How to Implement Soundproofing Measures for Coil Whine Mitigation?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an electromagnetic phenomenon that occurs in electronic devices, particularly in power supplies and other components with inductors or transformers. This high-frequency noise is caused by the vibration of electromagnetic coils or capacitors under varying electrical loads. The issue has become increasingly prevalent in modern electronics, especially in high-performance computing systems, gaming consoles, and power-intensive devices.

The phenomenon of coil whine has been observed since the early days of electronics, but it has gained more attention in recent years due to the increasing power demands and miniaturization of electronic devices. As components are packed more tightly and operate at higher frequencies, the likelihood of coil whine increases. This has led to a growing concern among manufacturers and consumers alike, as the noise can be both annoying and indicative of potential efficiency issues.

Coil whine is typically characterized by a high-pitched buzzing, whining, or squealing sound that varies in intensity based on the device's workload. The frequency of this noise can range from audible levels to ultrasonic frequencies, sometimes extending beyond human hearing capabilities. The sound is often more noticeable in quiet environments or when the device is under heavy load, such as during intense gaming sessions or complex computational tasks.

The root cause of coil whine lies in the physical properties of electromagnetic components. When alternating current flows through a coil, it creates a fluctuating magnetic field. This field can cause the coil's windings to vibrate at the same frequency as the current, resulting in audible noise. Similarly, capacitors can produce noise due to the expansion and contraction of their dielectric material under varying voltage conditions.

Several factors contribute to the severity of coil whine, including the quality of components, circuit design, power supply efficiency, and overall system architecture. Lower-quality components or poorly designed circuits are more susceptible to this issue. Additionally, the increasing complexity of modern electronic devices, with their multiple power states and dynamic load variations, can exacerbate the problem.

The impact of coil whine extends beyond mere annoyance. In professional environments, such as recording studios or quiet office spaces, the noise can be disruptive and affect productivity. For consumers, it can detract from the user experience, particularly in devices like high-end graphics cards or gaming consoles where immersion is crucial. Furthermore, persistent coil whine may indicate inefficiencies in power delivery, potentially leading to increased power consumption and reduced component lifespan.

As the demand for more powerful and compact electronic devices continues to grow, addressing coil whine has become a significant challenge for manufacturers. The issue intersects with various aspects of product design, including electrical engineering, materials science, and acoustic engineering. Consequently, developing effective soundproofing measures for coil whine mitigation requires a multidisciplinary approach, combining innovative materials, advanced circuit design techniques, and sophisticated noise cancellation technologies.

The phenomenon of coil whine has been observed since the early days of electronics, but it has gained more attention in recent years due to the increasing power demands and miniaturization of electronic devices. As components are packed more tightly and operate at higher frequencies, the likelihood of coil whine increases. This has led to a growing concern among manufacturers and consumers alike, as the noise can be both annoying and indicative of potential efficiency issues.

Coil whine is typically characterized by a high-pitched buzzing, whining, or squealing sound that varies in intensity based on the device's workload. The frequency of this noise can range from audible levels to ultrasonic frequencies, sometimes extending beyond human hearing capabilities. The sound is often more noticeable in quiet environments or when the device is under heavy load, such as during intense gaming sessions or complex computational tasks.

The root cause of coil whine lies in the physical properties of electromagnetic components. When alternating current flows through a coil, it creates a fluctuating magnetic field. This field can cause the coil's windings to vibrate at the same frequency as the current, resulting in audible noise. Similarly, capacitors can produce noise due to the expansion and contraction of their dielectric material under varying voltage conditions.

Several factors contribute to the severity of coil whine, including the quality of components, circuit design, power supply efficiency, and overall system architecture. Lower-quality components or poorly designed circuits are more susceptible to this issue. Additionally, the increasing complexity of modern electronic devices, with their multiple power states and dynamic load variations, can exacerbate the problem.

The impact of coil whine extends beyond mere annoyance. In professional environments, such as recording studios or quiet office spaces, the noise can be disruptive and affect productivity. For consumers, it can detract from the user experience, particularly in devices like high-end graphics cards or gaming consoles where immersion is crucial. Furthermore, persistent coil whine may indicate inefficiencies in power delivery, potentially leading to increased power consumption and reduced component lifespan.

