Coil Whine: Identifying Electromagnetic Interference

AUG 13, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Background and Objectives

Electromagnetic Interference (EMI) has been a persistent challenge in electronic systems since the advent of modern electronics. Coil whine, a specific manifestation of EMI, has gained increasing attention in recent years due to its prevalence in high-performance computing and power electronics. This phenomenon, characterized by audible noise emanating from electronic components, is not only a nuisance but can also indicate potential performance issues and energy inefficiencies.

The evolution of EMI as a field of study can be traced back to the early 20th century, with the proliferation of radio communications. As electronic devices became more complex and widespread, the need for understanding and mitigating EMI grew exponentially. The emergence of digital electronics in the latter half of the century further complicated the EMI landscape, introducing new sources of interference and necessitating more sophisticated mitigation techniques.

In the context of coil whine, the primary objective is to identify and characterize the sources of this specific form of EMI. This involves understanding the underlying physical mechanisms, such as magnetostriction and electromagnetic forces, that contribute to the generation of audible noise in electronic components. By gaining a comprehensive understanding of these processes, researchers and engineers aim to develop more effective strategies for mitigating coil whine and its associated effects.

The technological trajectory in this field is moving towards more precise measurement techniques and advanced modeling capabilities. These advancements are crucial for accurately identifying the sources of coil whine and predicting its occurrence in complex electronic systems. Additionally, there is a growing focus on developing materials and design methodologies that inherently reduce the susceptibility of components to EMI-induced vibrations.

As we look to the future, the goals for EMI management, particularly in relation to coil whine, are multifaceted. They include the development of standardized testing procedures for quantifying and characterizing coil whine, the creation of more sophisticated simulation tools for predicting EMI behavior in complex systems, and the integration of EMI considerations into the early stages of electronic design processes. Furthermore, there is an increasing emphasis on addressing EMI issues in emerging technologies, such as high-frequency power electronics and advanced computing architectures, where the challenges of coil whine are expected to become more pronounced.

The evolution of EMI as a field of study can be traced back to the early 20th century, with the proliferation of radio communications. As electronic devices became more complex and widespread, the need for understanding and mitigating EMI grew exponentially. The emergence of digital electronics in the latter half of the century further complicated the EMI landscape, introducing new sources of interference and necessitating more sophisticated mitigation techniques.

In the context of coil whine, the primary objective is to identify and characterize the sources of this specific form of EMI. This involves understanding the underlying physical mechanisms, such as magnetostriction and electromagnetic forces, that contribute to the generation of audible noise in electronic components. By gaining a comprehensive understanding of these processes, researchers and engineers aim to develop more effective strategies for mitigating coil whine and its associated effects.

The technological trajectory in this field is moving towards more precise measurement techniques and advanced modeling capabilities. These advancements are crucial for accurately identifying the sources of coil whine and predicting its occurrence in complex electronic systems. Additionally, there is a growing focus on developing materials and design methodologies that inherently reduce the susceptibility of components to EMI-induced vibrations.

As we look to the future, the goals for EMI management, particularly in relation to coil whine, are multifaceted. They include the development of standardized testing procedures for quantifying and characterizing coil whine, the creation of more sophisticated simulation tools for predicting EMI behavior in complex systems, and the integration of EMI considerations into the early stages of electronic design processes. Furthermore, there is an increasing emphasis on addressing EMI issues in emerging technologies, such as high-frequency power electronics and advanced computing architectures, where the challenges of coil whine are expected to become more pronounced.

Market Demand Analysis

The market demand for solutions addressing Coil Whine and Electromagnetic Interference (EMI) has been steadily growing across various industries. This demand is primarily driven by the increasing complexity of electronic devices and the need for improved performance and reliability in sensitive equipment.

In the consumer electronics sector, there is a rising awareness among users regarding the annoying high-pitched noise produced by coil whine in devices such as laptops, graphics cards, and power supplies. This has led to a surge in demand for quieter and more efficient components, pushing manufacturers to invest in EMI reduction technologies.

