Coil Whine and Frequency Variations: Technical Insights

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Origins

Coil whine is an electromagnetic phenomenon that occurs in electronic devices, particularly in power supplies and other components with inductors or transformers. This audible noise is a result of electromagnetic forces causing physical vibrations in the coils of these components. The origins of coil whine can be traced back to the fundamental principles of electromagnetism and the design of electronic circuits.

At its core, coil whine is caused by the interaction between magnetic fields and electrical currents. When an alternating current flows through a coil, it creates a fluctuating magnetic field. This changing magnetic field exerts forces on the coil's windings, causing them to vibrate at frequencies corresponding to the current's oscillations. These vibrations produce audible sound waves, which we perceive as coil whine.

The frequency of coil whine is directly related to the frequency of the electrical current flowing through the coil. In many electronic devices, this frequency is often in the audible range of human hearing, typically between 20 Hz and 20 kHz. Power supplies, for instance, often operate at frequencies that fall within this range, making coil whine a common issue in computer systems and other electronic equipment.

Several factors contribute to the intensity and prevalence of coil whine. The physical properties of the coil, including its size, shape, and material composition, play a significant role. Coils with looser windings or those made from materials more susceptible to magnetostriction (the change in a material's shape in response to a magnetic field) are more likely to produce audible whine.

The electrical characteristics of the circuit also influence coil whine. Rapid changes in current, such as those found in switch-mode power supplies, can exacerbate the problem. Additionally, resonance between the coil's natural frequency and the frequency of the electrical current can amplify the vibrations, leading to more pronounced whine.

Environmental factors can also affect coil whine. Temperature fluctuations can cause expansion or contraction of coil materials, potentially altering their vibrational characteristics. Mechanical stress on the coil or surrounding components can create additional pathways for vibration transmission, amplifying the audible noise.

Understanding the origins of coil whine is crucial for developing effective mitigation strategies. Engineers and designers must consider the complex interplay between electrical, magnetic, and mechanical factors when designing components and systems prone to this phenomenon. By addressing these fundamental causes, it becomes possible to minimize coil whine and improve the overall performance and user experience of electronic devices.

At its core, coil whine is caused by the interaction between magnetic fields and electrical currents. When an alternating current flows through a coil, it creates a fluctuating magnetic field. This changing magnetic field exerts forces on the coil's windings, causing them to vibrate at frequencies corresponding to the current's oscillations. These vibrations produce audible sound waves, which we perceive as coil whine.

The frequency of coil whine is directly related to the frequency of the electrical current flowing through the coil. In many electronic devices, this frequency is often in the audible range of human hearing, typically between 20 Hz and 20 kHz. Power supplies, for instance, often operate at frequencies that fall within this range, making coil whine a common issue in computer systems and other electronic equipment.

Several factors contribute to the intensity and prevalence of coil whine. The physical properties of the coil, including its size, shape, and material composition, play a significant role. Coils with looser windings or those made from materials more susceptible to magnetostriction (the change in a material's shape in response to a magnetic field) are more likely to produce audible whine.

The electrical characteristics of the circuit also influence coil whine. Rapid changes in current, such as those found in switch-mode power supplies, can exacerbate the problem. Additionally, resonance between the coil's natural frequency and the frequency of the electrical current can amplify the vibrations, leading to more pronounced whine.

Environmental factors can also affect coil whine. Temperature fluctuations can cause expansion or contraction of coil materials, potentially altering their vibrational characteristics. Mechanical stress on the coil or surrounding components can create additional pathways for vibration transmission, amplifying the audible noise.

Understanding the origins of coil whine is crucial for developing effective mitigation strategies. Engineers and designers must consider the complex interplay between electrical, magnetic, and mechanical factors when designing components and systems prone to this phenomenon. By addressing these fundamental causes, it becomes possible to minimize coil whine and improve the overall performance and user experience of electronic devices.

Market Impact Analysis

Coil whine and frequency variations have significant implications for various market sectors, particularly in electronics and power systems. The prevalence of this issue has led to increased consumer awareness and demand for quieter, more efficient devices. This shift in consumer preferences is driving manufacturers to invest in research and development to mitigate coil whine, potentially reshaping product design and manufacturing processes across industries.

In the consumer electronics market, coil whine has become a critical factor influencing purchasing decisions, especially for high-end products like gaming PCs, laptops, and graphics cards. Manufacturers who successfully address this issue gain a competitive edge, potentially increasing their market share and brand reputation. This has led to a growing market for specialized components and materials designed to reduce electromagnetic noise and vibrations.