As the demand for more powerful and compact electronic devices continues to grow, addressing coil whine has become a significant challenge for manufacturers. The issue intersects with various aspects of product design, including electrical engineering, materials science, and acoustic engineering. Consequently, developing effective soundproofing measures for coil whine mitigation requires a multidisciplinary approach, combining innovative materials, advanced circuit design techniques, and sophisticated noise cancellation technologies.

Market Need Analysis

The market demand for effective coil whine mitigation solutions has been steadily increasing in recent years, driven by the growing prevalence of electronic devices in both consumer and industrial sectors. Coil whine, a high-pitched noise produced by electromagnetic components, has become a significant concern for manufacturers and end-users alike, affecting product quality, user experience, and overall device performance.

In the consumer electronics market, there is a strong demand for quieter devices, particularly in personal computers, gaming consoles, and high-end audio equipment. Users are becoming increasingly sensitive to noise pollution, and coil whine can be a major source of irritation. This has led to a surge in customer complaints and negative product reviews, prompting manufacturers to prioritize soundproofing measures in their design processes.

The industrial sector also faces challenges related to coil whine, especially in power supply units, transformers, and large-scale electrical equipment. Noise reduction in these applications is crucial for workplace safety, compliance with noise regulations, and overall operational efficiency. Industries such as manufacturing, energy, and telecommunications are actively seeking solutions to mitigate coil whine in their equipment.

The automotive industry represents another significant market for coil whine mitigation technologies. As electric and hybrid vehicles gain popularity, the need for quiet and efficient power electronics becomes more pressing. Consumers expect a silent and comfortable driving experience, making coil whine reduction a key factor in vehicle design and engineering.

Market research indicates that the global noise control system market, which includes solutions for coil whine mitigation, is experiencing substantial growth. This growth is attributed to increasing urbanization, stricter noise pollution regulations, and the rising demand for quieter electronic devices and machinery.

The demand for coil whine mitigation solutions is not limited to hardware modifications. There is also a growing market for software-based approaches, such as adaptive noise cancellation algorithms and intelligent power management systems. These solutions are particularly attractive for manufacturers looking to address coil whine issues in existing products through firmware updates.

As awareness of the negative impacts of noise pollution on health and well-being continues to rise, the market for coil whine mitigation technologies is expected to expand further. This presents significant opportunities for companies specializing in acoustic engineering, materials science, and electronic design to develop innovative soundproofing measures tailored to address the specific challenges of coil whine in various applications.

In the consumer electronics market, there is a strong demand for quieter devices, particularly in personal computers, gaming consoles, and high-end audio equipment. Users are becoming increasingly sensitive to noise pollution, and coil whine can be a major source of irritation. This has led to a surge in customer complaints and negative product reviews, prompting manufacturers to prioritize soundproofing measures in their design processes.

The industrial sector also faces challenges related to coil whine, especially in power supply units, transformers, and large-scale electrical equipment. Noise reduction in these applications is crucial for workplace safety, compliance with noise regulations, and overall operational efficiency. Industries such as manufacturing, energy, and telecommunications are actively seeking solutions to mitigate coil whine in their equipment.

The automotive industry represents another significant market for coil whine mitigation technologies. As electric and hybrid vehicles gain popularity, the need for quiet and efficient power electronics becomes more pressing. Consumers expect a silent and comfortable driving experience, making coil whine reduction a key factor in vehicle design and engineering.

Market research indicates that the global noise control system market, which includes solutions for coil whine mitigation, is experiencing substantial growth. This growth is attributed to increasing urbanization, stricter noise pollution regulations, and the rising demand for quieter electronic devices and machinery.

The demand for coil whine mitigation solutions is not limited to hardware modifications. There is also a growing market for software-based approaches, such as adaptive noise cancellation algorithms and intelligent power management systems. These solutions are particularly attractive for manufacturers looking to address coil whine issues in existing products through firmware updates.

As awareness of the negative impacts of noise pollution on health and well-being continues to rise, the market for coil whine mitigation technologies is expected to expand further. This presents significant opportunities for companies specializing in acoustic engineering, materials science, and electronic design to develop innovative soundproofing measures tailored to address the specific challenges of coil whine in various applications.

Current Challenges

Coil whine mitigation through soundproofing measures faces several significant challenges in the current technological landscape. One of the primary obstacles is the complex nature of coil whine itself, which can occur at various frequencies and intensities depending on the specific electronic components and their operating conditions. This variability makes it difficult to develop a one-size-fits-all solution for soundproofing.