The automotive industry has also become a significant driver of market demand for EMI solutions. With the rapid adoption of electric and hybrid vehicles, the need for effective EMI management has become crucial. These vehicles contain numerous electronic components and high-power systems that can generate substantial electromagnetic interference, potentially affecting both vehicle performance and passenger comfort.

In the aerospace and defense sectors, the demand for EMI mitigation solutions remains consistently high. The critical nature of equipment used in these industries requires stringent EMI control to ensure reliable operation and prevent potential safety hazards. This has led to ongoing investments in advanced EMI shielding and noise reduction technologies.

The healthcare industry represents another growing market for EMI solutions. Medical devices and diagnostic equipment are highly sensitive to electromagnetic interference, which can compromise their accuracy and reliability. As healthcare facilities continue to adopt more advanced electronic systems, the demand for effective EMI management solutions is expected to increase.

Industrial automation and control systems also contribute significantly to the market demand. As factories become more digitized and interconnected, the potential for EMI-related issues grows. This has led to an increased focus on EMI-resistant components and shielding solutions in industrial settings.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, has seen a surge in demand for EMI mitigation technologies. The higher frequencies used in 5G systems are more susceptible to interference, necessitating advanced EMI control measures in both network infrastructure and consumer devices.

Overall, the market for Coil Whine and EMI identification and mitigation solutions is expected to continue its growth trajectory. This trend is fueled by the increasing integration of electronic systems across industries, stricter regulatory standards for electromagnetic compatibility, and growing consumer expectations for quieter and more reliable electronic devices.

In the consumer electronics sector, there is a rising awareness among users regarding the annoying high-pitched noise produced by coil whine in devices such as laptops, graphics cards, and power supplies. This has led to a surge in demand for quieter and more efficient components, pushing manufacturers to invest in EMI reduction technologies.

The automotive industry has also become a significant driver of market demand for EMI solutions. With the rapid adoption of electric and hybrid vehicles, the need for effective EMI management has become crucial. These vehicles contain numerous electronic components and high-power systems that can generate substantial electromagnetic interference, potentially affecting both vehicle performance and passenger comfort.

In the aerospace and defense sectors, the demand for EMI mitigation solutions remains consistently high. The critical nature of equipment used in these industries requires stringent EMI control to ensure reliable operation and prevent potential safety hazards. This has led to ongoing investments in advanced EMI shielding and noise reduction technologies.

The healthcare industry represents another growing market for EMI solutions. Medical devices and diagnostic equipment are highly sensitive to electromagnetic interference, which can compromise their accuracy and reliability. As healthcare facilities continue to adopt more advanced electronic systems, the demand for effective EMI management solutions is expected to increase.

Industrial automation and control systems also contribute significantly to the market demand. As factories become more digitized and interconnected, the potential for EMI-related issues grows. This has led to an increased focus on EMI-resistant components and shielding solutions in industrial settings.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, has seen a surge in demand for EMI mitigation technologies. The higher frequencies used in 5G systems are more susceptible to interference, necessitating advanced EMI control measures in both network infrastructure and consumer devices.

Overall, the market for Coil Whine and EMI identification and mitigation solutions is expected to continue its growth trajectory. This trend is fueled by the increasing integration of electronic systems across industries, stricter regulatory standards for electromagnetic compatibility, and growing consumer expectations for quieter and more reliable electronic devices.

EMI Challenges

Electromagnetic Interference (EMI) poses significant challenges in the context of coil whine, a phenomenon that affects various electronic devices. One of the primary challenges is the identification and isolation of EMI sources within complex electronic systems. As devices become more compact and integrated, pinpointing the exact origin of coil whine becomes increasingly difficult, requiring sophisticated diagnostic tools and techniques.

Another major challenge is the mitigation of EMI effects without compromising device performance or functionality. Traditional shielding methods may not always be effective or practical, especially in compact or high-frequency devices. Engineers must balance EMI reduction with other design considerations such as thermal management, cost-effectiveness, and overall product size.

The frequency range of coil whine presents its own set of challenges. Typically occurring in the audible spectrum (20 Hz to 20 kHz), it overlaps with human hearing sensitivity, making it particularly noticeable and potentially annoying to users. This necessitates not only technical solutions but also considerations of human factors and user experience in product design.

