How to Refine Techniques for Efficient Coil Whine Management?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an audible noise produced by electronic components, particularly inductors and transformers, when subjected to rapidly changing electrical currents. This phenomenon has been a persistent challenge in the electronics industry, affecting a wide range of devices from personal computers to power supplies and electric vehicles. The issue gained prominence in the 1990s with the widespread adoption of switch-mode power supplies and has since become a significant concern for manufacturers and consumers alike.

The primary cause of coil whine is the magnetostriction effect, where magnetic materials change shape under the influence of a magnetic field. As electrical currents fluctuate rapidly in modern electronic circuits, the resulting changes in magnetic fields cause minute physical vibrations in the coils. These vibrations, occurring at frequencies within the human audible range, manifest as the characteristic high-pitched whine or buzz.

The severity and frequency of coil whine can vary greatly depending on the specific components used, circuit design, and operating conditions. Factors such as power load, temperature, and even the age of the components can influence the intensity of the noise. In some cases, the whine may be barely noticeable, while in others, it can be significantly disruptive to users and potentially indicative of underlying performance issues.

As electronic devices have become more compact and powerful, the challenge of managing coil whine has intensified. Higher switching frequencies in modern power supplies, while beneficial for efficiency, can exacerbate the problem. Additionally, the trend towards miniaturization has led to components being packed more tightly, potentially amplifying the acoustic effects of coil vibrations.

The impact of coil whine extends beyond mere annoyance. In professional audio environments, such as recording studios or broadcast facilities, even minimal electronic noise can compromise the quality of audio production. In consumer electronics, persistent coil whine can lead to customer dissatisfaction and increased product returns, affecting brand reputation and sales.

Addressing coil whine has become a multifaceted challenge for engineers and designers. It involves a delicate balance between performance, efficiency, cost, and acoustic considerations. Traditional approaches have included using higher quality components, implementing acoustic dampening materials, and optimizing circuit layouts. However, as devices continue to evolve, more sophisticated and innovative solutions are required to effectively manage this persistent issue.

The primary cause of coil whine is the magnetostriction effect, where magnetic materials change shape under the influence of a magnetic field. As electrical currents fluctuate rapidly in modern electronic circuits, the resulting changes in magnetic fields cause minute physical vibrations in the coils. These vibrations, occurring at frequencies within the human audible range, manifest as the characteristic high-pitched whine or buzz.

The severity and frequency of coil whine can vary greatly depending on the specific components used, circuit design, and operating conditions. Factors such as power load, temperature, and even the age of the components can influence the intensity of the noise. In some cases, the whine may be barely noticeable, while in others, it can be significantly disruptive to users and potentially indicative of underlying performance issues.

As electronic devices have become more compact and powerful, the challenge of managing coil whine has intensified. Higher switching frequencies in modern power supplies, while beneficial for efficiency, can exacerbate the problem. Additionally, the trend towards miniaturization has led to components being packed more tightly, potentially amplifying the acoustic effects of coil vibrations.

The impact of coil whine extends beyond mere annoyance. In professional audio environments, such as recording studios or broadcast facilities, even minimal electronic noise can compromise the quality of audio production. In consumer electronics, persistent coil whine can lead to customer dissatisfaction and increased product returns, affecting brand reputation and sales.

Addressing coil whine has become a multifaceted challenge for engineers and designers. It involves a delicate balance between performance, efficiency, cost, and acoustic considerations. Traditional approaches have included using higher quality components, implementing acoustic dampening materials, and optimizing circuit layouts. However, as devices continue to evolve, more sophisticated and innovative solutions are required to effectively manage this persistent issue.

Market Demand Analysis

The market demand for efficient coil whine management techniques has been steadily increasing in recent years, driven by the growing consumer electronics industry and the push for higher performance in compact devices. Coil whine, a high-pitched noise produced by electromagnetic components under certain operating conditions, has become a significant concern for manufacturers and consumers alike.