Another challenge lies in the trade-off between effective soundproofing and thermal management. Electronic devices, particularly those prone to coil whine such as power supplies and graphics cards, often require efficient heat dissipation. Implementing comprehensive soundproofing measures can potentially impede airflow and heat transfer, leading to thermal issues that may affect performance and longevity of the components.

The miniaturization trend in electronics poses an additional hurdle for coil whine mitigation. As devices become smaller and more compact, the available space for implementing soundproofing materials and techniques becomes increasingly limited. This constraint makes it challenging to incorporate effective acoustic treatments without compromising the form factor or increasing the overall size of the device.

Cost considerations also present a significant challenge in implementing soundproofing measures for coil whine mitigation. High-quality acoustic materials and advanced dampening techniques can be expensive, potentially increasing the production costs of electronic devices. Manufacturers must balance the need for effective noise reduction with maintaining competitive pricing in the market.

Furthermore, the dynamic nature of electronic circuits complicates the implementation of soundproofing measures. Coil whine can be influenced by various factors such as voltage fluctuations, load changes, and even software-driven power management features. Developing soundproofing solutions that can adapt to these dynamic conditions while maintaining effectiveness across different operational states remains a complex challenge.

Regulatory compliance and safety standards add another layer of complexity to coil whine mitigation efforts. Any soundproofing measures implemented must not interfere with the device's compliance with electromagnetic compatibility (EMC) regulations or compromise safety features such as proper ventilation and fire resistance.

Lastly, the subjective nature of noise perception presents a challenge in quantifying the effectiveness of soundproofing measures. What may be considered acceptable noise levels for one user might be disruptive for another, making it difficult to establish universal standards for coil whine mitigation across different applications and user expectations.

Another challenge lies in the trade-off between effective soundproofing and thermal management. Electronic devices, particularly those prone to coil whine such as power supplies and graphics cards, often require efficient heat dissipation. Implementing comprehensive soundproofing measures can potentially impede airflow and heat transfer, leading to thermal issues that may affect performance and longevity of the components.

The miniaturization trend in electronics poses an additional hurdle for coil whine mitigation. As devices become smaller and more compact, the available space for implementing soundproofing materials and techniques becomes increasingly limited. This constraint makes it challenging to incorporate effective acoustic treatments without compromising the form factor or increasing the overall size of the device.

Cost considerations also present a significant challenge in implementing soundproofing measures for coil whine mitigation. High-quality acoustic materials and advanced dampening techniques can be expensive, potentially increasing the production costs of electronic devices. Manufacturers must balance the need for effective noise reduction with maintaining competitive pricing in the market.

Furthermore, the dynamic nature of electronic circuits complicates the implementation of soundproofing measures. Coil whine can be influenced by various factors such as voltage fluctuations, load changes, and even software-driven power management features. Developing soundproofing solutions that can adapt to these dynamic conditions while maintaining effectiveness across different operational states remains a complex challenge.

Regulatory compliance and safety standards add another layer of complexity to coil whine mitigation efforts. Any soundproofing measures implemented must not interfere with the device's compliance with electromagnetic compatibility (EMC) regulations or compromise safety features such as proper ventilation and fire resistance.

Lastly, the subjective nature of noise perception presents a challenge in quantifying the effectiveness of soundproofing measures. What may be considered acceptable noise levels for one user might be disruptive for another, making it difficult to establish universal standards for coil whine mitigation across different applications and user expectations.

Existing Solutions

01 Acoustic insulation materials for coil whine reduction

Various acoustic insulation materials can be used to reduce coil whine. These materials absorb sound waves and prevent them from propagating, effectively reducing the noise from electronic components. Common materials include foam, fiberglass, and specialized sound-absorbing panels. These can be applied to the interior of electronic devices or used to create barriers around noise-producing components.- Acoustic insulation materials for coil whine reduction: Various acoustic insulation materials can be used to reduce coil whine. These materials absorb sound waves and vibrations, effectively dampening the high-frequency noise produced by electrical coils. Common materials include foam, fiberglass, and specialized sound-absorbing panels. These can be applied to the interior of electronic devices or used to create barriers around noise-producing components.

- Vibration isolation techniques: Implementing vibration isolation techniques can help minimize coil whine. This involves using materials or components that absorb or redirect vibrations, preventing them from propagating through the device structure. Methods may include using rubber mounts, shock absorbers, or specialized damping materials to isolate the coil or other vibrating components from the rest of the device.

