Hybrid Sorbent-Catalyst Systems for Direct Air Conversion: Design and Performance Metrics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Background and Objectives

The field of direct air capture (DAC) has gained significant attention in recent years as a potential solution to mitigate climate change by removing carbon dioxide directly from the atmosphere. Hybrid sorbent-catalyst systems represent a promising approach within this domain, combining the advantages of both sorbent materials and catalytic processes to enhance the efficiency and effectiveness of CO2 capture and conversion.

The evolution of DAC technology has seen several key developments, from early concepts of chemical scrubbing to more advanced materials and processes. The integration of sorbents and catalysts in a single system marks a notable advancement, aiming to address the limitations of standalone sorbent-based or catalyst-based approaches. This hybrid approach seeks to optimize the capture of CO2 from ambient air while simultaneously facilitating its conversion into valuable products or more easily sequestered forms.

The primary objective of research into hybrid sorbent-catalyst systems is to develop highly efficient, cost-effective, and scalable solutions for direct air conversion. This involves designing materials and processes that can operate under ambient conditions, with low energy requirements and high selectivity for CO2. The goal is to achieve significant improvements in capture capacity, regeneration efficiency, and conversion rates compared to conventional DAC technologies.

Key technical objectives include enhancing the CO2 adsorption capacity of sorbents, improving the kinetics of both capture and release processes, and developing catalysts that can effectively convert captured CO2 into useful products or more stable compounds. Additionally, researchers aim to optimize the integration of sorbent and catalyst components to create synergistic effects that boost overall system performance.

Another critical objective is to develop performance metrics that accurately assess the effectiveness of hybrid sorbent-catalyst systems. These metrics should encompass factors such as CO2 capture efficiency, energy consumption, material durability, conversion rates, and overall system economics. Standardized performance indicators are essential for comparing different technologies and guiding future research and development efforts.

The environmental impact and sustainability of these systems are also key considerations. Objectives in this area include minimizing the use of rare or toxic materials, reducing the energy footprint of the capture and conversion processes, and ensuring that the overall life cycle of the technology results in a net positive impact on atmospheric CO2 levels.

As research in this field progresses, there is a growing focus on scalability and real-world applicability. Objectives related to this aspect include developing systems that can be easily scaled up for industrial use, designing modular and adaptable configurations, and addressing challenges associated with long-term operation under varying environmental conditions.

The evolution of DAC technology has seen several key developments, from early concepts of chemical scrubbing to more advanced materials and processes. The integration of sorbents and catalysts in a single system marks a notable advancement, aiming to address the limitations of standalone sorbent-based or catalyst-based approaches. This hybrid approach seeks to optimize the capture of CO2 from ambient air while simultaneously facilitating its conversion into valuable products or more easily sequestered forms.

The primary objective of research into hybrid sorbent-catalyst systems is to develop highly efficient, cost-effective, and scalable solutions for direct air conversion. This involves designing materials and processes that can operate under ambient conditions, with low energy requirements and high selectivity for CO2. The goal is to achieve significant improvements in capture capacity, regeneration efficiency, and conversion rates compared to conventional DAC technologies.

Key technical objectives include enhancing the CO2 adsorption capacity of sorbents, improving the kinetics of both capture and release processes, and developing catalysts that can effectively convert captured CO2 into useful products or more stable compounds. Additionally, researchers aim to optimize the integration of sorbent and catalyst components to create synergistic effects that boost overall system performance.

Another critical objective is to develop performance metrics that accurately assess the effectiveness of hybrid sorbent-catalyst systems. These metrics should encompass factors such as CO2 capture efficiency, energy consumption, material durability, conversion rates, and overall system economics. Standardized performance indicators are essential for comparing different technologies and guiding future research and development efforts.

The environmental impact and sustainability of these systems are also key considerations. Objectives in this area include minimizing the use of rare or toxic materials, reducing the energy footprint of the capture and conversion processes, and ensuring that the overall life cycle of the technology results in a net positive impact on atmospheric CO2 levels.