In the consumer electronics sector, particularly in high-end laptops, gaming consoles, and graphics cards, there is a strong demand for solutions that can mitigate or eliminate coil whine. This demand is fueled by user expectations for quiet operation, especially in premium devices where noise can detract from the overall user experience. The gaming industry, in particular, has shown a keen interest in coil whine reduction techniques, as gamers often use their systems for extended periods and are more likely to notice and be bothered by such noise.

The automotive industry is another major market driver for coil whine management solutions. As electric and hybrid vehicles gain popularity, the need for quiet and efficient power electronics becomes more critical. Coil whine in these vehicles can affect passenger comfort and potentially impact brand perception, making it a priority for automotive manufacturers to implement effective management techniques.

Industrial applications, including power supplies for data centers and telecommunications equipment, also contribute to the market demand. In these settings, coil whine can be indicative of inefficiencies or potential failures, making its management crucial for maintaining system reliability and energy efficiency.

The market for coil whine management solutions is expected to grow alongside the expansion of the Internet of Things (IoT) and smart home devices. As more electronic devices enter households and workplaces, the cumulative effect of coil whine from multiple sources becomes a more significant issue, driving demand for quieter components and better management techniques.

Manufacturers are increasingly recognizing coil whine management as a differentiating factor in product quality and customer satisfaction. This recognition is leading to increased investment in research and development of innovative solutions, ranging from improved component design to advanced noise cancellation technologies.

The global push for energy efficiency also plays a role in market demand. As electronic devices are designed to be more power-efficient, the components that can cause coil whine are often pushed to operate at higher frequencies, potentially exacerbating the issue. This creates a need for management techniques that can address coil whine without compromising on energy efficiency goals.

In summary, the market demand for efficient coil whine management techniques is robust and multifaceted, spanning various industries and driven by factors such as user experience, product quality, energy efficiency, and regulatory compliance. As electronic devices continue to proliferate and evolve, the importance of addressing coil whine is likely to grow, presenting ongoing opportunities for innovation and market growth in this field.

In the consumer electronics sector, particularly in high-end laptops, gaming consoles, and graphics cards, there is a strong demand for solutions that can mitigate or eliminate coil whine. This demand is fueled by user expectations for quiet operation, especially in premium devices where noise can detract from the overall user experience. The gaming industry, in particular, has shown a keen interest in coil whine reduction techniques, as gamers often use their systems for extended periods and are more likely to notice and be bothered by such noise.

The automotive industry is another major market driver for coil whine management solutions. As electric and hybrid vehicles gain popularity, the need for quiet and efficient power electronics becomes more critical. Coil whine in these vehicles can affect passenger comfort and potentially impact brand perception, making it a priority for automotive manufacturers to implement effective management techniques.

Industrial applications, including power supplies for data centers and telecommunications equipment, also contribute to the market demand. In these settings, coil whine can be indicative of inefficiencies or potential failures, making its management crucial for maintaining system reliability and energy efficiency.

The market for coil whine management solutions is expected to grow alongside the expansion of the Internet of Things (IoT) and smart home devices. As more electronic devices enter households and workplaces, the cumulative effect of coil whine from multiple sources becomes a more significant issue, driving demand for quieter components and better management techniques.

Manufacturers are increasingly recognizing coil whine management as a differentiating factor in product quality and customer satisfaction. This recognition is leading to increased investment in research and development of innovative solutions, ranging from improved component design to advanced noise cancellation technologies.

The global push for energy efficiency also plays a role in market demand. As electronic devices are designed to be more power-efficient, the components that can cause coil whine are often pushed to operate at higher frequencies, potentially exacerbating the issue. This creates a need for management techniques that can address coil whine without compromising on energy efficiency goals.

In summary, the market demand for efficient coil whine management techniques is robust and multifaceted, spanning various industries and driven by factors such as user experience, product quality, energy efficiency, and regulatory compliance. As electronic devices continue to proliferate and evolve, the importance of addressing coil whine is likely to grow, presenting ongoing opportunities for innovation and market growth in this field.