- Enclosure design for sound reduction: Optimizing the design of device enclosures can significantly reduce coil whine. This may involve creating sealed compartments, using sound-absorbing materials in the enclosure lining, or implementing resonance-canceling structures. The enclosure can be engineered to reflect or absorb sound waves, preventing them from escaping the device.

- Active noise cancellation systems: Active noise cancellation technology can be employed to counteract coil whine. This involves using microphones to detect the noise and generating an inverse sound wave to cancel it out. While traditionally used in headphones, this technology can be adapted for use in electronic devices to reduce coil whine and other electronic noises.

- Coil design and manufacturing improvements: Addressing coil whine at the source involves improving the design and manufacturing of the coils themselves. This can include using higher quality materials, implementing better winding techniques, or applying coatings that reduce vibration. Advanced manufacturing processes can help create coils that are less prone to producing audible noise during operation.

02 Vibration dampening techniques for coil whine mitigation

Vibration dampening techniques can be employed to reduce coil whine. These methods focus on minimizing the physical vibrations that cause the noise. Techniques may include using rubber or silicone mounts, applying damping compounds to coils, or implementing specialized vibration-absorbing materials. By reducing vibrations, the audible noise from coils can be significantly decreased.Expand Specific Solutions03 Enclosure design for coil whine soundproofing

Proper enclosure design plays a crucial role in soundproofing against coil whine. This involves creating sealed compartments within electronic devices to isolate noise-producing components. The enclosures can be lined with sound-absorbing materials and designed with baffles or labyrinths to trap sound waves. Additionally, the shape and material of the enclosure itself can be optimized for sound reduction.Expand Specific Solutions04 Active noise cancellation for coil whine

Active noise cancellation technology can be applied to counteract coil whine. This involves using microphones to detect the noise and generating an inverse sound wave to cancel it out. While traditionally used in headphones, this technology can be adapted for use in electronic devices to reduce coil whine at the source or in the surrounding environment.Expand Specific Solutions05 Electromagnetic shielding to reduce coil whine

Electromagnetic shielding can be effective in reducing coil whine. By encasing coils or other electromagnetic components in conductive materials, the electromagnetic fields that contribute to the noise can be contained. This not only helps in reducing the audible whine but also improves the overall electromagnetic compatibility of the device.Expand Specific Solutions

Key Industry Players

The soundproofing measures for coil whine mitigation market is in its growth stage, with increasing demand driven by the rising awareness of noise pollution in electronic devices. The global market size is estimated to be in the hundreds of millions of dollars, with steady growth projected. Technologically, solutions are evolving from basic insulation to advanced active noise cancellation techniques. Companies like Delta Electronics, Murata Manufacturing, and TDK Corp. are at the forefront, developing innovative materials and components for effective coil whine reduction. Other players such as DENSO Corp. and Samsung Electronics are also contributing to advancements in this field, particularly in automotive and consumer electronics applications.

Delta Electronics, Inc.

Technical Solution: Delta Electronics has developed advanced soundproofing measures for coil whine mitigation in power supplies and electronic components. Their approach involves a multi-layered solution combining electromagnetic shielding, vibration dampening, and acoustic absorption techniques. The company utilizes specialized materials such as ferrite cores and nanocrystalline alloys to reduce electromagnetic interference, which is a primary cause of coil whine[1]. Additionally, Delta has implemented innovative encapsulation methods, using high-density potting compounds to minimize vibrations and contain sound waves[3]. Their latest designs incorporate active noise cancellation technology, which detects and counteracts coil whine frequencies in real-time, significantly reducing audible noise in sensitive applications like data centers and home electronics[5].

Strengths: Comprehensive approach addressing multiple aspects of coil whine; integration of cutting-edge materials and active noise cancellation. Weaknesses: Potential increase in production costs; may require redesign of existing products to implement fully.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has pioneered innovative soundproofing techniques for coil whine mitigation, focusing on the design and manufacturing of high-quality inductors and transformers. Their approach centers on optimizing the coil winding process and material selection to minimize mechanical vibrations at their source. Murata employs advanced winding techniques, such as orthocyclic winding, which reduces air gaps between wire turns and enhances structural integrity[2]. They have also developed proprietary magnetic core materials with improved magnetostriction properties, significantly reducing the physical deformation that leads to coil whine[4]. Furthermore, Murata has implemented a unique coating process that applies a thin layer of vibration-damping material directly to the coil windings, effectively absorbing micro-vibrations before they can propagate as audible noise[6].

