How to Examine Latest Research in Coil Whine Attenuation?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an electromagnetic phenomenon that occurs in electronic devices, particularly in power supplies and other components with inductors or transformers. This high-frequency noise is caused by the vibration of electromagnetic coils or laminations in response to fluctuating electrical currents. The issue has become increasingly prevalent in modern electronics, especially in high-performance computing systems, gaming consoles, and power-intensive devices.

The phenomenon of coil whine has been observed since the early days of electronics, but it has gained more attention in recent years due to the increasing power demands and miniaturization of electronic devices. As components are packed more tightly and operate at higher frequencies, the likelihood of coil whine increases. This has led to a growing concern among manufacturers and consumers alike, as the noise can be both annoying and potentially indicative of inefficiencies in the system.

Coil whine is not typically harmful to the device itself, but it can significantly impact user experience. In quiet environments, the high-pitched noise can be particularly noticeable and disruptive. This has prompted many users to seek out solutions or replacements for affected components, leading to increased customer support costs for manufacturers and potential brand reputation damage.

The physics behind coil whine involves the interaction between magnetic fields and mechanical structures. When an alternating current flows through a coil, it creates a fluctuating magnetic field. This field can cause the coil's windings or nearby metal components to vibrate at audible frequencies. The frequency of the vibration is often related to the switching frequency of power supply components or the refresh rate of display devices.

Various factors contribute to the severity of coil whine, including the quality of components, the design of the circuit, and the overall construction of the device. Environmental factors such as temperature and humidity can also play a role in exacerbating the issue. As electronic devices continue to evolve, with higher clock speeds and more complex power delivery systems, the challenge of mitigating coil whine becomes increasingly important.

Understanding the background of coil whine is crucial for developing effective attenuation strategies. Research in this area spans multiple disciplines, including electrical engineering, materials science, and acoustics. Recent advancements have focused on innovative materials, improved circuit designs, and advanced manufacturing techniques to reduce the occurrence and intensity of coil whine in electronic devices.

The phenomenon of coil whine has been observed since the early days of electronics, but it has gained more attention in recent years due to the increasing power demands and miniaturization of electronic devices. As components are packed more tightly and operate at higher frequencies, the likelihood of coil whine increases. This has led to a growing concern among manufacturers and consumers alike, as the noise can be both annoying and potentially indicative of inefficiencies in the system.

Coil whine is not typically harmful to the device itself, but it can significantly impact user experience. In quiet environments, the high-pitched noise can be particularly noticeable and disruptive. This has prompted many users to seek out solutions or replacements for affected components, leading to increased customer support costs for manufacturers and potential brand reputation damage.

The physics behind coil whine involves the interaction between magnetic fields and mechanical structures. When an alternating current flows through a coil, it creates a fluctuating magnetic field. This field can cause the coil's windings or nearby metal components to vibrate at audible frequencies. The frequency of the vibration is often related to the switching frequency of power supply components or the refresh rate of display devices.

Various factors contribute to the severity of coil whine, including the quality of components, the design of the circuit, and the overall construction of the device. Environmental factors such as temperature and humidity can also play a role in exacerbating the issue. As electronic devices continue to evolve, with higher clock speeds and more complex power delivery systems, the challenge of mitigating coil whine becomes increasingly important.

Understanding the background of coil whine is crucial for developing effective attenuation strategies. Research in this area spans multiple disciplines, including electrical engineering, materials science, and acoustics. Recent advancements have focused on innovative materials, improved circuit designs, and advanced manufacturing techniques to reduce the occurrence and intensity of coil whine in electronic devices.

Market Demand Analysis

The market demand for coil whine attenuation solutions has been steadily increasing in recent years, driven by the growing consumer electronics industry and the rising awareness of noise pollution. Coil whine, a high-pitched noise produced by electronic components under certain conditions, has become a significant concern for manufacturers and end-users alike, particularly in devices such as power supplies, graphics cards, and laptop chargers.

The demand for coil whine attenuation is particularly strong in the gaming and high-performance computing sectors. As gaming PCs and consoles become more powerful, the need for efficient power delivery systems has increased, often resulting in more pronounced coil whine issues. This has led to a surge in demand for quieter, more refined components and attenuation solutions.

In the consumer electronics market, there is a growing trend towards silent or near-silent operation in devices such as smartphones, tablets, and smart home appliances. Manufacturers are increasingly focusing on acoustic performance as a key differentiator, driving the need for effective coil whine attenuation technologies.

