Coil Whine Reduction: Comparing Various Approaches

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an audible noise produced by electronic components, particularly inductors and transformers, when subjected to rapidly changing electrical currents. This phenomenon has become increasingly prevalent in modern electronic devices, especially in high-performance computing systems, power supplies, and consumer electronics. The issue gained prominence in the late 1990s and early 2000s as electronic devices became more compact and powerful, leading to higher switching frequencies and increased power densities.

The primary cause of coil whine is the magnetostriction effect, where magnetic materials change shape under the influence of a magnetic field. As electrical currents fluctuate rapidly through coils, the resulting magnetic field variations cause minute physical deformations in the coil's core material. These deformations occur at frequencies within the audible range, typically between 20 Hz and 20 kHz, producing the characteristic high-pitched whine or buzzing sound.

Coil whine has become a significant concern for manufacturers and consumers alike due to its impact on user experience and product quality perception. In quiet environments, even low-level coil whine can be noticeable and irritating to users. This issue is particularly problematic in devices designed for silent operation, such as high-end computers, gaming consoles, and audio equipment.

The severity of coil whine can vary greatly depending on factors such as component quality, circuit design, power supply characteristics, and operating conditions. It is often more pronounced under specific load conditions or during certain operations, making it challenging to identify and mitigate consistently. Furthermore, the subjective nature of sound perception adds complexity to addressing coil whine, as tolerance levels can vary significantly among individuals.

As electronic devices continue to evolve with higher performance requirements and more compact designs, the challenge of managing coil whine has become increasingly important. This has led to a growing focus on developing innovative solutions to reduce or eliminate coil whine across various industries. Manufacturers and researchers are exploring multiple approaches, including advanced materials science, improved circuit design techniques, and novel manufacturing processes to address this persistent issue.

The primary cause of coil whine is the magnetostriction effect, where magnetic materials change shape under the influence of a magnetic field. As electrical currents fluctuate rapidly through coils, the resulting magnetic field variations cause minute physical deformations in the coil's core material. These deformations occur at frequencies within the audible range, typically between 20 Hz and 20 kHz, producing the characteristic high-pitched whine or buzzing sound.

Coil whine has become a significant concern for manufacturers and consumers alike due to its impact on user experience and product quality perception. In quiet environments, even low-level coil whine can be noticeable and irritating to users. This issue is particularly problematic in devices designed for silent operation, such as high-end computers, gaming consoles, and audio equipment.

The severity of coil whine can vary greatly depending on factors such as component quality, circuit design, power supply characteristics, and operating conditions. It is often more pronounced under specific load conditions or during certain operations, making it challenging to identify and mitigate consistently. Furthermore, the subjective nature of sound perception adds complexity to addressing coil whine, as tolerance levels can vary significantly among individuals.

As electronic devices continue to evolve with higher performance requirements and more compact designs, the challenge of managing coil whine has become increasingly important. This has led to a growing focus on developing innovative solutions to reduce or eliminate coil whine across various industries. Manufacturers and researchers are exploring multiple approaches, including advanced materials science, improved circuit design techniques, and novel manufacturing processes to address this persistent issue.

Market Impact Analysis

The market impact of coil whine reduction technologies is significant across various industries, particularly in consumer electronics, automotive, and industrial equipment sectors. As consumers become increasingly sensitive to noise pollution and demand quieter devices, manufacturers are under pressure to implement effective coil whine reduction solutions. This trend is driving innovation and creating new market opportunities for companies specializing in noise reduction technologies.

In the consumer electronics market, the demand for silent operation in devices such as laptops, smartphones, and gaming consoles is growing. Manufacturers who can effectively reduce or eliminate coil whine gain a competitive edge, as it directly impacts user experience and product perception. This has led to increased investment in research and development of noise reduction technologies, with some companies even marketing their products as "whisper-quiet" or "silent operation" as a key selling point.

The automotive industry is another sector significantly impacted by coil whine reduction efforts. As electric and hybrid vehicles gain market share, the absence of engine noise makes other sounds, including coil whine, more noticeable. Manufacturers are investing heavily in noise, vibration, and harshness (NVH) reduction technologies to enhance the driving experience and meet increasingly stringent noise regulations. This has created a new sub-market for specialized acoustic materials and electronic components designed specifically for automotive applications.