Regulatory compliance adds another layer of complexity to EMI challenges. Different regions and industries have varying EMI standards and regulations, requiring manufacturers to adapt their designs to meet these diverse requirements. This can lead to increased development costs and longer time-to-market for global products.

The dynamic nature of EMI in modern electronic systems further complicates the issue. As devices switch between different power states or operational modes, the characteristics of EMI can change, making it challenging to implement consistent and effective mitigation strategies across all usage scenarios.

Interdisciplinary approaches are often required to address EMI challenges effectively. This involves collaboration between electrical engineers, materials scientists, and mechanical designers to develop holistic solutions that address EMI at multiple levels, from circuit design to system integration and packaging.

Emerging technologies and materials present both opportunities and challenges in EMI management. While advanced materials and design techniques offer new ways to combat EMI, they also introduce new variables and potential sources of interference that must be carefully evaluated and managed throughout the product development lifecycle.

Another major challenge is the mitigation of EMI effects without compromising device performance or functionality. Traditional shielding methods may not always be effective or practical, especially in compact or high-frequency devices. Engineers must balance EMI reduction with other design considerations such as thermal management, cost-effectiveness, and overall product size.

The frequency range of coil whine presents its own set of challenges. Typically occurring in the audible spectrum (20 Hz to 20 kHz), it overlaps with human hearing sensitivity, making it particularly noticeable and potentially annoying to users. This necessitates not only technical solutions but also considerations of human factors and user experience in product design.

Regulatory compliance adds another layer of complexity to EMI challenges. Different regions and industries have varying EMI standards and regulations, requiring manufacturers to adapt their designs to meet these diverse requirements. This can lead to increased development costs and longer time-to-market for global products.

The dynamic nature of EMI in modern electronic systems further complicates the issue. As devices switch between different power states or operational modes, the characteristics of EMI can change, making it challenging to implement consistent and effective mitigation strategies across all usage scenarios.

Interdisciplinary approaches are often required to address EMI challenges effectively. This involves collaboration between electrical engineers, materials scientists, and mechanical designers to develop holistic solutions that address EMI at multiple levels, from circuit design to system integration and packaging.

Emerging technologies and materials present both opportunities and challenges in EMI management. While advanced materials and design techniques offer new ways to combat EMI, they also introduce new variables and potential sources of interference that must be carefully evaluated and managed throughout the product development lifecycle.

Current EMI Solutions

01 Electromagnetic shielding techniques

Various electromagnetic shielding techniques are employed to reduce coil whine and electromagnetic interference. These methods include using conductive materials, specialized coatings, or enclosures to contain and absorb electromagnetic emissions from electronic components, particularly coils and transformers.- Electromagnetic shielding techniques: Various electromagnetic shielding techniques are employed to reduce coil whine and electromagnetic interference. These may include using conductive materials, specialized coatings, or enclosures to contain and absorb electromagnetic emissions from electronic components, particularly coils and transformers.

- Coil design optimization: Optimizing the design of coils and inductors can help minimize coil whine and reduce electromagnetic interference. This may involve using specific winding techniques, core materials, or geometries that reduce mechanical vibrations and electromagnetic emissions.

- Active noise cancellation: Implementation of active noise cancellation techniques to counteract coil whine. This may involve using additional circuitry or components to generate opposing electromagnetic fields or vibrations that cancel out the unwanted emissions from coils.

- Power supply and circuit design improvements: Enhancements in power supply design and overall circuit layout to minimize coil whine and electromagnetic interference. This may include using specialized filtering components, improved PCB layouts, or advanced power management techniques to reduce electrical noise and vibrations.

- Vibration damping and isolation: Utilization of vibration damping materials and isolation techniques to reduce mechanical vibrations associated with coil whine. This may involve using specialized mounting methods, shock-absorbing materials, or encapsulation techniques to minimize the propagation of vibrations from coils to other components or the device housing.