Current Challenges

Coil whine management presents several significant challenges in modern electronic devices, particularly in power supplies, transformers, and inductors. One of the primary obstacles is the inherent nature of electromagnetic forces in these components, which cause vibrations at specific frequencies, resulting in audible noise. This phenomenon is exacerbated by the increasing demand for higher power density and miniaturization in electronic devices, leading to more compact designs that are more susceptible to coil whine.

Another major challenge lies in the variability of coil whine across different units of the same product. Due to manufacturing tolerances and slight variations in component characteristics, the intensity and frequency of coil whine can differ significantly between otherwise identical devices. This inconsistency makes it difficult to implement a one-size-fits-all solution and necessitates a more adaptive approach to noise management.

The complexity of modern power delivery systems also contributes to the challenges in coil whine management. With the implementation of dynamic voltage and frequency scaling techniques for improved energy efficiency, the operating conditions of coils and transformers are constantly changing. This dynamic behavior can lead to intermittent or variable coil whine, making it harder to identify and mitigate the issue consistently.

Furthermore, the increasing use of high-frequency switching in power conversion circuits, while beneficial for efficiency and size reduction, can exacerbate coil whine issues. Higher switching frequencies can excite resonant frequencies in coils and transformers more easily, potentially leading to more pronounced audible noise.

The cost-effectiveness of coil whine solutions presents another significant challenge. Many effective techniques for reducing coil whine, such as using higher-quality materials or more complex shielding designs, can substantially increase production costs. This creates a difficult balance between performance, cost, and user experience that manufacturers must navigate.

Environmental factors also play a role in complicating coil whine management. Temperature variations, humidity, and mechanical stress can all affect the behavior of coils and transformers, potentially altering their acoustic properties over time or under different operating conditions. This variability makes it challenging to design solutions that remain effective across a wide range of environmental conditions.

Lastly, the regulatory landscape surrounding electronic noise emissions is becoming increasingly stringent. While coil whine may not always violate electromagnetic interference (EMI) regulations, it can still impact user experience and product perception. Meeting these evolving standards while maintaining performance and cost-effectiveness adds another layer of complexity to the challenge of efficient coil whine management.

Another major challenge lies in the variability of coil whine across different units of the same product. Due to manufacturing tolerances and slight variations in component characteristics, the intensity and frequency of coil whine can differ significantly between otherwise identical devices. This inconsistency makes it difficult to implement a one-size-fits-all solution and necessitates a more adaptive approach to noise management.

The complexity of modern power delivery systems also contributes to the challenges in coil whine management. With the implementation of dynamic voltage and frequency scaling techniques for improved energy efficiency, the operating conditions of coils and transformers are constantly changing. This dynamic behavior can lead to intermittent or variable coil whine, making it harder to identify and mitigate the issue consistently.

Furthermore, the increasing use of high-frequency switching in power conversion circuits, while beneficial for efficiency and size reduction, can exacerbate coil whine issues. Higher switching frequencies can excite resonant frequencies in coils and transformers more easily, potentially leading to more pronounced audible noise.

The cost-effectiveness of coil whine solutions presents another significant challenge. Many effective techniques for reducing coil whine, such as using higher-quality materials or more complex shielding designs, can substantially increase production costs. This creates a difficult balance between performance, cost, and user experience that manufacturers must navigate.

Environmental factors also play a role in complicating coil whine management. Temperature variations, humidity, and mechanical stress can all affect the behavior of coils and transformers, potentially altering their acoustic properties over time or under different operating conditions. This variability makes it challenging to design solutions that remain effective across a wide range of environmental conditions.

Lastly, the regulatory landscape surrounding electronic noise emissions is becoming increasingly stringent. While coil whine may not always violate electromagnetic interference (EMI) regulations, it can still impact user experience and product perception. Meeting these evolving standards while maintaining performance and cost-effectiveness adds another layer of complexity to the challenge of efficient coil whine management.