In the industrial equipment sector, the impact of coil whine reduction is twofold. First, it improves worker safety and comfort in manufacturing environments by reducing noise pollution. Second, it enhances the overall efficiency and lifespan of equipment by minimizing vibrations and associated wear and tear. This has led to increased demand for noise-reducing components and materials in industrial machinery, creating new opportunities for suppliers in this space.

The market for coil whine reduction solutions is also driving innovation in materials science and electronic component design. Companies are developing new magnetic materials, improved winding techniques, and advanced electronic control systems to address the root causes of coil whine. This has resulted in the emergence of specialized suppliers and consultancies focused on noise reduction technologies, contributing to job creation and economic growth in the tech sector.

Furthermore, the emphasis on coil whine reduction is influencing product design and manufacturing processes across industries. Companies are integrating noise reduction considerations earlier in the product development cycle, leading to changes in component selection, circuit board layout, and enclosure design. This holistic approach to noise reduction is creating new collaborations between acoustic engineers, electrical engineers, and industrial designers, fostering innovation and cross-disciplinary expertise.

In the consumer electronics market, the demand for silent operation in devices such as laptops, smartphones, and gaming consoles is growing. Manufacturers who can effectively reduce or eliminate coil whine gain a competitive edge, as it directly impacts user experience and product perception. This has led to increased investment in research and development of noise reduction technologies, with some companies even marketing their products as "whisper-quiet" or "silent operation" as a key selling point.

The automotive industry is another sector significantly impacted by coil whine reduction efforts. As electric and hybrid vehicles gain market share, the absence of engine noise makes other sounds, including coil whine, more noticeable. Manufacturers are investing heavily in noise, vibration, and harshness (NVH) reduction technologies to enhance the driving experience and meet increasingly stringent noise regulations. This has created a new sub-market for specialized acoustic materials and electronic components designed specifically for automotive applications.

In the industrial equipment sector, the impact of coil whine reduction is twofold. First, it improves worker safety and comfort in manufacturing environments by reducing noise pollution. Second, it enhances the overall efficiency and lifespan of equipment by minimizing vibrations and associated wear and tear. This has led to increased demand for noise-reducing components and materials in industrial machinery, creating new opportunities for suppliers in this space.

The market for coil whine reduction solutions is also driving innovation in materials science and electronic component design. Companies are developing new magnetic materials, improved winding techniques, and advanced electronic control systems to address the root causes of coil whine. This has resulted in the emergence of specialized suppliers and consultancies focused on noise reduction technologies, contributing to job creation and economic growth in the tech sector.

Furthermore, the emphasis on coil whine reduction is influencing product design and manufacturing processes across industries. Companies are integrating noise reduction considerations earlier in the product development cycle, leading to changes in component selection, circuit board layout, and enclosure design. This holistic approach to noise reduction is creating new collaborations between acoustic engineers, electrical engineers, and industrial designers, fostering innovation and cross-disciplinary expertise.

Technical Challenges

Coil whine reduction presents several significant technical challenges that researchers and engineers must address to develop effective solutions. One of the primary obstacles is the complex nature of coil whine itself, which can originate from various sources within electronic devices, making it difficult to isolate and mitigate.

The frequency range of coil whine typically falls between 1 kHz and 20 kHz, overlapping with human auditory sensitivity. This makes the issue particularly noticeable and potentially irritating to users. Developing solutions that can effectively target this specific frequency range without compromising device performance is a major technical hurdle.

Another challenge lies in the diverse range of electronic components that can contribute to coil whine. Power supplies, inductors, transformers, and capacitors are all potential culprits, each with unique characteristics that may require different mitigation strategies. This diversity complicates the development of universal solutions and necessitates a multi-faceted approach to coil whine reduction.

The miniaturization trend in electronic devices further exacerbates the coil whine problem. As components are packed more tightly together, the potential for electromagnetic interference and resonance increases, potentially amplifying coil whine effects. Engineers must find ways to address this issue while maintaining the compact form factors that consumers demand.

Temperature variations and manufacturing tolerances also pose significant challenges. Coil whine can be affected by changes in temperature, and slight variations in component specifications due to manufacturing processes can lead to inconsistent coil whine behavior across seemingly identical devices. Developing solutions that remain effective across a range of operating conditions and manufacturing variations is crucial.