02 Coil design optimization

Optimizing the design of coils and inductors can help minimize coil whine and reduce electromagnetic interference. This includes techniques such as adjusting winding patterns, using different core materials, or implementing advanced coil structures to reduce vibrations and electromagnetic emissions.Expand Specific Solutions03 Active noise cancellation

Active noise cancellation techniques can be applied to mitigate coil whine and electromagnetic interference. This involves using electronic circuits to generate counter-signals that neutralize the unwanted electromagnetic emissions or acoustic noise produced by coils and other components.Expand Specific Solutions04 Passive damping and isolation

Passive damping and isolation methods are used to reduce coil whine and electromagnetic interference. These techniques involve using materials or structures that absorb vibrations, isolate components, or dissipate energy to minimize the propagation of electromagnetic emissions and mechanical vibrations.Expand Specific Solutions05 EMI filtering and suppression

EMI filtering and suppression techniques are implemented to reduce electromagnetic interference caused by coil whine. This includes the use of specialized filters, capacitors, and other components designed to attenuate or block unwanted electromagnetic emissions across various frequency ranges.Expand Specific Solutions

Key EMI Industry Players

The electromagnetic interference (EMI) issue known as "coil whine" represents a mature technological challenge in the electronics industry. The market for EMI mitigation solutions is well-established, with a steady growth trajectory driven by the increasing complexity of electronic devices. Key players like Delta Electronics, Siemens, and Robert Bosch have developed advanced EMI suppression technologies, while automotive giants such as Toyota and Honda are actively addressing coil whine in electric vehicles. The competition is intense, with companies like Panasonic and Sharp focusing on consumer electronics applications. As the demand for quieter and more efficient electronic devices grows, the market for coil whine solutions is expected to expand, particularly in emerging sectors like IoT and renewable energy systems.

Siemens AG

Technical Solution: Siemens AG has developed advanced electromagnetic interference (EMI) mitigation techniques for coil whine reduction. Their approach involves a combination of hardware and software solutions. On the hardware side, they utilize specialized shielding materials and optimized PCB layouts to minimize electromagnetic emissions[1]. For software, Siemens has implemented adaptive frequency modulation algorithms that dynamically adjust the switching frequencies of power electronics to spread the EMI spectrum, reducing audible noise[3]. Additionally, they have developed active noise cancellation systems that use counter-phase signals to neutralize coil whine in sensitive equipment[5].

Strengths: Comprehensive approach combining hardware and software solutions. Weaknesses: May increase product complexity and cost.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has focused on innovative coil design and material selection to address coil whine issues. They have developed high-performance magnetic cores using advanced nanocrystalline materials that exhibit lower magnetostriction, reducing vibrations that cause coil whine[2]. Bosch has also implemented precision winding techniques and epoxy encapsulation methods to minimize mechanical resonances in their coils[4]. Furthermore, they have created intelligent power management systems that optimize current flow through coils, reducing sudden flux changes that contribute to electromagnetic interference[6].

Strengths: Focus on material science and coil construction techniques. Weaknesses: May be limited in addressing system-level EMI issues.

Core EMI Innovations

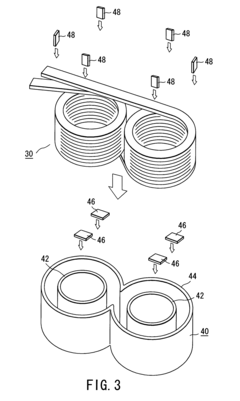

Coil component and fabrication method of the same

PatentInactiveUS7427909B2

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin, embedded within a magnetic core composed of a mixture of resin and magnetic powder, which provides enhanced structural integrity and noise suppression.

Reduction of EMI in pressure sensor using microstrip filter

PatentInactiveIN201641011789A

Innovation

- The implementation of a dual band microstrip patch antenna and a low-pass microstrip filter using the Greens Moments Method to mitigate EMI effects, specifically designed to reduce radiated emissions and susceptibility in the pressure sensor, employing a microstrip line with a dielectric substrate and a ground plane to filter out high-frequency interference.

EMI Regulations

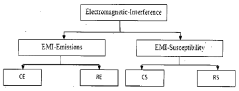

Electromagnetic Interference (EMI) regulations play a crucial role in managing and mitigating the effects of coil whine and other forms of electromagnetic disturbances. These regulations are established by various international and national bodies to ensure that electronic devices operate within acceptable limits of electromagnetic emissions and maintain electromagnetic compatibility (EMC) with other devices.

