How to Establish Competency in Coil Whine Detection Systems?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Detection Background and Objectives

Coil whine, a phenomenon characterized by high-frequency vibrations in electronic components, has become an increasingly significant concern in the electronics industry. As devices continue to shrink in size and increase in power efficiency, the audible noise produced by coil whine has emerged as a critical quality issue. This technical pre-research report aims to explore the background of coil whine detection systems and establish clear objectives for their development and implementation.

The history of coil whine detection can be traced back to the early days of electronic manufacturing, where quality control processes relied primarily on human auditory perception. However, as consumer expectations for product quality have risen and regulatory standards have become more stringent, the need for more sophisticated and reliable detection methods has grown exponentially.

In recent years, the proliferation of high-performance computing devices, power supplies, and electric vehicles has further amplified the importance of coil whine detection. These applications often involve components operating at high frequencies and power levels, making them particularly susceptible to coil whine issues. The automotive industry, in particular, has been a driving force behind advancements in coil whine detection, as the quiet operation of electric vehicles has made even minor acoustic disturbances more noticeable and potentially detrimental to user experience.

The primary objective of establishing competency in coil whine detection systems is to develop robust, accurate, and scalable methodologies for identifying and quantifying coil whine across a wide range of electronic devices and components. This involves creating standardized testing protocols, designing sensitive measurement equipment, and implementing advanced signal processing algorithms to distinguish coil whine from other forms of electronic noise.

Another crucial goal is to integrate coil whine detection seamlessly into existing manufacturing and quality control processes. This integration aims to enable real-time monitoring and early detection of potential issues, thereby reducing production costs and improving overall product quality. Additionally, there is a strong focus on developing predictive models that can anticipate coil whine problems based on component characteristics and operating conditions, allowing for proactive design modifications and mitigation strategies.

As the electronics industry continues to evolve, the objectives of coil whine detection systems are expanding to include not only identification but also active suppression techniques. This involves researching and developing innovative materials, component designs, and electronic control methods that can minimize or eliminate coil whine at its source. The ultimate aim is to create a comprehensive ecosystem of tools, techniques, and best practices that enable manufacturers to produce quieter, more reliable electronic devices across all sectors of the industry.

The history of coil whine detection can be traced back to the early days of electronic manufacturing, where quality control processes relied primarily on human auditory perception. However, as consumer expectations for product quality have risen and regulatory standards have become more stringent, the need for more sophisticated and reliable detection methods has grown exponentially.

In recent years, the proliferation of high-performance computing devices, power supplies, and electric vehicles has further amplified the importance of coil whine detection. These applications often involve components operating at high frequencies and power levels, making them particularly susceptible to coil whine issues. The automotive industry, in particular, has been a driving force behind advancements in coil whine detection, as the quiet operation of electric vehicles has made even minor acoustic disturbances more noticeable and potentially detrimental to user experience.

The primary objective of establishing competency in coil whine detection systems is to develop robust, accurate, and scalable methodologies for identifying and quantifying coil whine across a wide range of electronic devices and components. This involves creating standardized testing protocols, designing sensitive measurement equipment, and implementing advanced signal processing algorithms to distinguish coil whine from other forms of electronic noise.

Another crucial goal is to integrate coil whine detection seamlessly into existing manufacturing and quality control processes. This integration aims to enable real-time monitoring and early detection of potential issues, thereby reducing production costs and improving overall product quality. Additionally, there is a strong focus on developing predictive models that can anticipate coil whine problems based on component characteristics and operating conditions, allowing for proactive design modifications and mitigation strategies.

As the electronics industry continues to evolve, the objectives of coil whine detection systems are expanding to include not only identification but also active suppression techniques. This involves researching and developing innovative materials, component designs, and electronic control methods that can minimize or eliminate coil whine at its source. The ultimate aim is to create a comprehensive ecosystem of tools, techniques, and best practices that enable manufacturers to produce quieter, more reliable electronic devices across all sectors of the industry.

Market Demand Analysis for Coil Whine Detection

The market demand for coil whine detection systems has been steadily increasing in recent years, driven by the growing emphasis on product quality and user experience across various industries. Coil whine, a high-pitched noise produced by electronic components, has become a significant concern for manufacturers and consumers alike, particularly in consumer electronics, automotive, and industrial sectors.

