Adsorbent vs Membrane Approaches to DAC: When to Use Each Technology

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DAC Technology Evolution

Direct Air Capture (DAC) technology has undergone significant evolution since its inception, driven by the urgent need to address climate change and reduce atmospheric CO2 levels. The development of DAC can be traced back to the early 2000s when researchers began exploring methods to extract CO2 directly from ambient air.

Initially, DAC systems were primarily based on liquid sorbents, such as sodium hydroxide solutions. These early designs were energy-intensive and faced challenges in scalability. As research progressed, solid sorbents emerged as a promising alternative, offering improved efficiency and lower energy requirements.

The mid-2010s saw a shift towards more advanced adsorbent materials, including metal-organic frameworks (MOFs) and amine-functionalized silica. These materials demonstrated higher CO2 selectivity and capacity, leading to increased interest from both academic and industrial sectors.

Concurrently, membrane-based approaches for DAC began to gain traction. Early membrane technologies struggled with low permeability and selectivity, but advancements in material science led to the development of more efficient mixed-matrix and facilitated transport membranes.

A significant milestone in DAC evolution was the establishment of the first commercial plants in the late 2010s. These facilities, primarily using amine-based solid sorbents, demonstrated the feasibility of large-scale atmospheric CO2 capture.

Recent years have seen a convergence of adsorbent and membrane technologies, with hybrid systems emerging as a potential solution to overcome the limitations of individual approaches. These systems aim to combine the high selectivity of adsorbents with the continuous operation capabilities of membranes.

The evolution of DAC has also been marked by improvements in process integration and energy efficiency. Early systems required substantial thermal energy for sorbent regeneration, but newer designs incorporate low-grade heat sources and innovative heat management strategies to reduce overall energy consumption.

As DAC technology continues to mature, research efforts are focusing on enhancing CO2 capture rates, reducing costs, and improving the environmental footprint of the process. This includes exploring novel materials, optimizing system designs, and developing more efficient regeneration methods.

The trajectory of DAC evolution suggests a future where both adsorbent and membrane approaches play complementary roles. Adsorbent-based systems may dominate in scenarios requiring high purity CO2 output, while membrane technologies could excel in applications prioritizing continuous operation and lower energy consumption.

Initially, DAC systems were primarily based on liquid sorbents, such as sodium hydroxide solutions. These early designs were energy-intensive and faced challenges in scalability. As research progressed, solid sorbents emerged as a promising alternative, offering improved efficiency and lower energy requirements.

The mid-2010s saw a shift towards more advanced adsorbent materials, including metal-organic frameworks (MOFs) and amine-functionalized silica. These materials demonstrated higher CO2 selectivity and capacity, leading to increased interest from both academic and industrial sectors.

Concurrently, membrane-based approaches for DAC began to gain traction. Early membrane technologies struggled with low permeability and selectivity, but advancements in material science led to the development of more efficient mixed-matrix and facilitated transport membranes.

A significant milestone in DAC evolution was the establishment of the first commercial plants in the late 2010s. These facilities, primarily using amine-based solid sorbents, demonstrated the feasibility of large-scale atmospheric CO2 capture.

Recent years have seen a convergence of adsorbent and membrane technologies, with hybrid systems emerging as a potential solution to overcome the limitations of individual approaches. These systems aim to combine the high selectivity of adsorbents with the continuous operation capabilities of membranes.

The evolution of DAC has also been marked by improvements in process integration and energy efficiency. Early systems required substantial thermal energy for sorbent regeneration, but newer designs incorporate low-grade heat sources and innovative heat management strategies to reduce overall energy consumption.

As DAC technology continues to mature, research efforts are focusing on enhancing CO2 capture rates, reducing costs, and improving the environmental footprint of the process. This includes exploring novel materials, optimizing system designs, and developing more efficient regeneration methods.

The trajectory of DAC evolution suggests a future where both adsorbent and membrane approaches play complementary roles. Adsorbent-based systems may dominate in scenarios requiring high purity CO2 output, while membrane technologies could excel in applications prioritizing continuous operation and lower energy consumption.

