Lastly, the regulatory landscape poses its own set of challenges. As electronic devices become more prevalent and operate at higher frequencies, electromagnetic compatibility (EMC) standards are becoming more stringent. Addressing coil whine is not just a matter of improving signal quality but also of ensuring compliance with evolving regulatory requirements, which can vary across different regions and applications.

Current Mitigation

01 Electromagnetic shielding techniques

Implementing electromagnetic shielding techniques to reduce coil whine noise. This involves using materials or structures that can block or absorb electromagnetic interference, thereby minimizing the vibrations that cause coil whine. Shielding can be applied to the coil itself or to surrounding components to contain and reduce the noise.- Electromagnetic shielding techniques: Implementing electromagnetic shielding techniques can help reduce coil whine noise. This involves using materials or structures that block electromagnetic interference, which is often a source of coil whine. Shielding can be applied to the coil itself or to surrounding components to minimize noise transmission.

- Active noise cancellation: Active noise cancellation technology can be employed to counteract coil whine. This method involves generating sound waves that are opposite in phase to the coil whine, effectively canceling out the unwanted noise. Implementation may include microphones to detect the noise and speakers or actuators to produce the canceling waves.

- Mechanical damping and isolation: Applying mechanical damping and isolation techniques can reduce coil whine transmission. This involves using materials or structures that absorb vibrations, such as rubber mounts or foam padding. Isolating the coil or the entire device from surfaces that could amplify the noise can significantly reduce perceived coil whine.

- Optimized coil design and materials: Improving the design and materials of the coil itself can help minimize whine. This may include using different core materials, altering the winding pattern, or employing specialized coatings. The goal is to reduce the mechanical vibrations that cause the whine while maintaining the coil's electrical performance.

- Power supply and signal processing optimization: Optimizing power supply and signal processing can help reduce coil whine. This may involve using filtering techniques to clean up power signals, implementing frequency modulation to spread the noise across a wider spectrum, or using adaptive algorithms to adjust power delivery based on load conditions. These methods aim to minimize the electrical conditions that lead to coil whine.

02 Active noise cancellation

Employing active noise cancellation technology to counteract coil whine. This method involves generating sound waves that are opposite in phase to the coil whine, effectively canceling out the unwanted noise. The system can use microphones to detect the coil whine and speakers or actuators to produce the canceling sound waves.Expand Specific Solutions03 Mechanical damping and isolation

Utilizing mechanical damping and isolation techniques to reduce coil whine transmission. This approach involves using materials or structures that can absorb vibrations, such as rubber mounts or damping pads. By isolating the coil or the entire component from the rest of the system, the transmission of vibrations and resulting noise can be minimized.Expand Specific Solutions04 Optimized coil design and materials

Improving coil design and using advanced materials to reduce the likelihood of coil whine. This can include using different winding techniques, altering the shape or size of the coil, or employing materials with better electromagnetic properties. The goal is to minimize the physical vibrations that cause the whine at the source.Expand Specific Solutions05 Frequency modulation and power management

Implementing frequency modulation techniques and advanced power management systems to reduce coil whine. This approach involves adjusting the operating frequency of the coil or the power delivery to it, spreading the energy over a wider frequency range or avoiding resonant frequencies that cause audible whine. It may also include sophisticated control algorithms to optimize power delivery and minimize noise-inducing fluctuations.Expand Specific Solutions

Industry Leaders

The advanced methods for coil whine in signal processing applications represent a niche but growing field within the broader electronics industry. The market is currently in its early growth stage, with increasing demand driven by the need for noise reduction in various electronic devices. While the market size remains relatively small, it is expected to expand as more industries adopt these technologies. The technical maturity of coil whine reduction methods varies, with companies like Siemens AG, Robert Bosch GmbH, and Fujitsu Ltd. leading in research and development. These established players are leveraging their expertise in signal processing and electronics to develop innovative solutions. Meanwhile, specialized firms such as Harman International Industries, Inc. and MicroStrain, Inc. are focusing on niche applications, particularly in audio and sensor technologies.