The automotive industry is also experiencing the impact of coil whine concerns, particularly with the rise of electric vehicles (EVs). As EVs rely heavily on power electronics, the reduction of coil whine has become a key differentiator in the market. Manufacturers who can produce quieter, more refined EVs are likely to see increased consumer interest and sales, driving innovation in motor and inverter design.

In the renewable energy sector, particularly in solar and wind power systems, coil whine reduction is becoming increasingly important for improving overall system efficiency and reliability. Power converters and transformers that minimize electromagnetic noise are in higher demand, creating new opportunities for component manufacturers and system integrators.

The industrial automation and manufacturing sectors are also affected by coil whine issues. As factories and production lines become more automated and reliant on precision electronics, the need for quiet and stable power systems has grown. This has led to increased demand for advanced power supply units and motor control systems that minimize electromagnetic interference and acoustic noise.

The telecommunications industry faces challenges related to coil whine in network infrastructure equipment. As 5G networks continue to expand, the need for high-performance, low-noise power systems in base stations and data centers has intensified. Companies that can provide solutions to these challenges are likely to see growth in market share and revenue.

Overall, the market impact of coil whine and frequency variations is driving innovation across multiple industries, creating new opportunities for companies that can develop effective solutions. This trend is likely to continue as consumers and businesses increasingly prioritize quiet, efficient, and reliable electronic systems in their products and operations.

In the consumer electronics market, coil whine has become a critical factor influencing purchasing decisions, especially for high-end products like gaming PCs, laptops, and graphics cards. Manufacturers who successfully address this issue gain a competitive edge, potentially increasing their market share and brand reputation. This has led to a growing market for specialized components and materials designed to reduce electromagnetic noise and vibrations.

The automotive industry is also experiencing the impact of coil whine concerns, particularly with the rise of electric vehicles (EVs). As EVs rely heavily on power electronics, the reduction of coil whine has become a key differentiator in the market. Manufacturers who can produce quieter, more refined EVs are likely to see increased consumer interest and sales, driving innovation in motor and inverter design.

In the renewable energy sector, particularly in solar and wind power systems, coil whine reduction is becoming increasingly important for improving overall system efficiency and reliability. Power converters and transformers that minimize electromagnetic noise are in higher demand, creating new opportunities for component manufacturers and system integrators.

The industrial automation and manufacturing sectors are also affected by coil whine issues. As factories and production lines become more automated and reliant on precision electronics, the need for quiet and stable power systems has grown. This has led to increased demand for advanced power supply units and motor control systems that minimize electromagnetic interference and acoustic noise.

The telecommunications industry faces challenges related to coil whine in network infrastructure equipment. As 5G networks continue to expand, the need for high-performance, low-noise power systems in base stations and data centers has intensified. Companies that can provide solutions to these challenges are likely to see growth in market share and revenue.

Overall, the market impact of coil whine and frequency variations is driving innovation across multiple industries, creating new opportunities for companies that can develop effective solutions. This trend is likely to continue as consumers and businesses increasingly prioritize quiet, efficient, and reliable electronic systems in their products and operations.

Technical Challenges

Coil whine and frequency variations present significant technical challenges in modern electronic systems, particularly in power supplies, audio equipment, and high-performance computing devices. These issues stem from the complex interplay between electromagnetic forces and mechanical resonance in electrical components, primarily inductors and transformers.

One of the primary challenges is the identification and isolation of coil whine sources. The phenomenon can originate from various components within a system, making it difficult to pinpoint the exact cause. This complexity is further compounded by the fact that coil whine can be intermittent and load-dependent, varying with different operating conditions and power states.

The mitigation of coil whine poses another substantial challenge. Traditional approaches, such as potting or encapsulation of components, often prove insufficient in high-frequency applications. Engineers must balance the need for effective noise reduction with considerations of thermal management, cost-effectiveness, and overall system performance.

Frequency variations, closely related to coil whine, present their own set of challenges. These variations can lead to electromagnetic interference (EMI) issues, affecting not only the device itself but also nearby electronic equipment. Addressing this requires sophisticated EMI shielding techniques and careful circuit design to minimize harmonic distortions and unwanted resonances.

The miniaturization trend in electronics exacerbates these challenges. As devices become smaller and more densely packed, the proximity of components increases the likelihood of electromagnetic coupling and resonance effects. This trend necessitates innovative approaches to component design and layout to mitigate these issues within constrained spaces.

Another significant challenge lies in the realm of quality control and testing. Detecting and measuring coil whine and frequency variations requires specialized equipment and methodologies. Developing reliable, repeatable testing procedures that can accurately identify these issues in a production environment remains an ongoing challenge for manufacturers.