In the consumer electronics market, the demand for coil whine detection is particularly strong. As devices become more compact and powerful, the risk of coil whine increases. Manufacturers of smartphones, laptops, gaming consoles, and other personal electronic devices are investing in detection systems to ensure their products meet stringent quality standards and maintain customer satisfaction. The gaming industry, in particular, has shown a keen interest in coil whine detection, as high-performance graphics cards and power supplies are prone to this issue.

The automotive sector represents another significant market for coil whine detection systems. With the increasing electrification of vehicles and the integration of advanced electronics, the potential for coil whine has grown. Electric and hybrid vehicles, with their complex power management systems, are especially susceptible to this problem. Automotive manufacturers are seeking reliable detection methods to maintain the quiet and comfortable cabin environment that consumers expect.

In the industrial sector, the demand for coil whine detection is driven by the need for equipment reliability and workplace safety. Industrial machinery, power distribution systems, and large-scale electronic installations can all suffer from coil whine, potentially leading to reduced efficiency, increased maintenance costs, and even safety hazards. As a result, there is a growing market for detection systems that can identify and mitigate these issues in industrial settings.

The market for coil whine detection systems is also influenced by regulatory pressures and industry standards. Many countries have implemented strict noise emission regulations for electronic products, pushing manufacturers to adopt more sophisticated detection and mitigation techniques. This regulatory environment is expected to further drive the demand for advanced coil whine detection solutions in the coming years.

Looking at market trends, there is an increasing focus on integrating coil whine detection into the early stages of product development. This proactive approach allows manufacturers to address potential issues before products reach the market, reducing recall risks and improving overall product quality. As a result, there is a growing demand for detection systems that can be easily incorporated into existing design and testing processes.

The global nature of supply chains and manufacturing has also contributed to the expanding market for coil whine detection. With production often spread across multiple countries and suppliers, maintaining consistent quality standards has become more challenging. This has led to increased demand for standardized detection methods and equipment that can be implemented across diverse manufacturing environments.

In the consumer electronics market, the demand for coil whine detection is particularly strong. As devices become more compact and powerful, the risk of coil whine increases. Manufacturers of smartphones, laptops, gaming consoles, and other personal electronic devices are investing in detection systems to ensure their products meet stringent quality standards and maintain customer satisfaction. The gaming industry, in particular, has shown a keen interest in coil whine detection, as high-performance graphics cards and power supplies are prone to this issue.

The automotive sector represents another significant market for coil whine detection systems. With the increasing electrification of vehicles and the integration of advanced electronics, the potential for coil whine has grown. Electric and hybrid vehicles, with their complex power management systems, are especially susceptible to this problem. Automotive manufacturers are seeking reliable detection methods to maintain the quiet and comfortable cabin environment that consumers expect.

In the industrial sector, the demand for coil whine detection is driven by the need for equipment reliability and workplace safety. Industrial machinery, power distribution systems, and large-scale electronic installations can all suffer from coil whine, potentially leading to reduced efficiency, increased maintenance costs, and even safety hazards. As a result, there is a growing market for detection systems that can identify and mitigate these issues in industrial settings.

The market for coil whine detection systems is also influenced by regulatory pressures and industry standards. Many countries have implemented strict noise emission regulations for electronic products, pushing manufacturers to adopt more sophisticated detection and mitigation techniques. This regulatory environment is expected to further drive the demand for advanced coil whine detection solutions in the coming years.

Looking at market trends, there is an increasing focus on integrating coil whine detection into the early stages of product development. This proactive approach allows manufacturers to address potential issues before products reach the market, reducing recall risks and improving overall product quality. As a result, there is a growing demand for detection systems that can be easily incorporated into existing design and testing processes.

The global nature of supply chains and manufacturing has also contributed to the expanding market for coil whine detection. With production often spread across multiple countries and suppliers, maintaining consistent quality standards has become more challenging. This has led to increased demand for standardized detection methods and equipment that can be implemented across diverse manufacturing environments.

Current Challenges in Coil Whine Detection Technology

Coil whine detection systems face several significant challenges in their current state of development. One of the primary obstacles is the difficulty in distinguishing coil whine from other electronic noise sources. Electronic devices often produce a variety of sounds, including fan noise, electromagnetic interference, and other component vibrations. Isolating and identifying coil whine amidst this acoustic complexity requires sophisticated signal processing techniques and advanced filtering algorithms.