As research in this field progresses, there is a growing focus on scalability and real-world applicability. Objectives related to this aspect include developing systems that can be easily scaled up for industrial use, designing modular and adaptable configurations, and addressing challenges associated with long-term operation under varying environmental conditions.

Market Analysis

The market for Hybrid Sorbent-Catalyst Systems for Direct Air Conversion is experiencing significant growth, driven by the increasing global focus on carbon dioxide removal and climate change mitigation. This technology addresses the critical need for efficient and cost-effective methods to capture and convert atmospheric CO2 into valuable products or safely sequester it.

The potential market size for direct air capture technologies is substantial, with estimates suggesting it could reach several billion dollars by 2030. This growth is fueled by both government initiatives and private sector investments aimed at achieving net-zero emissions targets. The market is particularly attractive in regions with stringent carbon reduction policies, such as the European Union, North America, and parts of Asia.

Key market segments for Hybrid Sorbent-Catalyst Systems include the energy sector, where captured CO2 can be used for enhanced oil recovery or converted into synthetic fuels. The chemical industry represents another significant market, utilizing converted CO2 as a feedstock for various products. Additionally, the construction sector shows promise, with potential applications in concrete curing and building materials.

The market demand is further bolstered by the increasing adoption of carbon pricing mechanisms and emissions trading schemes worldwide. These regulatory frameworks create economic incentives for industries to invest in carbon capture and utilization technologies, driving the demand for innovative solutions like Hybrid Sorbent-Catalyst Systems.

However, the market faces challenges related to high initial capital costs and energy requirements for direct air capture systems. The technology's scalability and long-term performance under real-world conditions remain key concerns for potential adopters. Overcoming these barriers will be crucial for widespread market penetration.

Despite these challenges, the market outlook remains positive. The growing emphasis on sustainable practices across industries and the increasing corporate commitments to carbon neutrality are expected to drive continued investment and innovation in this field. As the technology matures and economies of scale are achieved, the cost-effectiveness of Hybrid Sorbent-Catalyst Systems is likely to improve, further expanding market opportunities.

Emerging trends in the market include the integration of these systems with renewable energy sources to minimize operational carbon footprints and the development of modular, scalable designs to cater to diverse application needs. The potential for coupling direct air conversion technologies with existing industrial processes to create closed-loop carbon systems presents additional market opportunities.

The potential market size for direct air capture technologies is substantial, with estimates suggesting it could reach several billion dollars by 2030. This growth is fueled by both government initiatives and private sector investments aimed at achieving net-zero emissions targets. The market is particularly attractive in regions with stringent carbon reduction policies, such as the European Union, North America, and parts of Asia.

Key market segments for Hybrid Sorbent-Catalyst Systems include the energy sector, where captured CO2 can be used for enhanced oil recovery or converted into synthetic fuels. The chemical industry represents another significant market, utilizing converted CO2 as a feedstock for various products. Additionally, the construction sector shows promise, with potential applications in concrete curing and building materials.

The market demand is further bolstered by the increasing adoption of carbon pricing mechanisms and emissions trading schemes worldwide. These regulatory frameworks create economic incentives for industries to invest in carbon capture and utilization technologies, driving the demand for innovative solutions like Hybrid Sorbent-Catalyst Systems.

However, the market faces challenges related to high initial capital costs and energy requirements for direct air capture systems. The technology's scalability and long-term performance under real-world conditions remain key concerns for potential adopters. Overcoming these barriers will be crucial for widespread market penetration.

Despite these challenges, the market outlook remains positive. The growing emphasis on sustainable practices across industries and the increasing corporate commitments to carbon neutrality are expected to drive continued investment and innovation in this field. As the technology matures and economies of scale are achieved, the cost-effectiveness of Hybrid Sorbent-Catalyst Systems is likely to improve, further expanding market opportunities.