The impact of environmental factors on coil whine and frequency stability adds another layer of complexity. Temperature fluctuations, humidity, and mechanical stress can all influence the behavior of electronic components, potentially exacerbating these issues. Designing systems that maintain stability across a wide range of operating conditions is a formidable engineering challenge.

Lastly, the increasing demand for high-efficiency power conversion in applications such as renewable energy systems and electric vehicles introduces new challenges. The use of high-frequency switching techniques in these applications can lead to more pronounced coil whine and frequency variation issues, requiring novel solutions that balance efficiency with noise reduction and electromagnetic compatibility.

One of the primary challenges is the identification and isolation of coil whine sources. The phenomenon can originate from various components within a system, making it difficult to pinpoint the exact cause. This complexity is further compounded by the fact that coil whine can be intermittent and load-dependent, varying with different operating conditions and power states.

The mitigation of coil whine poses another substantial challenge. Traditional approaches, such as potting or encapsulation of components, often prove insufficient in high-frequency applications. Engineers must balance the need for effective noise reduction with considerations of thermal management, cost-effectiveness, and overall system performance.

Frequency variations, closely related to coil whine, present their own set of challenges. These variations can lead to electromagnetic interference (EMI) issues, affecting not only the device itself but also nearby electronic equipment. Addressing this requires sophisticated EMI shielding techniques and careful circuit design to minimize harmonic distortions and unwanted resonances.

The miniaturization trend in electronics exacerbates these challenges. As devices become smaller and more densely packed, the proximity of components increases the likelihood of electromagnetic coupling and resonance effects. This trend necessitates innovative approaches to component design and layout to mitigate these issues within constrained spaces.

Another significant challenge lies in the realm of quality control and testing. Detecting and measuring coil whine and frequency variations requires specialized equipment and methodologies. Developing reliable, repeatable testing procedures that can accurately identify these issues in a production environment remains an ongoing challenge for manufacturers.

The impact of environmental factors on coil whine and frequency stability adds another layer of complexity. Temperature fluctuations, humidity, and mechanical stress can all influence the behavior of electronic components, potentially exacerbating these issues. Designing systems that maintain stability across a wide range of operating conditions is a formidable engineering challenge.

Lastly, the increasing demand for high-efficiency power conversion in applications such as renewable energy systems and electric vehicles introduces new challenges. The use of high-frequency switching techniques in these applications can lead to more pronounced coil whine and frequency variation issues, requiring novel solutions that balance efficiency with noise reduction and electromagnetic compatibility.

Mitigation Techniques

01 Measurement and analysis of coil whine frequency

Various techniques and devices are used to measure and analyze coil whine frequency in electronic components. These methods often involve specialized sensors, signal processing algorithms, and frequency analysis tools to detect and characterize the high-frequency vibrations associated with coil whine.- Measurement and analysis of coil whine frequency: Various techniques and devices are used to measure and analyze coil whine frequency in electronic components. These methods often involve specialized equipment to detect and quantify the high-frequency vibrations associated with coil whine, allowing for better understanding and mitigation of the issue.

- Coil design optimization to reduce whine: Researchers and engineers focus on optimizing coil designs to minimize or eliminate coil whine. This includes modifications to coil geometry, winding techniques, and material selection to reduce mechanical vibrations that cause the characteristic high-frequency noise.

- Frequency range identification of coil whine: Studies are conducted to identify the specific frequency ranges associated with coil whine in various electronic devices. This knowledge is crucial for developing targeted solutions and for designing appropriate noise reduction strategies in electronic products.

- Noise suppression techniques for coil whine: Various noise suppression techniques are employed to mitigate coil whine in electronic devices. These may include the use of dampening materials, encapsulation methods, or active noise cancellation technologies to reduce the audible effects of high-frequency vibrations.

- Testing and quality control for coil whine: Manufacturers implement testing and quality control procedures specifically designed to detect and address coil whine issues in electronic components and devices. These processes help ensure that products meet acceptable noise standards before reaching consumers.