Power efficiency requirements add another layer of complexity to coil whine reduction efforts. Many techniques for mitigating coil whine can potentially increase power consumption or reduce overall efficiency. Balancing the need for quiet operation with the demand for energy-efficient devices presents a significant technical challenge.

Lastly, the cost-effectiveness of coil whine reduction solutions is a major consideration. Implementing advanced materials, sophisticated damping techniques, or complex electronic filtering systems can significantly increase production costs. Developing affordable solutions that can be widely adopted across various product lines and market segments remains a key challenge in the field.

The frequency range of coil whine typically falls between 1 kHz and 20 kHz, overlapping with human auditory sensitivity. This makes the issue particularly noticeable and potentially irritating to users. Developing solutions that can effectively target this specific frequency range without compromising device performance is a major technical hurdle.

Another challenge lies in the diverse range of electronic components that can contribute to coil whine. Power supplies, inductors, transformers, and capacitors are all potential culprits, each with unique characteristics that may require different mitigation strategies. This diversity complicates the development of universal solutions and necessitates a multi-faceted approach to coil whine reduction.

The miniaturization trend in electronic devices further exacerbates the coil whine problem. As components are packed more tightly together, the potential for electromagnetic interference and resonance increases, potentially amplifying coil whine effects. Engineers must find ways to address this issue while maintaining the compact form factors that consumers demand.

Temperature variations and manufacturing tolerances also pose significant challenges. Coil whine can be affected by changes in temperature, and slight variations in component specifications due to manufacturing processes can lead to inconsistent coil whine behavior across seemingly identical devices. Developing solutions that remain effective across a range of operating conditions and manufacturing variations is crucial.

Power efficiency requirements add another layer of complexity to coil whine reduction efforts. Many techniques for mitigating coil whine can potentially increase power consumption or reduce overall efficiency. Balancing the need for quiet operation with the demand for energy-efficient devices presents a significant technical challenge.

Lastly, the cost-effectiveness of coil whine reduction solutions is a major consideration. Implementing advanced materials, sophisticated damping techniques, or complex electronic filtering systems can significantly increase production costs. Developing affordable solutions that can be widely adopted across various product lines and market segments remains a key challenge in the field.

Current Solutions

01 Electromagnetic shielding techniques

Implementing electromagnetic shielding techniques to reduce coil whine by isolating the coil from external electromagnetic interference and preventing the propagation of electromagnetic waves. This can involve using conductive materials or specialized coatings to create a barrier around the coil or sensitive components.- Electromagnetic shielding techniques: Implementing electromagnetic shielding techniques can help reduce coil whine by containing electromagnetic interference. This may involve using conductive materials or specialized coatings to encase the coil or other components, effectively blocking the transmission of electromagnetic waves that contribute to the whine.

- Vibration dampening and isolation: Employing vibration dampening and isolation methods can minimize coil whine by reducing mechanical resonance. This can include using rubber or silicone mounts, foam padding, or other shock-absorbing materials to isolate the coil from other components and prevent vibrations from propagating through the device.

- Coil design optimization: Optimizing the design of the coil itself can help reduce whine. This may involve adjusting the coil's shape, size, or winding pattern to minimize resonance and electromagnetic interference. Additionally, using high-quality materials and precision manufacturing techniques can improve coil performance and reduce unwanted noise.

- Power supply and circuit modifications: Modifying the power supply and associated circuits can help reduce coil whine. This may include implementing better voltage regulation, filtering techniques, or adjusting the frequency of power delivery to the coil. These modifications can help minimize electrical fluctuations that contribute to the whine.

- Active noise cancellation: Implementing active noise cancellation techniques can help counteract coil whine. This involves using sensors to detect the whine and generating an inverse sound wave to cancel it out. While more complex than passive methods, this approach can be highly effective in reducing perceived noise levels.