Existing Solutions

01 Reduction of electromagnetic noise in coils

Various techniques are employed to reduce electromagnetic noise, commonly known as coil whine, in electrical systems. These methods include optimizing coil design, using noise-absorbing materials, and implementing advanced winding techniques to minimize vibrations and improve overall efficiency.- Reduction of electromagnetic noise in coils: Various techniques are employed to reduce electromagnetic noise, commonly known as coil whine, in electrical systems. These methods include optimizing coil design, using noise-dampening materials, and implementing advanced winding techniques to minimize vibrations and improve overall efficiency.

- Efficiency improvement in power conversion systems: Innovations in power conversion systems focus on enhancing efficiency by reducing energy losses associated with coil whine. This involves advanced circuit designs, improved component selection, and optimized control strategies to minimize unwanted electromagnetic oscillations while maximizing power transfer.

- Coil design optimization for noise reduction: Specialized coil designs are developed to minimize acoustic noise generation. These designs incorporate factors such as winding patterns, core materials, and physical structures to reduce mechanical vibrations caused by electromagnetic forces, thereby improving both efficiency and noise performance.

- Advanced materials for coil efficiency and noise reduction: The use of advanced materials in coil construction plays a crucial role in improving efficiency and reducing coil whine. These materials may include high-performance magnetic cores, specialized insulation, and composite structures that dampen vibrations while maintaining excellent electromagnetic properties.

- Monitoring and control systems for coil performance: Sophisticated monitoring and control systems are implemented to optimize coil performance in real-time. These systems can detect and mitigate coil whine, adjust operating parameters for maximum efficiency, and provide diagnostic information for maintenance and improvement of coil-based devices.

02 Efficiency improvement in power conversion systems

Innovations in power conversion systems focus on enhancing efficiency while reducing coil whine. This involves advanced circuit designs, improved component selection, and optimized control strategies to minimize energy losses and acoustic noise generation during power conversion processes.Expand Specific Solutions03 Coil design optimization for noise reduction

Specialized coil designs are developed to minimize acoustic noise while maintaining or improving efficiency. These designs may incorporate novel geometries, materials, or winding patterns that reduce mechanical vibrations and electromagnetic interference, resulting in quieter operation.Expand Specific Solutions04 Active noise cancellation techniques

Advanced active noise cancellation methods are implemented to counteract coil whine. These techniques involve real-time monitoring of acoustic emissions and generating opposing signals to neutralize the noise, thereby improving the perceived efficiency and performance of the system.Expand Specific Solutions05 Thermal management for improved efficiency

Effective thermal management strategies are employed to enhance coil efficiency and reduce noise. These approaches include innovative cooling systems, temperature-resistant materials, and optimized heat dissipation techniques that maintain optimal operating conditions and minimize thermal-induced noise.Expand Specific Solutions

Key Industry Players

The coil whine management technology market is in a growth phase, driven by increasing demand for quieter electronic devices across various industries. The market size is expanding as more companies recognize the importance of noise reduction in consumer electronics, automotive systems, and industrial equipment. Technologically, the field is advancing rapidly, with companies like Robert Bosch GmbH, Siemens AG, and Continental Automotive GmbH leading innovation. These firms are developing sophisticated solutions for electromagnetic noise reduction, leveraging their expertise in automotive and industrial electronics. Asian players such as Mitsubishi Electric Corp. and vivo Mobile Communication Co., Ltd. are also making significant strides, particularly in consumer electronics applications. The technology's maturity varies across sectors, with automotive and industrial applications being more advanced than consumer electronics.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced techniques for efficient coil whine management in automotive applications. Their approach involves a combination of innovative design and material selection. They utilize high-quality magnetic core materials with low magnetostriction properties to reduce vibrations at the source. Additionally, Bosch implements advanced winding techniques and optimized coil geometries to minimize electromagnetic forces that contribute to coil whine. The company also employs sophisticated encapsulation methods using specialized resins that dampen vibrations and reduce acoustic emissions[1][3]. Furthermore, Bosch has integrated active noise control systems in some of their products, which use counter-phase sound waves to cancel out coil whine frequencies[5].