02 Reduction of coil whine through design optimization

Engineers employ various design strategies to minimize coil whine in electronic devices. These may include optimizing the physical structure of coils, using different materials, or implementing advanced winding techniques to reduce electromagnetic vibrations that cause the audible noise.Expand Specific Solutions03 Frequency detection in power supply units

Specific methods are developed to detect and analyze coil whine frequencies in power supply units of electronic devices. These techniques often focus on identifying problematic frequency ranges and implementing solutions to mitigate the issue in power delivery components.Expand Specific Solutions04 Active noise cancellation for coil whine

Active noise cancellation techniques are applied to counteract coil whine in electronic devices. These systems typically involve generating anti-phase signals to neutralize the unwanted high-frequency noise produced by coils and other components.Expand Specific Solutions05 Coil whine detection in automotive applications

Specialized methods are developed for detecting and addressing coil whine in automotive electrical systems. These techniques consider the unique challenges posed by the automotive environment and aim to improve the overall quality and reliability of vehicle electronics.Expand Specific Solutions

Industry Leaders

The coil whine and frequency variations technology landscape is in a mature stage, with a diverse range of established players competing in a sizable market. Companies like Robert Bosch GmbH, Murata Manufacturing, and Toyota Motor Corp. are leveraging their extensive experience in automotive and electronics to address this issue. The market is characterized by ongoing innovation, with firms such as ZF Friedrichshafen AG and DENSO Corp. focusing on developing advanced solutions to mitigate coil whine and improve frequency stability. As the demand for quieter and more efficient electronic systems grows across industries, companies like Yamaha Corp. and TDK Corp. are expanding their product offerings to capture market share in this competitive field.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced noise reduction techniques for coil whine in automotive applications. Their approach involves a combination of material selection, coil design optimization, and active noise cancellation. They use high-quality magnetic core materials with low magnetostriction to minimize vibrations[1]. Bosch's patented coil winding technique reduces air gaps and improves uniformity, decreasing frequency variations[2]. Additionally, they implement active noise control systems that use microphones to detect coil whine and generate anti-noise signals, effectively canceling out the unwanted frequencies[3].

Strengths: Comprehensive approach combining passive and active noise reduction techniques. Weaknesses: May increase complexity and cost of components.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has focused on developing innovative materials and designs to mitigate coil whine. They have created a proprietary ferrite material with enhanced magnetic properties that significantly reduces magnetostriction, a primary cause of coil whine[4]. Murata's advanced coil construction techniques, including multi-layer winding and vacuum impregnation, minimize air gaps and dampen vibrations[5]. They have also introduced a novel coil structure that incorporates a flexible, vibration-absorbing layer between the windings and the core, further reducing acoustic noise emissions[6].

Strengths: Expertise in materials science and coil design. Weaknesses: Solutions may be more suitable for smaller electronic devices rather than large industrial applications.