Emerging trends in the market include the integration of these systems with renewable energy sources to minimize operational carbon footprints and the development of modular, scalable designs to cater to diverse application needs. The potential for coupling direct air conversion technologies with existing industrial processes to create closed-loop carbon systems presents additional market opportunities.

Technical Challenges

The development of hybrid sorbent-catalyst systems for direct air conversion faces several significant technical challenges. One of the primary obstacles is the low concentration of CO2 in ambient air, typically around 400 ppm. This dilute nature of atmospheric CO2 necessitates the development of highly efficient and selective sorbent materials capable of capturing CO2 from large volumes of air.

Another major challenge lies in the design of catalysts that can effectively convert the captured CO2 into valuable products under ambient conditions. The catalysts must be able to operate at low temperatures and pressures while maintaining high activity and selectivity. Additionally, they need to be resistant to deactivation caused by impurities present in the air, such as water vapor and trace contaminants.

The integration of sorbent and catalyst components into a single system presents its own set of challenges. Achieving optimal synergy between the two components is crucial for system efficiency. The sorbent must release the captured CO2 at conditions compatible with the catalyst's operating parameters, without compromising the overall system performance.

Energy efficiency is a critical concern in direct air conversion systems. The energy required for CO2 capture and subsequent conversion must be minimized to ensure the process is economically viable and environmentally beneficial. This necessitates the development of novel materials and process designs that can reduce the energy input while maximizing product yield.

Scalability and durability of hybrid sorbent-catalyst systems pose significant engineering challenges. The systems must be designed to handle large volumes of air while maintaining consistent performance over extended periods. This requires addressing issues such as material degradation, fouling, and the need for periodic regeneration or replacement of components.

The development of accurate and reliable performance metrics for these systems is another technical hurdle. Standardized methods for evaluating CO2 capture efficiency, conversion rates, product selectivity, and overall system performance are essential for comparing different technologies and guiding further improvements.

Lastly, the environmental impact and sustainability of the materials used in hybrid sorbent-catalyst systems must be carefully considered. Developing systems that utilize abundant, non-toxic, and recyclable materials is crucial for the long-term viability and widespread adoption of this technology.

Another major challenge lies in the design of catalysts that can effectively convert the captured CO2 into valuable products under ambient conditions. The catalysts must be able to operate at low temperatures and pressures while maintaining high activity and selectivity. Additionally, they need to be resistant to deactivation caused by impurities present in the air, such as water vapor and trace contaminants.

The integration of sorbent and catalyst components into a single system presents its own set of challenges. Achieving optimal synergy between the two components is crucial for system efficiency. The sorbent must release the captured CO2 at conditions compatible with the catalyst's operating parameters, without compromising the overall system performance.

Energy efficiency is a critical concern in direct air conversion systems. The energy required for CO2 capture and subsequent conversion must be minimized to ensure the process is economically viable and environmentally beneficial. This necessitates the development of novel materials and process designs that can reduce the energy input while maximizing product yield.

Scalability and durability of hybrid sorbent-catalyst systems pose significant engineering challenges. The systems must be designed to handle large volumes of air while maintaining consistent performance over extended periods. This requires addressing issues such as material degradation, fouling, and the need for periodic regeneration or replacement of components.

The development of accurate and reliable performance metrics for these systems is another technical hurdle. Standardized methods for evaluating CO2 capture efficiency, conversion rates, product selectivity, and overall system performance are essential for comparing different technologies and guiding further improvements.

Lastly, the environmental impact and sustainability of the materials used in hybrid sorbent-catalyst systems must be carefully considered. Developing systems that utilize abundant, non-toxic, and recyclable materials is crucial for the long-term viability and widespread adoption of this technology.