Siemens AG

Technical Solution: Siemens AG has developed advanced methods for coil whine reduction in signal processing applications, focusing on their industrial and healthcare equipment. Their approach combines hardware and software solutions. On the hardware side, they use specialized magnetic shielding materials and optimized coil designs to minimize electromagnetic interference. For software, they implement adaptive noise cancellation algorithms that can identify and suppress coil whine frequencies in real-time[1]. Siemens has also introduced a novel technique called "frequency spreading" which distributes the coil whine energy across a wider frequency spectrum, making it less noticeable to human ears[2]. In their medical imaging devices, they've implemented a "silent mode" operation that adjusts power delivery to reduce coil whine during sensitive procedures[3].

Strengths: Comprehensive approach combining hardware and software solutions; Specialized techniques for medical applications. Weaknesses: May increase product cost; Some solutions might be application-specific and not universally applicable.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has made significant strides in addressing coil whine in automotive and industrial applications. Their approach focuses on both prevention and mitigation. For prevention, they've developed a proprietary coil design that reduces the likelihood of coil whine occurrence. This design incorporates advanced materials with improved magnetic properties and optimized winding techniques[4]. On the mitigation front, Bosch has implemented digital signal processing (DSP) algorithms that can detect and filter out coil whine frequencies in real-time. These algorithms are adaptive and can adjust to varying operating conditions, ensuring consistent performance across different environments[5]. Additionally, Bosch has introduced a novel "active noise control" system for their automotive products, which generates anti-noise signals to cancel out coil whine, significantly improving the in-car audio experience[6].

Strengths: Strong focus on automotive applications; Combination of preventive and mitigative measures. Weaknesses: Solutions may be more tailored to automotive sector; Potential increased complexity in product design.

Key Innovations

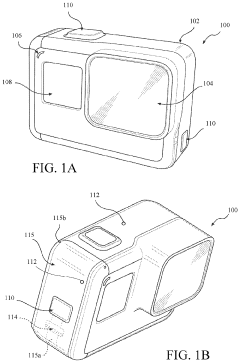

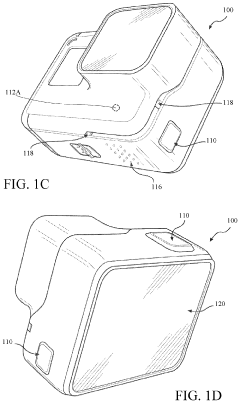

Method and apparatus for active reduction of mechanically coupled vibration in microphone signals

PatentActiveUS11871111B2

Innovation

- An image capture device equipped with a microphone, a vibration sensor, and a processor that upsamples the vibration signal to determine correlation values and filter coefficients, allowing for the active reduction of mechanical noise in microphone signals.

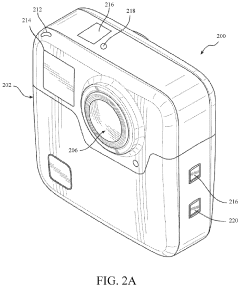

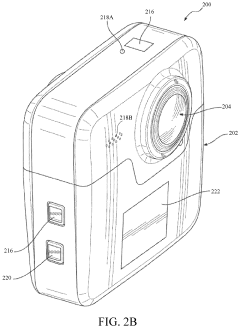

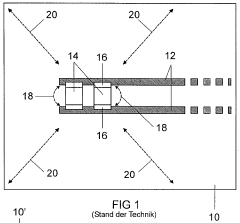

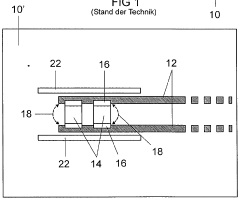

Printed circuit board with vibration-generating electronic component

PatentWO2008009308A1

Innovation

- Incorporating slots in the circuit board that prevent vibration propagation by interrupting surface waves and transverse vibrations, with slots running parallel to the electronic component's side walls to suppress vibrations efficiently.