Strengths: Comprehensive approach combining material science, design optimization, and active control systems. Weaknesses: Potential increase in production costs and complexity of manufacturing processes.

Siemens AG

Technical Solution: Siemens AG has developed a multi-faceted approach to coil whine management in their electrical systems and power electronics. Their strategy includes advanced electromagnetic simulation techniques to predict and mitigate coil whine at the design stage. Siemens utilizes proprietary software tools that model the interaction between electrical, magnetic, and mechanical forces to optimize coil designs[2]. They have also pioneered the use of novel core materials, such as amorphous and nanocrystalline alloys, which exhibit superior magnetic properties and reduced magnetostriction[4]. In addition, Siemens implements advanced manufacturing techniques, including precision winding and vacuum impregnation, to ensure tight coil construction and minimize vibration potential. For particularly sensitive applications, Siemens has developed active vibration control systems that use piezoelectric actuators to counteract coil vibrations in real-time[6].

Strengths: Holistic approach combining advanced simulation, material science, and active control. Weaknesses: High initial investment in research and development, potentially leading to higher product costs.

Core Technologies

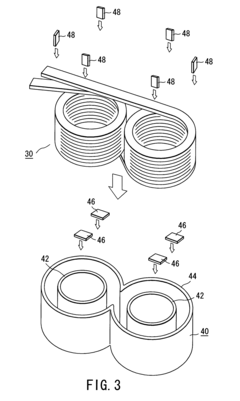

Coil component and fabrication method of the same

PatentInactiveUS7427909B2

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin, embedded within a magnetic core composed of a mixture of resin and magnetic powder, which provides enhanced structural integrity and noise suppression.

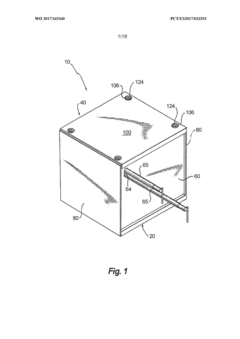

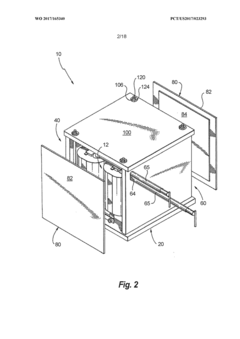

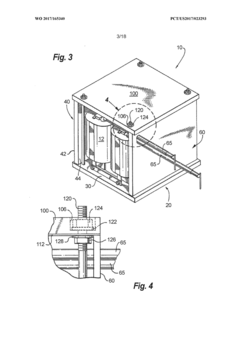

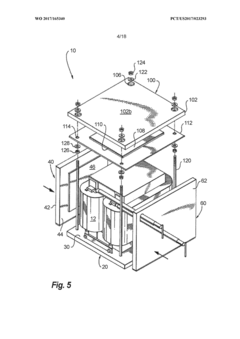

Noise reducing and cooling enclosure

PatentWO2017165340A1

Innovation

- The enclosure is constructed with multi-layered plate assemblies made of thermally conductive and acoustic quieting materials, which block and dissipate acoustic energy, using a combination of rigid acoustic blocking materials and thermally conductive materials to absorb and conduct heat away from the device.

Acoustic Standards

Acoustic standards play a crucial role in the management of coil whine, providing guidelines and benchmarks for acceptable noise levels in various environments. These standards are essential for manufacturers, engineers, and regulatory bodies to ensure that electronic devices meet specific noise emission requirements.

The International Electrotechnical Commission (IEC) has established several standards relevant to coil whine management. IEC 60601-1-8, for instance, sets noise limits for medical equipment, while IEC 62368-1 addresses audio/video, information, and communication technology equipment. These standards typically specify maximum sound pressure levels (SPLs) and frequency ranges that devices must adhere to.