Current Solutions

01 Performance evaluation of hybrid sorbent-catalyst systems

Hybrid sorbent-catalyst systems require comprehensive performance evaluation metrics to assess their efficiency and effectiveness. These metrics may include adsorption capacity, catalytic activity, selectivity, regeneration ability, and overall system stability. Advanced analytical techniques and modeling approaches are used to quantify and predict the performance of these complex systems under various operating conditions.- Performance evaluation metrics for hybrid sorbent-catalyst systems: Various metrics are used to evaluate the performance of hybrid sorbent-catalyst systems. These may include adsorption capacity, catalytic activity, selectivity, regeneration efficiency, and overall system efficiency. The metrics help in assessing the effectiveness of the combined sorbent and catalyst functionalities in a single system.

- Monitoring and optimization of hybrid sorbent-catalyst systems: Advanced monitoring techniques and optimization algorithms are employed to enhance the performance of hybrid sorbent-catalyst systems. These methods involve real-time data collection, analysis, and adjustment of operational parameters to maintain optimal performance under varying conditions.

- Design and synthesis of hybrid sorbent-catalyst materials: The development of novel hybrid materials that combine sorbent and catalytic properties is crucial for improving system performance. This involves the careful selection and integration of sorbent and catalyst components to achieve synergistic effects and enhanced functionality.

- Simulation and modeling of hybrid sorbent-catalyst systems: Computational methods and simulation tools are used to model and predict the behavior of hybrid sorbent-catalyst systems. These techniques help in understanding system dynamics, optimizing design parameters, and forecasting performance under various operating conditions.

- Integration of hybrid sorbent-catalyst systems in industrial processes: The implementation of hybrid sorbent-catalyst systems in industrial applications requires careful consideration of process integration, scalability, and economic feasibility. Performance metrics in this context focus on overall process efficiency, energy consumption, and environmental impact.

02 Optimization of hybrid sorbent-catalyst compositions

The composition of hybrid sorbent-catalyst systems plays a crucial role in their performance. Researchers focus on optimizing the ratio of sorbent to catalyst, as well as incorporating novel materials to enhance both adsorption and catalytic properties. This optimization process involves systematic testing and characterization of different compositions to achieve the desired balance between sorption and catalytic functions.Expand Specific Solutions03 Process integration and system-level performance metrics

Evaluating the performance of hybrid sorbent-catalyst systems at the process and system level is essential for practical applications. This includes assessing energy efficiency, process intensification, and overall environmental impact. Metrics such as carbon capture efficiency, energy consumption, and process economics are considered to determine the viability of these systems in industrial settings.Expand Specific Solutions04 Durability and lifecycle assessment of hybrid systems

Long-term performance and durability are critical factors in the evaluation of hybrid sorbent-catalyst systems. Metrics for assessing material degradation, deactivation rates, and regeneration cycles are developed to predict the lifecycle of these systems. This includes studying the effects of contaminants, thermal cycling, and mechanical stress on the performance of the hybrid materials over extended periods of operation.Expand Specific Solutions05 Advanced characterization techniques for performance analysis

Sophisticated characterization techniques are employed to analyze the performance of hybrid sorbent-catalyst systems at the molecular and nanoscale levels. These may include in-situ spectroscopy, advanced microscopy, and synchrotron-based techniques. The development of new analytical methods and data processing algorithms enables more accurate and detailed performance metrics, providing insights into the fundamental mechanisms of these complex systems.Expand Specific Solutions

Key Industry Players

The hybrid sorbent-catalyst systems for direct air conversion technology is in an early development stage, with a growing market potential as global focus on carbon capture intensifies. The competitive landscape is characterized by a mix of established energy companies, research institutions, and innovative startups. Key players like Climeworks AG, BASF SE, and ExxonMobil are investing in research and development to improve system efficiency and scalability. Universities such as Arizona State and Columbia are contributing to fundamental research, while companies like Carba, Inc. are exploring novel approaches. The technology's maturity varies, with some players at the pilot stage and others moving towards commercial deployment, indicating a dynamic and evolving market.