Carbon Removal Market

The carbon removal market has experienced significant growth in recent years, driven by increasing global awareness of climate change and the urgent need to reduce atmospheric carbon dioxide levels. This market encompasses various technologies and approaches aimed at capturing and sequestering carbon dioxide from the atmosphere, with Direct Air Capture (DAC) emerging as a promising solution.

The global carbon removal market is projected to expand rapidly in the coming decades. According to industry reports, the market size for carbon capture and storage technologies is expected to grow substantially, with estimates ranging from tens to hundreds of billions of dollars by 2050. This growth is fueled by both public and private sector investments, as well as supportive government policies and regulations.

Direct Air Capture, a key component of the carbon removal market, has garnered significant attention and investment. Several companies have developed and deployed DAC technologies, with both adsorbent and membrane-based approaches showing promise. The market for DAC is still in its early stages but is poised for rapid expansion as the technology matures and costs decrease.

Demand for carbon removal solutions is driven by various factors, including corporate sustainability goals, national and international climate commitments, and the growing recognition of the need for negative emissions technologies to meet global climate targets. Many large corporations have pledged to achieve net-zero emissions, creating a substantial market for carbon removal credits and technologies.

The carbon removal market is characterized by a diverse range of players, from startups developing innovative capture technologies to established energy companies investing in large-scale carbon capture and storage projects. Government support, in the form of research funding, tax incentives, and regulatory frameworks, plays a crucial role in shaping the market landscape and driving innovation.

Challenges in the carbon removal market include high costs, scalability issues, and the need for supportive infrastructure and policies. However, ongoing technological advancements and increasing investment are expected to address these challenges over time. The market is also influenced by factors such as carbon pricing mechanisms, international climate agreements, and public perception of carbon removal technologies.

As the carbon removal market continues to evolve, it is likely to see increased competition, technological breakthroughs, and the emergence of new business models. The integration of carbon removal solutions into broader climate mitigation strategies and the development of robust carbon markets are expected to further drive growth and innovation in this sector.

The global carbon removal market is projected to expand rapidly in the coming decades. According to industry reports, the market size for carbon capture and storage technologies is expected to grow substantially, with estimates ranging from tens to hundreds of billions of dollars by 2050. This growth is fueled by both public and private sector investments, as well as supportive government policies and regulations.

Direct Air Capture, a key component of the carbon removal market, has garnered significant attention and investment. Several companies have developed and deployed DAC technologies, with both adsorbent and membrane-based approaches showing promise. The market for DAC is still in its early stages but is poised for rapid expansion as the technology matures and costs decrease.

Demand for carbon removal solutions is driven by various factors, including corporate sustainability goals, national and international climate commitments, and the growing recognition of the need for negative emissions technologies to meet global climate targets. Many large corporations have pledged to achieve net-zero emissions, creating a substantial market for carbon removal credits and technologies.

The carbon removal market is characterized by a diverse range of players, from startups developing innovative capture technologies to established energy companies investing in large-scale carbon capture and storage projects. Government support, in the form of research funding, tax incentives, and regulatory frameworks, plays a crucial role in shaping the market landscape and driving innovation.

Challenges in the carbon removal market include high costs, scalability issues, and the need for supportive infrastructure and policies. However, ongoing technological advancements and increasing investment are expected to address these challenges over time. The market is also influenced by factors such as carbon pricing mechanisms, international climate agreements, and public perception of carbon removal technologies.

As the carbon removal market continues to evolve, it is likely to see increased competition, technological breakthroughs, and the emergence of new business models. The integration of carbon removal solutions into broader climate mitigation strategies and the development of robust carbon markets are expected to further drive growth and innovation in this sector.

Adsorbent vs Membrane

Direct Air Capture (DAC) technologies are crucial in the fight against climate change, with adsorbent and membrane approaches emerging as two primary contenders. Adsorbents, typically solid materials with high surface areas, capture CO2 through physical or chemical interactions. These materials, such as zeolites, metal-organic frameworks (MOFs), or amine-functionalized sorbents, can be regenerated through temperature or pressure swings.