Strengths: Addresses coil whine at the component level; highly effective for a wide range of applications. Weaknesses: May be more challenging to implement in existing designs; potentially higher component costs.

Core Technologies

Methods and systems for magnetic stimulation

PatentPendingUS20220080217A1

Innovation

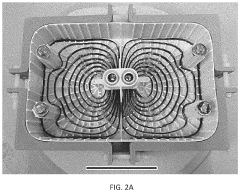

- A double-containment coil design with an air gap and sound-absorbing materials, where the winding block is mounted at acoustic nodes to minimize vibrations and sound transmission, and an outer casing with optimized thickness and sound-absorbing panels to reduce acoustic noise.

Material Advancements

Material advancements play a crucial role in the development of effective soundproofing measures for coil whine mitigation. Recent innovations in material science have led to the creation of new compounds and composites specifically designed to absorb and dampen high-frequency vibrations associated with coil whine. These materials offer improved performance over traditional soundproofing solutions, providing more targeted and efficient noise reduction.

One significant advancement is the development of viscoelastic polymers with enhanced damping properties. These materials exhibit both viscous and elastic characteristics, allowing them to effectively dissipate vibrational energy across a wide frequency range. When applied as coatings or interlayers in electronic components, these polymers can significantly reduce the transmission of coil whine-induced vibrations.

Nanocomposite materials have also emerged as promising candidates for coil whine mitigation. By incorporating nanoparticles into polymer matrices, researchers have created materials with exceptional sound absorption capabilities. These nanocomposites can be tailored to target specific frequency ranges, making them particularly effective for addressing the high-frequency noise associated with coil whine.

Advances in metamaterials have opened up new possibilities for soundproofing. These engineered structures, composed of precisely arranged subwavelength units, can manipulate acoustic waves in ways not possible with conventional materials. Acoustic metamaterials designed to create frequency bandgaps or negative refraction effects show great potential for redirecting or absorbing coil whine-induced vibrations.

The development of multi-layered acoustic materials has also contributed to improved soundproofing solutions. By combining different materials with complementary properties, engineers can create composite structures that provide broadband noise reduction. These multi-layered systems often incorporate combinations of dense, rigid materials for reflection and porous, absorptive materials for energy dissipation.

Advancements in aerogel technology have led to the creation of ultra-lightweight, highly porous materials with excellent sound absorption properties. These materials, characterized by their low density and high surface area, can effectively trap and dissipate acoustic energy. When used in conjunction with other soundproofing measures, aerogels can significantly enhance overall noise reduction performance.

The integration of phase-change materials (PCMs) into soundproofing solutions represents another innovative approach. PCMs can absorb and release thermal energy during phase transitions, which can be leveraged to dampen vibrations and reduce noise. By incorporating PCMs into electronic component enclosures or surrounding structures, it is possible to create adaptive soundproofing systems that respond to temperature fluctuations associated with device operation.

One significant advancement is the development of viscoelastic polymers with enhanced damping properties. These materials exhibit both viscous and elastic characteristics, allowing them to effectively dissipate vibrational energy across a wide frequency range. When applied as coatings or interlayers in electronic components, these polymers can significantly reduce the transmission of coil whine-induced vibrations.

Nanocomposite materials have also emerged as promising candidates for coil whine mitigation. By incorporating nanoparticles into polymer matrices, researchers have created materials with exceptional sound absorption capabilities. These nanocomposites can be tailored to target specific frequency ranges, making them particularly effective for addressing the high-frequency noise associated with coil whine.

Advances in metamaterials have opened up new possibilities for soundproofing. These engineered structures, composed of precisely arranged subwavelength units, can manipulate acoustic waves in ways not possible with conventional materials. Acoustic metamaterials designed to create frequency bandgaps or negative refraction effects show great potential for redirecting or absorbing coil whine-induced vibrations.

The development of multi-layered acoustic materials has also contributed to improved soundproofing solutions. By combining different materials with complementary properties, engineers can create composite structures that provide broadband noise reduction. These multi-layered systems often incorporate combinations of dense, rigid materials for reflection and porous, absorptive materials for energy dissipation.