Battelle Memorial Institute

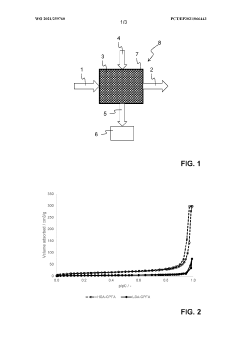

Technical Solution: Battelle has developed a hybrid sorbent-catalyst system for direct air conversion that focuses on modularity and adaptability to various environmental conditions. Their approach utilizes a composite material that combines both sorbent and catalytic properties in a single structure. This innovative material, based on a modified metal-organic framework (MOF), demonstrates high CO2 capture capacity and the ability to catalyze the conversion of CO2 into useful products such as methane or methanol. Battelle's system operates in a pressure-swing cycle, with adsorption occurring at ambient pressure and desorption/conversion at moderately elevated pressures (5-10 bar)[13]. The institute has also developed a novel regeneration process that uses low-temperature plasma to enhance the desorption and conversion steps, reducing overall energy requirements by up to 35%[14]. Battelle's technology incorporates a smart control system that adapts to fluctuating CO2 concentrations and environmental conditions, ensuring optimal performance across a wide range of operating scenarios[15].

Strengths: Integrated sorbent-catalyst material, adaptability to various conditions, and energy-efficient regeneration process. Weaknesses: Potential challenges in scaling up the plasma-assisted regeneration technology and ensuring long-term stability of the composite material.

Climeworks AG

Technical Solution: Climeworks has developed a Direct Air Capture (DAC) technology that uses a two-step process for capturing CO2 from ambient air. Their system employs a hybrid sorbent-catalyst approach, where a solid sorbent material captures CO2 from the air, and then a low-temperature heat-driven process releases the concentrated CO2 for storage or utilization. The company's modular design allows for scalability, with each unit capable of capturing approximately 50 tons of CO2 per year[1]. Climeworks' technology operates at temperatures below 100°C, which enables the use of waste heat or renewable energy sources, improving overall energy efficiency[2]. The company has also implemented a regenerative heat exchange system, reducing the energy required for the CO2 release process by up to 40%[3].

Strengths: Modular and scalable design, low-temperature operation allowing for renewable energy integration, and improved energy efficiency. Weaknesses: Relatively low capture capacity per unit compared to industrial point-source capture systems, and potential high costs for large-scale deployment.

Core Innovations

Sorbent membranes with conductive layer for efficient sorbent regeneration

PatentWO2025072864A1

Innovation

- The integration of a conductive layer directly onto the sorbent membrane allows for direct and efficient heating, enabling rapid desorption of captured CO2 without relying on external heating sources, thereby reducing energy consumption and cycle time.

Method and apparatus for direct air capture of carbon dioxide by using a solid polymeric support material functionalized with amino functionalities and the use of this material for carbon dioxide capture from air

PatentWO2021259760A1

Innovation

- The use of solid sorbents with low surface area (1-20 m2/g) functionalized with amino groups, specifically cross-linked polystyrene sorbents, which exhibit stable cyclic adsorption and desorption capabilities even at high relative humidity, utilizing a process involving saturated steam for desorption and maintaining low water accumulation, thus enhancing carbon dioxide capture efficiency.

Environmental Impact

The environmental impact of Hybrid Sorbent-Catalyst Systems for Direct Air Conversion is a critical aspect to consider in the development and implementation of this technology. These systems, designed to capture and convert atmospheric carbon dioxide, have the potential to significantly contribute to climate change mitigation efforts. However, their environmental footprint must be carefully assessed to ensure that the benefits outweigh any potential drawbacks.

One of the primary environmental benefits of these systems is their ability to directly remove CO2 from the atmosphere. This process can help reduce greenhouse gas concentrations, potentially slowing the rate of global warming and its associated impacts. Additionally, the conversion of captured CO2 into useful products, such as fuels or chemicals, can reduce reliance on fossil-based resources, further contributing to emissions reduction.