Another major challenge lies in the variability of coil whine characteristics across different devices and operating conditions. The frequency, amplitude, and pattern of coil whine can vary significantly depending on factors such as power supply quality, component quality, device load, and even ambient temperature. This variability makes it challenging to develop universal detection methods that can accurately identify coil whine across a wide range of electronic products.

The miniaturization of electronic devices presents an additional hurdle for coil whine detection systems. As components become smaller and more densely packed, the acoustic signatures become more complex and harder to isolate. This trend necessitates the development of more sensitive and precise detection technologies capable of operating in confined spaces with minimal interference.

Sensitivity and false positive rates remain critical issues in coil whine detection. Overly sensitive systems may trigger false alarms, leading to unnecessary interventions or product rejections. Conversely, systems with low sensitivity may fail to detect subtle but potentially problematic coil whine, compromising product quality and user experience. Striking the right balance between sensitivity and specificity is a ongoing challenge for system designers.

The integration of coil whine detection systems into existing manufacturing and quality control processes poses logistical and technical challenges. Implementing these systems often requires modifications to production lines, additional testing stages, and the training of personnel. Moreover, the real-time analysis of coil whine data in high-volume production environments demands significant computational resources and efficient data management systems.

Lastly, the lack of standardized metrics and thresholds for acceptable coil whine levels complicates the development and implementation of detection systems. Different industries and applications may have varying tolerances for coil whine, making it difficult to establish universal criteria for detection and classification. This absence of standardization hinders the widespread adoption of coil whine detection technologies and complicates cross-industry comparisons and benchmarking efforts.

Another major challenge lies in the variability of coil whine characteristics across different devices and operating conditions. The frequency, amplitude, and pattern of coil whine can vary significantly depending on factors such as power supply quality, component quality, device load, and even ambient temperature. This variability makes it challenging to develop universal detection methods that can accurately identify coil whine across a wide range of electronic products.

The miniaturization of electronic devices presents an additional hurdle for coil whine detection systems. As components become smaller and more densely packed, the acoustic signatures become more complex and harder to isolate. This trend necessitates the development of more sensitive and precise detection technologies capable of operating in confined spaces with minimal interference.

Sensitivity and false positive rates remain critical issues in coil whine detection. Overly sensitive systems may trigger false alarms, leading to unnecessary interventions or product rejections. Conversely, systems with low sensitivity may fail to detect subtle but potentially problematic coil whine, compromising product quality and user experience. Striking the right balance between sensitivity and specificity is a ongoing challenge for system designers.

The integration of coil whine detection systems into existing manufacturing and quality control processes poses logistical and technical challenges. Implementing these systems often requires modifications to production lines, additional testing stages, and the training of personnel. Moreover, the real-time analysis of coil whine data in high-volume production environments demands significant computational resources and efficient data management systems.

Lastly, the lack of standardized metrics and thresholds for acceptable coil whine levels complicates the development and implementation of detection systems. Different industries and applications may have varying tolerances for coil whine, making it difficult to establish universal criteria for detection and classification. This absence of standardization hinders the widespread adoption of coil whine detection technologies and complicates cross-industry comparisons and benchmarking efforts.

Existing Coil Whine Detection Solutions

01 Acoustic detection and analysis of coil whine

Systems and methods for detecting and analyzing coil whine using acoustic sensors and signal processing techniques. This approach involves capturing sound emissions from electronic devices, isolating coil whine frequencies, and applying advanced algorithms to characterize and quantify the whine. The analysis can help in identifying faulty components or predicting potential failures in electronic systems.- Acoustic detection of coil whine: Systems and methods for detecting coil whine using acoustic sensors. These systems can identify and analyze the characteristic high-frequency sounds produced by electronic components, particularly in power supplies and other electrical devices. The detection may involve advanced signal processing techniques to isolate coil whine from background noise.

- Machine learning for coil whine analysis: Implementation of machine learning algorithms to improve the accuracy and efficiency of coil whine detection. These systems can be trained on large datasets of coil whine samples to recognize patterns and predict potential issues. The use of AI can help in distinguishing coil whine from other electronic noises and environmental sounds.

- Preventive maintenance using coil whine data: Utilization of coil whine detection data for predictive maintenance of electronic systems. By monitoring changes in coil whine characteristics over time, these systems can predict potential failures or degradation of components before they occur, allowing for proactive maintenance and reducing downtime.