Membrane-based systems, on the other hand, utilize selective permeation to separate CO2 from air. These membranes are often made from polymers or advanced materials with specific pore sizes or chemical properties that allow CO2 to pass through while blocking other gases. The separation process is driven by pressure or concentration gradients across the membrane.

The choice between adsorbent and membrane technologies depends on various factors, including capture efficiency, energy requirements, scalability, and operational conditions. Adsorbents generally offer high selectivity and capacity for CO2 capture, making them suitable for applications where high purity is required. They can operate effectively at atmospheric pressure, which is advantageous for DAC applications.

Membrane systems, while potentially less energy-intensive in certain configurations, may struggle with the low CO2 concentration in ambient air. However, they offer continuous operation and can be more compact, making them attractive for space-constrained applications or where integration with existing processes is necessary.

Adsorbent technologies are currently more mature in the DAC field, with several large-scale projects already operational or in development. Companies like Climeworks and Carbon Engineering have demonstrated the feasibility of adsorbent-based DAC at commercial scales. Membrane technologies, while showing promise, are still largely in the research and development phase for DAC applications.

The decision to use adsorbent or membrane technology also depends on the specific end-use of the captured CO2. For applications requiring high-purity CO2, such as synthetic fuel production or food-grade CO2, adsorbent technologies may be preferred due to their higher selectivity. Membrane systems might be more suitable for applications where moderate purity is acceptable, or where integration with other gas separation processes is beneficial.

In practice, hybrid systems combining both adsorbent and membrane technologies are being explored to leverage the strengths of each approach. These hybrid systems aim to optimize energy efficiency, capture rates, and overall system performance by utilizing membranes for initial concentration of CO2 followed by adsorbent-based purification.

Membrane-based systems, on the other hand, utilize selective permeation to separate CO2 from air. These membranes are often made from polymers or advanced materials with specific pore sizes or chemical properties that allow CO2 to pass through while blocking other gases. The separation process is driven by pressure or concentration gradients across the membrane.

The choice between adsorbent and membrane technologies depends on various factors, including capture efficiency, energy requirements, scalability, and operational conditions. Adsorbents generally offer high selectivity and capacity for CO2 capture, making them suitable for applications where high purity is required. They can operate effectively at atmospheric pressure, which is advantageous for DAC applications.

Membrane systems, while potentially less energy-intensive in certain configurations, may struggle with the low CO2 concentration in ambient air. However, they offer continuous operation and can be more compact, making them attractive for space-constrained applications or where integration with existing processes is necessary.

Adsorbent technologies are currently more mature in the DAC field, with several large-scale projects already operational or in development. Companies like Climeworks and Carbon Engineering have demonstrated the feasibility of adsorbent-based DAC at commercial scales. Membrane technologies, while showing promise, are still largely in the research and development phase for DAC applications.

The decision to use adsorbent or membrane technology also depends on the specific end-use of the captured CO2. For applications requiring high-purity CO2, such as synthetic fuel production or food-grade CO2, adsorbent technologies may be preferred due to their higher selectivity. Membrane systems might be more suitable for applications where moderate purity is acceptable, or where integration with other gas separation processes is beneficial.

In practice, hybrid systems combining both adsorbent and membrane technologies are being explored to leverage the strengths of each approach. These hybrid systems aim to optimize energy efficiency, capture rates, and overall system performance by utilizing membranes for initial concentration of CO2 followed by adsorbent-based purification.

Current DAC Solutions

01 Adsorption materials for CO2 capture

Direct Air Capture (DAC) systems utilize specialized adsorption materials to efficiently capture CO2 from ambient air. These materials are designed to have high selectivity and capacity for CO2, enabling effective removal of greenhouse gases from the atmosphere. The development of novel adsorbents with improved performance characteristics is a key focus in advancing DAC technology.- Adsorption materials for CO2 capture: Direct Air Capture (DAC) systems utilize specialized adsorption materials to efficiently capture CO2 from ambient air. These materials are designed to have high selectivity and capacity for CO2, enabling effective removal of greenhouse gases from the atmosphere. The development of novel adsorbents with improved performance characteristics is a key focus in advancing DAC technology.