However, the environmental impact of these systems extends beyond their carbon capture capabilities. The production and operation of hybrid sorbent-catalyst systems require energy and resources, which must be factored into their overall environmental assessment. The energy intensity of the capture and conversion processes, as well as the sourcing of materials for sorbents and catalysts, can influence the net environmental benefit of these technologies.

Land use is another important consideration. Large-scale deployment of direct air conversion systems may require significant land area, potentially competing with other land uses such as agriculture or natural habitats. The siting of these systems must be carefully planned to minimize ecological disruption and maximize their effectiveness in capturing atmospheric CO2.

Water consumption is a critical factor to evaluate, particularly in water-stressed regions. Some direct air capture technologies require substantial amounts of water for cooling or regeneration processes. Optimizing water use efficiency and exploring alternative cooling methods are essential for minimizing the environmental impact on local water resources.

The lifecycle environmental impact of hybrid sorbent-catalyst systems must also be considered. This includes the production, transportation, and eventual disposal or recycling of system components. Developing sustainable supply chains and implementing circular economy principles in the design and operation of these systems can help mitigate their overall environmental footprint.

Furthermore, the potential for unintended consequences must be carefully evaluated. For instance, the large-scale removal of CO2 from the atmosphere could have localized effects on plant growth or ecosystem dynamics. Long-term monitoring and research are necessary to understand and mitigate any unforeseen environmental impacts of these technologies.

In conclusion, while hybrid sorbent-catalyst systems for direct air conversion offer promising potential for carbon dioxide removal, their environmental impact must be holistically assessed. Balancing their benefits in climate change mitigation against potential environmental trade-offs is crucial for ensuring the sustainable development and deployment of these technologies.

One of the primary environmental benefits of these systems is their ability to directly remove CO2 from the atmosphere. This process can help reduce greenhouse gas concentrations, potentially slowing the rate of global warming and its associated impacts. Additionally, the conversion of captured CO2 into useful products, such as fuels or chemicals, can reduce reliance on fossil-based resources, further contributing to emissions reduction.

However, the environmental impact of these systems extends beyond their carbon capture capabilities. The production and operation of hybrid sorbent-catalyst systems require energy and resources, which must be factored into their overall environmental assessment. The energy intensity of the capture and conversion processes, as well as the sourcing of materials for sorbents and catalysts, can influence the net environmental benefit of these technologies.

Land use is another important consideration. Large-scale deployment of direct air conversion systems may require significant land area, potentially competing with other land uses such as agriculture or natural habitats. The siting of these systems must be carefully planned to minimize ecological disruption and maximize their effectiveness in capturing atmospheric CO2.

Water consumption is a critical factor to evaluate, particularly in water-stressed regions. Some direct air capture technologies require substantial amounts of water for cooling or regeneration processes. Optimizing water use efficiency and exploring alternative cooling methods are essential for minimizing the environmental impact on local water resources.

The lifecycle environmental impact of hybrid sorbent-catalyst systems must also be considered. This includes the production, transportation, and eventual disposal or recycling of system components. Developing sustainable supply chains and implementing circular economy principles in the design and operation of these systems can help mitigate their overall environmental footprint.

Furthermore, the potential for unintended consequences must be carefully evaluated. For instance, the large-scale removal of CO2 from the atmosphere could have localized effects on plant growth or ecosystem dynamics. Long-term monitoring and research are necessary to understand and mitigate any unforeseen environmental impacts of these technologies.

In conclusion, while hybrid sorbent-catalyst systems for direct air conversion offer promising potential for carbon dioxide removal, their environmental impact must be holistically assessed. Balancing their benefits in climate change mitigation against potential environmental trade-offs is crucial for ensuring the sustainable development and deployment of these technologies.

Economic Feasibility

The economic feasibility of Hybrid Sorbent-Catalyst Systems for Direct Air Conversion is a critical factor in determining their potential for widespread adoption and commercialization. These systems offer a promising approach to carbon dioxide removal and utilization, but their economic viability remains a key consideration for investors, policymakers, and industry stakeholders.