- Integration with IoT and smart systems: Incorporation of coil whine detection capabilities into Internet of Things (IoT) devices and smart systems. This integration allows for real-time monitoring and reporting of coil whine issues across networks of devices, enabling centralized management and analysis of electronic component health in various applications.

- Quality control in manufacturing: Application of coil whine detection systems in manufacturing processes for quality control. These systems can be used to test and validate electronic components and assemblies during production, ensuring that products meet specified noise standards before they are shipped to customers.

02 Machine learning for coil whine pattern recognition

Utilization of machine learning algorithms to recognize and classify coil whine patterns. These systems can be trained on large datasets of coil whine samples to improve detection accuracy and automate the diagnosis process. The AI-driven approach enables real-time monitoring and predictive maintenance of electronic devices prone to coil whine issues.Expand Specific Solutions03 Integration of coil whine detection in quality control systems

Incorporation of coil whine detection capabilities into manufacturing and quality control processes. This integration allows for early identification of potential coil whine issues during production, enabling manufacturers to address problems before products reach consumers. The system can be used for both in-line testing and final product inspection.Expand Specific Solutions04 Remote monitoring and diagnostics for coil whine

Development of remote monitoring systems that can detect and analyze coil whine in deployed electronic devices. These systems use network connectivity to transmit acoustic data to centralized analysis platforms, allowing for continuous monitoring and early warning of developing issues. This approach enables proactive maintenance and reduces downtime for critical electronic systems.Expand Specific Solutions05 Coil whine suppression and mitigation techniques

Methods and systems for actively suppressing or mitigating coil whine in electronic devices. These techniques may include adaptive noise cancellation, resonance frequency shifting, or dynamic power management to reduce the occurrence or intensity of coil whine. The systems can be integrated into device firmware or hardware to provide real-time whine reduction.Expand Specific Solutions

Key Players in Coil Whine Detection Industry

The coil whine detection systems market is in an early growth stage, characterized by increasing demand for noise reduction in electronic devices. The market size is expanding as more industries recognize the importance of addressing coil whine issues. Technologically, the field is evolving rapidly, with companies like Halliburton Energy Services, Yamaha Corp., and Mitsubishi Electric Corp. leading innovation. These firms are developing advanced detection and mitigation techniques, leveraging their expertise in acoustics and electronics. The technology's maturity varies, with some basic detection methods well-established, while more sophisticated solutions are still emerging. Companies like Carrier Corp. and Snap-On, Inc. are also contributing to the field, potentially applying their industrial expertise to enhance detection systems' reliability and efficiency.

Chinese Academy of Sciences Institute of Acoustics

Technical Solution: The Chinese Academy of Sciences Institute of Acoustics has developed advanced coil whine detection systems utilizing machine learning algorithms and high-precision acoustic sensors. Their approach combines spectral analysis with deep neural networks to accurately identify and classify coil whine frequencies in various electronic devices. The system employs a multi-channel microphone array for spatial localization of noise sources, enabling precise identification of problematic components[1]. Additionally, they have implemented adaptive noise cancellation techniques to isolate coil whine from ambient noise, significantly improving detection accuracy in real-world environments[3].

Strengths: Cutting-edge AI integration, high precision spatial localization, and adaptive noise cancellation. Weaknesses: Potentially high computational requirements and complexity in implementation for smaller devices.

DENSO Corp.

Technical Solution: DENSO Corp. has developed a comprehensive coil whine detection system specifically tailored for automotive applications. Their approach integrates advanced signal processing techniques with specialized hardware designed to withstand harsh vehicle environments. The system utilizes a network of strategically placed microphones throughout the vehicle, combined with accelerometers to detect structural vibrations[2]. DENSO's proprietary algorithms analyze both acoustic and vibration data in real-time, allowing for early detection of coil whine issues in various automotive components, including electric motors, power inverters, and charging systems[4]. The system also incorporates machine learning capabilities to adapt to different vehicle models and improve detection accuracy over time.

Strengths: Automotive-specific design, real-time analysis capabilities, and integration of both acoustic and vibration data. Weaknesses: Potentially limited applicability outside automotive sector, and may require significant customization for different vehicle types.