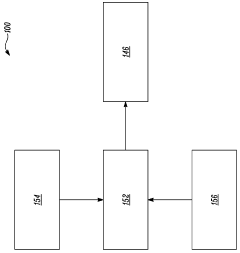

- Regeneration and CO2 release processes: Efficient regeneration of capture materials and controlled release of concentrated CO2 are crucial aspects of DAC systems. This involves developing optimized heating or pressure swing processes to desorb captured CO2 from the adsorbent materials. Innovations in this area aim to reduce energy consumption and improve the overall efficiency of the carbon capture cycle.

- System integration and process optimization: DAC technologies require careful integration of various components and optimization of process parameters to achieve high performance and cost-effectiveness. This includes designing efficient air handling systems, heat management strategies, and control systems to maximize CO2 capture rates while minimizing energy consumption and operational costs.

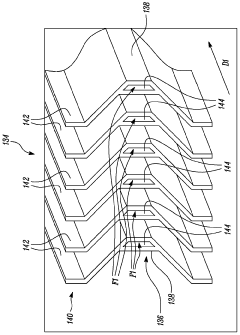

- Modular and scalable DAC designs: Development of modular and scalable DAC systems is essential for widespread deployment and adaptation to various environmental conditions and capture capacity requirements. These designs focus on creating standardized units that can be easily manufactured, transported, and assembled on-site, allowing for flexible implementation and capacity expansion as needed.

- Integration with carbon utilization and storage: Advancing DAC technology involves developing integrated solutions that combine CO2 capture with utilization or long-term storage options. This includes exploring synergies with enhanced oil recovery, synthetic fuel production, or geological sequestration to create closed-loop carbon management systems and improve the economic viability of DAC operations.

02 Regeneration processes for DAC systems

Efficient regeneration of CO2 capture materials is crucial for the continuous operation of DAC systems. Various methods are employed to release captured CO2 and prepare the adsorbents for reuse, including temperature swing adsorption (TSA), pressure swing adsorption (PSA), and vacuum swing adsorption (VSA). Optimizing these regeneration processes can significantly improve the overall efficiency and cost-effectiveness of DAC technology.Expand Specific Solutions03 Integration of DAC with renewable energy sources

To minimize the carbon footprint of DAC operations, integration with renewable energy sources is being explored. This approach involves coupling DAC systems with solar, wind, or geothermal power to provide the energy required for CO2 capture and regeneration processes. Such integration can enhance the sustainability and environmental benefits of DAC technology.Expand Specific Solutions04 Modular and scalable DAC designs

Developing modular and scalable DAC systems is essential for widespread deployment and adaptation to various geographical and operational contexts. These designs allow for easier transportation, installation, and expansion of DAC facilities. Modular approaches also enable more flexible integration with existing infrastructure and can be tailored to specific capacity requirements.Expand Specific Solutions05 CO2 utilization and storage methods

Effective utilization and storage of captured CO2 are critical components of DAC technology. Various approaches are being developed, including conversion of CO2 into valuable products, enhanced oil recovery, and geological sequestration. These methods aim to create economic incentives for DAC implementation while ensuring long-term storage of captured carbon dioxide.Expand Specific Solutions

Key DAC Industry Players

The direct air capture (DAC) technology market is in its early growth stage, characterized by rapid innovation and increasing competition. The market size is expanding, driven by growing demand for carbon removal solutions, though still relatively small compared to established climate technologies. Technologically, both adsorbent and membrane approaches are advancing, with companies like Climeworks AG and Carboncapture, Inc. leading in adsorbent-based DAC, while firms such as W. L. Gore & Associates explore membrane technologies. The competitive landscape includes established industrial players like Siemens Energy and Volkswagen AG entering the field, alongside specialized startups and research institutions. Overall, the technology is progressing towards commercial viability, but further development is needed to reduce costs and scale up operations.