Innovative Solutions

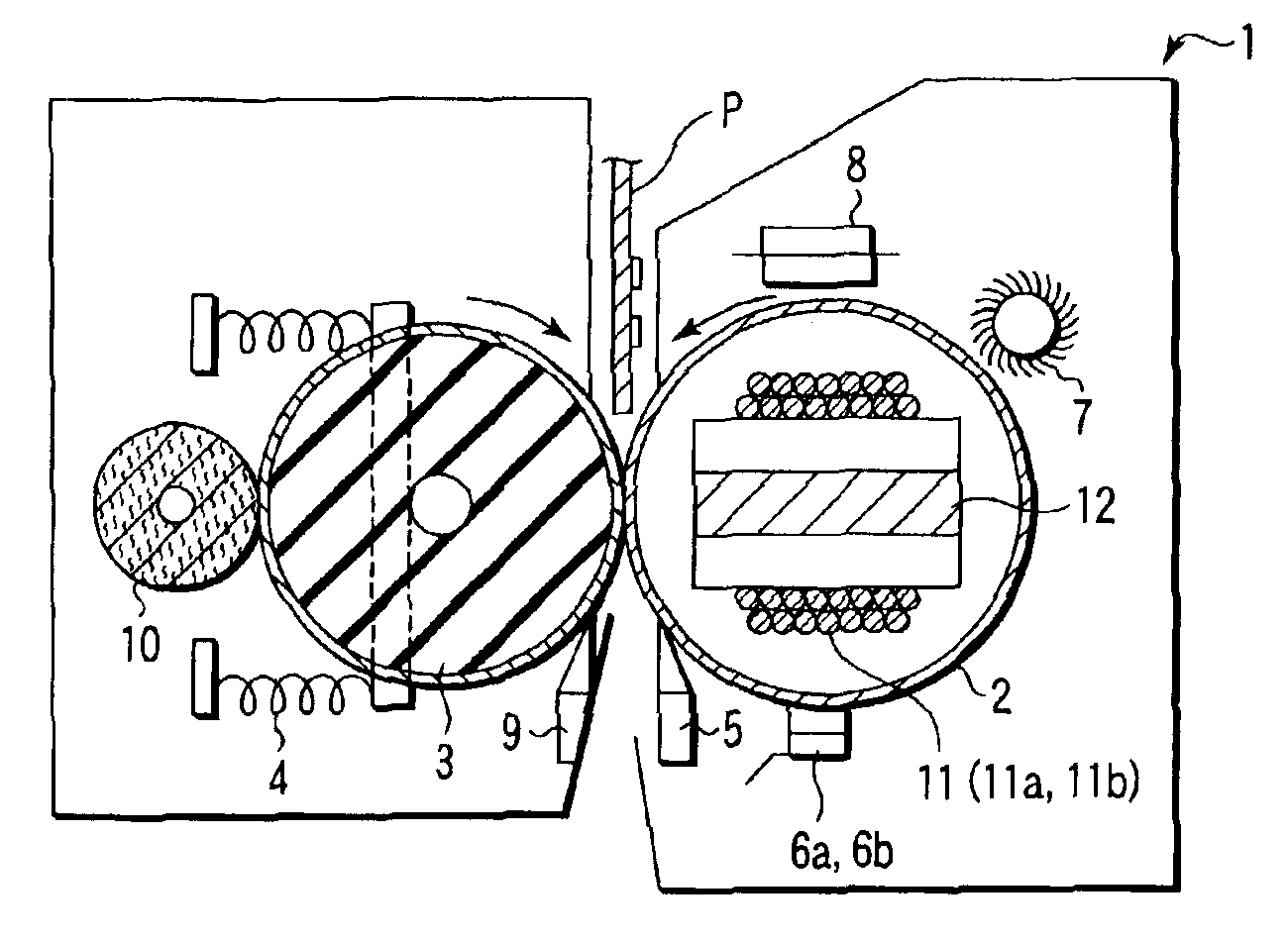

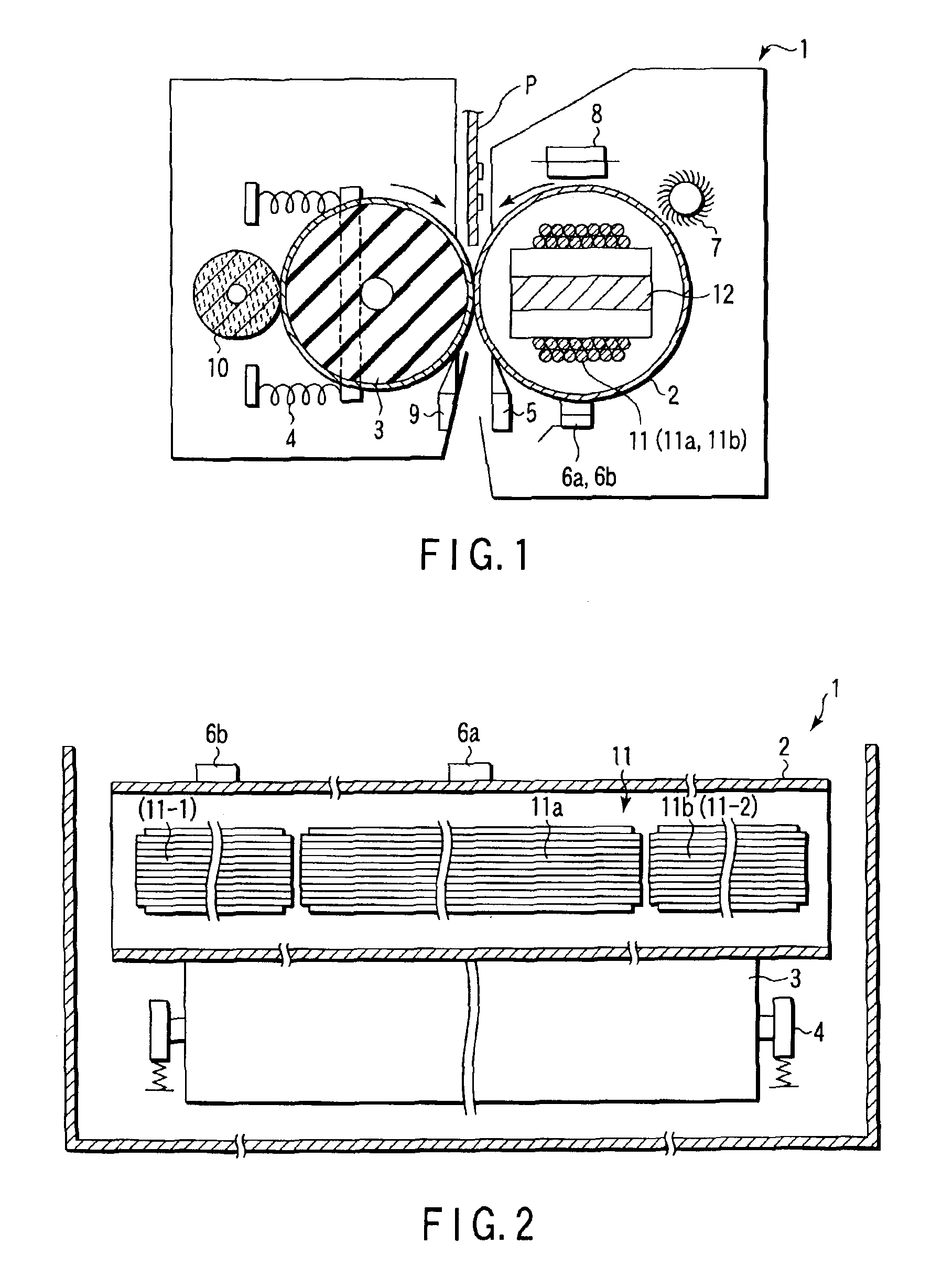

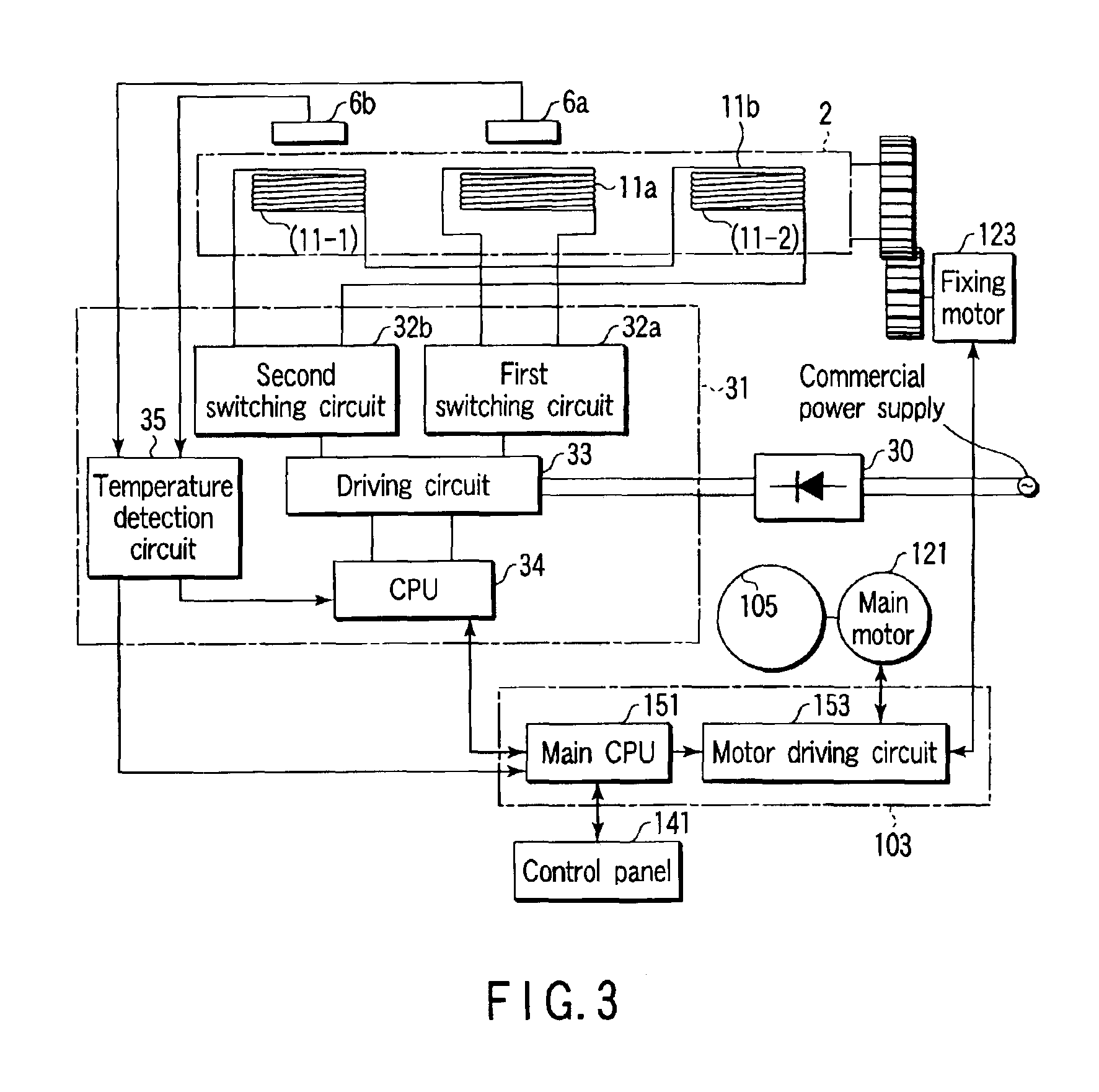

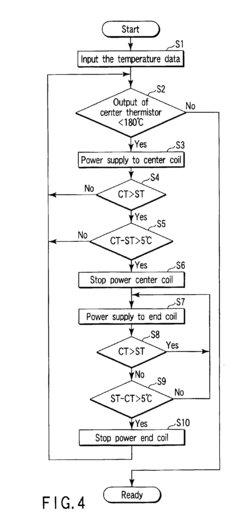

Fixing unit

PatentInactiveUS6889018B2

Innovation

- A fixing device with a cylindrical or belt-like heat-producing member, press member, and multiple coil members, equipped with temperature detection mechanisms and a driving control mechanism that adjusts power supply based on temperature differences to maintain even heating and minimize interference noise.

Acoustic Standards

Acoustic standards play a crucial role in addressing the challenges posed by coil whine and frequency variations in electronic devices. These standards provide a framework for measuring, evaluating, and mitigating acoustic emissions, ensuring that products meet acceptable noise levels and maintain user comfort.

The International Electrotechnical Commission (IEC) has established several standards relevant to coil whine and frequency variations. IEC 60704-1 outlines general methods for determining airborne acoustical noise emitted by household and similar electrical appliances. This standard serves as a foundation for measuring and characterizing acoustic emissions, including those resulting from coil whine.

Specific to electronic equipment, IEC 62368-1 addresses safety requirements for audio, video, information, and communication technology equipment. While primarily focused on safety, this standard also considers acoustic noise emissions as part of its comprehensive approach to product evaluation.