02 Vibration dampening and isolation

Employing vibration dampening and isolation methods to minimize coil whine by reducing mechanical vibrations. This can include using shock-absorbing materials, mounting systems, or enclosures designed to absorb and dissipate vibrational energy from the coil.Expand Specific Solutions03 Coil design optimization

Optimizing the design of the coil itself to reduce whine, including adjustments to coil geometry, winding techniques, and material selection. This can involve using specialized core materials, altering the coil's shape, or implementing advanced winding patterns to minimize resonance and vibration.Expand Specific Solutions04 Active noise cancellation

Implementing active noise cancellation techniques to counteract coil whine by generating opposing sound waves or vibrations. This can involve using sensors to detect the whine and producing a canceling signal through dedicated speakers or actuators.Expand Specific Solutions05 Power supply and signal conditioning

Improving power supply quality and signal conditioning to reduce coil whine by minimizing electrical noise and harmonics. This can include using high-quality power supplies, implementing filtering techniques, or employing advanced control algorithms to optimize the electrical signals driving the coil.Expand Specific Solutions

Industry Leaders

The coil whine reduction market is in a growth phase, driven by increasing demand for quieter electronic devices across various industries. The market size is expanding as manufacturers seek to improve product quality and user experience. Technologically, coil whine reduction is advancing, with companies like Murata Manufacturing, Robert Bosch, and Mitsubishi Electric leading innovation. These firms are developing sophisticated solutions, including advanced materials, improved circuit designs, and noise-canceling technologies. The competitive landscape is diverse, with both established electronics giants and specialized component manufacturers vying for market share. As consumer expectations for silent operation rise, we can expect continued investment and technological progress in this field.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced noise suppression techniques for coil whine reduction. Their approach involves the use of specialized ceramic capacitors and inductors designed to minimize electromagnetic interference (EMI) and acoustic noise. The company's multilayer ceramic capacitors (MLCCs) with low equivalent series inductance (ESL) are particularly effective in reducing high-frequency noise associated with coil whine[1]. Additionally, Murata has implemented innovative shielding solutions and optimized PCB layouts to further mitigate coil whine issues in various electronic devices[2].

Strengths: Expertise in passive components, wide range of noise suppression products, and advanced material science. Weaknesses: May require integration with other components for comprehensive solutions.

Robert Bosch GmbH

Technical Solution: Bosch has developed a multi-faceted approach to coil whine reduction, particularly in automotive applications. Their strategy includes the use of advanced power electronics with optimized switching frequencies to minimize audible noise. Bosch's engineers have implemented active noise cancellation techniques in their electronic control units (ECUs) to counteract coil whine in real-time[3]. Furthermore, they have developed specialized encapsulation materials and mechanical damping solutions to absorb vibrations and reduce the propagation of coil whine in vehicle components[4].

Strengths: Comprehensive approach combining electronics and mechanical solutions, extensive automotive expertise. Weaknesses: Solutions may be more tailored to automotive sector, potentially limiting applicability in other industries.

Key Innovations

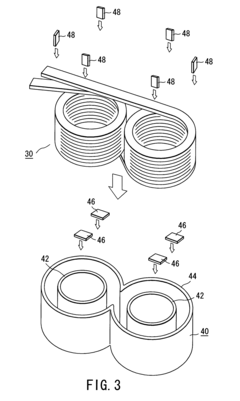

Coil component and fabrication method of the same

PatentInactiveUS7427909B2

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin, embedded within a magnetic core composed of a mixture of resin and magnetic powder, which provides enhanced structural integrity and noise suppression.

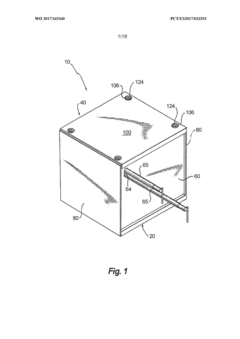

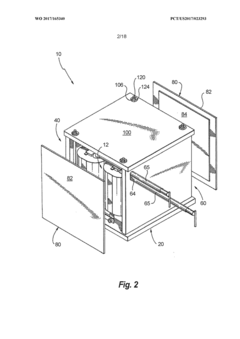

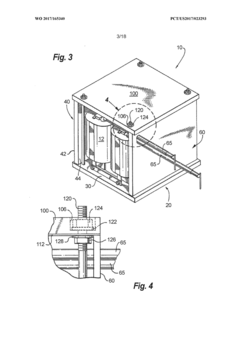

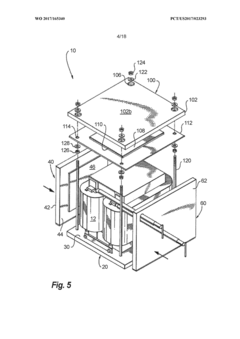

Noise reducing and cooling enclosure

PatentWO2017165340A1

Innovation

- The enclosure is constructed with multi-layered plate assemblies made of thermally conductive and acoustic quieting materials, which block and dissipate acoustic energy, using a combination of rigid acoustic blocking materials and thermally conductive materials to absorb and conduct heat away from the device.