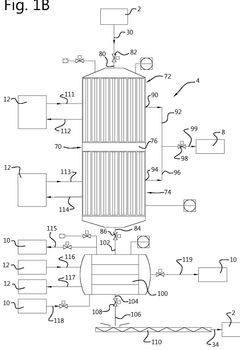

Climeworks AG

Technical Solution: Climeworks employs a two-step direct air capture (DAC) process using solid sorbent technology. Their modular CO2 collectors use a highly selective filter material to capture atmospheric CO2. The process involves air being drawn into the collector with a fan, where CO2 is captured on the surface of the filter material. Once the filter is saturated, the collector is closed and heated to around 100°C, which releases high-purity CO2 that can be collected for utilization or storage. This cycle is repeated every few hours to continuously remove CO2 from ambient air [1][3]. Climeworks' technology can be powered by waste heat or renewable energy, making it adaptable to various locations and energy sources [2].

Strengths: Modular and scalable design, high CO2 selectivity, low-temperature regeneration, and ability to use renewable energy. Weaknesses: Relatively high energy consumption for regeneration and potential for filter material degradation over time.

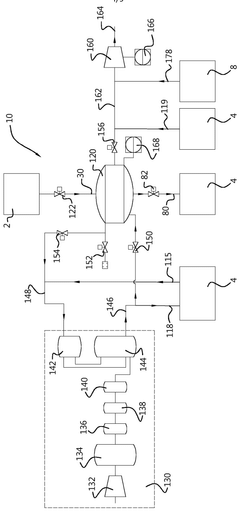

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced membrane technology for various applications, including potential use in direct air capture (DAC) systems. Their ePTFE (expanded polytetrafluoroethylene) membranes offer high permeability and selectivity for gas separation. In the context of DAC, Gore's membranes could be applied in a membrane-based approach, where CO2 is selectively separated from other atmospheric gases. The membrane system would likely operate on pressure or concentration gradients to drive CO2 separation. While specific details of Gore's DAC membrane technology are not publicly available, their expertise in creating high-performance, durable membranes suggests potential for efficient, long-lasting DAC systems with lower energy requirements compared to some adsorbent-based approaches [4][5].

Strengths: High selectivity and permeability, potential for lower energy consumption, and durability of ePTFE membranes. Weaknesses: Possible challenges in scaling up membrane systems for large-scale atmospheric CO2 capture and potential fouling issues in real-world conditions.

DAC Core Innovations

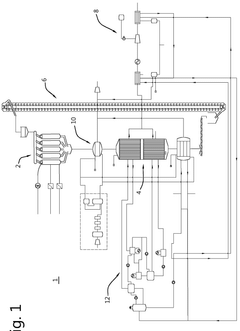

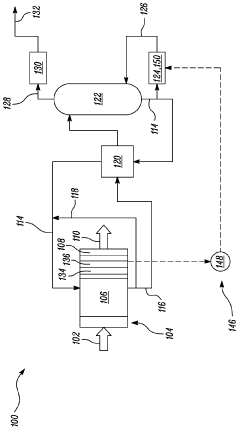

System and method for direct air capture

PatentWO2025141054A1

Innovation

- A system utilizing an adsorber section, regeneration section with multiple desorption stages at distinct temperature levels under vacuum, a transport section, and a heat recovery system with a two-stage heat pump assembly to optimize energy use, incorporating granular sorbent material and high-purity nitrogen purge to enhance adsorption efficiency.

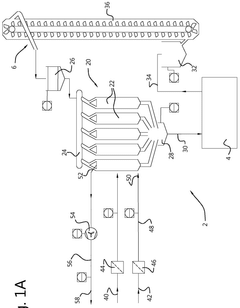

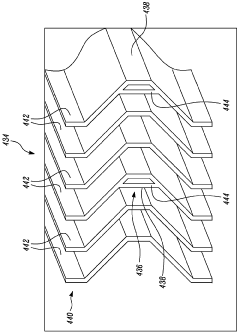

Direct air capture system and method

PatentPendingGB2624212A

Innovation

- Incorporating a mist eliminator and a cooling device in a heat exchange relationship to capture drift/droplets and reduce the temperature of the airflow, thereby reducing evaporation rates and water loss, with optional integration of a refrigeration circuit and heat exchangers to optimize energy use and capture waste heat for further processing.