Advancements in aerogel technology have led to the creation of ultra-lightweight, highly porous materials with excellent sound absorption properties. These materials, characterized by their low density and high surface area, can effectively trap and dissipate acoustic energy. When used in conjunction with other soundproofing measures, aerogels can significantly enhance overall noise reduction performance.

The integration of phase-change materials (PCMs) into soundproofing solutions represents another innovative approach. PCMs can absorb and release thermal energy during phase transitions, which can be leveraged to dampen vibrations and reduce noise. By incorporating PCMs into electronic component enclosures or surrounding structures, it is possible to create adaptive soundproofing systems that respond to temperature fluctuations associated with device operation.

Acoustic Testing Methods

Acoustic testing methods play a crucial role in evaluating the effectiveness of soundproofing measures for coil whine mitigation. These methods involve a systematic approach to measuring and analyzing sound levels, frequencies, and propagation patterns associated with coil whine in electronic devices.

One of the primary acoustic testing methods is the use of anechoic chambers. These specialized rooms are designed to eliminate external noise and reflections, providing an ideal environment for isolating and measuring coil whine. Within these chambers, high-precision microphones are strategically placed to capture sound emissions from the device under test. The data collected is then analyzed using advanced signal processing techniques to identify the specific frequencies and intensities of coil whine.

Another important testing method is the application of sound intensity mapping. This technique involves using an array of microphones to create a visual representation of sound distribution around the device. By moving the microphone array across a predefined grid, technicians can generate a detailed map of sound intensity levels, helping to pinpoint the exact locations where coil whine is most prominent.

Frequency analysis is a critical component of acoustic testing for coil whine. Fast Fourier Transform (FFT) algorithms are employed to break down the complex sound waves into their constituent frequencies. This analysis allows engineers to identify the specific harmonic components of coil whine, which is essential for developing targeted mitigation strategies.

To simulate real-world conditions, acoustic testing often incorporates environmental stress testing. This involves subjecting the device to various operating conditions, such as different power loads, temperatures, and humidity levels, while continuously monitoring acoustic emissions. Such comprehensive testing helps ensure that soundproofing measures remain effective across a range of operational scenarios.

Comparative testing is another valuable method in the acoustic testing arsenal. This approach involves testing multiple iterations of a device or comparing different soundproofing solutions side by side. By maintaining consistent testing conditions and methodologies, engineers can accurately assess the relative effectiveness of various mitigation techniques.

Lastly, long-term acoustic monitoring is employed to evaluate the durability and consistency of soundproofing measures over time. This method involves continuous or periodic acoustic measurements over extended periods, sometimes spanning weeks or months, to detect any degradation in soundproofing performance or changes in coil whine characteristics.

One of the primary acoustic testing methods is the use of anechoic chambers. These specialized rooms are designed to eliminate external noise and reflections, providing an ideal environment for isolating and measuring coil whine. Within these chambers, high-precision microphones are strategically placed to capture sound emissions from the device under test. The data collected is then analyzed using advanced signal processing techniques to identify the specific frequencies and intensities of coil whine.

Another important testing method is the application of sound intensity mapping. This technique involves using an array of microphones to create a visual representation of sound distribution around the device. By moving the microphone array across a predefined grid, technicians can generate a detailed map of sound intensity levels, helping to pinpoint the exact locations where coil whine is most prominent.

Frequency analysis is a critical component of acoustic testing for coil whine. Fast Fourier Transform (FFT) algorithms are employed to break down the complex sound waves into their constituent frequencies. This analysis allows engineers to identify the specific harmonic components of coil whine, which is essential for developing targeted mitigation strategies.

To simulate real-world conditions, acoustic testing often incorporates environmental stress testing. This involves subjecting the device to various operating conditions, such as different power loads, temperatures, and humidity levels, while continuously monitoring acoustic emissions. Such comprehensive testing helps ensure that soundproofing measures remain effective across a range of operational scenarios.

Comparative testing is another valuable method in the acoustic testing arsenal. This approach involves testing multiple iterations of a device or comparing different soundproofing solutions side by side. By maintaining consistent testing conditions and methodologies, engineers can accurately assess the relative effectiveness of various mitigation techniques.

Lastly, long-term acoustic monitoring is employed to evaluate the durability and consistency of soundproofing measures over time. This method involves continuous or periodic acoustic measurements over extended periods, sometimes spanning weeks or months, to detect any degradation in soundproofing performance or changes in coil whine characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!