Acoustic Standards

Acoustic standards play a crucial role in the evaluation and mitigation of coil whine in electronic devices. These standards provide a framework for measuring, assessing, and controlling noise emissions, including the high-frequency sounds associated with coil whine. The International Electrotechnical Commission (IEC) has established several relevant standards, such as IEC 60601-1-2 for medical equipment and IEC 61000-3-2 for harmonic current emissions.

One of the most widely recognized standards for acoustic noise measurement is ISO 3744, which specifies methods for determining sound power levels of noise sources using sound pressure. This standard is particularly relevant for assessing coil whine, as it provides guidelines for measuring high-frequency noise in controlled environments.

The ECMA-74 standard, developed by the European Computer Manufacturers Association, is specifically tailored for information technology and telecommunications equipment. It outlines procedures for measuring airborne noise emitted by such devices, including methods applicable to coil whine assessment.

In the United States, the American National Standards Institute (ANSI) has developed ANSI S12.10, which provides guidelines for the measurement of airborne noise emitted by computer and business equipment. This standard is often used in conjunction with ISO 3744 for comprehensive noise evaluations.

For automotive applications, the SAE J1030 standard addresses interior sound quality, including methods for identifying and quantifying various noise sources, which can be adapted for coil whine analysis in vehicle electronics.

Compliance with these acoustic standards is essential for manufacturers seeking to reduce coil whine in their products. The standards provide benchmarks for acceptable noise levels and guide the development of noise reduction techniques. They also ensure consistency in measurement methodologies across different laboratories and testing facilities.

Implementing these standards in coil whine reduction efforts involves several steps. First, engineers must establish a baseline measurement of the device's acoustic emissions using the prescribed methods. This is followed by the application of various noise reduction techniques, such as encapsulation, damping materials, or circuit redesigns. The effectiveness of these interventions is then evaluated through repeated measurements, ensuring compliance with the relevant acoustic standards.

It's important to note that while these standards provide valuable guidelines, they may not always fully address the specific challenges posed by coil whine. The high-frequency nature of coil whine and its potential to occur intermittently can sometimes fall outside the typical measurement ranges or procedures outlined in general acoustic standards. As a result, some manufacturers and researchers are developing supplementary testing protocols specifically tailored to coil whine assessment and reduction.

One of the most widely recognized standards for acoustic noise measurement is ISO 3744, which specifies methods for determining sound power levels of noise sources using sound pressure. This standard is particularly relevant for assessing coil whine, as it provides guidelines for measuring high-frequency noise in controlled environments.

The ECMA-74 standard, developed by the European Computer Manufacturers Association, is specifically tailored for information technology and telecommunications equipment. It outlines procedures for measuring airborne noise emitted by such devices, including methods applicable to coil whine assessment.

In the United States, the American National Standards Institute (ANSI) has developed ANSI S12.10, which provides guidelines for the measurement of airborne noise emitted by computer and business equipment. This standard is often used in conjunction with ISO 3744 for comprehensive noise evaluations.

For automotive applications, the SAE J1030 standard addresses interior sound quality, including methods for identifying and quantifying various noise sources, which can be adapted for coil whine analysis in vehicle electronics.

Compliance with these acoustic standards is essential for manufacturers seeking to reduce coil whine in their products. The standards provide benchmarks for acceptable noise levels and guide the development of noise reduction techniques. They also ensure consistency in measurement methodologies across different laboratories and testing facilities.

Implementing these standards in coil whine reduction efforts involves several steps. First, engineers must establish a baseline measurement of the device's acoustic emissions using the prescribed methods. This is followed by the application of various noise reduction techniques, such as encapsulation, damping materials, or circuit redesigns. The effectiveness of these interventions is then evaluated through repeated measurements, ensuring compliance with the relevant acoustic standards.

It's important to note that while these standards provide valuable guidelines, they may not always fully address the specific challenges posed by coil whine. The high-frequency nature of coil whine and its potential to occur intermittently can sometimes fall outside the typical measurement ranges or procedures outlined in general acoustic standards. As a result, some manufacturers and researchers are developing supplementary testing protocols specifically tailored to coil whine assessment and reduction.