DAC Policy Landscape

The Direct Air Capture (DAC) policy landscape has evolved significantly in recent years, reflecting growing recognition of the technology's potential role in climate change mitigation. Governments worldwide are increasingly implementing policies to support DAC development and deployment, with varying approaches and levels of commitment.

In the United States, the 45Q tax credit has been a key driver for DAC projects. This policy provides a financial incentive of up to $180 per ton of CO2 captured and permanently stored, making DAC more economically viable. The Inflation Reduction Act of 2022 further enhanced these incentives, increasing the credit amount and extending the eligibility period. Additionally, the Department of Energy has launched funding programs specifically targeting DAC research and development.

The European Union has also taken steps to support DAC through its Innovation Fund, which provides grants for innovative low-carbon technologies. The EU's Carbon Border Adjustment Mechanism, while not directly targeting DAC, creates a more favorable environment for carbon capture technologies by putting a price on carbon emissions associated with imported goods.

At the international level, the Paris Agreement has indirectly bolstered support for DAC by setting ambitious climate targets that may require negative emissions technologies. This has led to increased interest in DAC among policymakers and investors globally.

Several countries have implemented specific policies to promote DAC. For instance, Canada has introduced a federal carbon pricing system and investment tax credits for carbon capture technologies, including DAC. The United Kingdom has included DAC in its industrial decarbonization strategy and allocated funding for research and pilot projects.

Despite these positive developments, the policy landscape for DAC remains fragmented and inconsistent across jurisdictions. Many countries lack specific policies addressing DAC, relying instead on broader climate and energy policies. This inconsistency creates challenges for technology developers and investors seeking to scale up DAC deployment.

Furthermore, there is ongoing debate about the role of DAC in climate policy. Some argue that it should be a central component of mitigation strategies, while others express concerns about potential moral hazard and the need to prioritize emissions reductions. This debate influences policy decisions and the allocation of resources to DAC development.

As the technology continues to mature, it is likely that the policy landscape will evolve further. Key areas of focus may include standardization of carbon accounting methodologies for DAC, integration of DAC into carbon markets and trading schemes, and development of regulatory frameworks for large-scale deployment and CO2 storage.

In the United States, the 45Q tax credit has been a key driver for DAC projects. This policy provides a financial incentive of up to $180 per ton of CO2 captured and permanently stored, making DAC more economically viable. The Inflation Reduction Act of 2022 further enhanced these incentives, increasing the credit amount and extending the eligibility period. Additionally, the Department of Energy has launched funding programs specifically targeting DAC research and development.

The European Union has also taken steps to support DAC through its Innovation Fund, which provides grants for innovative low-carbon technologies. The EU's Carbon Border Adjustment Mechanism, while not directly targeting DAC, creates a more favorable environment for carbon capture technologies by putting a price on carbon emissions associated with imported goods.

At the international level, the Paris Agreement has indirectly bolstered support for DAC by setting ambitious climate targets that may require negative emissions technologies. This has led to increased interest in DAC among policymakers and investors globally.

Several countries have implemented specific policies to promote DAC. For instance, Canada has introduced a federal carbon pricing system and investment tax credits for carbon capture technologies, including DAC. The United Kingdom has included DAC in its industrial decarbonization strategy and allocated funding for research and pilot projects.

Despite these positive developments, the policy landscape for DAC remains fragmented and inconsistent across jurisdictions. Many countries lack specific policies addressing DAC, relying instead on broader climate and energy policies. This inconsistency creates challenges for technology developers and investors seeking to scale up DAC deployment.

Furthermore, there is ongoing debate about the role of DAC in climate policy. Some argue that it should be a central component of mitigation strategies, while others express concerns about potential moral hazard and the need to prioritize emissions reductions. This debate influences policy decisions and the allocation of resources to DAC development.

As the technology continues to mature, it is likely that the policy landscape will evolve further. Key areas of focus may include standardization of carbon accounting methodologies for DAC, integration of DAC into carbon markets and trading schemes, and development of regulatory frameworks for large-scale deployment and CO2 storage.

DAC Environmental Impact

Direct Air Capture (DAC) technologies, including adsorbent and membrane approaches, have significant environmental implications that must be carefully considered. The environmental impact of DAC systems extends beyond their primary function of carbon dioxide removal from the atmosphere.