Regulatory Compliance

Regulatory compliance is a critical aspect of advanced methods for coil whine reduction in signal processing applications. As these techniques are implemented in various electronic devices, adherence to established standards and regulations is paramount to ensure product safety, electromagnetic compatibility, and market acceptance.

The primary regulatory bodies governing electromagnetic interference (EMI) and electromagnetic compatibility (EMC) include the Federal Communications Commission (FCC) in the United States, the European Union's CE marking requirements, and the International Special Committee on Radio Interference (CISPR). These organizations set forth stringent guidelines that manufacturers must follow to mitigate electromagnetic emissions, including those resulting from coil whine.

For signal processing applications, compliance with FCC Part 15 regulations is essential for devices sold in the US market. This regulation specifies limits for both conducted and radiated emissions across different frequency ranges. Similarly, the EU's EMC Directive 2014/30/EU mandates that electronic equipment must not generate electromagnetic disturbances above specified levels and must have an adequate level of immunity to electromagnetic interference.

Specific standards such as EN 55032 for multimedia equipment and EN 61000-3-2 for harmonic current emissions are particularly relevant to signal processing applications. These standards outline test methods and limits for various types of equipment, including those that may be susceptible to coil whine issues.

Compliance testing for coil whine reduction methods typically involves specialized equipment such as anechoic chambers, spectrum analyzers, and EMI receivers. Manufacturers must demonstrate that their products meet the prescribed limits across a wide range of frequencies, often extending from 150 kHz to 30 MHz for conducted emissions and 30 MHz to 1 GHz for radiated emissions.

It is important to note that regulatory compliance is not a one-time process but an ongoing commitment. As new technologies emerge and existing standards evolve, manufacturers must continually assess and update their coil whine reduction methods to maintain compliance. This may involve periodic retesting, documentation updates, and potentially redesigns to address any new regulatory requirements or changes in emission profiles.

Moreover, regulatory compliance extends beyond EMI/EMC considerations. Advanced methods for coil whine reduction must also adhere to product safety standards, such as those set by Underwriters Laboratories (UL) or the International Electrotechnical Commission (IEC). These standards ensure that the implemented solutions do not compromise the overall safety and reliability of the signal processing equipment.

The primary regulatory bodies governing electromagnetic interference (EMI) and electromagnetic compatibility (EMC) include the Federal Communications Commission (FCC) in the United States, the European Union's CE marking requirements, and the International Special Committee on Radio Interference (CISPR). These organizations set forth stringent guidelines that manufacturers must follow to mitigate electromagnetic emissions, including those resulting from coil whine.

For signal processing applications, compliance with FCC Part 15 regulations is essential for devices sold in the US market. This regulation specifies limits for both conducted and radiated emissions across different frequency ranges. Similarly, the EU's EMC Directive 2014/30/EU mandates that electronic equipment must not generate electromagnetic disturbances above specified levels and must have an adequate level of immunity to electromagnetic interference.

Specific standards such as EN 55032 for multimedia equipment and EN 61000-3-2 for harmonic current emissions are particularly relevant to signal processing applications. These standards outline test methods and limits for various types of equipment, including those that may be susceptible to coil whine issues.

Compliance testing for coil whine reduction methods typically involves specialized equipment such as anechoic chambers, spectrum analyzers, and EMI receivers. Manufacturers must demonstrate that their products meet the prescribed limits across a wide range of frequencies, often extending from 150 kHz to 30 MHz for conducted emissions and 30 MHz to 1 GHz for radiated emissions.

It is important to note that regulatory compliance is not a one-time process but an ongoing commitment. As new technologies emerge and existing standards evolve, manufacturers must continually assess and update their coil whine reduction methods to maintain compliance. This may involve periodic retesting, documentation updates, and potentially redesigns to address any new regulatory requirements or changes in emission profiles.