The American National Standards Institute (ANSI) and the Acoustical Society of America (ASA) have jointly developed ANSI/ASA S12.10, which provides methods for the measurement and reporting of noise emissions from computer and business equipment. This standard is particularly relevant for addressing coil whine in electronic devices, as it establishes procedures for measuring and documenting acoustic emissions under various operating conditions.

In the European Union, the Eco-design Directive (2009/125/EC) sets requirements for the environmental performance of energy-related products, including noise emissions. This directive has led to the development of specific implementing measures for various product categories, some of which address acoustic performance and indirectly impact coil whine mitigation efforts.

The ISO 7779 standard, developed by the International Organization for Standardization, specifies methods for measuring and reporting noise emission of information technology and telecommunications equipment. This standard is particularly relevant for addressing coil whine in computer systems, power supplies, and other electronic components.

Compliance with these acoustic standards often requires manufacturers to implement noise reduction techniques, such as improved component selection, optimized circuit design, and enhanced cooling solutions. These efforts not only address coil whine and frequency variations but also contribute to overall product quality and user satisfaction.

As technology evolves, acoustic standards continue to be updated to address emerging challenges. For instance, the increasing prevalence of high-frequency switching power supplies and advanced electronic components has led to a greater focus on high-frequency noise emissions in recent standard revisions.

The International Electrotechnical Commission (IEC) has established several standards relevant to coil whine and frequency variations. IEC 60704-1 outlines general methods for determining airborne acoustical noise emitted by household and similar electrical appliances. This standard serves as a foundation for measuring and characterizing acoustic emissions, including those resulting from coil whine.

Specific to electronic equipment, IEC 62368-1 addresses safety requirements for audio, video, information, and communication technology equipment. While primarily focused on safety, this standard also considers acoustic noise emissions as part of its comprehensive approach to product evaluation.

The American National Standards Institute (ANSI) and the Acoustical Society of America (ASA) have jointly developed ANSI/ASA S12.10, which provides methods for the measurement and reporting of noise emissions from computer and business equipment. This standard is particularly relevant for addressing coil whine in electronic devices, as it establishes procedures for measuring and documenting acoustic emissions under various operating conditions.

In the European Union, the Eco-design Directive (2009/125/EC) sets requirements for the environmental performance of energy-related products, including noise emissions. This directive has led to the development of specific implementing measures for various product categories, some of which address acoustic performance and indirectly impact coil whine mitigation efforts.