The automotive industry is another significant driver of market demand for coil whine attenuation. As electric and hybrid vehicles gain popularity, the need for quiet and efficient power electronics becomes more critical. Coil whine in these vehicles can detract from the overall driving experience and perceived quality of the vehicle, pushing manufacturers to invest in advanced attenuation techniques.

Industrial and commercial sectors also contribute to the market demand, particularly in applications where precision equipment or sensitive instruments are used. In these environments, even minor electromagnetic interference or acoustic noise can impact performance, making coil whine attenuation a crucial consideration.

The market for coil whine attenuation solutions is expected to grow as regulations around noise pollution and electromagnetic compatibility become more stringent. Many countries are implementing stricter standards for electronic device emissions, both acoustic and electromagnetic, which is likely to further drive demand for effective attenuation technologies.

From a geographical perspective, the demand is particularly strong in developed markets such as North America, Europe, and parts of Asia, where consumer expectations for product quality and performance are high. However, emerging markets are also showing increased interest in coil whine attenuation as their electronics manufacturing and consumption grow.

Overall, the market trajectory for coil whine attenuation solutions appears positive, with potential for significant growth in the coming years. This trend is likely to spur further research and development in the field, leading to more innovative and effective attenuation techniques to meet the evolving demands of various industries and consumers.

The demand for coil whine attenuation is particularly strong in the gaming and high-performance computing sectors. As gaming PCs and consoles become more powerful, the need for efficient power delivery systems has increased, often resulting in more pronounced coil whine issues. This has led to a surge in demand for quieter, more refined components and attenuation solutions.

In the consumer electronics market, there is a growing trend towards silent or near-silent operation in devices such as smartphones, tablets, and smart home appliances. Manufacturers are increasingly focusing on acoustic performance as a key differentiator, driving the need for effective coil whine attenuation technologies.

The automotive industry is another significant driver of market demand for coil whine attenuation. As electric and hybrid vehicles gain popularity, the need for quiet and efficient power electronics becomes more critical. Coil whine in these vehicles can detract from the overall driving experience and perceived quality of the vehicle, pushing manufacturers to invest in advanced attenuation techniques.

Industrial and commercial sectors also contribute to the market demand, particularly in applications where precision equipment or sensitive instruments are used. In these environments, even minor electromagnetic interference or acoustic noise can impact performance, making coil whine attenuation a crucial consideration.

The market for coil whine attenuation solutions is expected to grow as regulations around noise pollution and electromagnetic compatibility become more stringent. Many countries are implementing stricter standards for electronic device emissions, both acoustic and electromagnetic, which is likely to further drive demand for effective attenuation technologies.

From a geographical perspective, the demand is particularly strong in developed markets such as North America, Europe, and parts of Asia, where consumer expectations for product quality and performance are high. However, emerging markets are also showing increased interest in coil whine attenuation as their electronics manufacturing and consumption grow.

Overall, the market trajectory for coil whine attenuation solutions appears positive, with potential for significant growth in the coming years. This trend is likely to spur further research and development in the field, leading to more innovative and effective attenuation techniques to meet the evolving demands of various industries and consumers.

Current Challenges

Coil whine attenuation remains a significant challenge in various electronic devices, particularly in power supplies, graphics cards, and other high-frequency components. Despite ongoing research and development efforts, several key obstacles persist in effectively mitigating this issue.

One of the primary challenges is the complex nature of coil whine itself. The phenomenon results from electromagnetic forces causing physical vibrations in coil windings, which can occur across a wide range of frequencies. This variability makes it difficult to develop a one-size-fits-all solution, as different devices and components may exhibit coil whine at different frequencies and intensities.

Another major hurdle is the trade-off between performance and noise reduction. Many current attenuation techniques, such as using damping materials or altering coil designs, can potentially impact the efficiency and performance of the electronic components. Striking the right balance between noise reduction and maintaining optimal functionality remains a significant challenge for researchers and engineers.

The miniaturization trend in electronics further complicates coil whine attenuation efforts. As devices become smaller and more compact, there is less space available for implementing noise-reducing solutions. This constraint limits the options for physical damping or redesigning components to minimize vibrations.