Core Innovations in Coil Whine Detection Systems

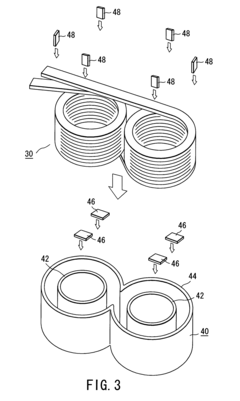

Coil component and fabrication method of the same

PatentInactiveUS7427909B2

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin, embedded within a magnetic core composed of a mixture of resin and magnetic powder, which provides enhanced structural integrity and noise suppression.

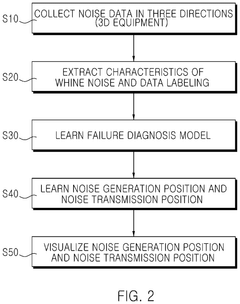

AI-based noise generation diagnosis apparatus and method of PE components for electric vehicle

PatentActiveUS12112591B2

Innovation

- An AI-based noise generation diagnosis apparatus and method using a plurality of microphones to collect noise data from multiple directions, extract feature vectors, and learn noise generation and transmission positions, combined with visualization using cameras to identify abnormal states and failure positions in PE components like motors and inverters within electric vehicles.

Acoustic Testing Standards and Regulations

Acoustic testing standards and regulations play a crucial role in establishing competency in coil whine detection systems. These standards provide a framework for consistent and reliable measurement of acoustic emissions, ensuring that coil whine detection methods are accurate, repeatable, and comparable across different testing environments.

The International Organization for Standardization (ISO) has developed several standards relevant to acoustic testing, including ISO 3744 and ISO 3745. These standards outline procedures for determining sound power levels and sound energy levels of noise sources using sound pressure. They provide guidance on measurement techniques, environmental conditions, and data analysis methods, which are essential for accurate coil whine detection.

In the context of electronic devices, the ECMA-74 standard is particularly relevant. This standard, developed by the European Computer Manufacturers Association, specifies methods for measuring and reporting noise emissions from information technology and telecommunications equipment. It includes procedures for measuring sound power levels and declaring noise emission values, which can be adapted for coil whine detection in various electronic components.

The International Electrotechnical Commission (IEC) has also contributed to acoustic testing standards with IEC 60704-2-13, which specifically addresses noise emitted by household and similar electrical appliances. While not directly focused on coil whine, this standard provides valuable insights into measurement techniques for low-level noise emissions that can be applied to coil whine detection systems.

Regulatory bodies in different regions have adopted these international standards and developed their own requirements. For instance, the European Union's Eco-design Directive (2009/125/EC) sets noise emission limits for various product categories, indirectly influencing the need for accurate coil whine detection. In the United States, the Occupational Safety and Health Administration (OSHA) has established noise exposure limits in workplace environments, which can impact the design and implementation of coil whine detection systems in industrial settings.

To establish competency in coil whine detection systems, it is essential to adhere to these standards and regulations. This involves calibrating measurement equipment according to specified procedures, conducting tests in controlled acoustic environments, and analyzing data using standardized methods. Additionally, staying informed about updates to these standards and emerging regulations is crucial for maintaining competency in this field.

Implementing these standards and regulations in coil whine detection systems ensures that the results are reliable and comparable across different testing facilities. This standardization facilitates effective communication between manufacturers, testing laboratories, and end-users, ultimately contributing to the improvement of product quality and the reduction of unwanted acoustic emissions in electronic devices.

The International Organization for Standardization (ISO) has developed several standards relevant to acoustic testing, including ISO 3744 and ISO 3745. These standards outline procedures for determining sound power levels and sound energy levels of noise sources using sound pressure. They provide guidance on measurement techniques, environmental conditions, and data analysis methods, which are essential for accurate coil whine detection.

In the context of electronic devices, the ECMA-74 standard is particularly relevant. This standard, developed by the European Computer Manufacturers Association, specifies methods for measuring and reporting noise emissions from information technology and telecommunications equipment. It includes procedures for measuring sound power levels and declaring noise emission values, which can be adapted for coil whine detection in various electronic components.

The International Electrotechnical Commission (IEC) has also contributed to acoustic testing standards with IEC 60704-2-13, which specifically addresses noise emitted by household and similar electrical appliances. While not directly focused on coil whine, this standard provides valuable insights into measurement techniques for low-level noise emissions that can be applied to coil whine detection systems.

Regulatory bodies in different regions have adopted these international standards and developed their own requirements. For instance, the European Union's Eco-design Directive (2009/125/EC) sets noise emission limits for various product categories, indirectly influencing the need for accurate coil whine detection. In the United States, the Occupational Safety and Health Administration (OSHA) has established noise exposure limits in workplace environments, which can impact the design and implementation of coil whine detection systems in industrial settings.