One of the primary economic challenges facing these systems is the high capital cost associated with their development and implementation. The specialized materials required for both the sorbent and catalyst components can be expensive to produce at scale. Additionally, the complex integration of these components into a functional system necessitates significant engineering and design costs. However, as research progresses and manufacturing techniques improve, there is potential for cost reductions through economies of scale and technological advancements.

Operating costs represent another crucial aspect of economic feasibility. Energy consumption is a major factor, as the regeneration of sorbents and the catalytic conversion processes can be energy-intensive. The development of more efficient regeneration methods and catalysts with lower activation energies could significantly improve the economic outlook. Furthermore, the sourcing and replacement of sorbent materials over time must be considered in long-term cost projections.

The economic viability of these systems is also heavily influenced by the value of the products generated through direct air conversion. The ability to produce valuable chemicals or fuels from captured CO2 could offset operational costs and potentially generate revenue streams. Market demand for these products, as well as their pricing relative to conventional alternatives, will play a crucial role in determining the overall economic feasibility.

Policy and regulatory frameworks have a substantial impact on the economic landscape for these technologies. Carbon pricing mechanisms, tax incentives, and government subsidies for carbon capture and utilization technologies can significantly alter the economic equation. As global efforts to combat climate change intensify, supportive policies could enhance the economic attractiveness of Hybrid Sorbent-Catalyst Systems.

Scalability and integration with existing infrastructure are additional economic considerations. The ability to deploy these systems at various scales and in diverse geographic locations could expand their market potential. Moreover, integration with renewable energy sources to power the conversion processes could improve both environmental and economic performance.

In conclusion, while Hybrid Sorbent-Catalyst Systems for Direct Air Conversion face economic challenges, ongoing research and development efforts, coupled with evolving market conditions and policy support, could enhance their economic feasibility. A comprehensive economic analysis must consider not only direct costs and revenues but also broader societal benefits and long-term environmental impacts to fully assess the potential of these innovative systems.

One of the primary economic challenges facing these systems is the high capital cost associated with their development and implementation. The specialized materials required for both the sorbent and catalyst components can be expensive to produce at scale. Additionally, the complex integration of these components into a functional system necessitates significant engineering and design costs. However, as research progresses and manufacturing techniques improve, there is potential for cost reductions through economies of scale and technological advancements.

Operating costs represent another crucial aspect of economic feasibility. Energy consumption is a major factor, as the regeneration of sorbents and the catalytic conversion processes can be energy-intensive. The development of more efficient regeneration methods and catalysts with lower activation energies could significantly improve the economic outlook. Furthermore, the sourcing and replacement of sorbent materials over time must be considered in long-term cost projections.

The economic viability of these systems is also heavily influenced by the value of the products generated through direct air conversion. The ability to produce valuable chemicals or fuels from captured CO2 could offset operational costs and potentially generate revenue streams. Market demand for these products, as well as their pricing relative to conventional alternatives, will play a crucial role in determining the overall economic feasibility.

Policy and regulatory frameworks have a substantial impact on the economic landscape for these technologies. Carbon pricing mechanisms, tax incentives, and government subsidies for carbon capture and utilization technologies can significantly alter the economic equation. As global efforts to combat climate change intensify, supportive policies could enhance the economic attractiveness of Hybrid Sorbent-Catalyst Systems.

Scalability and integration with existing infrastructure are additional economic considerations. The ability to deploy these systems at various scales and in diverse geographic locations could expand their market potential. Moreover, integration with renewable energy sources to power the conversion processes could improve both environmental and economic performance.

In conclusion, while Hybrid Sorbent-Catalyst Systems for Direct Air Conversion face economic challenges, ongoing research and development efforts, coupled with evolving market conditions and policy support, could enhance their economic feasibility. A comprehensive economic analysis must consider not only direct costs and revenues but also broader societal benefits and long-term environmental impacts to fully assess the potential of these innovative systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!