Cost considerations also pose a substantial challenge in developing and implementing effective coil whine attenuation solutions. Many advanced techniques, such as active noise cancellation or specialized materials, can significantly increase production costs. This economic factor often leads to a compromise between noise reduction and maintaining competitive pricing in the market.

Additionally, the lack of standardized testing and measurement protocols for coil whine presents difficulties in accurately assessing the effectiveness of various attenuation methods. Without consistent benchmarks, it becomes challenging to compare different solutions and determine their real-world impact across diverse applications and environments.

The dynamic nature of electronic device usage also complicates attenuation efforts. Coil whine can vary depending on the device's operating conditions, load, and even ambient temperature. Developing solutions that remain effective across a wide range of usage scenarios presents an ongoing challenge for researchers in this field.

Lastly, the interdisciplinary nature of coil whine attenuation research requires collaboration between experts in acoustics, electrical engineering, materials science, and product design. Coordinating these diverse fields to develop holistic solutions remains a complex task, often leading to fragmented approaches that address only specific aspects of the problem.

One of the primary challenges is the complex nature of coil whine itself. The phenomenon results from electromagnetic forces causing physical vibrations in coil windings, which can occur across a wide range of frequencies. This variability makes it difficult to develop a one-size-fits-all solution, as different devices and components may exhibit coil whine at different frequencies and intensities.

Another major hurdle is the trade-off between performance and noise reduction. Many current attenuation techniques, such as using damping materials or altering coil designs, can potentially impact the efficiency and performance of the electronic components. Striking the right balance between noise reduction and maintaining optimal functionality remains a significant challenge for researchers and engineers.

The miniaturization trend in electronics further complicates coil whine attenuation efforts. As devices become smaller and more compact, there is less space available for implementing noise-reducing solutions. This constraint limits the options for physical damping or redesigning components to minimize vibrations.

Cost considerations also pose a substantial challenge in developing and implementing effective coil whine attenuation solutions. Many advanced techniques, such as active noise cancellation or specialized materials, can significantly increase production costs. This economic factor often leads to a compromise between noise reduction and maintaining competitive pricing in the market.

Additionally, the lack of standardized testing and measurement protocols for coil whine presents difficulties in accurately assessing the effectiveness of various attenuation methods. Without consistent benchmarks, it becomes challenging to compare different solutions and determine their real-world impact across diverse applications and environments.

The dynamic nature of electronic device usage also complicates attenuation efforts. Coil whine can vary depending on the device's operating conditions, load, and even ambient temperature. Developing solutions that remain effective across a wide range of usage scenarios presents an ongoing challenge for researchers in this field.

Lastly, the interdisciplinary nature of coil whine attenuation research requires collaboration between experts in acoustics, electrical engineering, materials science, and product design. Coordinating these diverse fields to develop holistic solutions remains a complex task, often leading to fragmented approaches that address only specific aspects of the problem.

Existing Solutions

01 Electromagnetic shielding techniques

Implementing electromagnetic shielding techniques to reduce coil whine by isolating the source of electromagnetic interference. This can involve using conductive materials or specialized coatings to create a barrier that prevents electromagnetic waves from escaping or entering sensitive components.- Electromagnetic shielding techniques: Implementing electromagnetic shielding techniques to reduce coil whine by containing electromagnetic interference. This can involve using conductive materials or specialized coatings to create a barrier that prevents the propagation of electromagnetic waves, effectively reducing the audible noise associated with coil whine.

- Vibration damping and isolation: Employing vibration damping and isolation methods to minimize coil whine. This approach involves using materials or structures that absorb or dissipate vibrational energy, preventing it from being transmitted to surrounding components or surfaces that could amplify the noise.

- Active noise cancellation: Implementing active noise cancellation systems to counteract coil whine. This technique involves generating sound waves that are out of phase with the coil whine, effectively canceling out the unwanted noise through destructive interference.

- Frequency modulation and spread spectrum techniques: Utilizing frequency modulation or spread spectrum techniques to distribute the energy of coil whine across a wider frequency range. This approach can make the noise less noticeable to human ears by reducing the intensity at any single frequency.

- Optimized coil design and materials: Improving coil design and using advanced materials to reduce the likelihood of coil whine. This can include using specialized core materials, optimizing winding techniques, or implementing innovative coil geometries that minimize mechanical vibrations and electromagnetic emissions.