The International Electrotechnical Commission (IEC) sets global standards for EMC, with IEC 61000 being the primary series of standards addressing electromagnetic compatibility. These standards define the limits for electromagnetic emissions and immunity for various types of equipment and environments.

In the United States, the Federal Communications Commission (FCC) enforces EMI regulations. The FCC Part 15 rules govern unintentional radiators, which include most electronic devices that may produce coil whine. These rules specify the maximum allowable levels of electromagnetic emissions for different device categories and operating frequencies.

The European Union enforces EMC regulations through the EMC Directive (2014/30/EU). This directive requires all electronic equipment sold in the EU to comply with specific EMC standards, ensuring that devices do not generate excessive electromagnetic disturbances and are sufficiently immune to external interference.

For automotive applications, where coil whine can be particularly problematic, standards such as CISPR 25 and ISO 11452 provide guidelines for vehicle manufacturers to manage electromagnetic emissions and immunity. These standards are crucial for ensuring the reliable operation of electronic systems in vehicles.

In the aerospace industry, strict EMI regulations are enforced to maintain the safety and reliability of aircraft systems. Standards like RTCA DO-160 and MIL-STD-461 define the EMC requirements for airborne equipment, addressing issues such as coil whine in avionics systems.

Compliance with EMI regulations often requires manufacturers to implement various design techniques and shielding methods to reduce electromagnetic emissions. This may include the use of EMI suppression components, proper PCB layout design, and enclosure shielding.

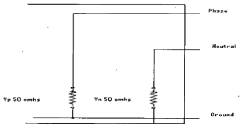

Testing for EMI compliance typically involves specialized equipment and procedures. Anechoic chambers are used to measure radiated emissions, while conducted emissions are measured using line impedance stabilization networks (LISN). These tests help identify sources of electromagnetic interference, including coil whine, and ensure that devices meet the required regulatory standards.

As technology advances and devices become more complex, EMI regulations continue to evolve. Regulatory bodies regularly update their standards to address new challenges in electromagnetic compatibility, including emerging issues related to high-frequency switching in power electronics and the increasing prevalence of wireless communication technologies.

The International Electrotechnical Commission (IEC) sets global standards for EMC, with IEC 61000 being the primary series of standards addressing electromagnetic compatibility. These standards define the limits for electromagnetic emissions and immunity for various types of equipment and environments.

In the United States, the Federal Communications Commission (FCC) enforces EMI regulations. The FCC Part 15 rules govern unintentional radiators, which include most electronic devices that may produce coil whine. These rules specify the maximum allowable levels of electromagnetic emissions for different device categories and operating frequencies.

The European Union enforces EMC regulations through the EMC Directive (2014/30/EU). This directive requires all electronic equipment sold in the EU to comply with specific EMC standards, ensuring that devices do not generate excessive electromagnetic disturbances and are sufficiently immune to external interference.

For automotive applications, where coil whine can be particularly problematic, standards such as CISPR 25 and ISO 11452 provide guidelines for vehicle manufacturers to manage electromagnetic emissions and immunity. These standards are crucial for ensuring the reliable operation of electronic systems in vehicles.

In the aerospace industry, strict EMI regulations are enforced to maintain the safety and reliability of aircraft systems. Standards like RTCA DO-160 and MIL-STD-461 define the EMC requirements for airborne equipment, addressing issues such as coil whine in avionics systems.

Compliance with EMI regulations often requires manufacturers to implement various design techniques and shielding methods to reduce electromagnetic emissions. This may include the use of EMI suppression components, proper PCB layout design, and enclosure shielding.

Testing for EMI compliance typically involves specialized equipment and procedures. Anechoic chambers are used to measure radiated emissions, while conducted emissions are measured using line impedance stabilization networks (LISN). These tests help identify sources of electromagnetic interference, including coil whine, and ensure that devices meet the required regulatory standards.