Moreover, regulatory compliance extends beyond EMI/EMC considerations. Advanced methods for coil whine reduction must also adhere to product safety standards, such as those set by Underwriters Laboratories (UL) or the International Electrotechnical Commission (IEC). These standards ensure that the implemented solutions do not compromise the overall safety and reliability of the signal processing equipment.

Acoustic Performance

Coil whine, a common issue in signal processing applications, significantly impacts the acoustic performance of electronic devices. This high-frequency noise, typically ranging from 2 kHz to 20 kHz, is produced by electromagnetic vibrations in coils and transformers. The acoustic performance of devices affected by coil whine is characterized by a distinct, often irritating, high-pitched sound that can be detrimental to user experience and overall product quality.

The severity of coil whine's impact on acoustic performance varies depending on several factors, including the device's design, component quality, and operating conditions. In signal processing applications, where precision and clarity of signals are paramount, coil whine can introduce unwanted noise that interferes with the intended audio output. This interference can manifest as background hiss, buzzing, or high-frequency tones that distort the original signal and reduce the overall fidelity of the audio reproduction.

Measuring and quantifying the acoustic performance impact of coil whine involves sophisticated testing methodologies. These typically include anechoic chamber testing, frequency response analysis, and psychoacoustic evaluations. The results of these tests are often expressed in terms of sound pressure levels (SPL), frequency spectra, and subjective listener assessments. Advanced signal processing techniques, such as spectral analysis and noise floor measurements, are employed to isolate and characterize the coil whine components within the overall acoustic output.

The presence of coil whine can significantly degrade the signal-to-noise ratio (SNR) in audio systems, particularly in high-fidelity applications. This degradation can lead to reduced dynamic range, decreased clarity, and a perceived loss of audio quality. In professional audio equipment, where even minor imperfections can be critical, the acoustic performance impact of coil whine can be particularly problematic, potentially rendering equipment unsuitable for studio or live performance use.

Mitigating the acoustic performance impact of coil whine in signal processing applications involves a multi-faceted approach. This may include improved circuit design to minimize electromagnetic interactions, the use of higher quality components with better electromagnetic shielding, and the implementation of active noise cancellation techniques. Advanced methods such as adaptive filtering and real-time digital signal processing can also be employed to detect and suppress coil whine-induced noise, thereby improving the overall acoustic performance of the system.

The severity of coil whine's impact on acoustic performance varies depending on several factors, including the device's design, component quality, and operating conditions. In signal processing applications, where precision and clarity of signals are paramount, coil whine can introduce unwanted noise that interferes with the intended audio output. This interference can manifest as background hiss, buzzing, or high-frequency tones that distort the original signal and reduce the overall fidelity of the audio reproduction.

Measuring and quantifying the acoustic performance impact of coil whine involves sophisticated testing methodologies. These typically include anechoic chamber testing, frequency response analysis, and psychoacoustic evaluations. The results of these tests are often expressed in terms of sound pressure levels (SPL), frequency spectra, and subjective listener assessments. Advanced signal processing techniques, such as spectral analysis and noise floor measurements, are employed to isolate and characterize the coil whine components within the overall acoustic output.

The presence of coil whine can significantly degrade the signal-to-noise ratio (SNR) in audio systems, particularly in high-fidelity applications. This degradation can lead to reduced dynamic range, decreased clarity, and a perceived loss of audio quality. In professional audio equipment, where even minor imperfections can be critical, the acoustic performance impact of coil whine can be particularly problematic, potentially rendering equipment unsuitable for studio or live performance use.

Mitigating the acoustic performance impact of coil whine in signal processing applications involves a multi-faceted approach. This may include improved circuit design to minimize electromagnetic interactions, the use of higher quality components with better electromagnetic shielding, and the implementation of active noise cancellation techniques. Advanced methods such as adaptive filtering and real-time digital signal processing can also be employed to detect and suppress coil whine-induced noise, thereby improving the overall acoustic performance of the system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!