Adsorbent-based DAC systems typically require substantial energy inputs for the regeneration of sorbent materials. This energy demand can lead to indirect emissions if not sourced from renewable energy. The production and disposal of adsorbent materials also contribute to the overall environmental footprint. However, adsorbent systems often have the advantage of using less water compared to some membrane-based approaches.

Membrane-based DAC technologies, on the other hand, may have lower energy requirements for operation but can be more water-intensive. The manufacturing process for high-performance membranes may involve the use of specialized materials and chemicals, potentially resulting in additional environmental concerns related to production and end-of-life disposal.

Both approaches require infrastructure development, which can impact local ecosystems through land use changes and potential habitat disruption. The scale of DAC deployment necessary to make a significant impact on atmospheric CO2 levels would require extensive facilities, potentially leading to landscape alterations and associated ecological effects.

Water usage is a critical environmental consideration for DAC technologies. While membrane systems often require more water for operation, some adsorbent systems also use water for cooling or as part of the CO2 capture process. In water-stressed regions, the implementation of DAC could exacerbate existing water scarcity issues.

The life cycle assessment of DAC technologies reveals that the environmental benefits of carbon removal must be weighed against the impacts of material production, energy consumption, and waste generation. The carbon payback period – the time required for the DAC system to remove more CO2 than was emitted during its construction and operation – is a crucial metric for evaluating overall environmental efficacy.

Potential positive environmental impacts of DAC include the possibility of utilizing captured CO2 for beneficial purposes, such as enhanced oil recovery or the production of synthetic fuels, which could offset the use of fossil resources. Additionally, large-scale DAC implementation could contribute to local cooling effects, potentially mitigating urban heat island phenomena in deployed areas.

In conclusion, the environmental impact of DAC technologies is multifaceted, encompassing energy use, water consumption, land use, and material lifecycle considerations. The choice between adsorbent and membrane approaches should be made with careful consideration of local environmental conditions and available resources to minimize negative impacts while maximizing the potential for atmospheric carbon dioxide removal.

Adsorbent-based DAC systems typically require substantial energy inputs for the regeneration of sorbent materials. This energy demand can lead to indirect emissions if not sourced from renewable energy. The production and disposal of adsorbent materials also contribute to the overall environmental footprint. However, adsorbent systems often have the advantage of using less water compared to some membrane-based approaches.

Membrane-based DAC technologies, on the other hand, may have lower energy requirements for operation but can be more water-intensive. The manufacturing process for high-performance membranes may involve the use of specialized materials and chemicals, potentially resulting in additional environmental concerns related to production and end-of-life disposal.

Both approaches require infrastructure development, which can impact local ecosystems through land use changes and potential habitat disruption. The scale of DAC deployment necessary to make a significant impact on atmospheric CO2 levels would require extensive facilities, potentially leading to landscape alterations and associated ecological effects.

Water usage is a critical environmental consideration for DAC technologies. While membrane systems often require more water for operation, some adsorbent systems also use water for cooling or as part of the CO2 capture process. In water-stressed regions, the implementation of DAC could exacerbate existing water scarcity issues.

The life cycle assessment of DAC technologies reveals that the environmental benefits of carbon removal must be weighed against the impacts of material production, energy consumption, and waste generation. The carbon payback period – the time required for the DAC system to remove more CO2 than was emitted during its construction and operation – is a crucial metric for evaluating overall environmental efficacy.

Potential positive environmental impacts of DAC include the possibility of utilizing captured CO2 for beneficial purposes, such as enhanced oil recovery or the production of synthetic fuels, which could offset the use of fossil resources. Additionally, large-scale DAC implementation could contribute to local cooling effects, potentially mitigating urban heat island phenomena in deployed areas.

In conclusion, the environmental impact of DAC technologies is multifaceted, encompassing energy use, water consumption, land use, and material lifecycle considerations. The choice between adsorbent and membrane approaches should be made with careful consideration of local environmental conditions and available resources to minimize negative impacts while maximizing the potential for atmospheric carbon dioxide removal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!