In the context of consumer electronics, the European Union's Eco-design Directive (2009/125/EC) includes provisions for noise emissions from various products. This directive has led to the development of specific regulations for different product categories, such as computers and televisions, which must comply with certain noise limits during operation.

The American National Standards Institute (ANSI) and the Acoustical Society of America (ASA) have jointly developed standards like ANSI/ASA S12.10, which outlines methods for measuring noise emitted by computer and business equipment. This standard is particularly relevant for addressing coil whine in electronic devices.

For automotive applications, the Society of Automotive Engineers (SAE) has established standards like SAE J1030, which provides guidelines for measuring and reporting noise levels in vehicle interiors. These standards are crucial for managing coil whine in automotive electronics and ensuring passenger comfort.

In industrial settings, the Occupational Safety and Health Administration (OSHA) in the United States has set permissible noise exposure limits. While these primarily focus on worker safety, they indirectly influence the design of industrial equipment to minimize noise, including coil whine.

The International Organization for Standardization (ISO) has also contributed to acoustic standards with ISO 3745, which specifies methods for determining sound power levels of noise sources. This standard is particularly useful for characterizing the acoustic output of electronic components, including those prone to coil whine.

Compliance with these acoustic standards often requires sophisticated measurement techniques and specialized equipment. Anechoic chambers, sound level meters, and spectrum analyzers are commonly used to assess noise emissions and ensure adherence to relevant standards.

As technology evolves, acoustic standards are periodically updated to address new challenges and incorporate advancements in noise reduction techniques. This ongoing refinement of standards drives innovation in coil whine management, pushing manufacturers to develop more efficient and quieter electronic components.

The International Electrotechnical Commission (IEC) has established several standards relevant to coil whine management. IEC 60601-1-8, for instance, sets noise limits for medical equipment, while IEC 62368-1 addresses audio/video, information, and communication technology equipment. These standards typically specify maximum sound pressure levels (SPLs) and frequency ranges that devices must adhere to.

In the context of consumer electronics, the European Union's Eco-design Directive (2009/125/EC) includes provisions for noise emissions from various products. This directive has led to the development of specific regulations for different product categories, such as computers and televisions, which must comply with certain noise limits during operation.

The American National Standards Institute (ANSI) and the Acoustical Society of America (ASA) have jointly developed standards like ANSI/ASA S12.10, which outlines methods for measuring noise emitted by computer and business equipment. This standard is particularly relevant for addressing coil whine in electronic devices.

For automotive applications, the Society of Automotive Engineers (SAE) has established standards like SAE J1030, which provides guidelines for measuring and reporting noise levels in vehicle interiors. These standards are crucial for managing coil whine in automotive electronics and ensuring passenger comfort.

In industrial settings, the Occupational Safety and Health Administration (OSHA) in the United States has set permissible noise exposure limits. While these primarily focus on worker safety, they indirectly influence the design of industrial equipment to minimize noise, including coil whine.

The International Organization for Standardization (ISO) has also contributed to acoustic standards with ISO 3745, which specifies methods for determining sound power levels of noise sources. This standard is particularly useful for characterizing the acoustic output of electronic components, including those prone to coil whine.

Compliance with these acoustic standards often requires sophisticated measurement techniques and specialized equipment. Anechoic chambers, sound level meters, and spectrum analyzers are commonly used to assess noise emissions and ensure adherence to relevant standards.

As technology evolves, acoustic standards are periodically updated to address new challenges and incorporate advancements in noise reduction techniques. This ongoing refinement of standards drives innovation in coil whine management, pushing manufacturers to develop more efficient and quieter electronic components.

Environmental Impact

Coil whine, a high-frequency noise produced by electronic components, has become an increasingly significant concern in the realm of electronic device manufacturing and usage. As techniques for efficient coil whine management continue to evolve, it is crucial to consider the environmental impact of these solutions. The reduction of coil whine not only improves user experience but also contributes to the overall sustainability of electronic products.