The ISO 7779 standard, developed by the International Organization for Standardization, specifies methods for measuring and reporting noise emission of information technology and telecommunications equipment. This standard is particularly relevant for addressing coil whine in computer systems, power supplies, and other electronic components.

Compliance with these acoustic standards often requires manufacturers to implement noise reduction techniques, such as improved component selection, optimized circuit design, and enhanced cooling solutions. These efforts not only address coil whine and frequency variations but also contribute to overall product quality and user satisfaction.

As technology evolves, acoustic standards continue to be updated to address emerging challenges. For instance, the increasing prevalence of high-frequency switching power supplies and advanced electronic components has led to a greater focus on high-frequency noise emissions in recent standard revisions.

Power Efficiency

Power efficiency is a critical aspect in the context of coil whine and frequency variations. The phenomenon of coil whine, characterized by high-frequency vibrations in electronic components, can significantly impact the overall power efficiency of a system. As electronic devices become more compact and powerful, the need for efficient power management becomes increasingly important.

One of the primary concerns related to coil whine is its potential to increase power consumption. The vibrations caused by coil whine represent wasted energy, which is converted into unwanted sound rather than useful work. This energy loss can accumulate over time, leading to reduced battery life in portable devices and increased electricity costs in stationary systems.

Furthermore, the frequency variations associated with coil whine can introduce instability in power delivery. These fluctuations may cause voltage ripples and electromagnetic interference, potentially affecting the performance of sensitive components within the system. As a result, additional power may be required to maintain stable operation, further reducing overall efficiency.

To address these issues, engineers and manufacturers have developed various strategies to improve power efficiency in the presence of coil whine. One approach involves the use of advanced materials and construction techniques for inductors and transformers, which are common sources of coil whine. By employing materials with superior magnetic properties and optimizing coil designs, it is possible to minimize energy losses and reduce the occurrence of audible vibrations.

Another important aspect of power efficiency in this context is the implementation of sophisticated power management systems. These systems can dynamically adjust voltage and frequency levels to optimize performance while minimizing power consumption. By fine-tuning operating parameters in real-time, it is possible to reduce the conditions that lead to coil whine while maintaining system stability.

The integration of active noise cancellation techniques has also shown promise in mitigating the effects of coil whine on power efficiency. By generating counter-signals to neutralize unwanted vibrations, these systems can reduce energy losses associated with mechanical oscillations. This approach not only improves efficiency but also enhances the overall user experience by reducing audible noise.

As the demand for high-performance, energy-efficient electronic devices continues to grow, addressing the challenges posed by coil whine and frequency variations becomes increasingly important. Ongoing research in this field focuses on developing innovative solutions that balance power efficiency with performance and reliability. By tackling these issues, manufacturers can create products that not only meet consumer expectations for performance but also contribute to broader energy conservation efforts.

One of the primary concerns related to coil whine is its potential to increase power consumption. The vibrations caused by coil whine represent wasted energy, which is converted into unwanted sound rather than useful work. This energy loss can accumulate over time, leading to reduced battery life in portable devices and increased electricity costs in stationary systems.

Furthermore, the frequency variations associated with coil whine can introduce instability in power delivery. These fluctuations may cause voltage ripples and electromagnetic interference, potentially affecting the performance of sensitive components within the system. As a result, additional power may be required to maintain stable operation, further reducing overall efficiency.

To address these issues, engineers and manufacturers have developed various strategies to improve power efficiency in the presence of coil whine. One approach involves the use of advanced materials and construction techniques for inductors and transformers, which are common sources of coil whine. By employing materials with superior magnetic properties and optimizing coil designs, it is possible to minimize energy losses and reduce the occurrence of audible vibrations.

Another important aspect of power efficiency in this context is the implementation of sophisticated power management systems. These systems can dynamically adjust voltage and frequency levels to optimize performance while minimizing power consumption. By fine-tuning operating parameters in real-time, it is possible to reduce the conditions that lead to coil whine while maintaining system stability.

The integration of active noise cancellation techniques has also shown promise in mitigating the effects of coil whine on power efficiency. By generating counter-signals to neutralize unwanted vibrations, these systems can reduce energy losses associated with mechanical oscillations. This approach not only improves efficiency but also enhances the overall user experience by reducing audible noise.

As the demand for high-performance, energy-efficient electronic devices continues to grow, addressing the challenges posed by coil whine and frequency variations becomes increasingly important. Ongoing research in this field focuses on developing innovative solutions that balance power efficiency with performance and reliability. By tackling these issues, manufacturers can create products that not only meet consumer expectations for performance but also contribute to broader energy conservation efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!