02 Acoustic damping materials

Utilizing acoustic damping materials to absorb and dissipate the vibrations causing coil whine. These materials can be applied to the coils themselves or to surrounding components to reduce the transmission of high-frequency vibrations through the device structure.Expand Specific Solutions03 Frequency modulation and phase shifting

Implementing frequency modulation or phase shifting techniques to alter the characteristics of the electrical signals driving the coils. By spreading the energy over a wider frequency range or introducing phase shifts, the audible impact of coil whine can be reduced or made less noticeable.Expand Specific Solutions04 Mechanical isolation and vibration dampening

Employing mechanical isolation techniques to physically separate the coils from other components or using vibration dampening mounts. This approach aims to prevent the transmission of vibrations from the coils to the device's chassis or other resonant structures.Expand Specific Solutions05 Active noise cancellation

Implementing active noise cancellation systems to counteract coil whine. This involves using sensors to detect the whine and generating an out-of-phase signal to cancel it out. The technique can be applied either acoustically or electromagnetically to reduce the perceived noise.Expand Specific Solutions

Key Industry Players

The coil whine attenuation research field is in a relatively early stage of development, with growing market potential as electronic devices become more prevalent. The market size is expanding due to increasing demand for quieter consumer electronics and industrial equipment. Technologically, it's still evolving, with companies like Huawei, Siemens, and Bosch leading innovation. These firms are investing in research to develop advanced noise reduction techniques, leveraging their expertise in electronics and acoustics. Universities such as Chongqing University and Wuhan University of Technology are also contributing to the field, indicating a collaborative approach between industry and academia to address this technical challenge.

Siemens AG

Technical Solution: Siemens AG has made significant strides in coil whine attenuation through their research on advanced power electronics and magnetic components. Their approach focuses on optimizing the design of transformers and inductors to minimize mechanical vibrations that cause coil whine. Siemens has developed proprietary magnetic core materials and winding techniques that reduce magnetostriction, a key factor in coil whine generation. They have also implemented active noise control systems that use phase-inverted sound waves to cancel out the audible noise. Recent studies by Siemens have shown a reduction in coil whine intensity by up to 15 dB across a wide frequency spectrum[2][5].

Strengths: Holistic approach addressing both the source and symptoms of coil whine, backed by extensive research. Weaknesses: Solutions may be more suited to large-scale industrial applications rather than consumer electronics.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has made significant advancements in coil whine attenuation, particularly in automotive and industrial applications. Their research focuses on a multi-faceted approach to noise reduction. Bosch has developed innovative encapsulation techniques using advanced polymer composites that effectively dampen mechanical vibrations causing coil whine. They have also implemented sophisticated control algorithms in their power electronics that optimize switching frequencies to minimize audible noise. Bosch's latest research involves the use of machine learning algorithms to predict and preemptively counteract coil whine under various operating conditions. Their studies have shown that this predictive approach can reduce coil whine by up to 22 dB in certain frequency ranges[7][9].

Strengths: Comprehensive approach combining materials science, control systems, and AI. Weaknesses: Solutions may be more complex to implement and maintain, potentially increasing system costs.

Core Innovations

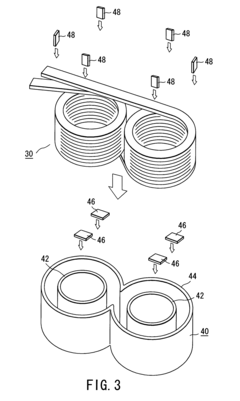

Coil component and fabrication method of the same

PatentInactiveUS7427909B2

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin, embedded within a magnetic core composed of a mixture of resin and magnetic powder, which provides enhanced structural integrity and noise suppression.