One of the primary environmental benefits of effective coil whine management is the potential for extended device lifespan. By mitigating the vibrations and stress on electronic components caused by coil whine, manufacturers can enhance the durability of their products. This increased longevity directly translates to reduced electronic waste, a growing environmental concern in the age of rapid technological advancement.

Moreover, the techniques employed in coil whine management often involve the use of specialized materials and coatings. The development of eco-friendly, biodegradable alternatives to traditional damping materials presents an opportunity for reducing the environmental footprint of electronic devices. Researchers are exploring natural fibers and bio-based polymers as potential substitutes for synthetic damping compounds, aligning coil whine management with broader sustainability goals.

Energy efficiency is another critical aspect of the environmental impact of coil whine management. Advanced techniques that minimize energy loss due to vibrations and electromagnetic interference can contribute to overall device efficiency. This reduction in power consumption not only benefits the end-user through extended battery life but also lessens the demand on power grids, indirectly reducing carbon emissions associated with energy production.

The manufacturing processes involved in implementing coil whine management solutions also warrant environmental consideration. Techniques such as precision molding and advanced encapsulation methods may require specialized equipment and materials. Optimizing these processes for minimal waste and energy consumption is essential for ensuring that the environmental benefits of coil whine reduction are not offset by increased manufacturing impacts.

Furthermore, the acoustic pollution reduction achieved through effective coil whine management extends beyond user comfort to environmental benefits. In urban environments, where the cumulative effect of electronic device noise can be significant, minimizing coil whine contributes to overall noise pollution reduction. This aspect of environmental impact, while often overlooked, plays a role in maintaining healthier ecosystems, particularly for sound-sensitive wildlife in urban and suburban areas.

As the electronics industry continues to prioritize sustainability, the environmental impact of coil whine management techniques will likely gain increased attention. Future research and development in this field should focus on holistic approaches that consider the entire lifecycle of electronic devices, from material sourcing to end-of-life disposal. By integrating environmental considerations into the core of coil whine management strategies, the industry can move towards more sustainable and eco-friendly electronic products.

One of the primary environmental benefits of effective coil whine management is the potential for extended device lifespan. By mitigating the vibrations and stress on electronic components caused by coil whine, manufacturers can enhance the durability of their products. This increased longevity directly translates to reduced electronic waste, a growing environmental concern in the age of rapid technological advancement.

Moreover, the techniques employed in coil whine management often involve the use of specialized materials and coatings. The development of eco-friendly, biodegradable alternatives to traditional damping materials presents an opportunity for reducing the environmental footprint of electronic devices. Researchers are exploring natural fibers and bio-based polymers as potential substitutes for synthetic damping compounds, aligning coil whine management with broader sustainability goals.

Energy efficiency is another critical aspect of the environmental impact of coil whine management. Advanced techniques that minimize energy loss due to vibrations and electromagnetic interference can contribute to overall device efficiency. This reduction in power consumption not only benefits the end-user through extended battery life but also lessens the demand on power grids, indirectly reducing carbon emissions associated with energy production.

The manufacturing processes involved in implementing coil whine management solutions also warrant environmental consideration. Techniques such as precision molding and advanced encapsulation methods may require specialized equipment and materials. Optimizing these processes for minimal waste and energy consumption is essential for ensuring that the environmental benefits of coil whine reduction are not offset by increased manufacturing impacts.

Furthermore, the acoustic pollution reduction achieved through effective coil whine management extends beyond user comfort to environmental benefits. In urban environments, where the cumulative effect of electronic device noise can be significant, minimizing coil whine contributes to overall noise pollution reduction. This aspect of environmental impact, while often overlooked, plays a role in maintaining healthier ecosystems, particularly for sound-sensitive wildlife in urban and suburban areas.

As the electronics industry continues to prioritize sustainability, the environmental impact of coil whine management techniques will likely gain increased attention. Future research and development in this field should focus on holistic approaches that consider the entire lifecycle of electronic devices, from material sourcing to end-of-life disposal. By integrating environmental considerations into the core of coil whine management strategies, the industry can move towards more sustainable and eco-friendly electronic products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!