To establish competency in coil whine detection systems, it is essential to adhere to these standards and regulations. This involves calibrating measurement equipment according to specified procedures, conducting tests in controlled acoustic environments, and analyzing data using standardized methods. Additionally, staying informed about updates to these standards and emerging regulations is crucial for maintaining competency in this field.

Implementing these standards and regulations in coil whine detection systems ensures that the results are reliable and comparable across different testing facilities. This standardization facilitates effective communication between manufacturers, testing laboratories, and end-users, ultimately contributing to the improvement of product quality and the reduction of unwanted acoustic emissions in electronic devices.

Cost-Benefit Analysis of Coil Whine Detection Implementation

Implementing coil whine detection systems in electronic devices requires careful consideration of the associated costs and benefits. The initial investment in developing and integrating these systems can be substantial, encompassing research and development expenses, specialized equipment procurement, and potential redesigns of existing product lines. However, the long-term benefits often outweigh these upfront costs.

One of the primary advantages of coil whine detection is the significant improvement in product quality and user experience. By identifying and mitigating coil whine issues early in the production process, manufacturers can reduce the number of defective units reaching consumers, thereby decreasing return rates and warranty claims. This not only leads to cost savings but also enhances brand reputation and customer satisfaction.

The implementation of coil whine detection systems can also lead to increased production efficiency. Automated detection methods can quickly identify problematic components or assemblies, allowing for immediate corrective action. This reduces the time and labor required for manual quality control processes and minimizes production line disruptions.

From a competitive standpoint, investing in coil whine detection capabilities can provide a significant market advantage. As consumers become more aware of and sensitive to electronic noise issues, products with superior acoustic performance are likely to command higher prices and market share. This can potentially offset the initial implementation costs and contribute to long-term revenue growth.

However, it's important to consider the ongoing operational costs associated with coil whine detection systems. These may include maintenance of specialized equipment, training of personnel, and potential increases in production time. Additionally, the complexity added to the manufacturing process may initially lead to slower production rates, which should be factored into the cost-benefit analysis.

In terms of regulatory compliance, implementing robust coil whine detection can help manufacturers meet increasingly stringent noise emission standards. This proactive approach can prevent costly product recalls and legal issues, further justifying the investment in detection systems.

Ultimately, the cost-benefit analysis of coil whine detection implementation should consider both quantitative factors, such as reduced defect rates and warranty costs, and qualitative aspects like improved brand perception and customer loyalty. Companies must weigh these benefits against the initial and ongoing costs to determine the most appropriate level of investment in coil whine detection technology for their specific product lines and market positioning.

One of the primary advantages of coil whine detection is the significant improvement in product quality and user experience. By identifying and mitigating coil whine issues early in the production process, manufacturers can reduce the number of defective units reaching consumers, thereby decreasing return rates and warranty claims. This not only leads to cost savings but also enhances brand reputation and customer satisfaction.

The implementation of coil whine detection systems can also lead to increased production efficiency. Automated detection methods can quickly identify problematic components or assemblies, allowing for immediate corrective action. This reduces the time and labor required for manual quality control processes and minimizes production line disruptions.

From a competitive standpoint, investing in coil whine detection capabilities can provide a significant market advantage. As consumers become more aware of and sensitive to electronic noise issues, products with superior acoustic performance are likely to command higher prices and market share. This can potentially offset the initial implementation costs and contribute to long-term revenue growth.

However, it's important to consider the ongoing operational costs associated with coil whine detection systems. These may include maintenance of specialized equipment, training of personnel, and potential increases in production time. Additionally, the complexity added to the manufacturing process may initially lead to slower production rates, which should be factored into the cost-benefit analysis.

In terms of regulatory compliance, implementing robust coil whine detection can help manufacturers meet increasingly stringent noise emission standards. This proactive approach can prevent costly product recalls and legal issues, further justifying the investment in detection systems.

Ultimately, the cost-benefit analysis of coil whine detection implementation should consider both quantitative factors, such as reduced defect rates and warranty costs, and qualitative aspects like improved brand perception and customer loyalty. Companies must weigh these benefits against the initial and ongoing costs to determine the most appropriate level of investment in coil whine detection technology for their specific product lines and market positioning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!