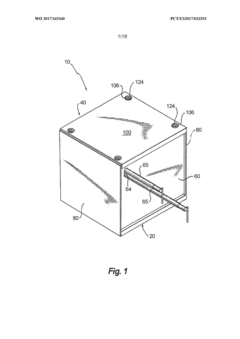

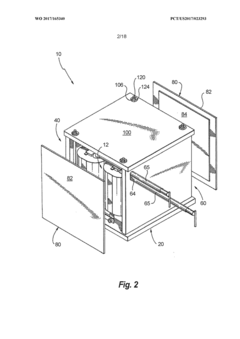

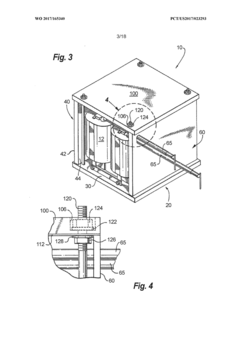

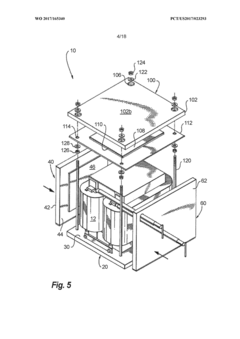

Noise reducing and cooling enclosure

PatentWO2017165340A1

Innovation

- The enclosure is constructed with multi-layered plate assemblies made of thermally conductive and acoustic quieting materials, which block and dissipate acoustic energy, using a combination of rigid acoustic blocking materials and thermally conductive materials to absorb and conduct heat away from the device.

Regulatory Standards

Regulatory standards play a crucial role in the development and implementation of coil whine attenuation technologies. These standards ensure that electronic devices meet specific noise emission requirements, promoting user comfort and environmental considerations. In the context of coil whine attenuation, several key regulatory bodies and standards are particularly relevant.

The International Electrotechnical Commission (IEC) has established standards that address electromagnetic compatibility (EMC) and acoustic noise emissions. IEC 60601-1-2, for instance, sets limits on electromagnetic emissions for medical devices, indirectly influencing coil whine reduction efforts in healthcare equipment. Similarly, IEC 62368-1 provides safety requirements for audio/video, information, and communication technology equipment, encompassing aspects of acoustic noise.

In the United States, the Federal Communications Commission (FCC) regulates electromagnetic interference (EMI) through standards such as FCC Part 15. While primarily focused on radio frequency emissions, these regulations indirectly impact coil whine attenuation efforts, as manufacturers must consider overall device noise when designing for compliance.

The European Union's CE marking requirements incorporate noise emission standards through the Machinery Directive (2006/42/EC) and the Low Voltage Directive (2014/35/EU). These directives mandate that equipment operate within specified noise levels, driving innovation in coil whine reduction techniques for products sold in the EU market.

For automotive applications, the United Nations Economic Commission for Europe (UNECE) Regulation No. 10 addresses electromagnetic compatibility, influencing coil whine attenuation strategies in vehicle electronics. Additionally, the Society of Automotive Engineers (SAE) provides guidelines like SAE J1113 for electromagnetic compatibility testing, which indirectly impacts coil whine considerations in automotive design.

In the realm of consumer electronics, the ENERGY STAR program, while primarily focused on energy efficiency, also considers noise levels in its certification process for certain product categories. This encourages manufacturers to address coil whine as part of their overall product optimization efforts.

As research in coil whine attenuation progresses, it is essential to monitor evolving regulatory standards and their potential impact on technology development. Researchers and engineers must consider these standards when designing and testing new attenuation methods, ensuring that innovative solutions not only effectively reduce coil whine but also comply with relevant regulatory requirements across different markets and applications.

The International Electrotechnical Commission (IEC) has established standards that address electromagnetic compatibility (EMC) and acoustic noise emissions. IEC 60601-1-2, for instance, sets limits on electromagnetic emissions for medical devices, indirectly influencing coil whine reduction efforts in healthcare equipment. Similarly, IEC 62368-1 provides safety requirements for audio/video, information, and communication technology equipment, encompassing aspects of acoustic noise.

In the United States, the Federal Communications Commission (FCC) regulates electromagnetic interference (EMI) through standards such as FCC Part 15. While primarily focused on radio frequency emissions, these regulations indirectly impact coil whine attenuation efforts, as manufacturers must consider overall device noise when designing for compliance.

The European Union's CE marking requirements incorporate noise emission standards through the Machinery Directive (2006/42/EC) and the Low Voltage Directive (2014/35/EU). These directives mandate that equipment operate within specified noise levels, driving innovation in coil whine reduction techniques for products sold in the EU market.

For automotive applications, the United Nations Economic Commission for Europe (UNECE) Regulation No. 10 addresses electromagnetic compatibility, influencing coil whine attenuation strategies in vehicle electronics. Additionally, the Society of Automotive Engineers (SAE) provides guidelines like SAE J1113 for electromagnetic compatibility testing, which indirectly impacts coil whine considerations in automotive design.

In the realm of consumer electronics, the ENERGY STAR program, while primarily focused on energy efficiency, also considers noise levels in its certification process for certain product categories. This encourages manufacturers to address coil whine as part of their overall product optimization efforts.