Material Advancements

Material advancements play a crucial role in the reduction of coil whine, offering innovative solutions to mitigate this persistent issue in electronic devices. Recent developments in material science have led to significant improvements in the acoustic properties of components used in coil assemblies, transformers, and other electromagnetic devices prone to coil whine.

One of the most promising advancements is the development of advanced magnetic materials with enhanced magnetostriction properties. These materials exhibit reduced dimensional changes under magnetic fields, thereby minimizing the mechanical vibrations that contribute to coil whine. Nanocrystalline soft magnetic materials, such as FINEMET and NANOPERM, have shown remarkable potential in this regard, offering high permeability and low core losses while maintaining excellent mechanical stability.

Another area of focus has been the improvement of insulation materials used in coil windings. Novel polymer composites with enhanced damping characteristics have been engineered to absorb and dissipate vibrational energy more effectively. These materials, often incorporating nanoparticles or specialized molecular structures, can significantly reduce the transmission of mechanical vibrations from the coil to the surrounding structure.

Advancements in ceramic and composite materials have also contributed to coil whine reduction. High-performance ceramics with tailored acoustic properties are being used to create more effective isolation and damping systems for electromagnetic components. These materials offer excellent thermal stability and electrical insulation properties while providing superior vibration absorption capabilities.

The development of advanced adhesives and potting compounds has further enhanced the ability to mitigate coil whine. These materials are designed to encapsulate coils and transformers, providing both structural support and vibration damping. New formulations with improved viscoelastic properties can effectively absorb and dissipate energy across a wide frequency range, addressing the complex nature of coil whine.

Researchers are also exploring the potential of metamaterials in coil whine reduction. These engineered materials with unique structural properties can manipulate acoustic waves, potentially offering unprecedented control over sound propagation and vibration isolation. While still in the early stages of development, metamaterials hold promise for creating highly effective noise suppression solutions for electromagnetic devices.

In conclusion, material advancements are driving significant progress in coil whine reduction strategies. By combining innovative magnetic materials, advanced insulation techniques, and novel damping solutions, engineers are developing more effective approaches to mitigate this persistent issue in electronic devices. As research in material science continues to evolve, we can expect further breakthroughs that will contribute to quieter and more efficient electronic systems.

One of the most promising advancements is the development of advanced magnetic materials with enhanced magnetostriction properties. These materials exhibit reduced dimensional changes under magnetic fields, thereby minimizing the mechanical vibrations that contribute to coil whine. Nanocrystalline soft magnetic materials, such as FINEMET and NANOPERM, have shown remarkable potential in this regard, offering high permeability and low core losses while maintaining excellent mechanical stability.

Another area of focus has been the improvement of insulation materials used in coil windings. Novel polymer composites with enhanced damping characteristics have been engineered to absorb and dissipate vibrational energy more effectively. These materials, often incorporating nanoparticles or specialized molecular structures, can significantly reduce the transmission of mechanical vibrations from the coil to the surrounding structure.

Advancements in ceramic and composite materials have also contributed to coil whine reduction. High-performance ceramics with tailored acoustic properties are being used to create more effective isolation and damping systems for electromagnetic components. These materials offer excellent thermal stability and electrical insulation properties while providing superior vibration absorption capabilities.

The development of advanced adhesives and potting compounds has further enhanced the ability to mitigate coil whine. These materials are designed to encapsulate coils and transformers, providing both structural support and vibration damping. New formulations with improved viscoelastic properties can effectively absorb and dissipate energy across a wide frequency range, addressing the complex nature of coil whine.

Researchers are also exploring the potential of metamaterials in coil whine reduction. These engineered materials with unique structural properties can manipulate acoustic waves, potentially offering unprecedented control over sound propagation and vibration isolation. While still in the early stages of development, metamaterials hold promise for creating highly effective noise suppression solutions for electromagnetic devices.

In conclusion, material advancements are driving significant progress in coil whine reduction strategies. By combining innovative magnetic materials, advanced insulation techniques, and novel damping solutions, engineers are developing more effective approaches to mitigate this persistent issue in electronic devices. As research in material science continues to evolve, we can expect further breakthroughs that will contribute to quieter and more efficient electronic systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!