As technology advances and devices become more complex, EMI regulations continue to evolve. Regulatory bodies regularly update their standards to address new challenges in electromagnetic compatibility, including emerging issues related to high-frequency switching in power electronics and the increasing prevalence of wireless communication technologies.

EMI Testing Methods

Electromagnetic Interference (EMI) testing methods are crucial for identifying and mitigating coil whine issues in electronic devices. These methods involve a range of techniques and equipment designed to measure, analyze, and characterize electromagnetic emissions from various components, particularly coils and transformers.

One of the primary EMI testing methods is the use of anechoic chambers. These specialized rooms are designed to absorb electromagnetic waves, creating an isolated environment for accurate EMI measurements. Within these chambers, engineers can conduct controlled tests to identify the sources and characteristics of coil whine without external interference.

Another essential technique is near-field scanning. This method involves using specialized probes to measure electromagnetic fields in close proximity to the device under test. By systematically scanning the surface of a circuit board or component, engineers can create detailed maps of EMI hotspots, helping to pinpoint the exact location and intensity of coil whine sources.

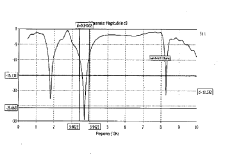

Spectrum analyzers play a vital role in EMI testing. These instruments allow technicians to visualize the frequency spectrum of electromagnetic emissions, enabling the identification of specific frequencies associated with coil whine. This information is crucial for developing targeted mitigation strategies and ensuring compliance with EMC standards.

Time-domain reflectometry (TDR) is another valuable tool in the EMI testing arsenal. TDR can help identify impedance mismatches and discontinuities in circuit traces that may contribute to coil whine. By analyzing the reflection of high-frequency signals, engineers can optimize circuit layouts to minimize EMI.

Conducted emissions testing is essential for assessing the EMI that propagates through power and signal lines. This method involves measuring the electromagnetic noise that travels along cables and wires, which can be a significant contributor to coil whine in interconnected systems.

Radiated emissions testing complements conducted emissions testing by measuring the electromagnetic fields emitted into the surrounding space. This is typically performed in an open area test site (OATS) or a semi-anechoic chamber, using specialized antennas to capture and quantify radiated EMI across a wide frequency range.

Advanced EMI testing methods also include the use of 3D electromagnetic field simulators. These software tools allow engineers to model and predict EMI behavior before physical prototypes are built, significantly reducing development time and costs.

One of the primary EMI testing methods is the use of anechoic chambers. These specialized rooms are designed to absorb electromagnetic waves, creating an isolated environment for accurate EMI measurements. Within these chambers, engineers can conduct controlled tests to identify the sources and characteristics of coil whine without external interference.

Another essential technique is near-field scanning. This method involves using specialized probes to measure electromagnetic fields in close proximity to the device under test. By systematically scanning the surface of a circuit board or component, engineers can create detailed maps of EMI hotspots, helping to pinpoint the exact location and intensity of coil whine sources.

Spectrum analyzers play a vital role in EMI testing. These instruments allow technicians to visualize the frequency spectrum of electromagnetic emissions, enabling the identification of specific frequencies associated with coil whine. This information is crucial for developing targeted mitigation strategies and ensuring compliance with EMC standards.

Time-domain reflectometry (TDR) is another valuable tool in the EMI testing arsenal. TDR can help identify impedance mismatches and discontinuities in circuit traces that may contribute to coil whine. By analyzing the reflection of high-frequency signals, engineers can optimize circuit layouts to minimize EMI.

Conducted emissions testing is essential for assessing the EMI that propagates through power and signal lines. This method involves measuring the electromagnetic noise that travels along cables and wires, which can be a significant contributor to coil whine in interconnected systems.

Radiated emissions testing complements conducted emissions testing by measuring the electromagnetic fields emitted into the surrounding space. This is typically performed in an open area test site (OATS) or a semi-anechoic chamber, using specialized antennas to capture and quantify radiated EMI across a wide frequency range.

Advanced EMI testing methods also include the use of 3D electromagnetic field simulators. These software tools allow engineers to model and predict EMI behavior before physical prototypes are built, significantly reducing development time and costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!