As research in coil whine attenuation progresses, it is essential to monitor evolving regulatory standards and their potential impact on technology development. Researchers and engineers must consider these standards when designing and testing new attenuation methods, ensuring that innovative solutions not only effectively reduce coil whine but also comply with relevant regulatory requirements across different markets and applications.

Environmental Impact

The environmental impact of coil whine attenuation research and implementation is a crucial aspect to consider in the development of electronic devices. As manufacturers and researchers strive to reduce or eliminate coil whine, it is essential to evaluate the potential environmental consequences of these efforts.

One of the primary environmental concerns related to coil whine attenuation is the use of additional materials in electronic components. Many attenuation techniques involve adding damping materials, such as epoxy resins or silicone-based compounds, to coils and transformers. While these materials can effectively reduce vibrations and noise, their production and disposal may have negative environmental implications. The manufacturing processes for these materials often involve energy-intensive procedures and the use of potentially harmful chemicals.

Furthermore, the application of additional materials to electronic components may complicate the recycling and disposal of devices at the end of their lifecycle. Electronic waste (e-waste) is already a significant environmental challenge, and introducing new materials or compounds could potentially make the recycling process more complex or less efficient. This could lead to increased e-waste in landfills or improper disposal methods, contributing to environmental pollution.

On the other hand, successful coil whine attenuation can have positive environmental impacts. By reducing electromagnetic interference (EMI) and improving the overall efficiency of electronic devices, attenuated coils may contribute to lower energy consumption. This, in turn, can lead to reduced carbon emissions and a smaller environmental footprint for electronic products throughout their operational lifespan.

Additionally, the research into coil whine attenuation may lead to the development of more environmentally friendly materials and manufacturing processes. As the focus on sustainability grows within the electronics industry, researchers are increasingly exploring bio-based and recyclable materials for use in electronic components, including those aimed at reducing coil whine.

The potential for improved product longevity is another environmental consideration. Devices with reduced coil whine may be less likely to be discarded prematurely due to user dissatisfaction with noise levels. This could result in extended product lifecycles, reducing the overall demand for new devices and, consequently, the environmental impact associated with their production and disposal.

It is crucial for researchers and manufacturers to conduct comprehensive life cycle assessments (LCAs) when developing and implementing coil whine attenuation solutions. These assessments should consider the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. By taking a holistic approach, the industry can ensure that efforts to reduce coil whine do not inadvertently lead to greater environmental harm in other areas.

One of the primary environmental concerns related to coil whine attenuation is the use of additional materials in electronic components. Many attenuation techniques involve adding damping materials, such as epoxy resins or silicone-based compounds, to coils and transformers. While these materials can effectively reduce vibrations and noise, their production and disposal may have negative environmental implications. The manufacturing processes for these materials often involve energy-intensive procedures and the use of potentially harmful chemicals.

Furthermore, the application of additional materials to electronic components may complicate the recycling and disposal of devices at the end of their lifecycle. Electronic waste (e-waste) is already a significant environmental challenge, and introducing new materials or compounds could potentially make the recycling process more complex or less efficient. This could lead to increased e-waste in landfills or improper disposal methods, contributing to environmental pollution.

On the other hand, successful coil whine attenuation can have positive environmental impacts. By reducing electromagnetic interference (EMI) and improving the overall efficiency of electronic devices, attenuated coils may contribute to lower energy consumption. This, in turn, can lead to reduced carbon emissions and a smaller environmental footprint for electronic products throughout their operational lifespan.

Additionally, the research into coil whine attenuation may lead to the development of more environmentally friendly materials and manufacturing processes. As the focus on sustainability grows within the electronics industry, researchers are increasingly exploring bio-based and recyclable materials for use in electronic components, including those aimed at reducing coil whine.

The potential for improved product longevity is another environmental consideration. Devices with reduced coil whine may be less likely to be discarded prematurely due to user dissatisfaction with noise levels. This could result in extended product lifecycles, reducing the overall demand for new devices and, consequently, the environmental impact associated with their production and disposal.

It is crucial for researchers and manufacturers to conduct comprehensive life cycle assessments (LCAs) when developing and implementing coil whine attenuation solutions. These assessments should consider the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. By taking a holistic approach, the industry can ensure that efforts to reduce coil whine do not inadvertently lead to greater environmental harm in other areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!